A suspension rail vehicle pickup system

A rail car and electric system technology, applied to the elevated railway system with suspended vehicles, current collectors, motor vehicles, etc., can solve the problems of high cost, excessive volume, and large volume, and achieve the effect of high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to understand the implementation process and implementation effect of the present invention more clearly, the following will be described in detail in conjunction with the accompanying drawings. It should be understood that the embodiments do not limit the protection scope of the present invention.

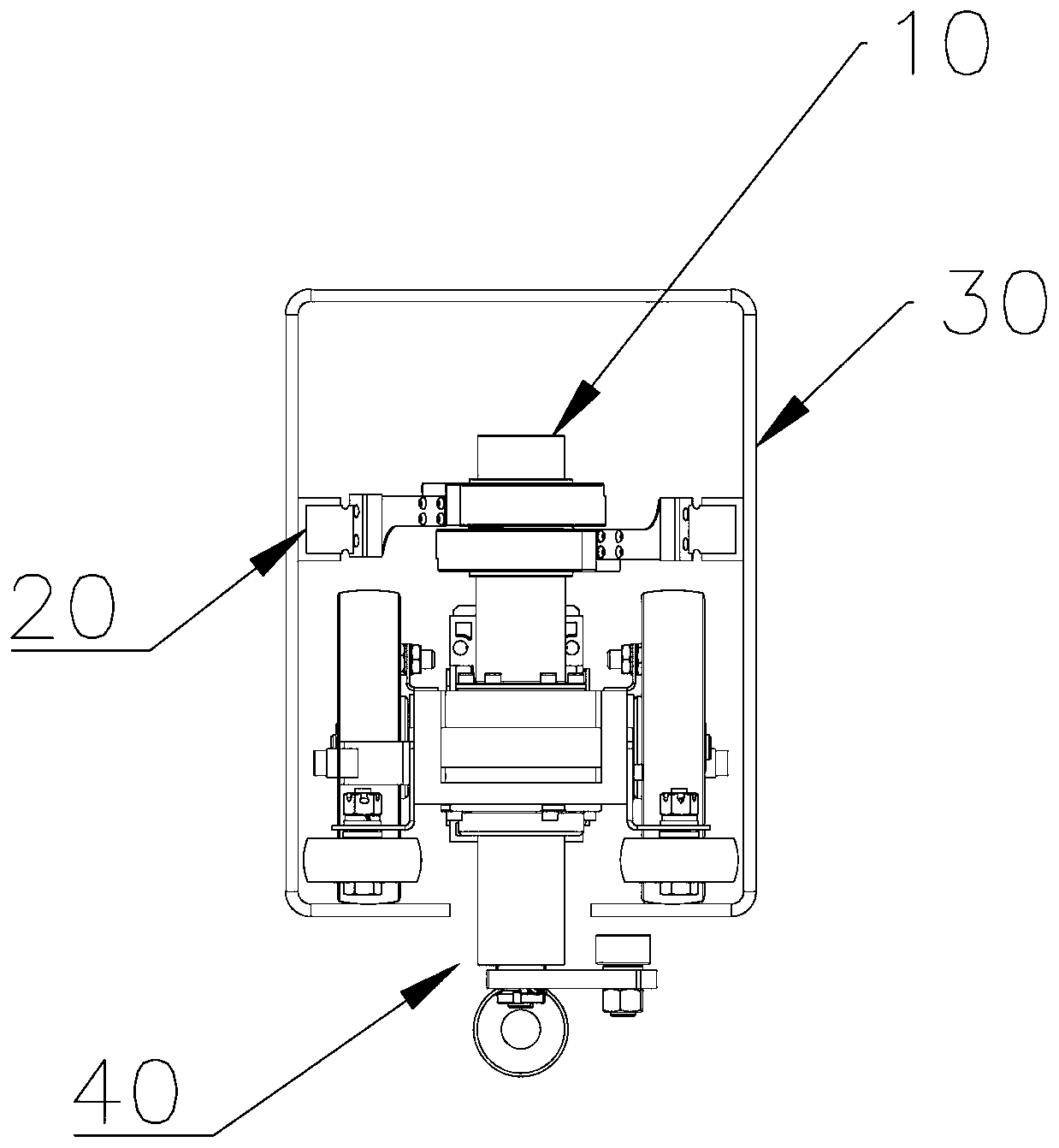

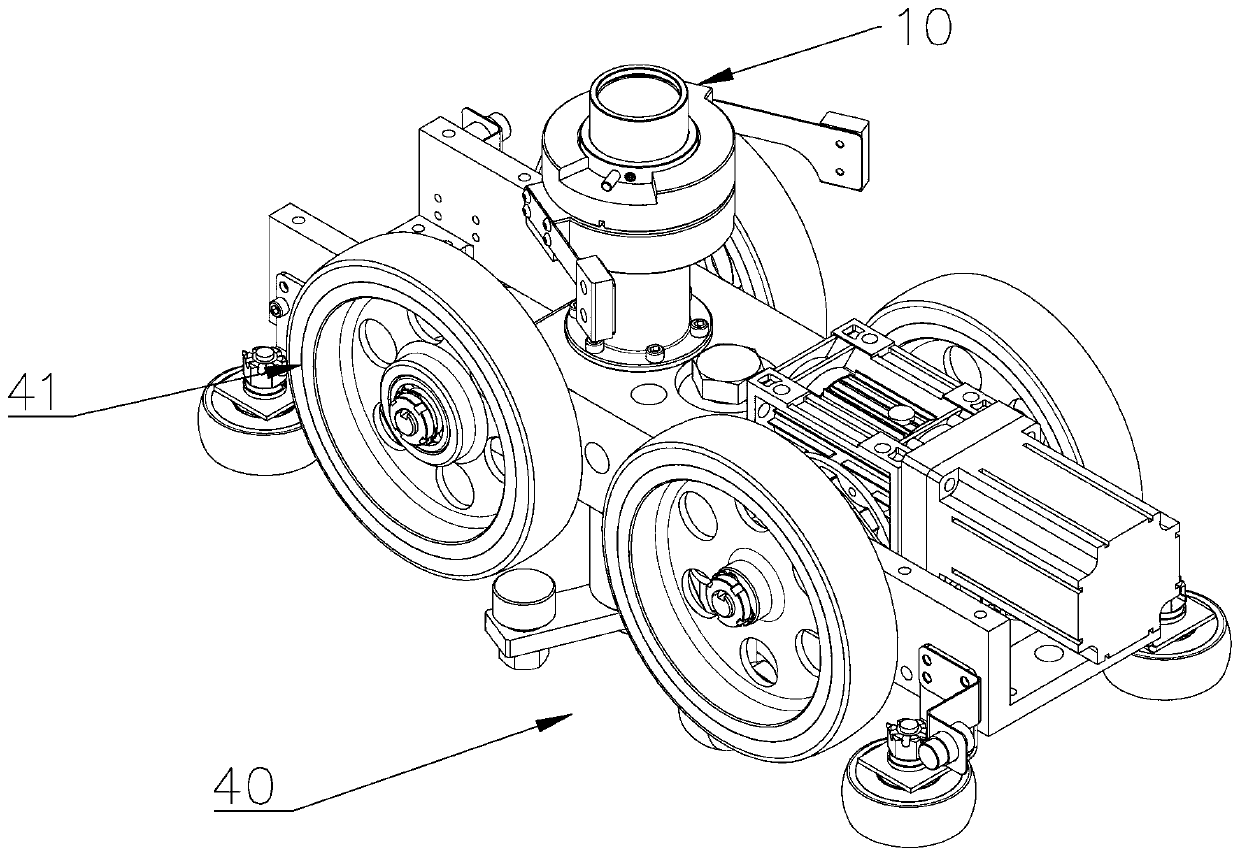

[0027] A suspension rail car power-taking system, such as figure 1 Shown: include power-taking device 10, power supply device 20, railcar traveling mechanism 40 and track 30, railcar is suspended below railcar traveling mechanism 40. Such as figure 2 As shown, the rail car traveling mechanism 40 is provided with two sets of front and rear travel wheels 41, all or part of the travel wheels walk along the track 30 under the action of the motor, and the motor takes power from the power supply connected to the power supply device 20 through the power taking device 10.

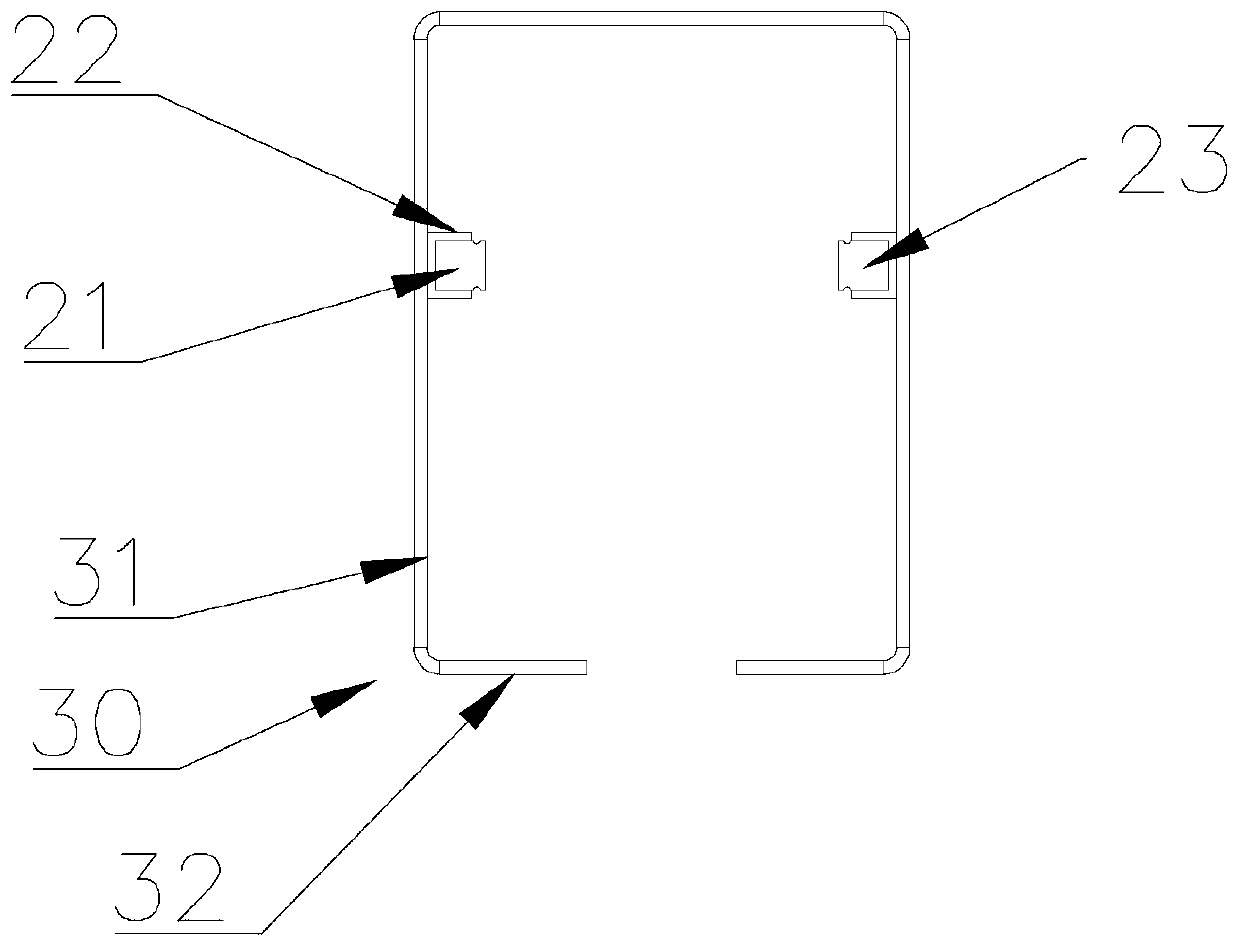

[0028] Such as image 3 As shown, the power supply device 20 includes a positive trolley line 21 ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap