Two-axle bogie with locking function

A bogie and functional technology, which is applied in the direction of the bogie, the device for lateral relative movement between the bottom frame and the bogie, the installation of the axle box, etc., which can solve the problem that the rigid side bearing cannot generate stable rotational friction torque and cannot meet the requirements of railway equipment rescue. Equipment speed requirements, inability to effectively suppress vehicle meandering, etc., to achieve large bearing capacity, meet bearing requirements, and prevent vehicles from overturning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

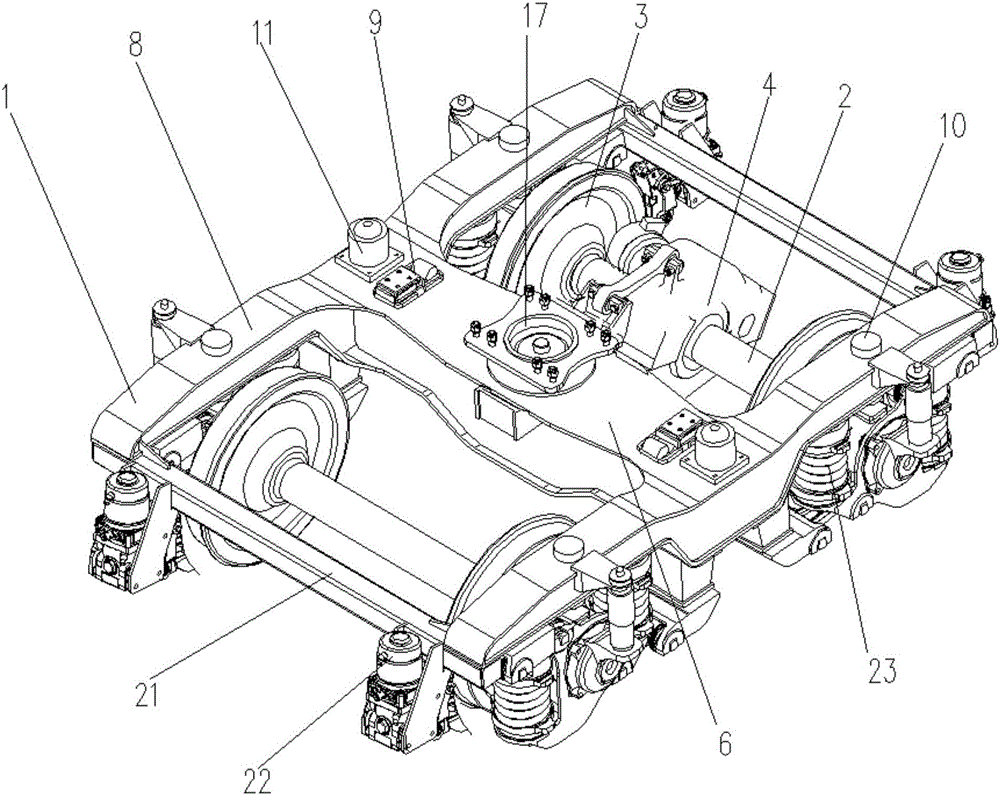

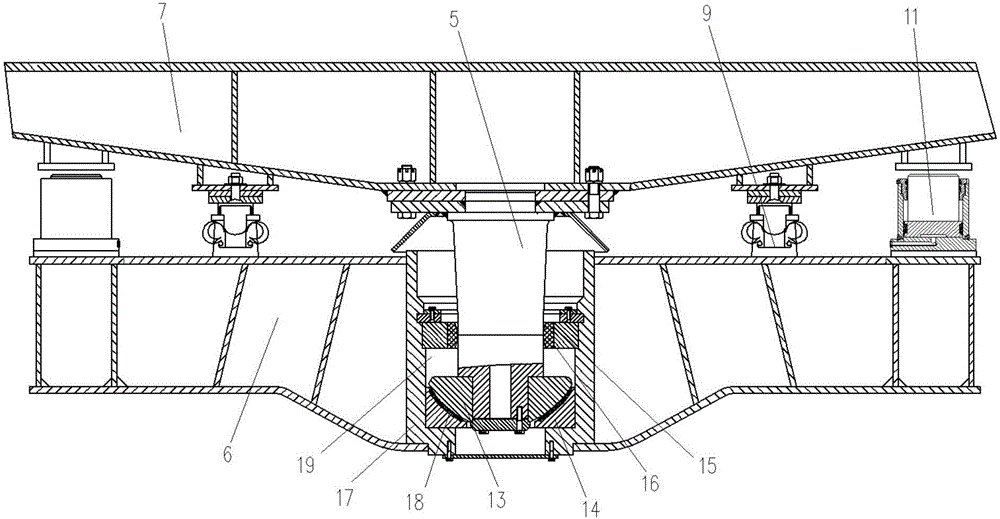

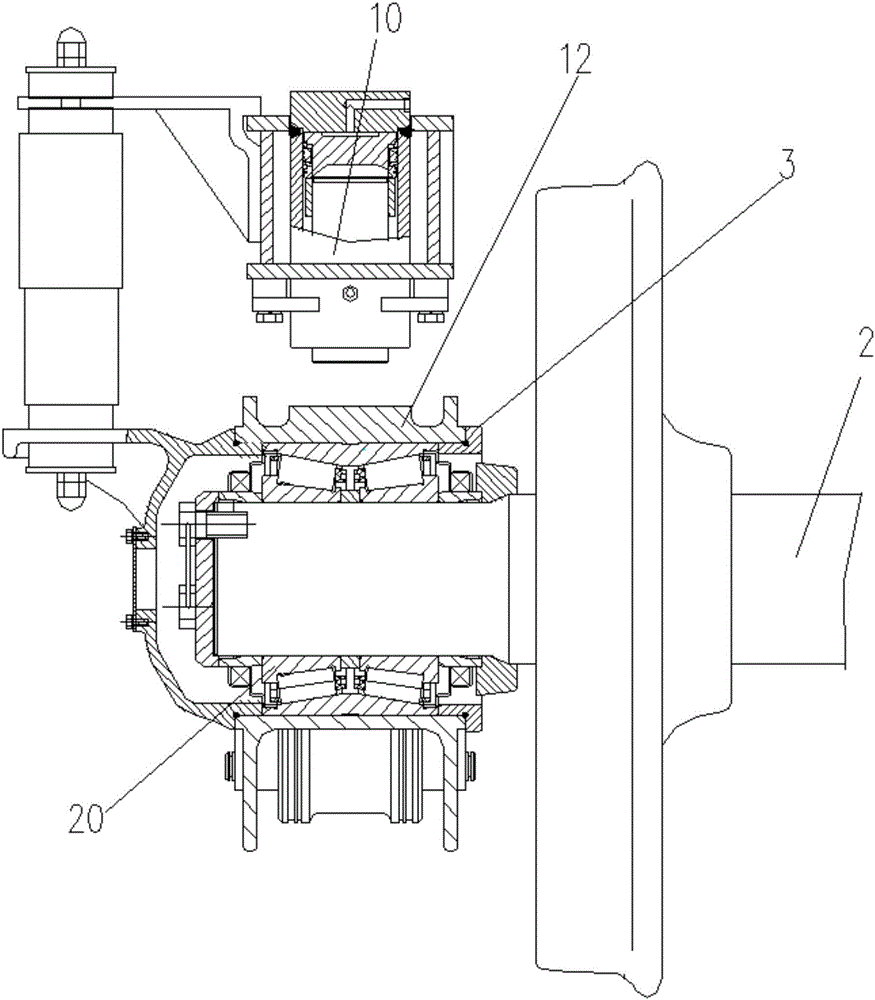

[0020] Attached below Figure 1-5 An embodiment of the present invention is described.

[0021] The two-axle bogie with locking function has a frame 1, an axle 2 is installed on the frame 1 and a wheel-to-axle box 3 is arranged at both ends of the axle 2, and a driving device 4 is installed on the axle 2 at one end of the frame 1, The middle part of the beam 6 of the frame 1 is provided with a central ball pin traction device and the central ball pin traction device is fixedly connected with the vehicle frame 7 above the frame 1. The contact elastic friction side bearing 9 and the constant contact elastic friction side bearing 9 are supported on the bottom of the vehicle frame 7 and cooperate with the central ball pin traction device to support the vehicle frame 7 on the top of the frame 1, and the side beam 8 of the frame 1 is provided with There is a locking device that forms a rigid support between the frame 1 and the vehicle frame 7, and between the frame 1 and the wheel-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com