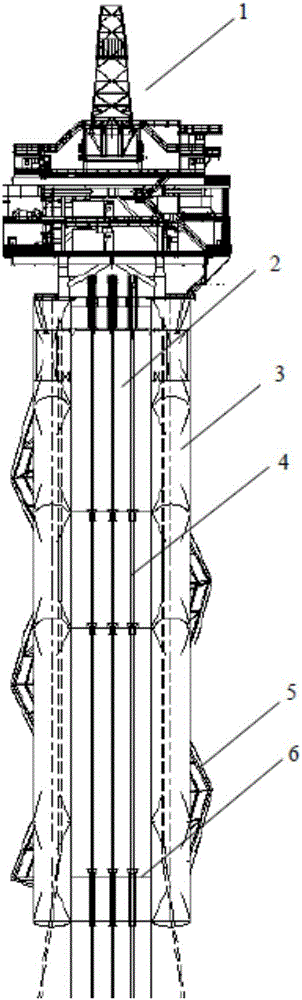

Multiple-upright-integrated single-column platform

An integrated single and column platform technology, used in ships, special-purpose ships, floating buildings, etc., can solve the problems of difficult maintenance of truss structures, loss of oil storage capacity, etc. Time-consuming in the early stage of development and the effect of small overall movement range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

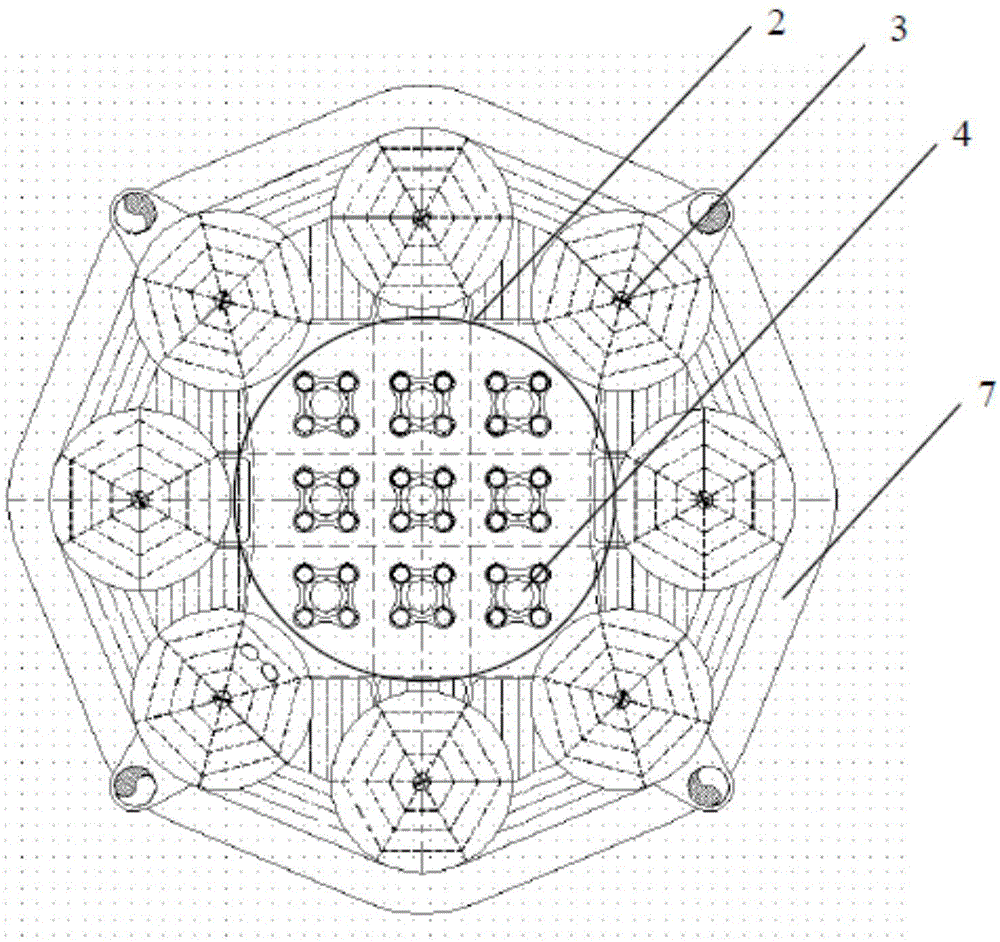

[0024] The invention provides a single-column platform suitable for deep-sea oil and gas development and adopting an integrated classic multi-column design. The main body of the platform is integrated with a single column and a bunch of small-sized columns attached to its outer wall, and is equipped with multiple top tensioned risers and support structures. In the construction of the platform, large-diameter cylindrical structures are avoided, and small-diameter cylindrical groups are used instead, which reduces the difficulty and cost of construction. Each small-sized column can be flexibly assembled inside to meet different development needs, and greatly increases the platform functions. diversity. Each small-sized column is divided into a plurality of horizontal cabins through the horizontal deck structure. The form of the platform completely retains the advantages of the traditional single-column platform, that is, it has excellent stability and motion characteristics, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com