Integrated retainer for linear module

A linear module and cage technology, applied in the direction of linear motion bearings, bearings, bearing components, etc., can solve the problems of poor integrity of the circulation system and the bearing system, vibration of the linear slider, and low assembly efficiency of the slider, etc. The effect of avoiding splicing and assembling, smooth operation and shortening of assembly time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

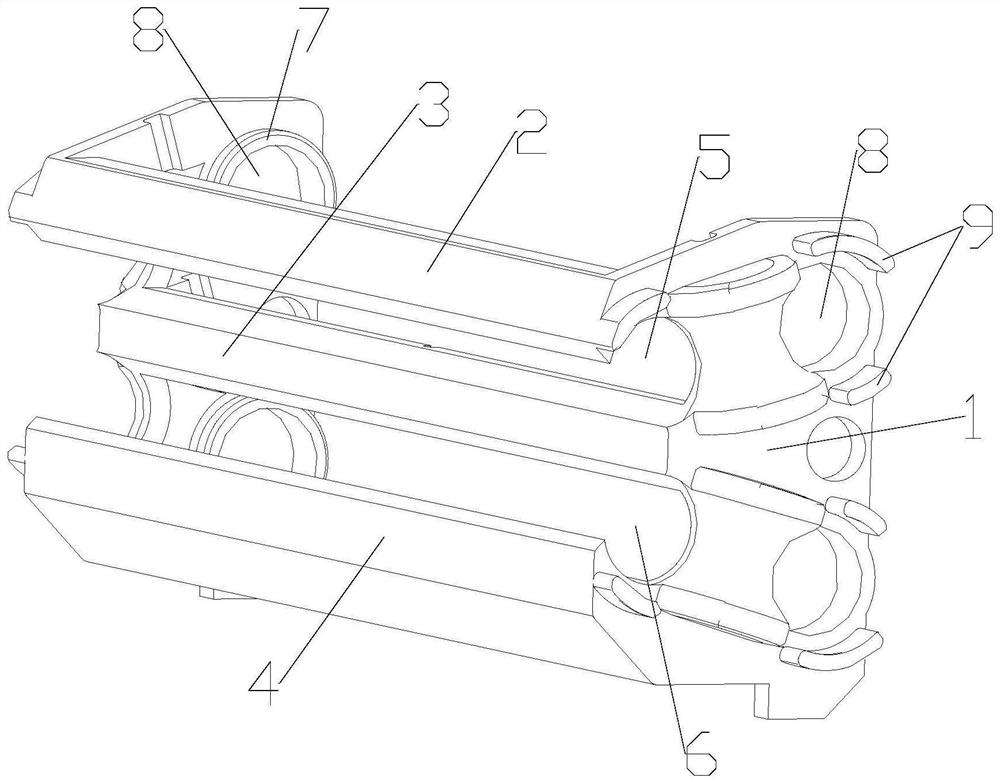

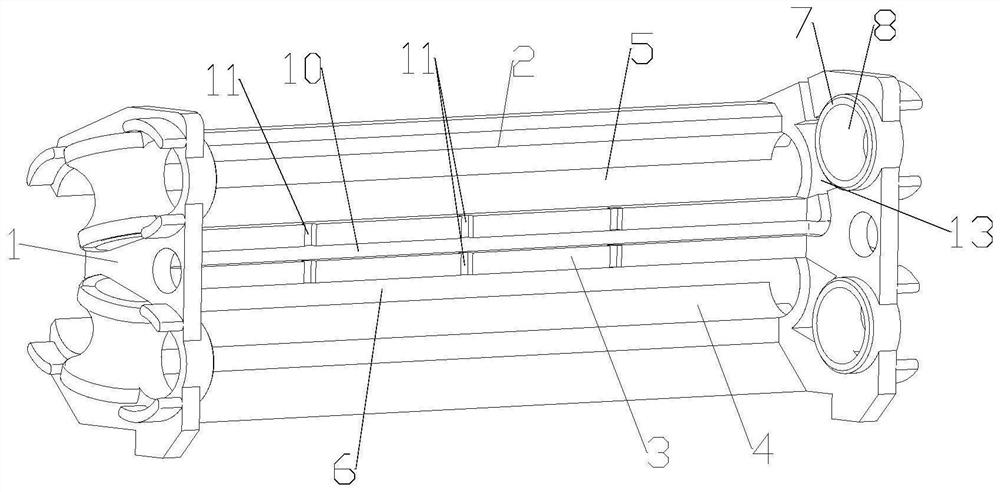

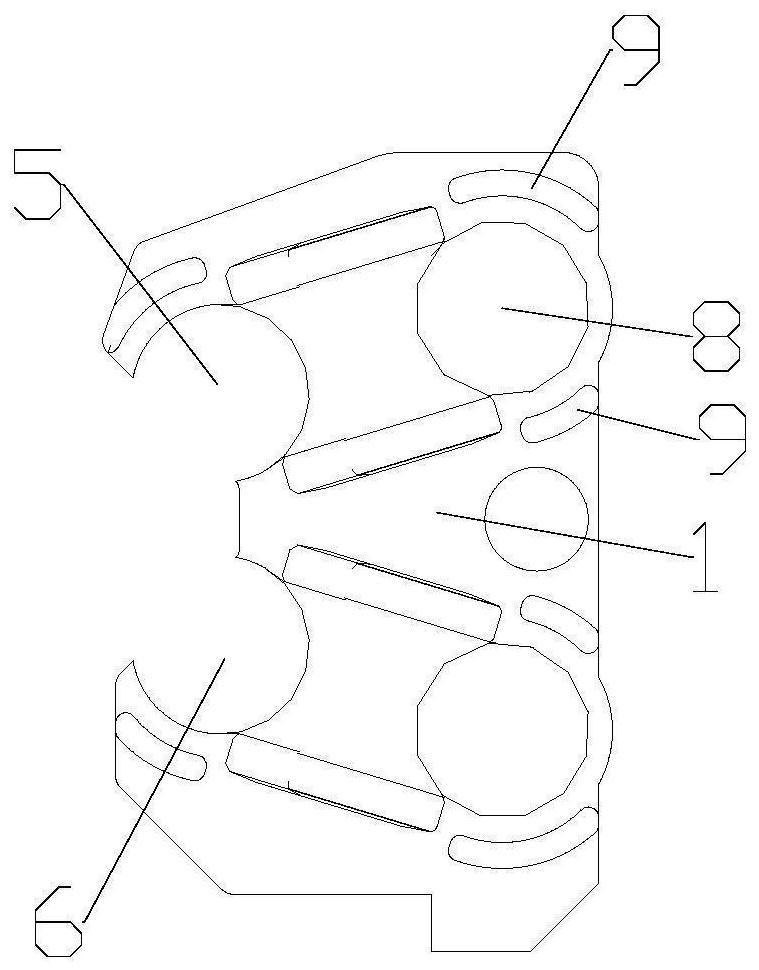

[0022] Such as figure 1 As shown, an integrated cage used on a linear module in this embodiment includes a pair of oppositely arranged inner circulation components 1, an upper cage component 2 fixedly connected between a pair of inner circulation components 1, The middle cage part 3 and the lower cage part 4, a pair of inner circulation parts 1, the upper cage part 2, the middle cage part 3 and the lower cage part 4 are integrally formed and connected; the upper cage part 2 and The middle cage parts 3 are arranged in parallel at intervals and form the upper rolling grooves 5 of the balls. The middle cage parts 3 and the lower cage parts 4 are arranged in parallel at intervals and form the lower rolling grooves 6 of the balls. The inner circulation part 1 The inner surface of the inner surface is provided with a clamping part 7 that is stuck at the port of the slider raceway. The inner circulation, the upper cage part, the lower cage part and the middle cage part are integrally...

Embodiment 2

[0026] Such as figure 1 As shown, an integrated cage used on a linear module in this embodiment includes a pair of oppositely arranged inner circulation components 1, an upper cage component 2 fixedly connected between a pair of inner circulation components 1, The middle cage part 3 and the lower cage part 4, a pair of inner circulation parts 1, the upper cage part 2, the middle cage part 3 and the lower cage part 4 are integrally formed and connected; the upper cage part 2 and The middle cage parts 3 are arranged in parallel at intervals and form the upper rolling grooves 5 of the balls. The middle cage parts 3 and the lower cage parts 4 are arranged in parallel at intervals and form the lower rolling grooves 6 of the balls. The inner circulation part 1 The inner surface of the inner surface is provided with a clamping part 7 that is stuck at the port of the slider raceway. The inner circulation, the upper cage part, the lower cage part and the middle cage part are integrally...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com