Device and method for ejecting shipboard aircraft by combining secondary springs

A two-stage spring and carrier-based aircraft technology, applied in the direction of launch/drag transmission, can solve the problems of low acceleration, high acceleration, pilot fainting, etc., and achieve the effect of preventing fainting and satisfying the speed of leaving the ship

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

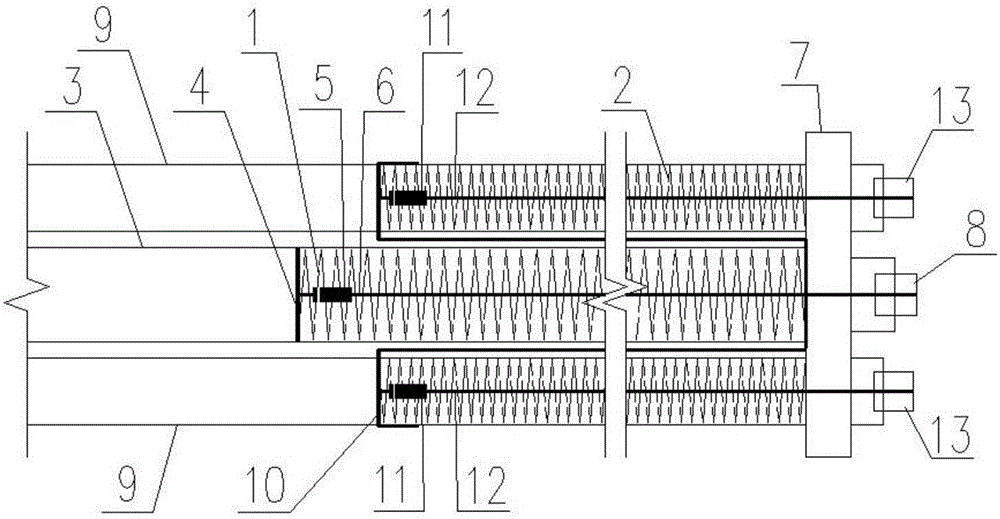

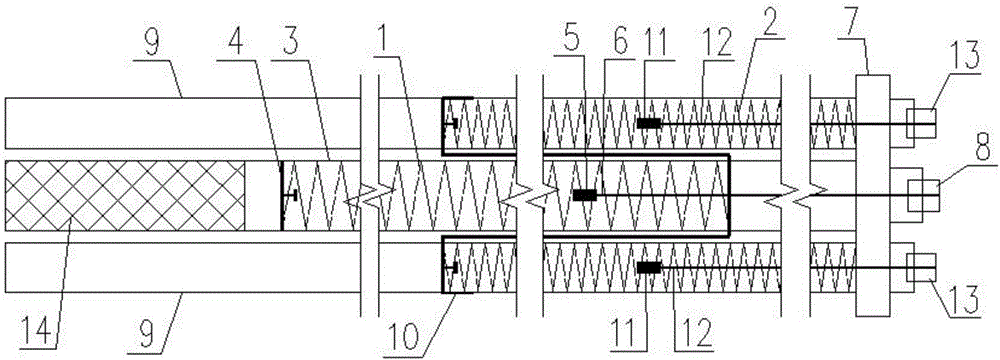

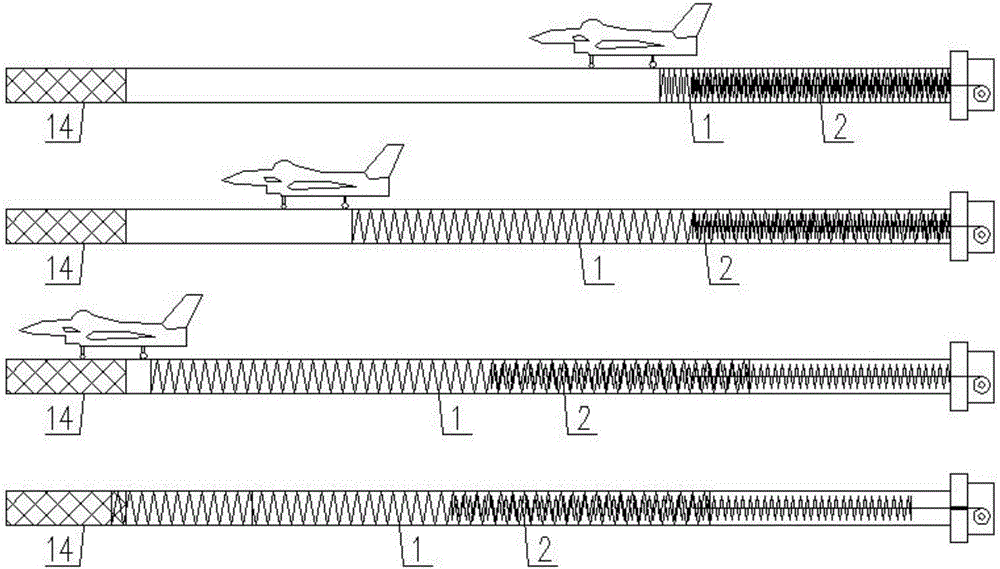

[0031] The wire diameter of the primary spring is 0.235m, the outer diameter is 1.2m, the number of turns is 84, the total length is 39.5m, the compressed length is 20m, and the compressed length is 19.5m. , compared with the solid spring, the mass can be reduced by 36%. Considering the mass of the carrier aircraft is 50T, the maximum acceleration is 99m / s^2, and the maximum speed is 160km / h. The wire diameter of the secondary spring is 0.15m, the outer diameter is 0.7m, the number of turns is 93, the total length is 27m, the compressed length is 13m, and the compressed length is 14m. , compared with the solid spring, the mass can be reduced by 49%. The two secondary springs push the carrier aircraft and the primary spring at the same time, with a maximum acceleration of 60.5m / s^2 and a maximum pushing speed of 101km / h. Ultimately, the carrier-based aircraft can obtain a departure speed of 160+101=261km / h. Calculate the ejection total stroke 20+13=33m according to the total c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com