A kind of ultra-low temperature drilling fluid for deep sea and permafrost drilling

A drilling fluid and ultra-low temperature technology, applied in the field of water-based drilling fluid, to achieve the effects of avoiding wellbore instability, good compatibility, and good rheology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

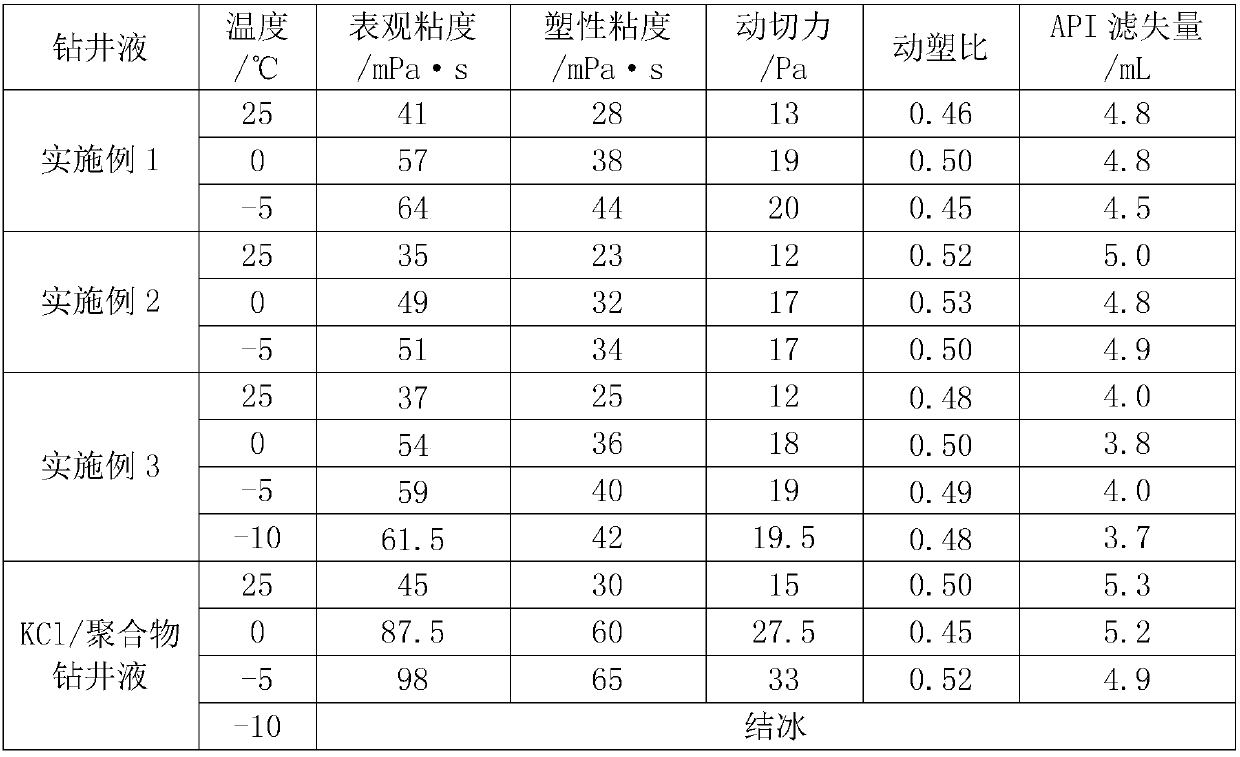

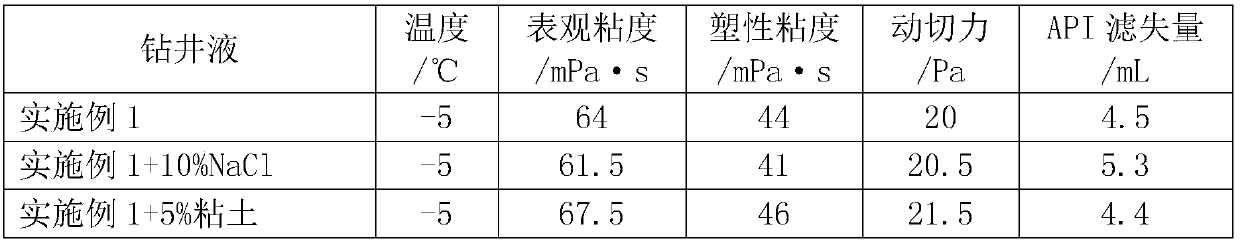

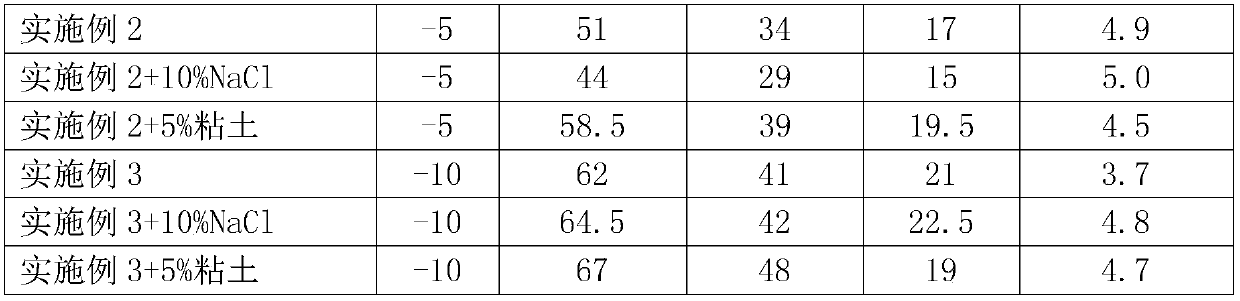

Embodiment 1

[0042] Embodiment 1: preparation of ultra-low temperature drilling fluid for deep-sea oil and gas drilling, including the following components by mass:

[0043] 100 parts of water, 2 parts of sodium bentonite, 2.5 parts of amino polymer, 2 parts of polyethylene glycol, 1 part of humic acid-aluminum, 0.2 parts of polyanionic cellulose PAC-HV, partially hydrolyzed polyacrylamide PHPA0. 05 parts, sulfonated phenolic resin SD-1025.5 parts, potassium chloride 4 parts, sodium chloride 25 parts, liquid lubricant SD-505 1 part, barite 20 parts.

[0044] The amine-based polymer used in this embodiment is prepared by the following method:

[0045] 330 g of diethylene glycol bis(3-aminopropyl) ether and 0.33 g of potassium hydroxide were added to a high-temperature and high-pressure reactor with a volume of 1 L, the reactor was evacuated and heated, and stirring was started at the same time at a stirring rate of 300 r / min. When the temperature was raised to 90° C., 26.4 g of ethylene ox...

Embodiment 2

[0047] Embodiment 2: preparation of ultra-low temperature drilling fluid for deep-sea gas hydrate drilling, including the following components by mass:

[0048] 100 parts of water, 2 parts of amino polymer, 1 part of polyethylene glycol, 1 part of humic acid-aluminum, 0.2 part of xanthan gum XC, 0.05 part of polyacrylamide PAM, polyanionic cellulose PAC-LV0.4 4.5 parts of sulfonated phenolic resin SD-102, 4 parts of potassium chloride, 0.5 parts of polyvinylpyrrolidone, 10 parts of sodium chloride, and 0.2 parts of lecithin.

[0049] The preparation method of the amine-based polymer used in this example is the same as that in Example 1.

[0050] The humic acid-aluminum used in the present embodiment is prepared by the following method: the mixture of 144 grams of humic acid and 211.3 grams of aluminum hydroxide and aluminum chloride (molar ratio 1: 1) in acidic conditions Reaction and synthesis at 90°C.

Embodiment 3

[0051] Example 3: preparing an ultra-low temperature drilling fluid for natural gas hydrate drilling in permafrost regions, including the following components in parts by mass:

[0052] 100 parts of water, 2.5 parts of sodium bentonite, 1 part of amino polymer, 0.5 part of polyethylene glycol, 0.8 part of humic acid-aluminum, 0.1 part of xanthan gum XC, 0.10 part of polyacrylamide PAM, polyanion fiber 0.4 parts of plain PAC-LV, 4 parts of sulfonated lignite resin, 0.5 parts of polyvinylpyrrolidone, 1 part of liquid lubricant SD-505, 20 parts of sodium chloride, and 0.2 parts of lecithin.

[0053] The amine-based polymer used in this embodiment is prepared by the following method:

[0054] Add 330 g of polyoxyethylene propylene diamine and 0.33 g of potassium hydroxide into a high-temperature and high-pressure reactor with a volume of 1 L, vacuumize the reactor, and start stirring at the same time at a rate of 300 r / min. When the temperature was raised to 90° C., 26.4 g of eth...

PUM

| Property | Measurement | Unit |

|---|---|---|

| freezing point | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com