An oil-in-water emulsified drilling fluid resistant to high temperature of 240°C

A technology for emulsified drilling fluid and oil-in-water, which is applied in the directions of drilling compositions, chemical instruments and methods to achieve the effects of less damage to the reservoir, good lubrication and stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

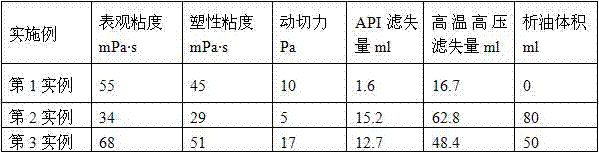

Examples

Embodiment 1

[0043] First determine the weight of each part according to the preparation requirements, and then weigh the raw materials according to the following parts by weight.

[0044] 70 parts of water;

[0045] 30 parts of 5# white oil;

[0046] 0.2 parts of caustic soda;

[0047] 3.0 parts of tackifiers are prepared by mixing attapulgite clay and sepiolite, and the ratio of attapulgite clay to sepiolite is 3.5:1.5;

[0048] 5.0 parts of the main emulsifier, made of fatty alcohol polyoxyethylene ether sulfosuccinic acid monoester disodium, rosin acid sodium, fatty alcohol polyoxyethylene ether AEO9 at a temperature of 80 ° C and 10,000 rpm under high-speed stirring for 20 Prepared in minutes, the ratio of fatty alcohol polyoxyethylene ether sulfosuccinic monoester disodium: sodium rosinate: fatty alcohol polyoxyethylene ether AEO9 is 2: 2.5: 1.5;

[0049] 1.0 parts of co-emulsifier, prepared by mixing calcium dodecylbenzenesulfonate, vegetable oleic acid, and 5# white oil at a tem...

Embodiment 2

[0055] First determine the weight of each part according to the preparation requirements, and then weigh the raw materials according to the following parts by weight.

[0056] 70 parts of water;

[0057] 30 parts of 5# white oil;

[0058] 0.1 parts of caustic soda;

[0059] 2.0 parts of tackifier, made by mixing attapulgite clay and sepiolite, the ratio of attapulgite clay to sepiolite is 3:1;

[0060] 4.0 parts of the main emulsifier, made of fatty alcohol polyoxyethylene ether sulfosuccinic acid monoester disodium, rosin acid sodium, fatty alcohol polyoxyethylene ether AEO9 at a temperature of 80 ° C and 10,000 rpm under high-speed stirring for 20 Prepared in minutes, the ratio of fatty alcohol polyoxyethylene ether sulfosuccinic monoester disodium: sodium rosinate: fatty alcohol polyoxyethylene ether AEO9 is 1: 2: 1;

[0061] 1.0 parts of co-emulsifier, prepared by mixing calcium dodecylbenzenesulfonate, vegetable oleic acid, and 5# white oil at a temperature of 80°C and s...

Embodiment 3

[0067] First determine the weight of each part according to the preparation requirements, and then weigh the raw materials according to the following parts by weight.

[0068] 70 parts of water;

[0069] 30 parts of 5# white oil;

[0070] 0.4 parts of caustic soda;

[0071] 4.0 parts of tackifier, made by mixing attapulgite clay and sepiolite, the ratio of attapulgite clay to sepiolite is 4:2;

[0072] 6.0 parts of the main emulsifier, made of fatty alcohol polyoxyethylene ether sulfosuccinic acid monoester disodium, rosin acid sodium, fatty alcohol polyoxyethylene ether AEO9 at a temperature of 80 ° C and 10,000 rpm under high-speed stirring for 20 Prepared in minutes, the ratio of fatty alcohol polyoxyethylene ether sulfosuccinate disodium: sodium abietate: fatty alcohol polyoxyethylene ether AEO9 is 3:3:2;

[0073] 3.0 parts of co-emulsifier, prepared by mixing calcium dodecylbenzenesulfonate, vegetable oleic acid, and 5# white oil at a temperature of 80°C and stirring a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com