Clamping fastening type wall panel

A wall panel and buckle-type technology, which is applied to building components, buildings, ceilings, etc., can solve the problems of inconvenient replacement, damage to wall panels, waste, etc., and achieve the effect of cost saving and overall weight reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

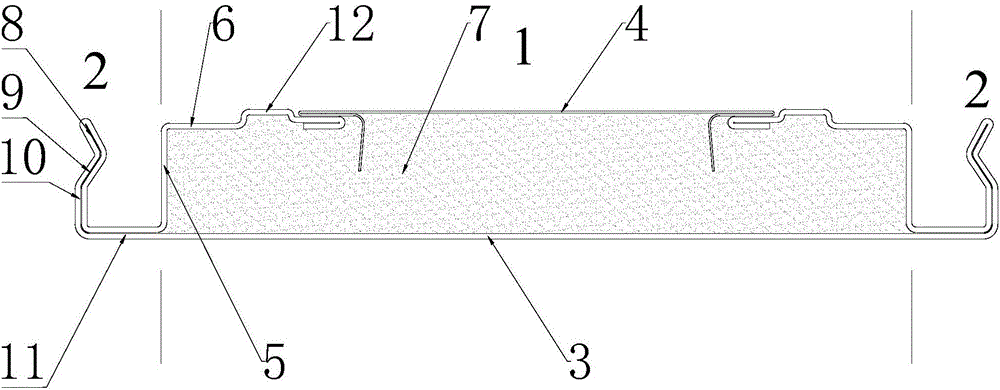

[0018] Example one, combination figure 1 , The snap-in wall panel involved in this embodiment is a flat seam wall panel, which includes a wall panel body 1 and a connecting portion 2; the wall panel body 1 includes a panel 3, a back board 4, a vertical board 5, and a back board support portion 6. And the filling layer 7; the connecting portion 2 includes a first bending section 8, a second bending section 9 and a third bending section 10; the connecting portion 2 also includes a connecting bending section 11 with the wall panel body; the third bending The section 10 is perpendicular to the connecting section 11; the second bending section 9 is bent in the direction of the wall panel body 1; the first bending section 8 is reversely bent relative to the second bending section 9. The back plate supporting portion 6 is provided with a protrusion 12; the free end of the end of the back plate supporting portion 6 is bent inward. The panel 3, the connecting part 2, the vertical plate ...

Example Embodiment

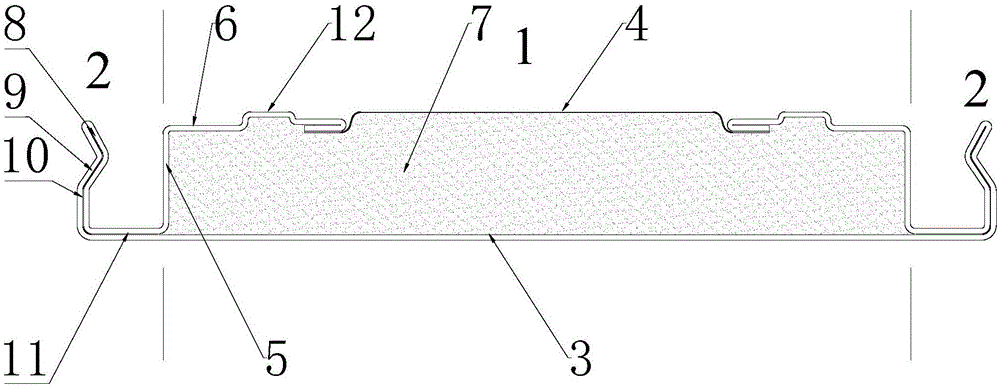

[0020] Example two, reference figure 2 The difference between the snap-in wall panel involved in this embodiment and the embodiment is that the backplane 2 used is aluminum foil paper. In the production process of the snap-on wall panel involved in this embodiment, the wall panel body 1 expands when polyurethane is foamed, and combined with the crawler-type production line, the thickness of the snap-on wall panel involved in this embodiment can be controlled. The foaming of polyurethane enables the two ends of the aluminum foil paper to be fixed under the back plate support 6.

Example Embodiment

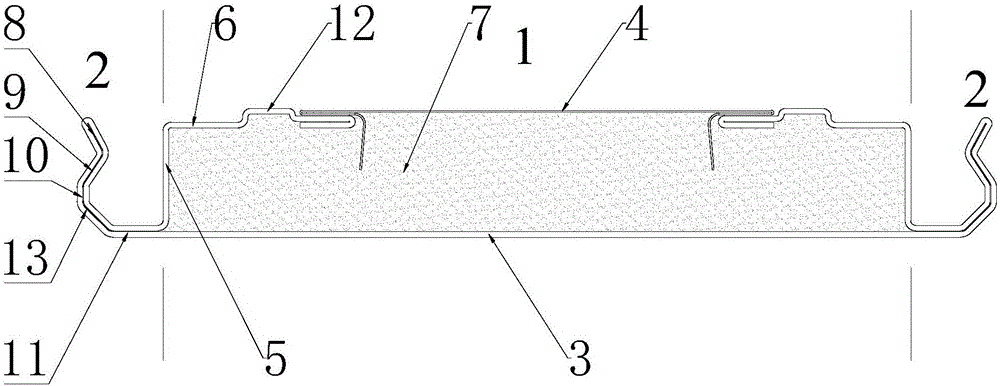

[0021] Example three, reference image 3 The snap-in wall panel involved in this embodiment is a V-shaped wall panel. The difference from the first embodiment is that the connecting portion 2 further includes a fourth bending section 13, and the first bending section 8 and the connecting section 11 pass through the The four bending sections 13 are connected. The arrangement of the fourth bending section 13 enables the two adjacent snap-in wall panels to form a V-shaped groove during assembly of the snap-in wall panel in this embodiment.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap