An environmentally friendly cycle power generation device for power plants supported by big data

A cyclic power generation and big data technology, applied in steam engine installations, machines/engines, mechanical equipment, etc., can solve problems such as affecting the production process temperature and production efficiency, polluting the environment, and heavy workload.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

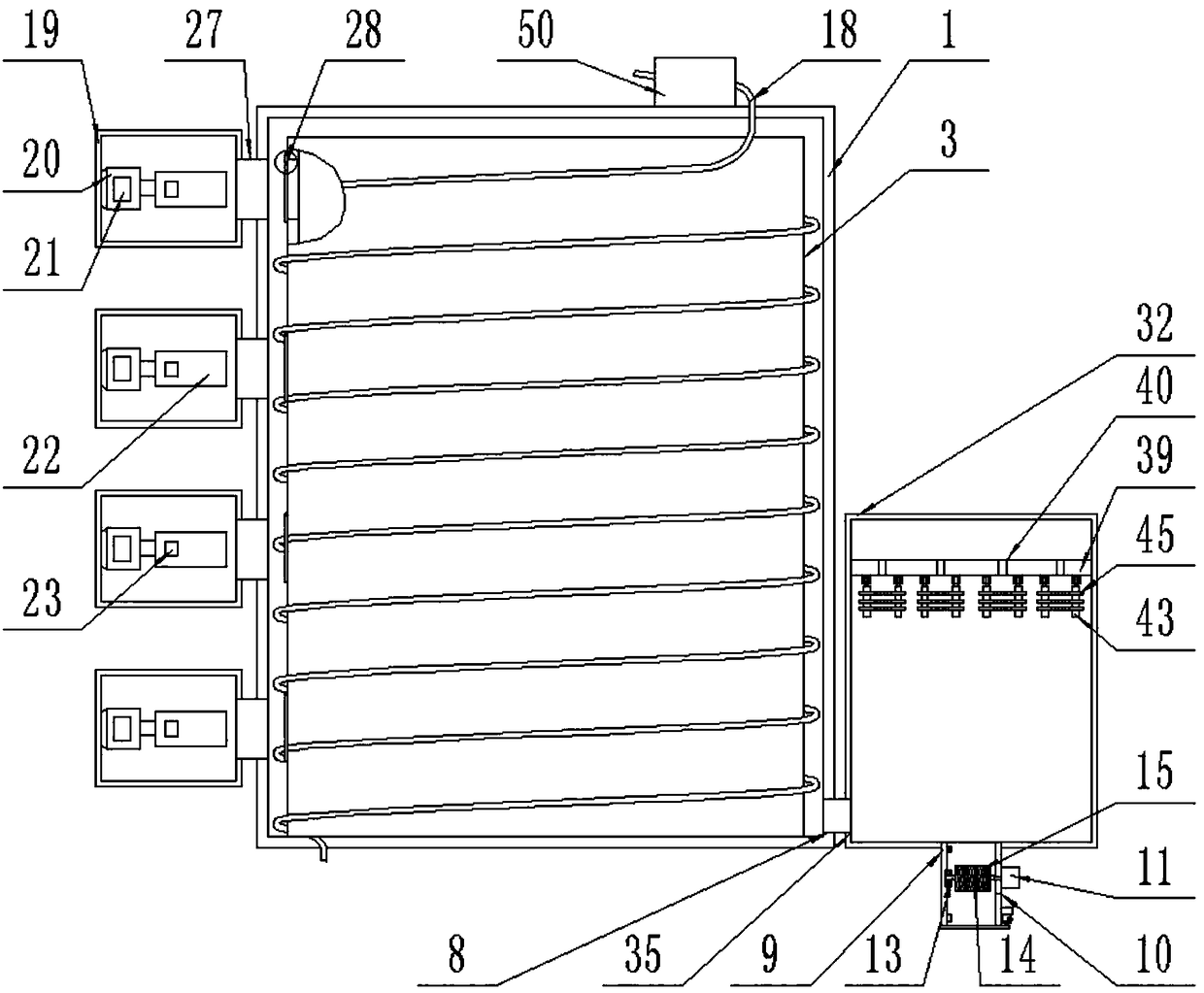

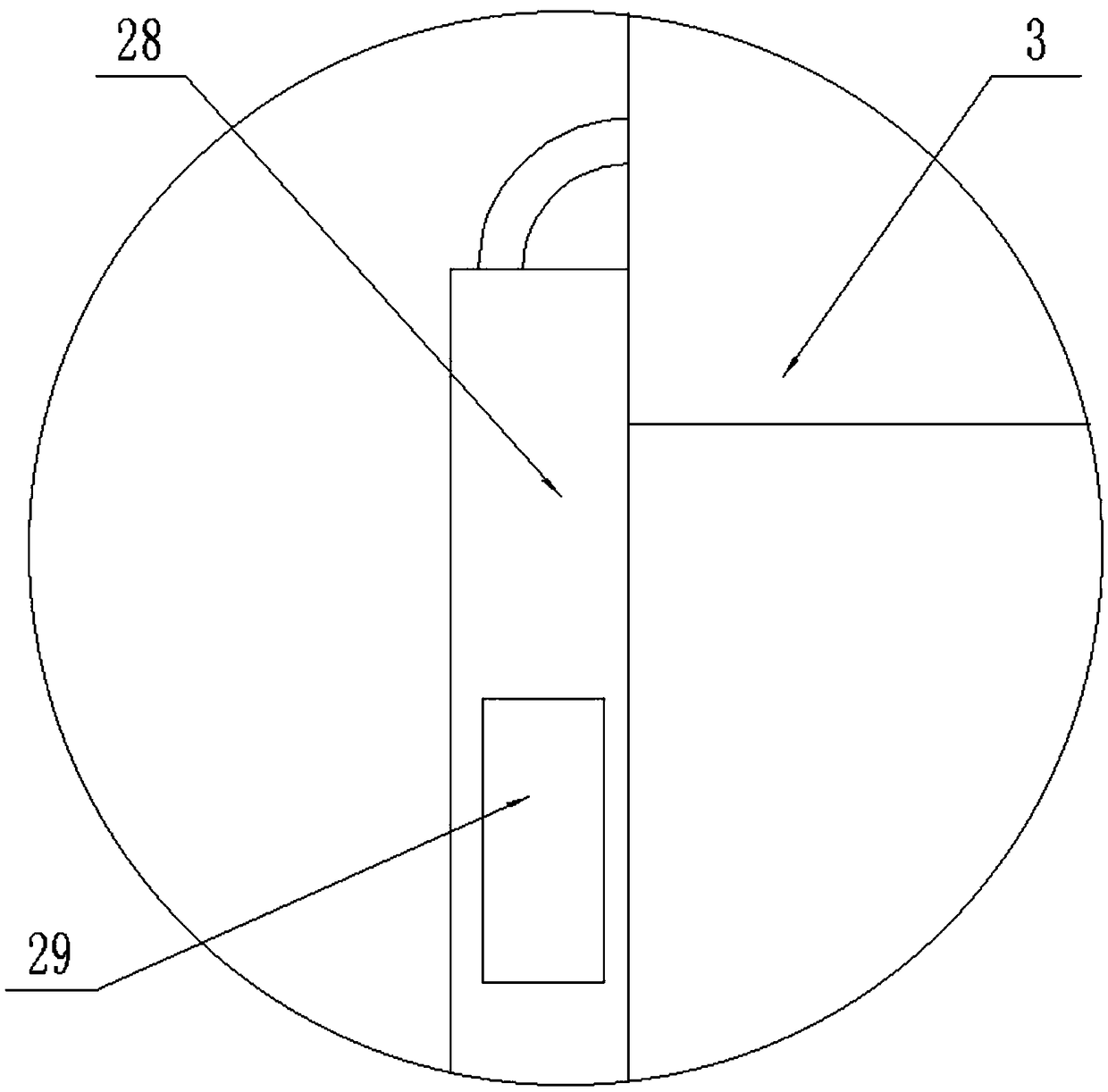

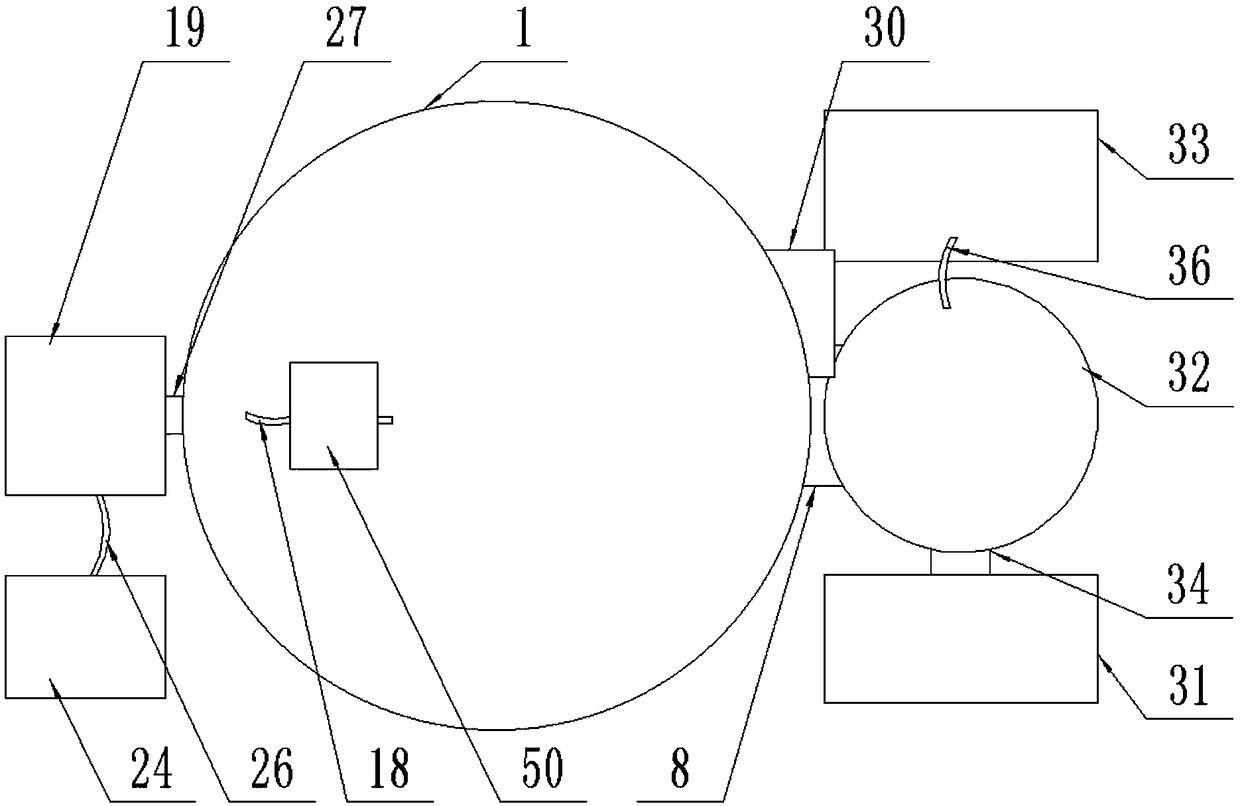

[0027] The present invention is specifically described below in conjunction with accompanying drawing, as Figure 1-11As shown, a big data-supported power plant environment-friendly cycle power generation device includes a boiler body 1 fixedly installed on the ground, and a pulverized coal feed port 2 is provided on the bottom side surface of the boiler body 1. The boiler body 1 is provided with a heat transfer cylinder 3, and the bottom side surface of the heat transfer cylinder 3 is provided with a pulverized coal feed port 2, and the inner bottom of the heat transfer cylinder 3 is provided with a pulverized coal feed port. The combustion tank 4 corresponding to the mouth 2, the inner surface of the combustion tank 4 is fixedly installed with a uniformly distributed blower 5, the inside of the blower 5 is provided with a blower starting device 6 and a fan wind adjustment device 7, the bottom of the boiler body 1 A waste gas outlet port 8 is provided on the side surface, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com