Computer monitoring quantitative waste gas detection electric power equipment for waste water purification coal material crushing groove wheel conveyance

A technology of computer monitoring and wastewater purification, which is applied in the direction of program control, measuring devices, and analyzing materials in sequence/logic controllers, and can solve problems affecting measurement accuracy, heavy workload, and affecting production process temperature and production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

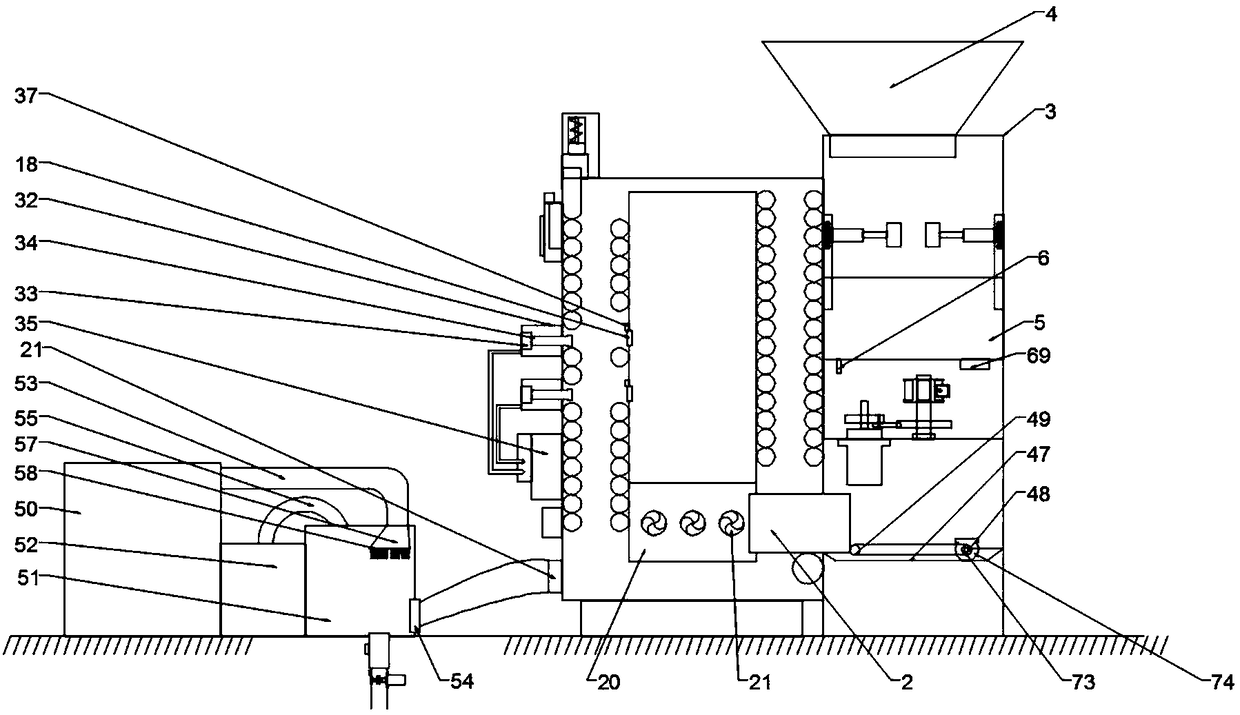

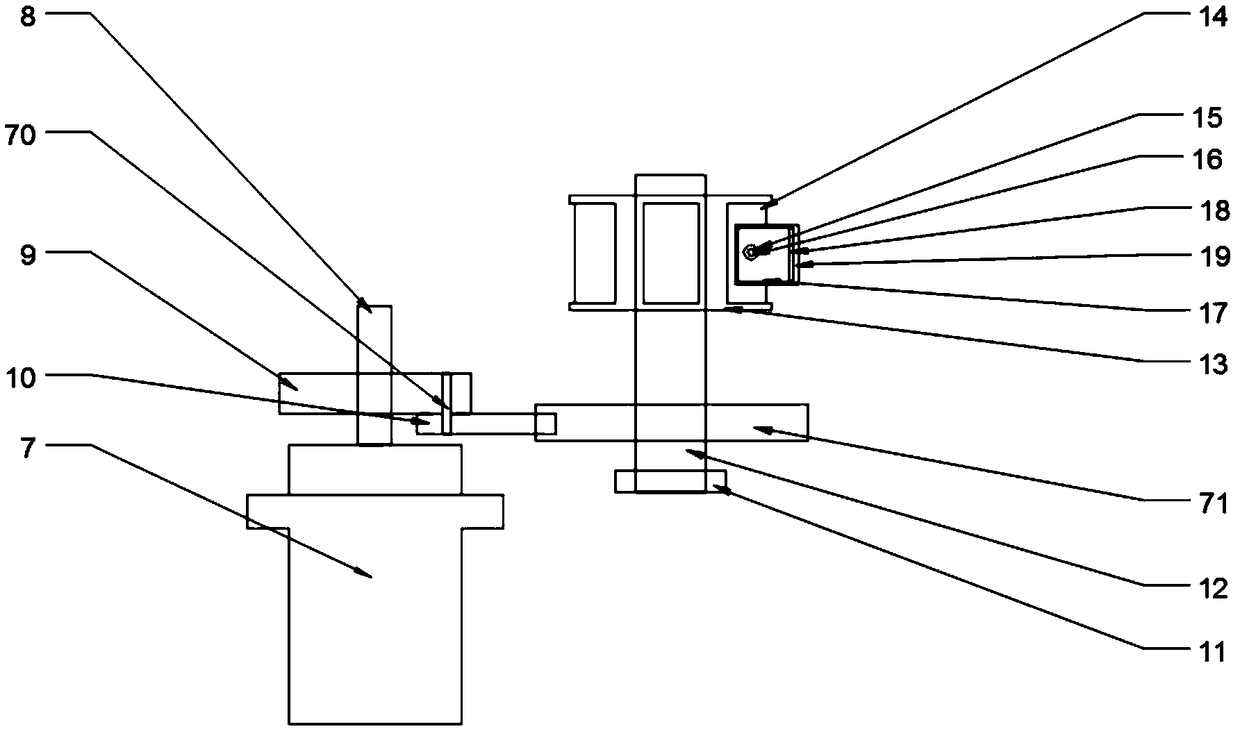

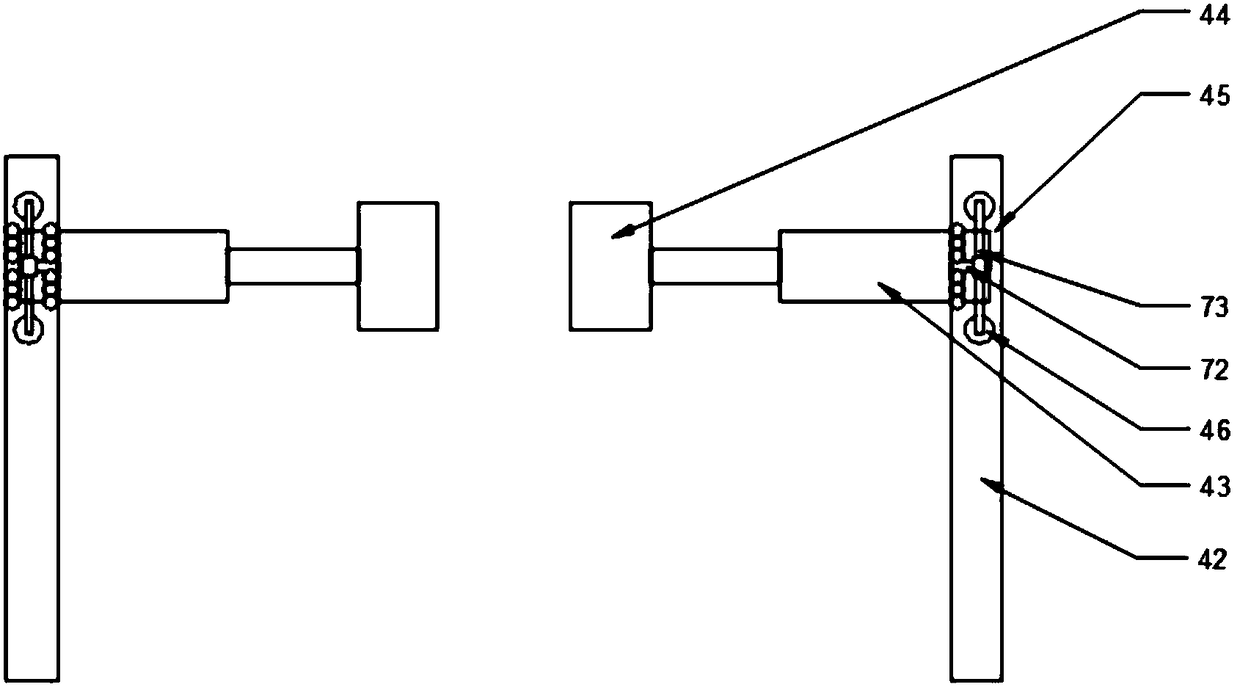

[0023] The present invention is specifically described below in conjunction with accompanying drawing, as Figure 1-7As shown, a computer monitors and quantitatively detects exhaust gas power equipment for waste water purification, coal pulverization and slot wheel transportation, including a boiler body 1, which is fixedly installed on the ground, and coal is installed on the bottom side surface of the boiler body 1. The powder feed port 2, the outer surface of the boiler body 1 is provided with a pulverizing and feeding mechanism, and the pulverizing and feeding mechanism is fixedly installed on the side surface of the coal-fired pulverizing box 3 on the side surface of the boiler body 1, located in the coal-fired pulverizing box The conical coal-fired block feed port 4 on the upper surface of the body 3, the coal-fired block crushing mechanism fixedly installed in the coal-fired crushing box body 3 and corresponding to the conical coal-fired block feed port 4, and the coal-f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com