Power generating equipment adopting permanent-magnet grooved wheels for conveying and central computer for controlling and being capable of treating waste gas and water

A central computer and waste water treatment technology, applied in control systems, combustion equipment, lighting and heating equipment, etc., can solve problems such as polluting the environment, inconvenient operation, and heavy workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

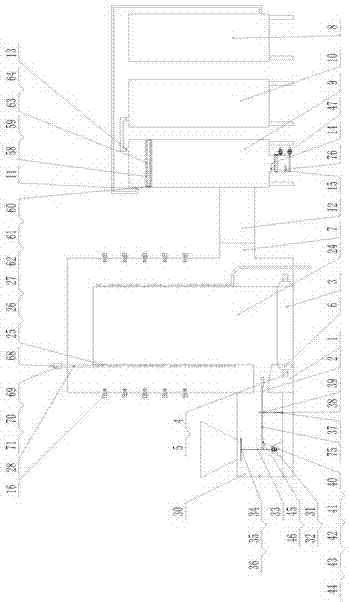

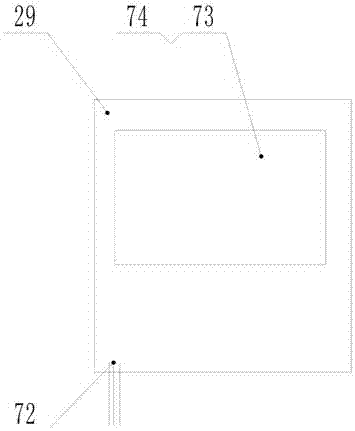

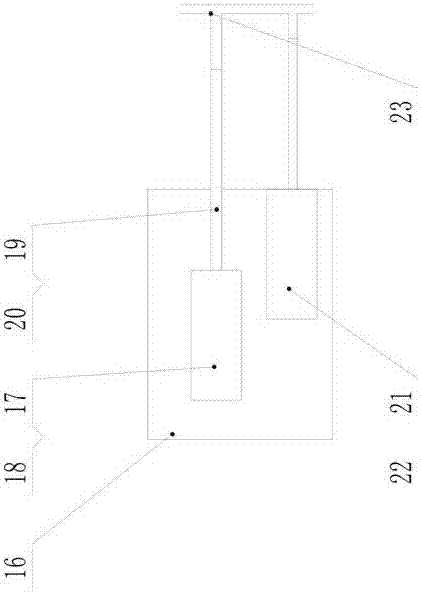

[0020] The present invention is specifically described below in conjunction with accompanying drawing, as Figure 1-4As shown, a permanent magnet sheave that can treat waste gas and wastewater is used to transport central computer-controlled power generation equipment, including a boiler body. The bottom side surface of the boiler body is provided with a pulverized coal feed port, and the outer surface of the boiler body is provided with Quantitative sheave rotation mechanism, the inner surface of the combustion tank is fixed with uniformly distributed blowers, the blower is equipped with a blower starting device and a fan wind adjustment device, and the bottom surface of the boiler body is provided with a waste gas outlet. The waste gas outlet end is connected with a waste gas recovery and purification mechanism, and the waste gas recovery and purification mechanism consists of a waste gas purification solution storage box fixed on the ground side of the boiler body, a tank bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com