A High Temperature Resistant Single Vane Swing Cylinder

A technology of swinging cylinder and single blade, applied in the direction of fluid pressure actuating device, etc., can solve the problems of seal failure and unusability, and achieve the effect of large rotation angle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

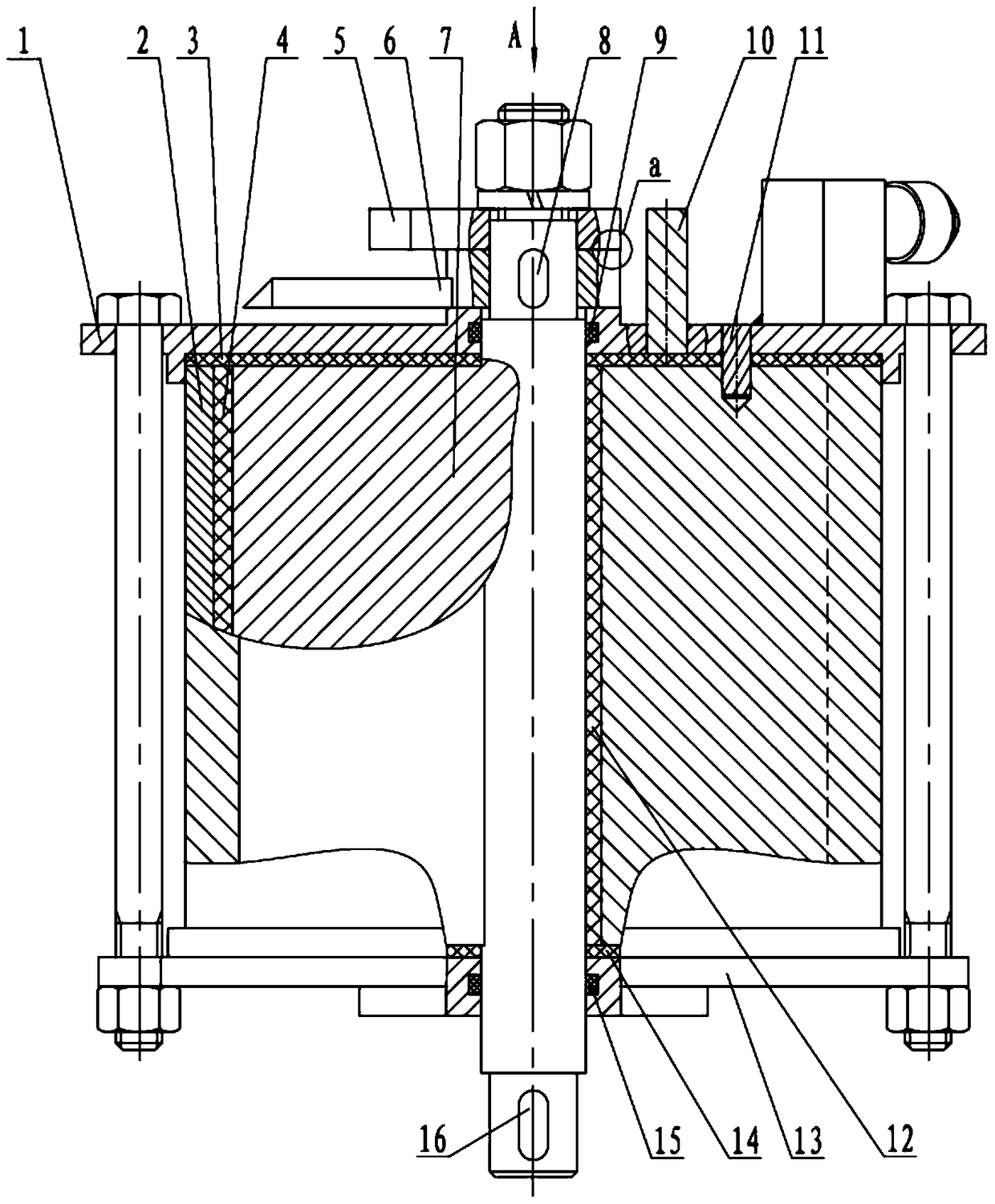

[0027] Provides a high-temperature-resistant single-vane swing cylinder, including an upper cover 1, a housing 2, an upper sealing gasket 3, a vane sealing strip 4, a stop rod 5, a vane position indicating rod 6, a vane shaft 7, and an upper cover seal Ring 9, stop pile 10, positioning pin 11, casing sealing strip 12, lower cover 13, lower sealing gasket 14, lower cover sealing ring 15;

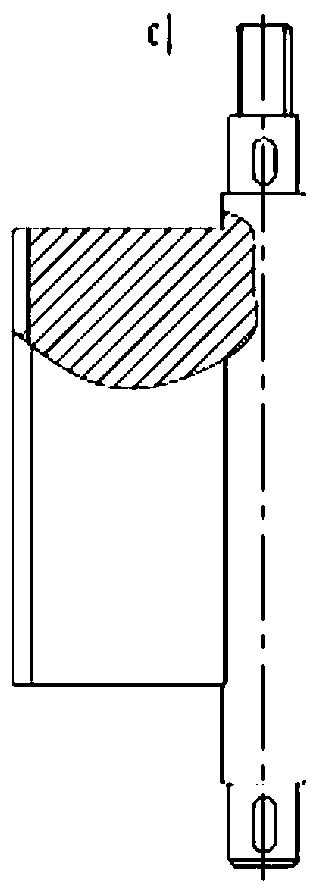

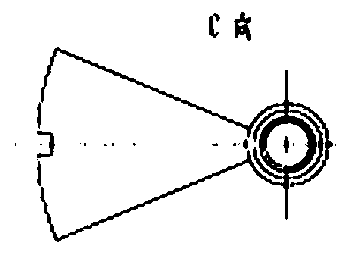

[0028] The upper cover 1, the lower cover 13 and the housing form a cavity structure, and an axially extending protrusion is arranged in the housing. The axial section of the protrusion is fan-shaped, and a There is a shaft support seat, and the blade rotating shaft 7 is supported on the central through holes of the upper cover 1 and the lower cover 13 and the shaft support seat; the blade rotating shaft 7 is provided with a blade, and the blade is located in the cavity structure;

[0029] Sealing gaskets are arranged on the inner surfaces of the upper cover and the lower cover, and the seali...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com