Clamping device

A clamping device and clamping piece technology, applied in the direction of friction clamping of detachable fasteners, connecting components, mechanical equipment, etc., can solve problems such as hidden dangers, inconvenient replacement, inconvenient replacement of batteries, etc., and achieve convenient operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

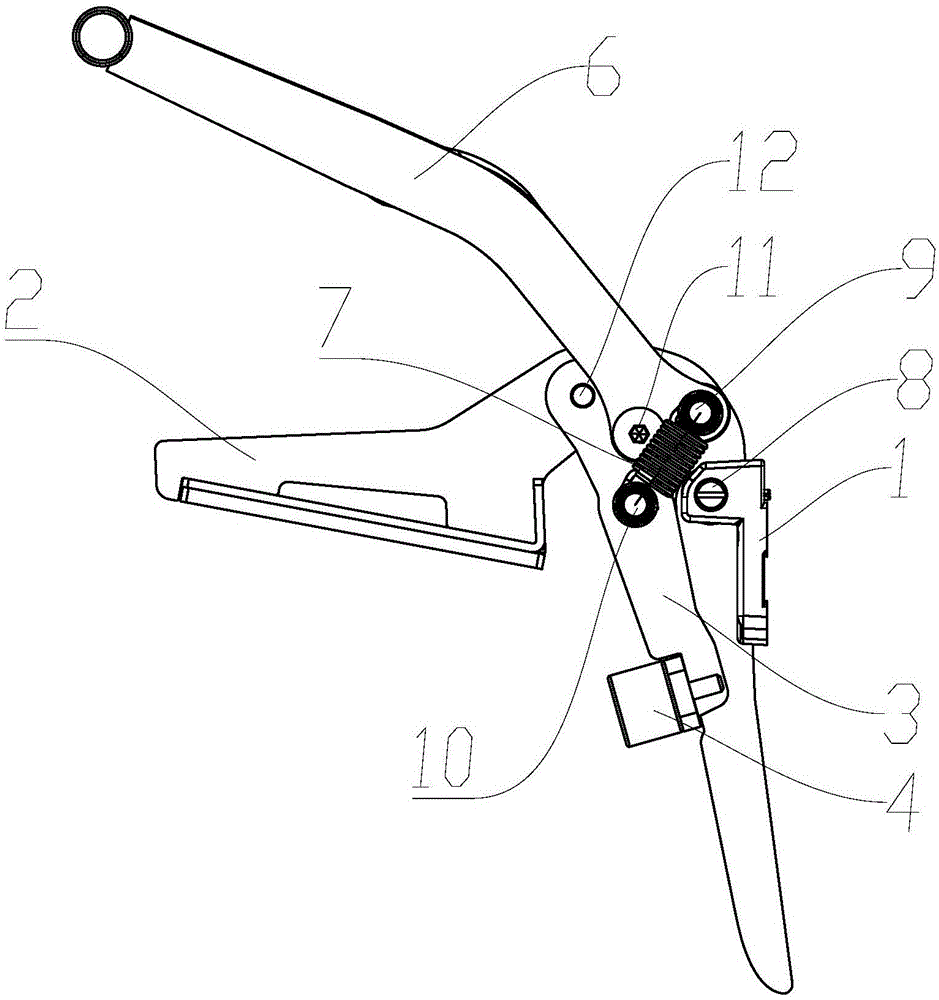

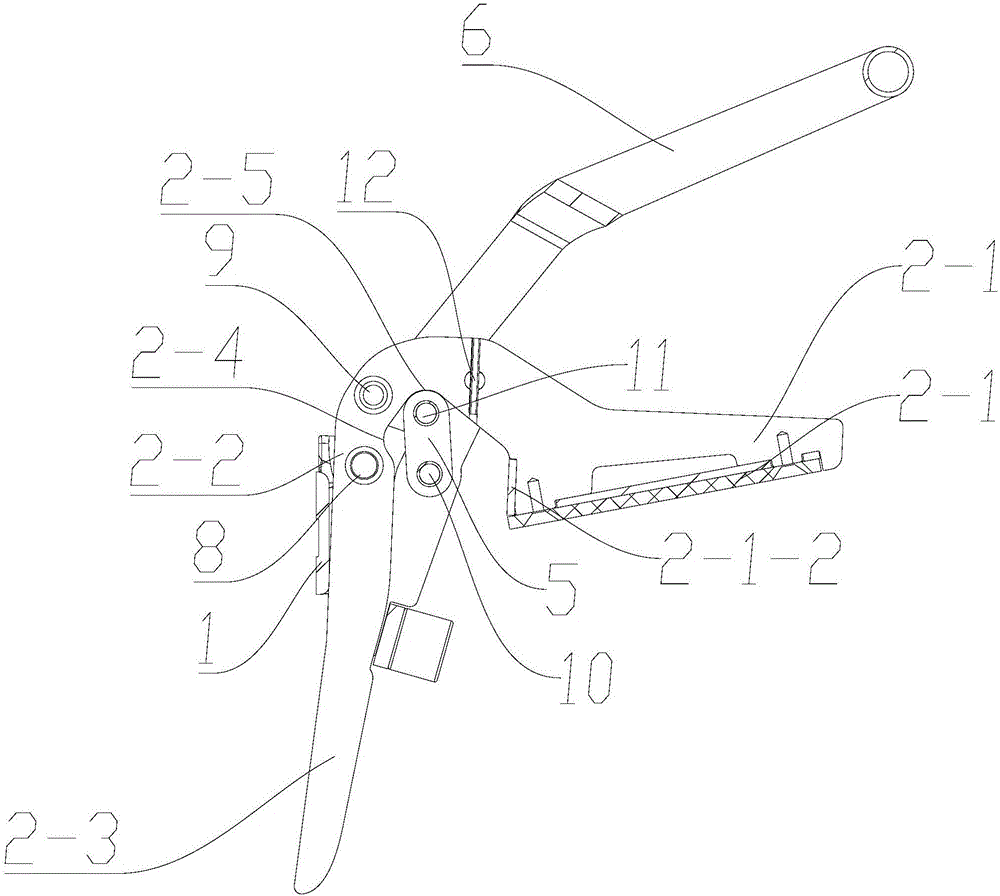

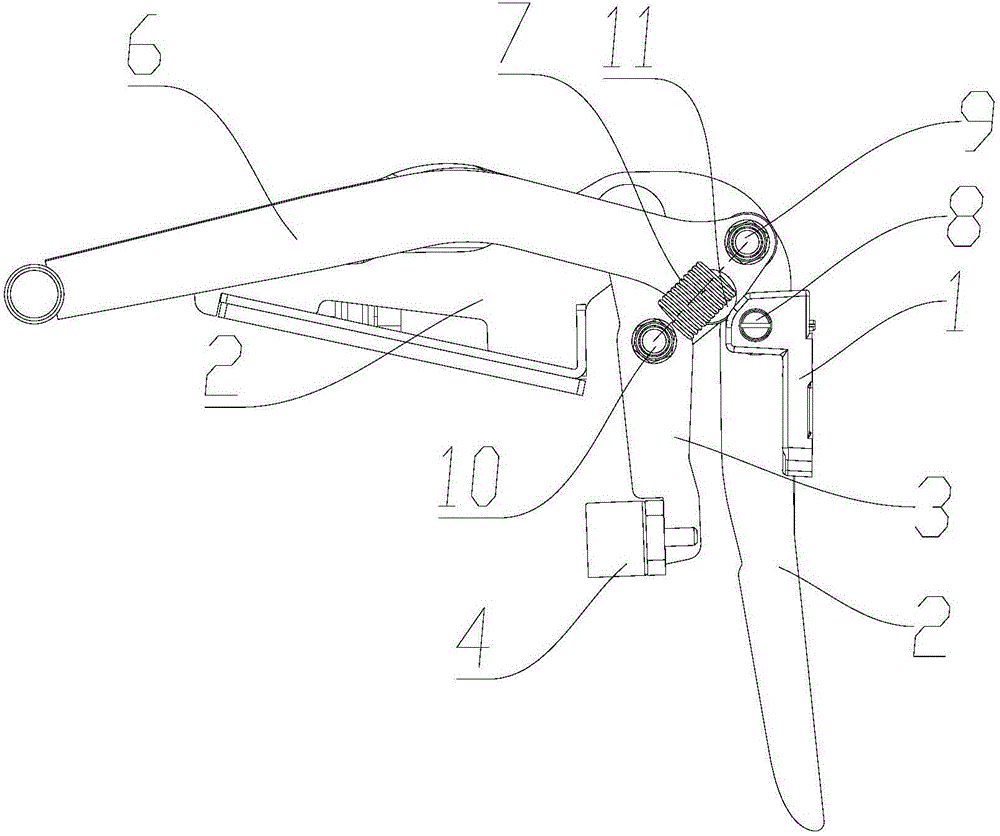

[0022] Such as Figure 1 to Figure 6 As shown, this embodiment is a clamping device for battery lateral movement, including a mounting base 1, a clamping part I2 and a clamping part II3, wherein the clamping part I2 is in the shape of a 7, and the clamping part I2 is from top to bottom The bottom is divided into guide clamping section 2-1, rotating shaft installation section 2-3 and limiting section 2-3 in turn.

[0023] In this example, the mounting base 1 is installed on the vehicle frame via bolts, and the clamping part I2 is rotatably connected to the mounting base 1 through the rotating shaft A8 of the rotating shaft mounting section 2-2 installed thereon. When there is no external force, the guide clamping section 2-1 rotates downward around the rotating shaft A8 until the limit section touches the vehicle frame. At this time, the direction of the guide clamping section 2-1 facing the battery has an inclined upward slope, forming The guide portion 2-1-1; the clamping po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com