Gear control device for tractor

A control device and tractor technology, applied in the field of tractors, can solve problems such as high labor intensity, poor comfort, and easy deformation, and achieve the effects of simple and compact structure, reliable gear shifting, and light and sensitive operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

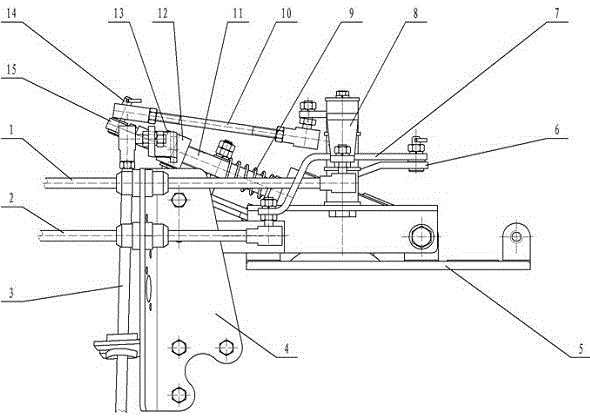

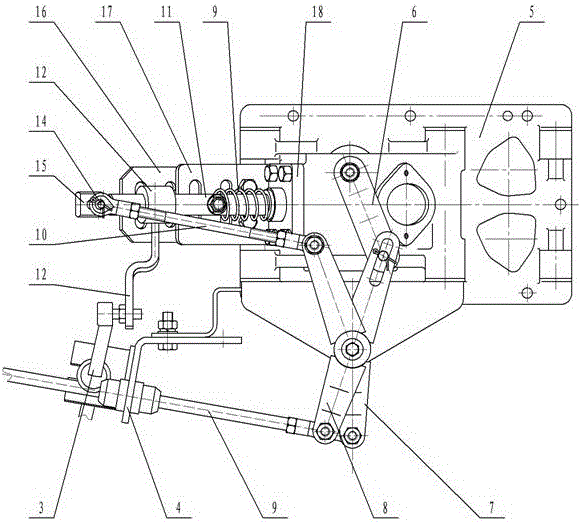

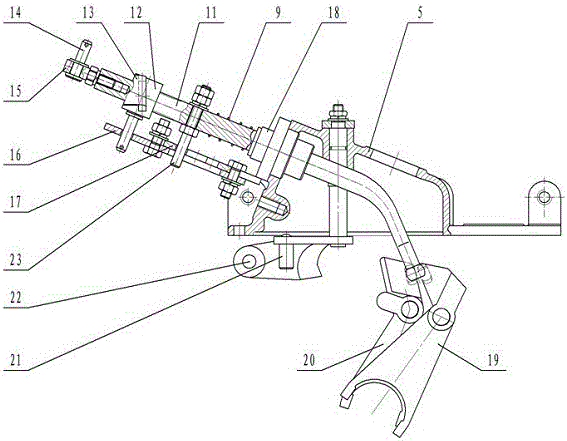

[0012] refer to figure 1 , figure 2 , image 3 , The high and low gear operating mechanism is made up of auxiliary speed shifting fork rotating arm 6, auxiliary speed changing flexible shaft rotating arm 7, auxiliary speed changing rotating arm 21, auxiliary speed changing shifting fork 22. Auxiliary shift fork 22 is installed in the gearbox. One end of the auxiliary transmission arm 21 is inserted into the fork groove of the auxiliary transmission shift fork 22, and its square head part passes through the installation hole of the transmission cover 5, and is connected with the square hole of the auxiliary transmission shift fork arm 6, and then locked with a nut tight. When pushing and pulling the auxiliary transmission flexible shaft rotating arm 7, the auxiliary transmission fork rotating arm 6 can be driven to rotate the auxiliary transmission rotating arm 21 so as to promote the displacement of the auxiliary transmission shifting fork 22 to realize switching between h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com