High-precision assembling and positioning method for groove type solar condenser array

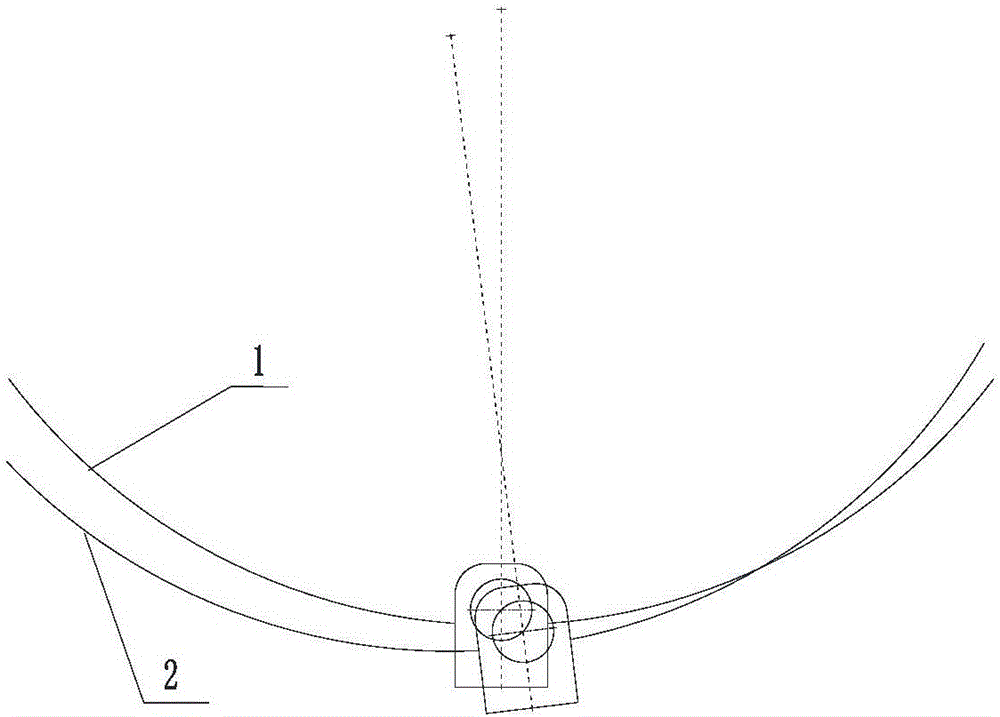

A trough-type solar energy and positioning method technology, which is applied in the field of high-precision assembly and positioning of trough-type solar concentrator arrays, can solve problems affecting the assembly accuracy of the light field and the progress of the project, and achieve the effect of improving installation efficiency and installation accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Example embodiments will now be described more fully with reference to the accompanying drawings. However, the example embodiments can be implemented in various forms, and should not be construed as being limited to the embodiments set forth herein; on the contrary, the provision of these embodiments makes the present invention more comprehensive and complete, and fully conveys the concept of the example embodiments To those skilled in the art.

[0029] A method for high-precision assembly and positioning of trough-type solar concentrator arrays, the steps include:

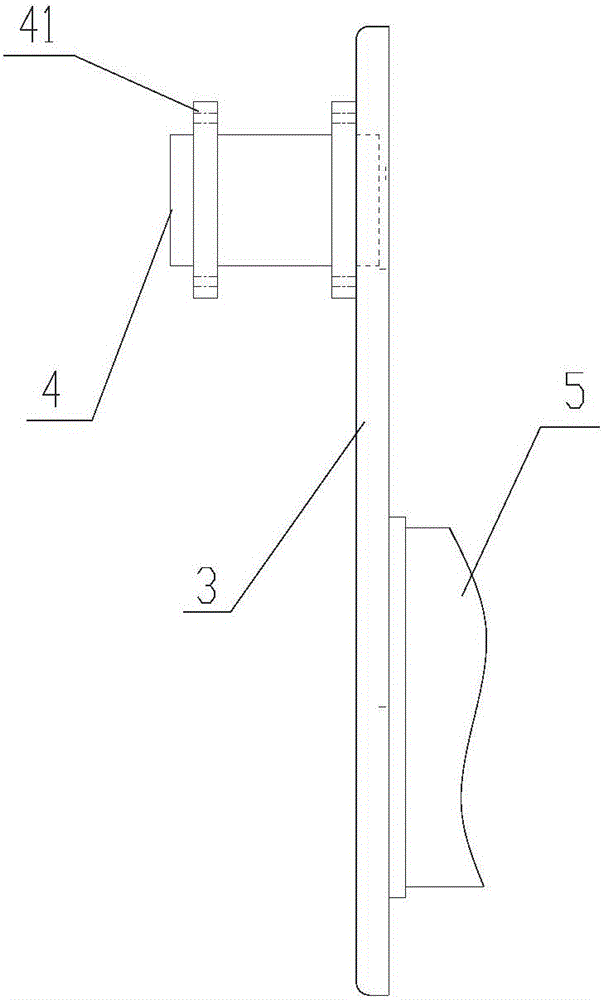

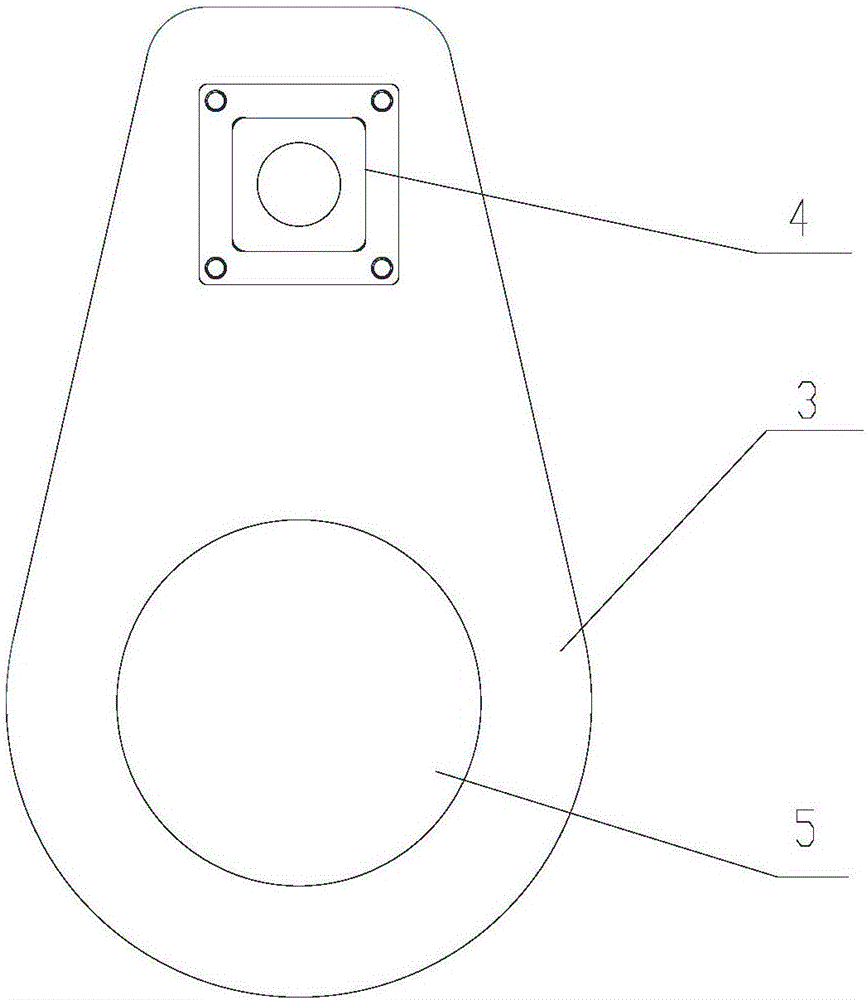

[0030] Such as figure 2 Shown is a schematic diagram of the side connection of the end plate 3, the connecting shaft 4, and the torque tube 8 in the present invention; image 3 Shown is a schematic diagram of the front connection of the end plate 3, the connecting shaft 4, and the torque tube 8 in the present invention.

[0031] Step 1: The cross section of the end of the connecting shaft 4 is rectangular. Insta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com