a marching fixer

A technology of marching fixer and fixing pin, which is applied to the fixation of guns, weapon accessories, offensive equipment, etc., can solve the problems of reducing the mobility of equipment and complex structure, and achieves improved reliability, good temperature adaptability, and strong mobility. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

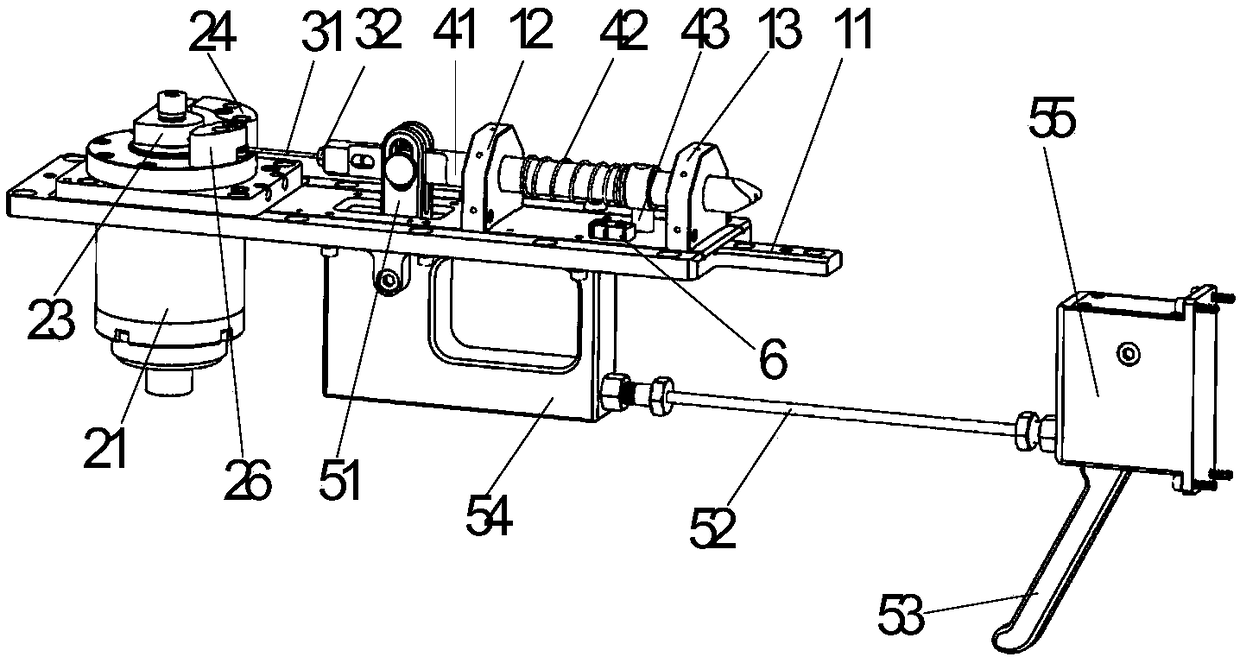

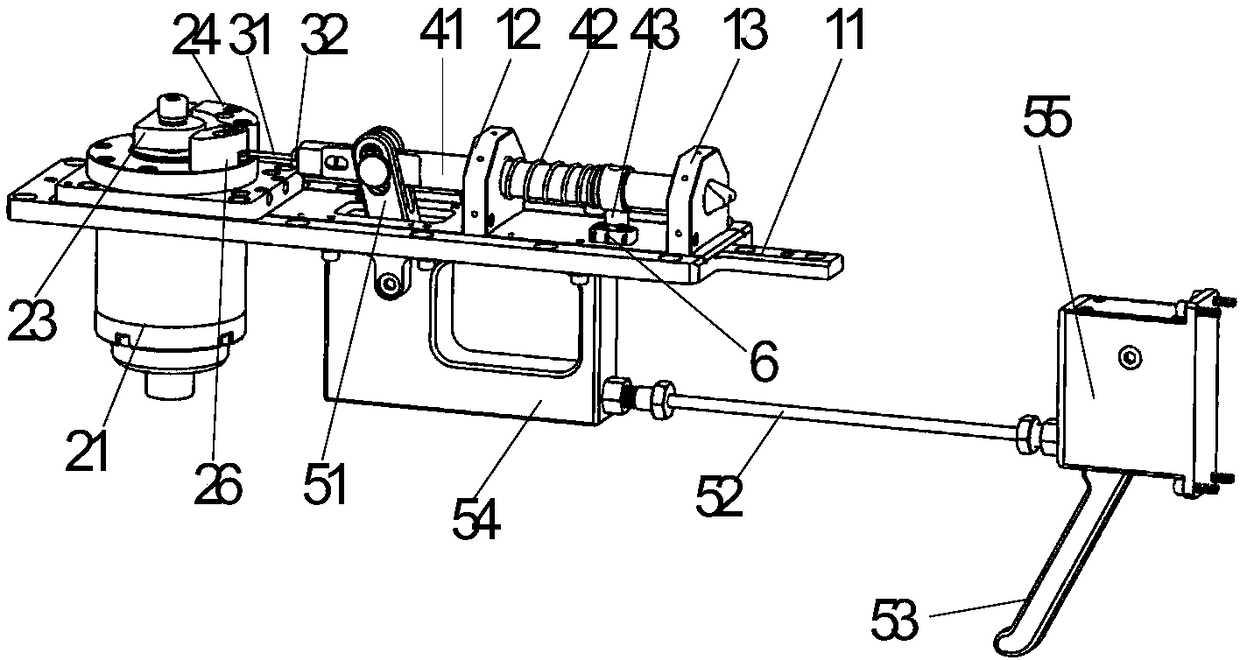

[0039] Such as figure 1 with 2 As shown, a marching fixer provided by Embodiment 1 of the present invention includes a base assembly 1 , a motor drive module 2 , a wire rope assembly 3 , a fixing pin assembly 4 , a manual unlock assembly 5 and a travel switch 6 .

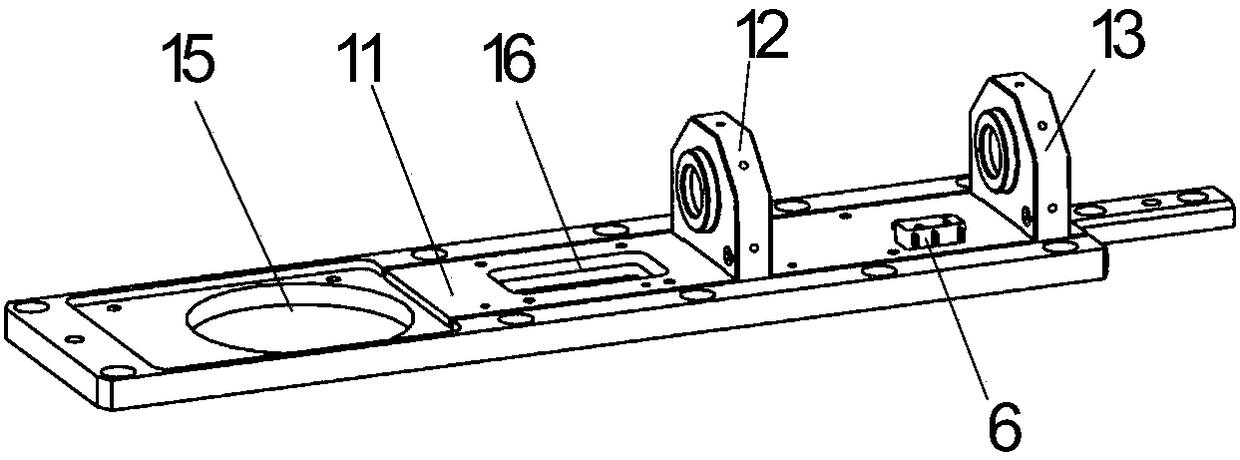

[0040] Such as image 3 As shown, the base assembly 1 includes a base plate 11, a front bearing seat 12 and a rear bearing seat 13, the front bearing seat 12 and the rear bearing seat 13 are fixedly arranged on the upper surface of the end portion of the base plate 11 from the inside to the outside, and the other side of the base plate 11 The upper surface of one end is sequentially provided with a manual unlocking component mounting hole 16 and an automatic unlocking component mounting hole 15 from the inside to the outside. In addition, a travel switch 6 is also arranged between the front bearing seat 12 and the rear bearing seat 13 of the base plate 11 .

[0041] Such as Figure 4 As shown, the fixed pin asse...

Embodiment 2

[0047] A marching fixer provided by Embodiment 2 of the present invention is similar to the structure of Embodiment 1 of the present invention, the difference is that, as Figure 10 As shown, in the inner holes of the front bearing seat 12 and the rear bearing seat 13 of the base assembly 1, the front guide tube 17 and the rear guide tube 18 are sleeved respectively to further support and accurately guide the fixed pin 41; in addition ,Such as Figure 11 As shown, in the motor drive module, a reduction mechanism 222 is also provided between the torque motor 21 and the hard block 23. Specifically, the reduction mechanism 222 is a pair of gears, and the torque motor 21 drives the hard block 23 to rotate through the pair of gears 222. , to achieve further precise control and stable operation; Figure 12 As shown, the outer ends of the release block 24 and the return block 26 are respectively provided with a release buffer pad 25 and a return buffer pad 27. When the unlocking is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com