Linear variable differential transformer type sensor and winding method

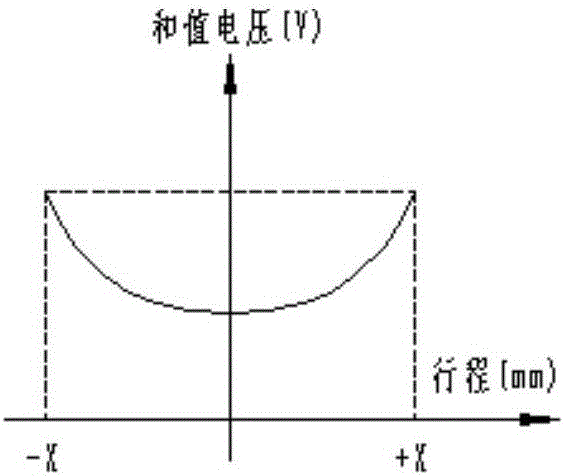

A differential transformer type, winding method technology, applied in the direction of converting sensor output, using electromagnetic/magnetic devices to transmit sensing components, instruments, etc. Monitoring and other issues to achieve the effect of facilitating online monitoring and improving the itinerary

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

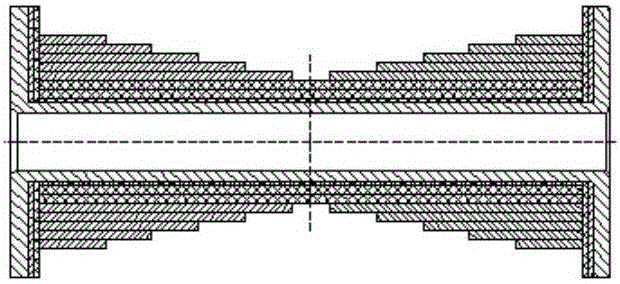

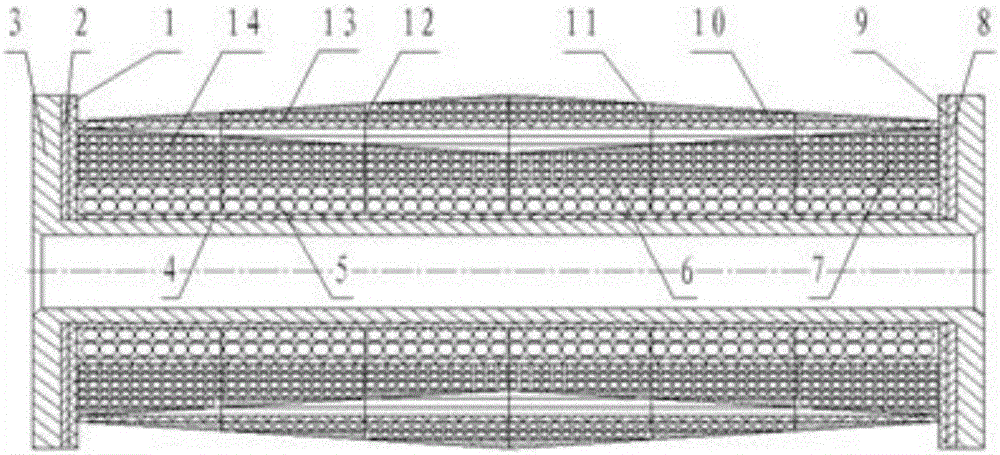

[0026] The specific implementation of the variable differential transformer type sensor with the first secondary coil 7 and the fourth secondary coil 14 wound with 4 layers is given below:

[0027] The linear variable differential transformer sensor includes a first polytetrafluoroethylene coil 1, a soft magnetic alloy coil 2, a coil former 3, a first polyimide film 4, a primary coil 5, a second polyimide film 6, The first secondary coil 7, the soft magnetic alloy coil 8, the second polytetrafluoroethylene coil 9, the third polyimide film 10, the second secondary coil 11, the third secondary coil 12, the fourth polyimide Amine film 13, the fourth secondary coil 14; wherein the second secondary coil 11 and the fourth secondary coil 14 are wound by the same enameled wire to become the secondary coil A; the first secondary coil 7 and the third secondary coil 12 is wound by the same enameled wire and becomes the secondary coil B;

[0028] The first polytetrafluoroethylene coil 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com