A mounting assembly suitable for monitoring rotating parts of rolling bearings

A technology for rotating components and installing components, which is applied in the testing of mechanical components, testing of machine/structural components, and measuring devices. Effect reduction, general effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The specific implementation process of the present invention will be further explained below in conjunction with the accompanying drawings.

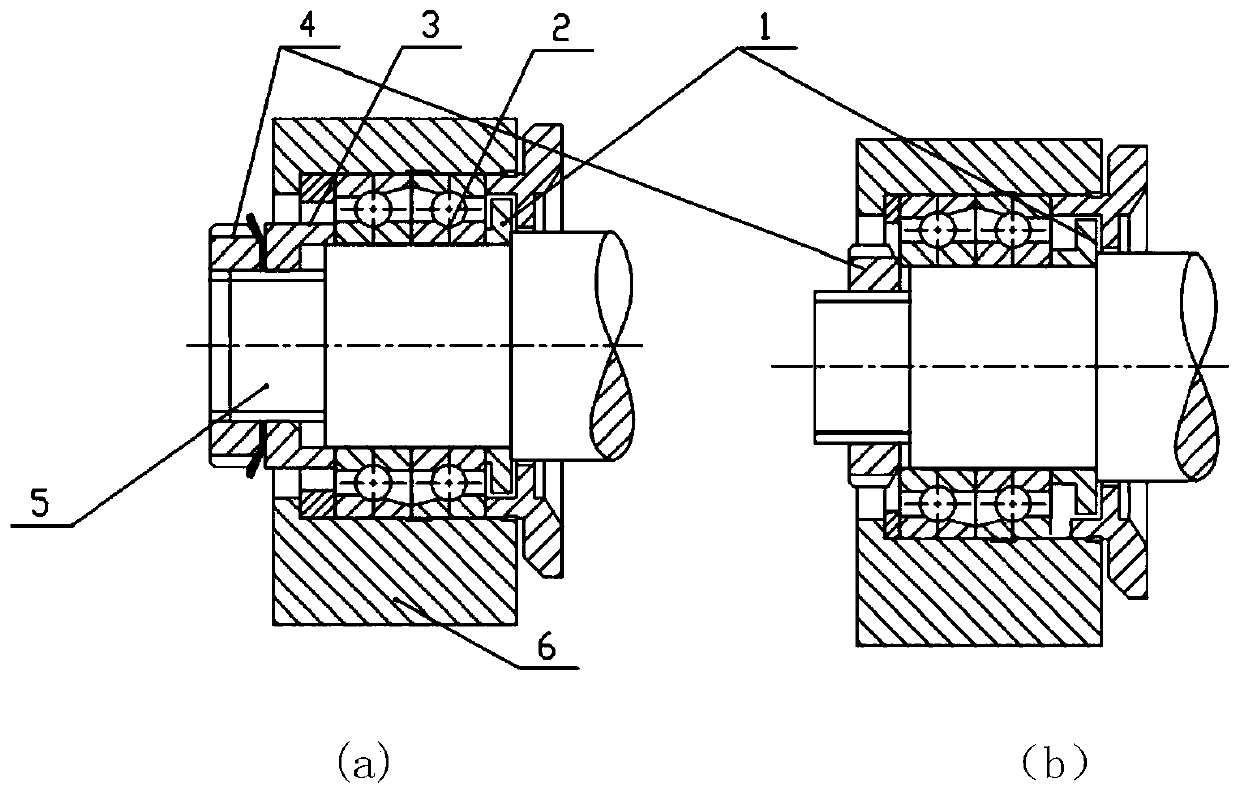

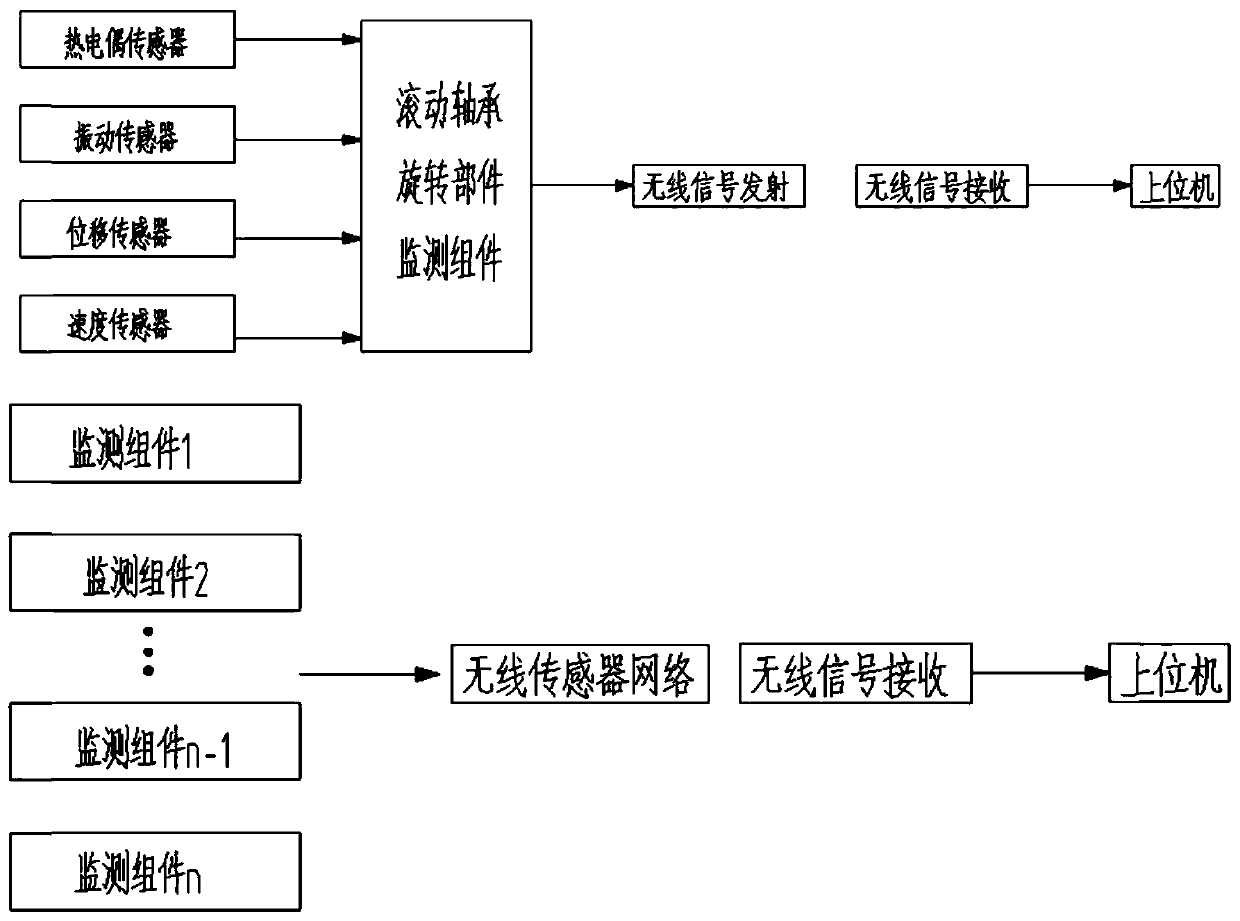

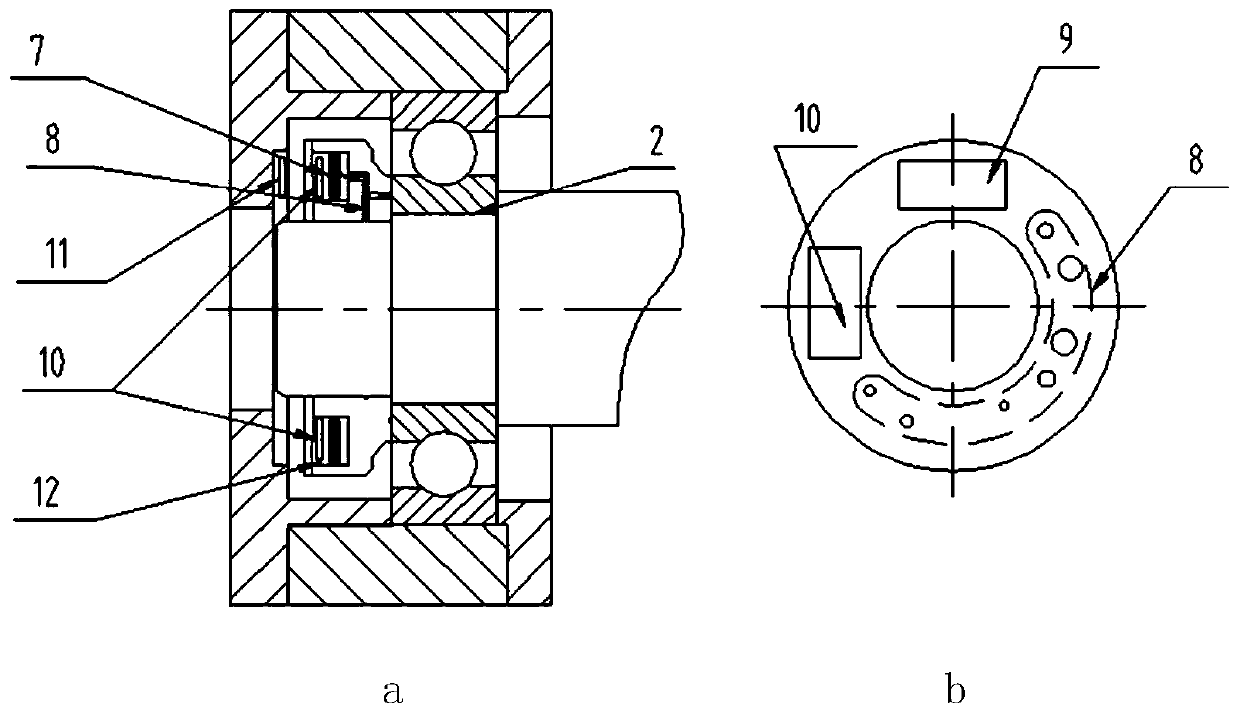

[0027] refer to figure 1 , image 3 , an installation assembly suitable for monitoring rotating parts of rolling bearings, characterized in that a test system 7 is embedded on the rotating assemblies 1, 3, 4 close to the bearing 2, and the test system 7 includes a sensor module 8, a wireless communication module 9 and a wireless charging receiving module 10 to realize the status monitoring of the rotating parts of the bearing. Rolling bearings usually adopt the method of fixing the outer ring and rotating the inner ring. This manual uses this working method as an example to describe it. The working method of rotating the outer ring and fixing the inner ring is also applicable.

[0028] The rotating assembly includes a lock nut 4 and a spacer 1, 3, and the lock nut 4 and the spacer 1, 3 are radially provided with a groove 12 alon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com