Display baseplate, manufacturing method thereof and display device

A technology for a display substrate and a manufacturing method, which is applied to identification devices, instruments, nonlinear optics, etc., can solve the problems of reduced picture display quality and inconsistent level difference of the display device, and achieves the effect of improving the picture display quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

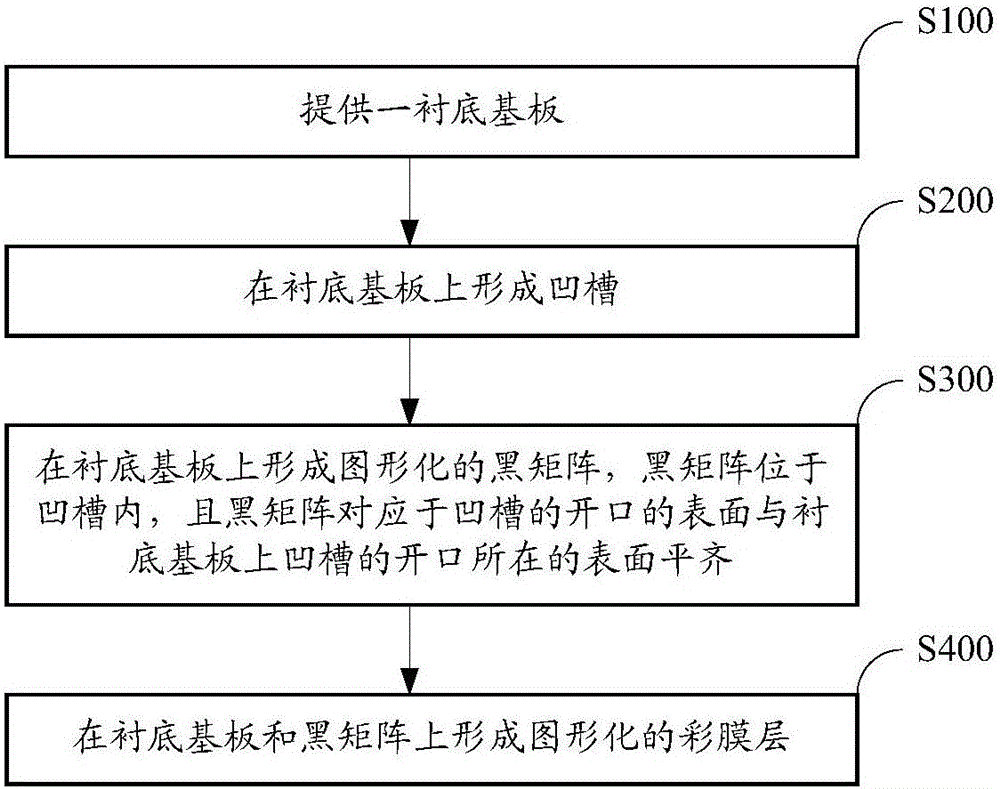

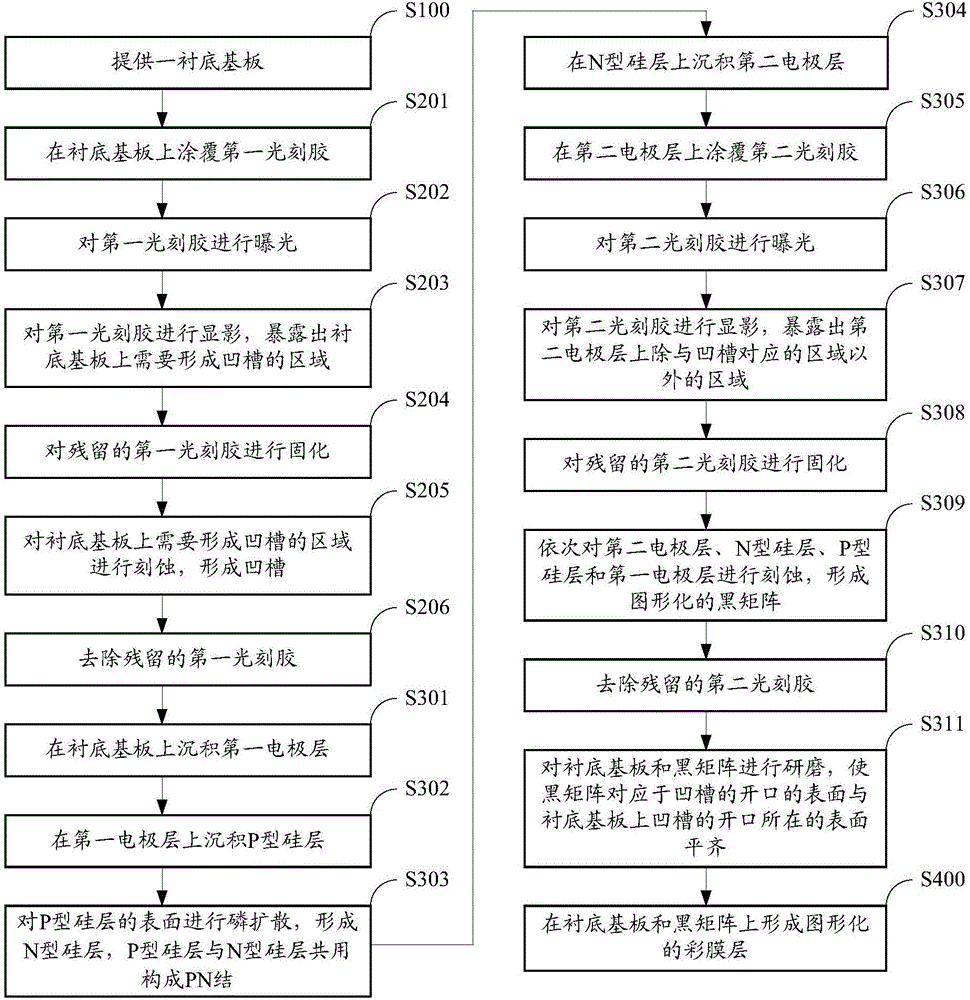

[0032] In order to further illustrate the display substrate, the manufacturing method thereof, and the display device provided by the embodiments of the present invention, a detailed description will be given below in conjunction with the accompanying drawings.

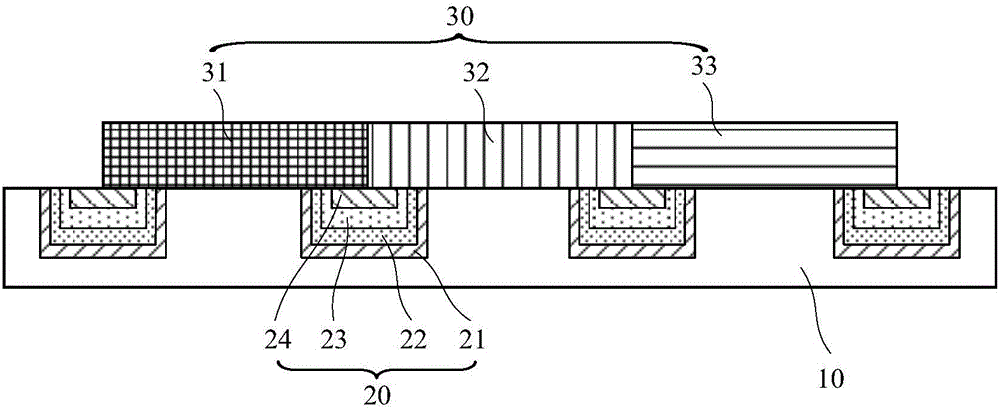

[0033] see figure 1 The display substrate provided by the embodiment of the present invention includes a base substrate 10 and a patterned black matrix 20, the base substrate 10 is provided with a groove, the black matrix 20 is located in the groove, and the black matrix 20 corresponds to the opening of the groove The surface is flush with the surface where the opening of the groove on the base substrate 10 is located.

[0034] For example, see figure 1 , in the display substrate provided by the embodiment of the present invention, the base substrate 10 is provided with grooves, such as figure 1 As shown, the opening of the groove is located at figure 1 The upper surface of the substrate substrate 10, namely figur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com