Optical membrane material, color film substrate, manufacturing method of color film substrate and display device

A technology of optical film materials and color film substrates, which is applied in the field of optoelectronics, can solve the problems of small viewing angles of liquid crystal displays, and achieve the effects of eliminating optical compensation films, reducing costs, and avoiding color shift

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] In order to make the object, technical solution and advantages of the present invention clearer, the implementation manner of the present invention will be further described in detail below in conjunction with the accompanying drawings.

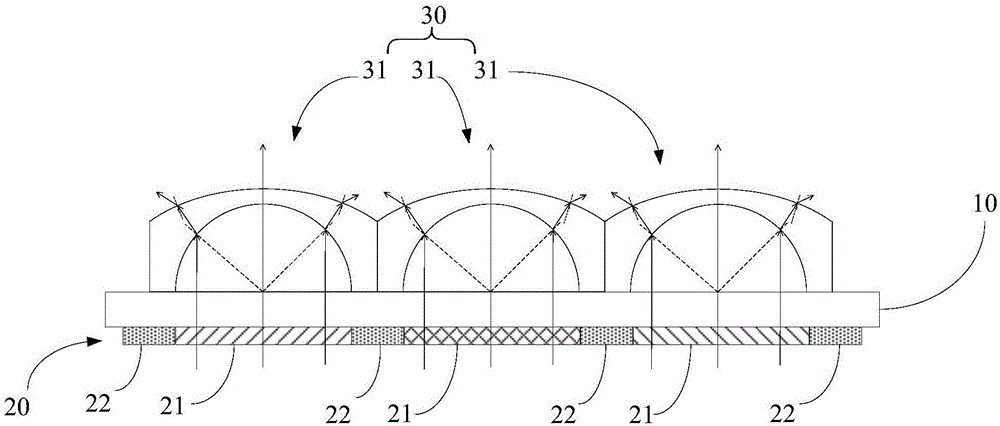

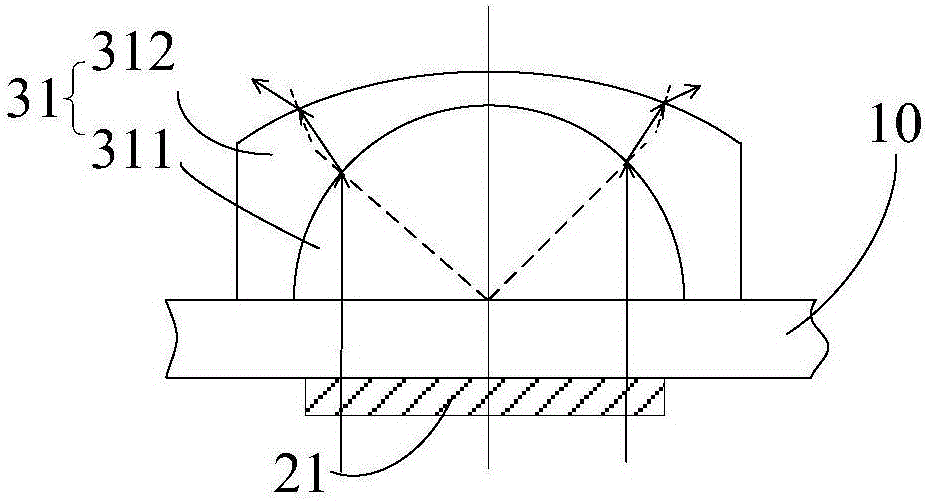

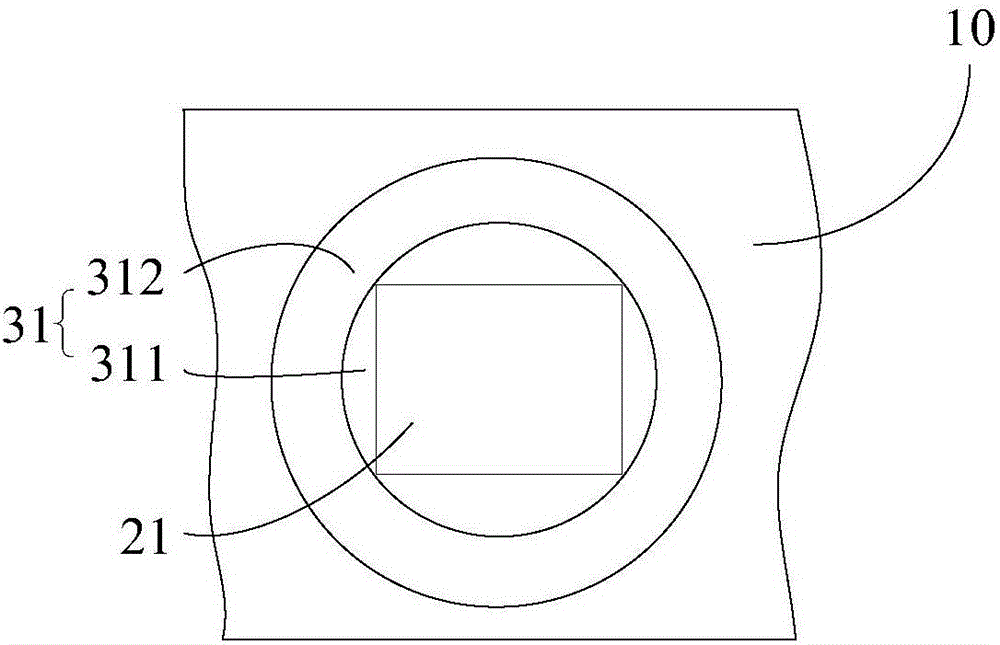

[0055] figure 1 is a schematic structural view of the color filter substrate provided by the embodiment of the present invention, as shown in figure 1 As shown, the color filter substrate includes a base 10, a color-resist layer 20, and a diffuser layer 30, wherein the color-resist layer 20 and the diffuser layer 30 are arranged on the base 10, and the color-resist layer 20 and the diffuser layer 30 are respectively located on two sides of the base 10. On the other hand, the color resistance layer 20 includes a plurality of color resistance blocks 21 arranged in an array, and the divergence layer 30 includes a plurality of divergence structures 31 corresponding to the plurality of color resistance blocks 21, and each divergence structu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com