Production executing system, method for monitoring data exception and method for monitoring production

A technology of production execution system and monitoring data, which is applied in the direction of general control system, control/regulation system, program control, etc., and can solve the problems of abnormal monitoring data and low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

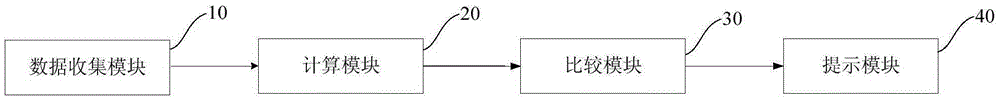

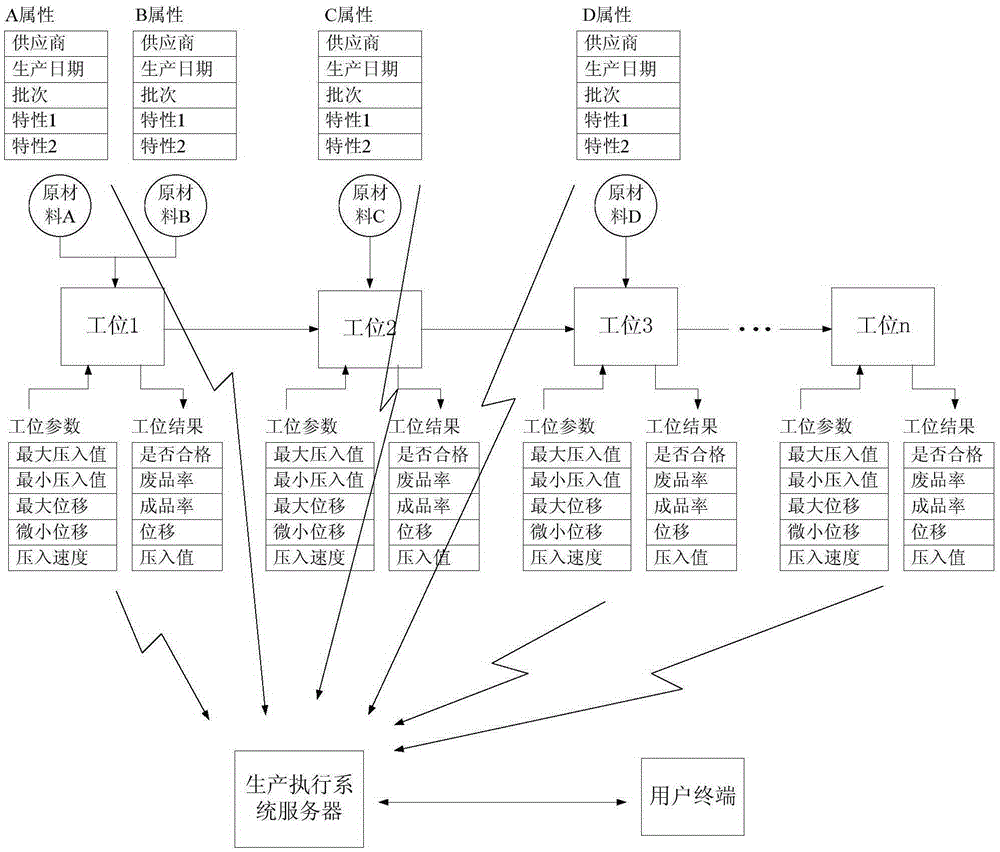

[0040] Combination below Figure 1 ~ Figure 3 The method for monitoring abnormal data of the present invention is specifically described, figure 1 It is a schematic diagram of the structure of the production execution system, including:

[0041] The data collection module 10 is used to collect the input data and output data on each station on the production line, wherein, the structural schematic diagram of the production line refers to figure 2As shown in , the production line includes several stations, such as station 1, station 2, station 3..., the data collection module 10 automatically collects some input data and output data on each station on the production line, the input The data includes raw material attributes and station parameters on each station. Raw material attributes include raw material suppliers, batches, production dates and their characteristics. It is understandable that each station can have one or more raw materials. This In the embodiment, take stat...

Embodiment 2

[0058] The difference between this embodiment and the first embodiment is that at a certain moment, more than two input data among several input data are changed at the same time, and they are treated as a whole, for example, the data of raw material A in station 1 is changed at the same time. Batch and press speed. Before the change and after the change, the significance of the output data on each workstation is calculated within a plurality of time widths. The method for calculating the significance is the same as that in Embodiment 1, and will not be repeated here.

[0059] According to the calculated significance results, determine whether the impact of the above changes on the output results at the workstation is significant. If the significance is greater than the confidence coefficient, the production execution system will prompt the manager that the change of the above two input data has a significant impact on the output result of a certain station. Through the metho...

Embodiment 3

[0061] Using the above-mentioned production execution system, this embodiment also provides a method for monitoring production, which is combined below figure 1 , figure 2 and Figure 4 Describes methods for monitoring production.

[0062] Execute step S11, refer to figure 1 As shown in , the data collection module 10 automatically collects the input data and output data of a station in the production line, and this step is the same as that in Embodiment 1, and will not be repeated here. The input data includes several parameters, each parameter has a plurality of set values, several combinations are formed between each set value of each parameter, and the input data formed by each combination produces several batches of products. For example, in this embodiment, take raw material A and raw material B of station 1 as an example for illustration, raw material A is provided by two suppliers, namely supplier A and supplier B, and raw material B is provided by two suppliers, n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com