Torque motor driver for electro-hydraulic servo valve testing

A technology of electro-hydraulic servo valve and torque motor, applied in instruments, adjusting electrical variables, control/regulating systems, etc., can solve the problems of narrow output range and low precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

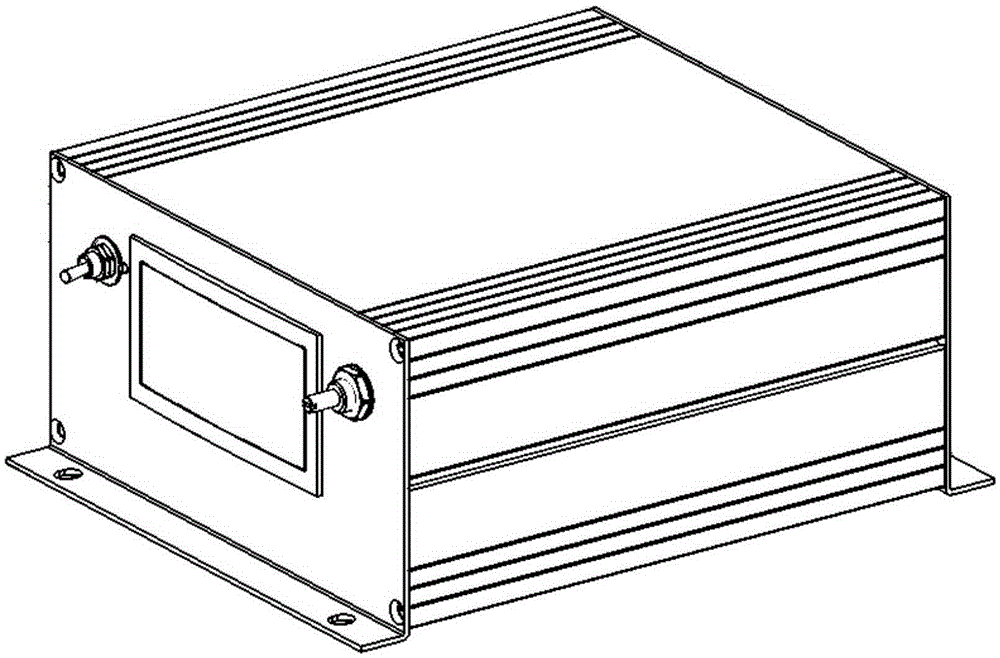

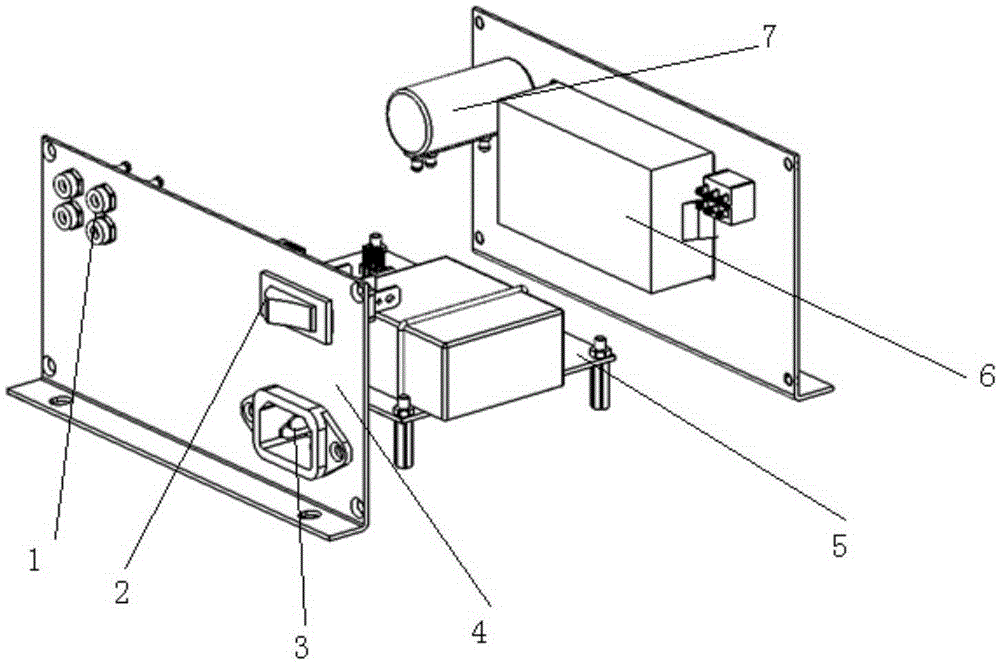

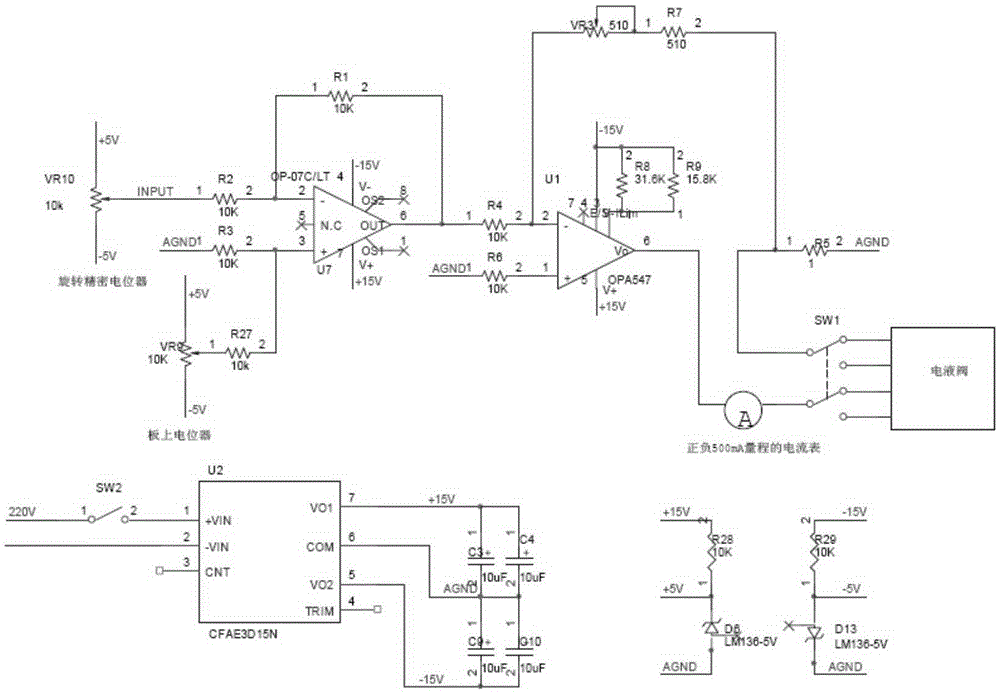

[0022] Provides a torque motor drive instrument for testing electro-hydraulic servo valves, including a box body, coil positive and negative terminal assembly, ammeter, power switch, power socket, precision potentiometer and integrated circuit board; the coil positive and negative terminal assembly , ammeter, power switch, power socket, integrated circuit board and precision potentiometer are all fixedly installed on the box body; the integrated circuit board is integrated with an AC-to-DC power supply module, an amplifying bias circuit module and a voltage-current conversion circuit module; the power switch has indicator light; the precision potentiometer has an adjustment knob; the power socket (3) is used to connect the 220V mains and connect the 220V mains to the AC-to-DC power module of the integrated circuit board; the power switch (2) controls the power socket (3 ) on and off;

[0023] The AC to DC power module converts 220V mains power into positive and negative 15V ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com