A kind of mobile terminal 3D glass cover plate and manufacturing method thereof

A glass cover and mobile terminal technology, which is applied in the direction of instruments, coatings, computing, etc., can solve the problems of light leakage, 3D glass cover light leakage, 3D glass cover mass production process, etc., and achieve the effect of simplifying the process and reducing product costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

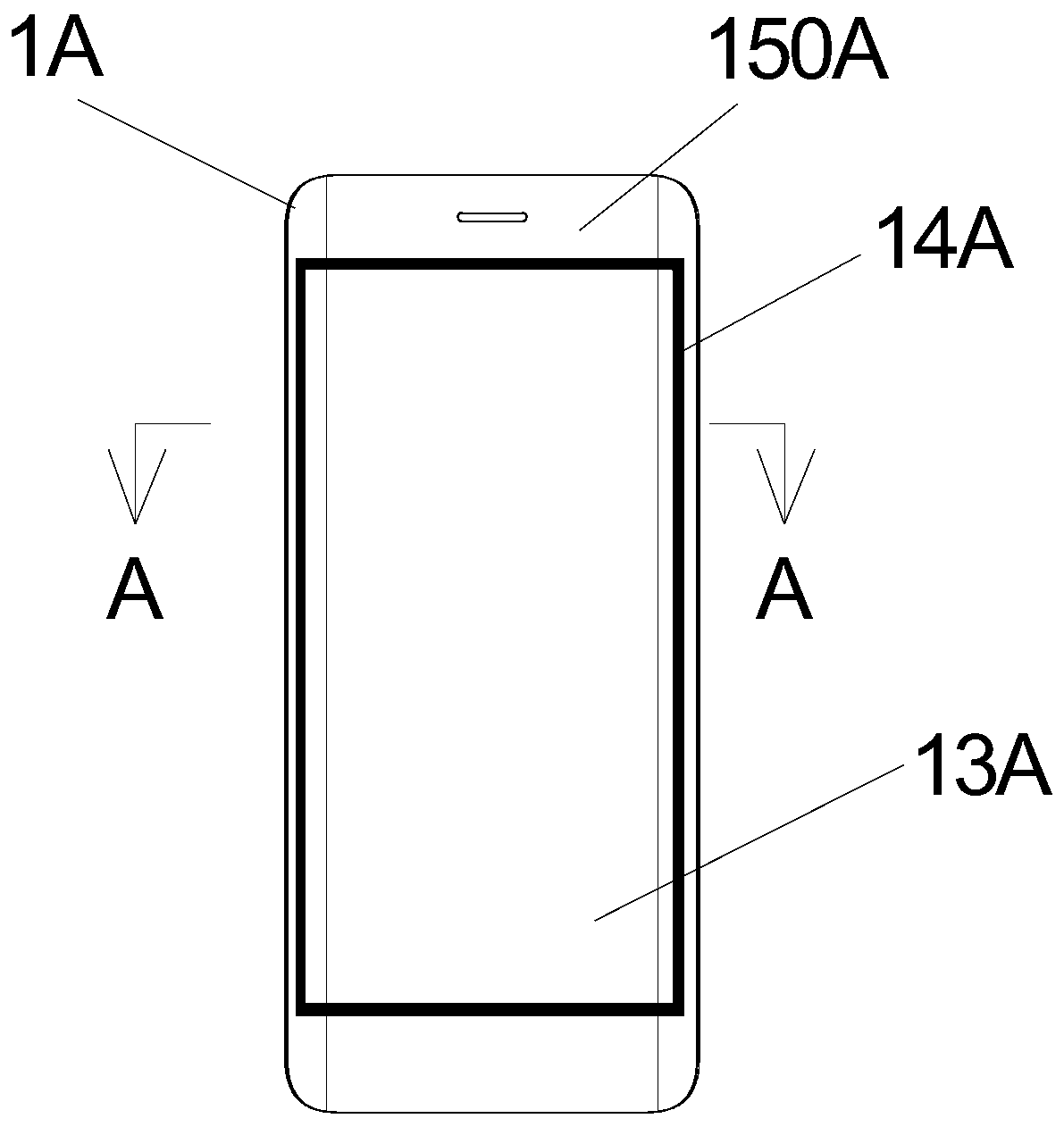

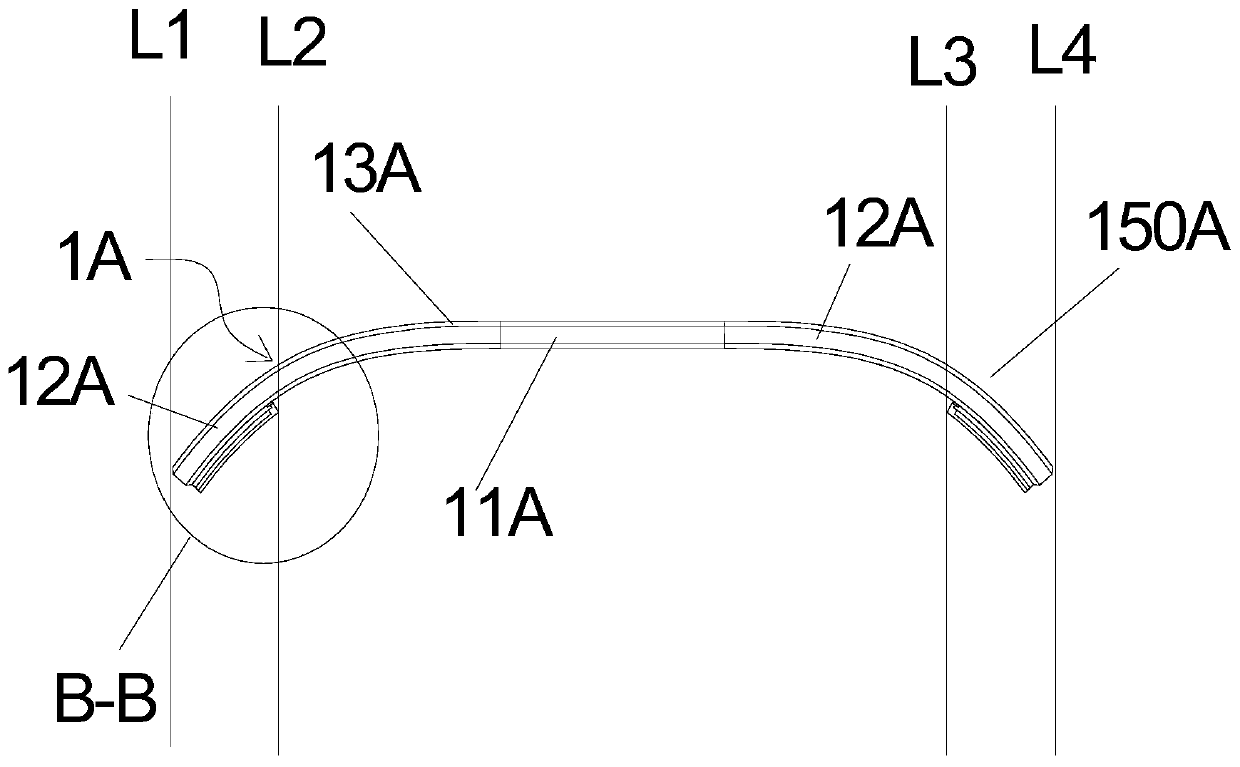

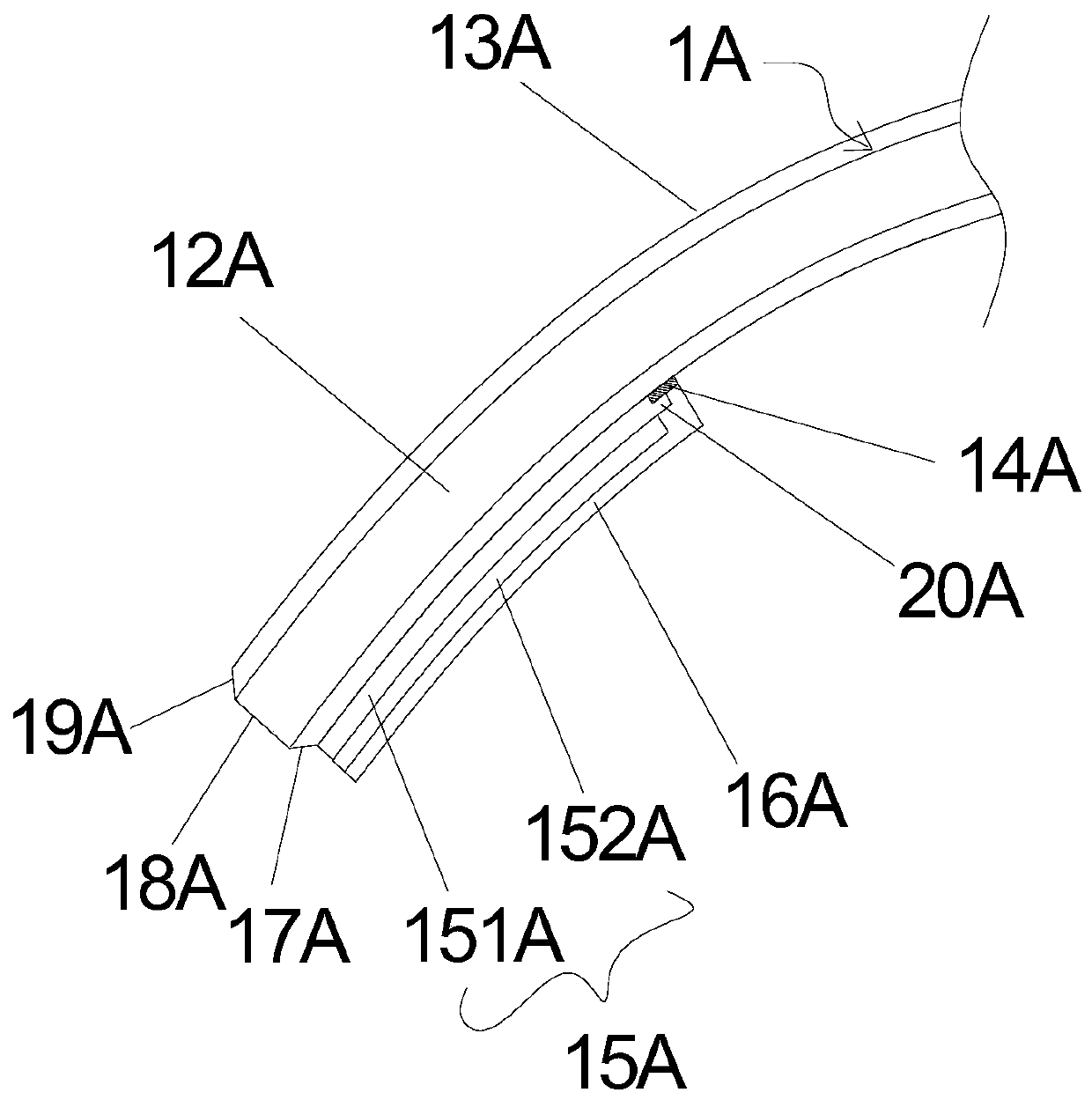

[0033] Such as Figure 5 , Figure 6 As shown, a mobile terminal 3D glass cover of the present invention includes a glass cover body 1 and an ink covering part 2 arranged on the bottom surface 15 of the glass cover body 1. The glass cover body 1 includes a middle flat part 11 and The 3D curved part 12 located at the edge, the middle of the ink covering part 2 encloses a transparent visible area 13, the glass cover body 1 includes a top surface 14, a bottom surface 15, and a side surface 16 connecting the top surface 14 and the bottom surface 15, and the ink covering part 2 extends To the side 16, part or the whole side 16 is covered. The ink covering portion 2 forms an ink shading area 24 (invisible area), and four dividing lines L1, L2, L3, L4 are marked in the figure; wherein between the dividing lines L1 and L2, between the dividing lines L3 and L4 are the ink shading areas 24 (invisible area); between the boundary lines L3 and L2 is a transparent visible area 13 . The 3...

Embodiment 2

[0040] A method for manufacturing a mobile terminal 3D glass cover of the present invention, the mobile terminal 3D glass cover described in this embodiment has the same structure as the mobile terminal 3D glass cover described in Embodiment 1, as Figure 7 As shown, it is achieved through the following steps:

[0041] Process 1. Production of the inner ink black frame 21: spray a layer of black photosensitive ink on the bottom surface of the 3D glass cover body 1, then expose to UV light, develop and etch to obtain the inner ink black frame 21;

[0042] Process 2. Production of the white ink layer 22: on the basis of process 1, spray white photosensitive ink on the bottom surface of the 3D glass cover plate body 1, the inner chamfer surface 161 and the surface of the vertical surface 162, and then expose it by UV light. After developing and etching, the white ink layer 22 is obtained.

[0043] Process 3. Production of black ink layer 23: on the basis of process 2, spray a la...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com