Patents

Literature

93results about How to "Avoid refraction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

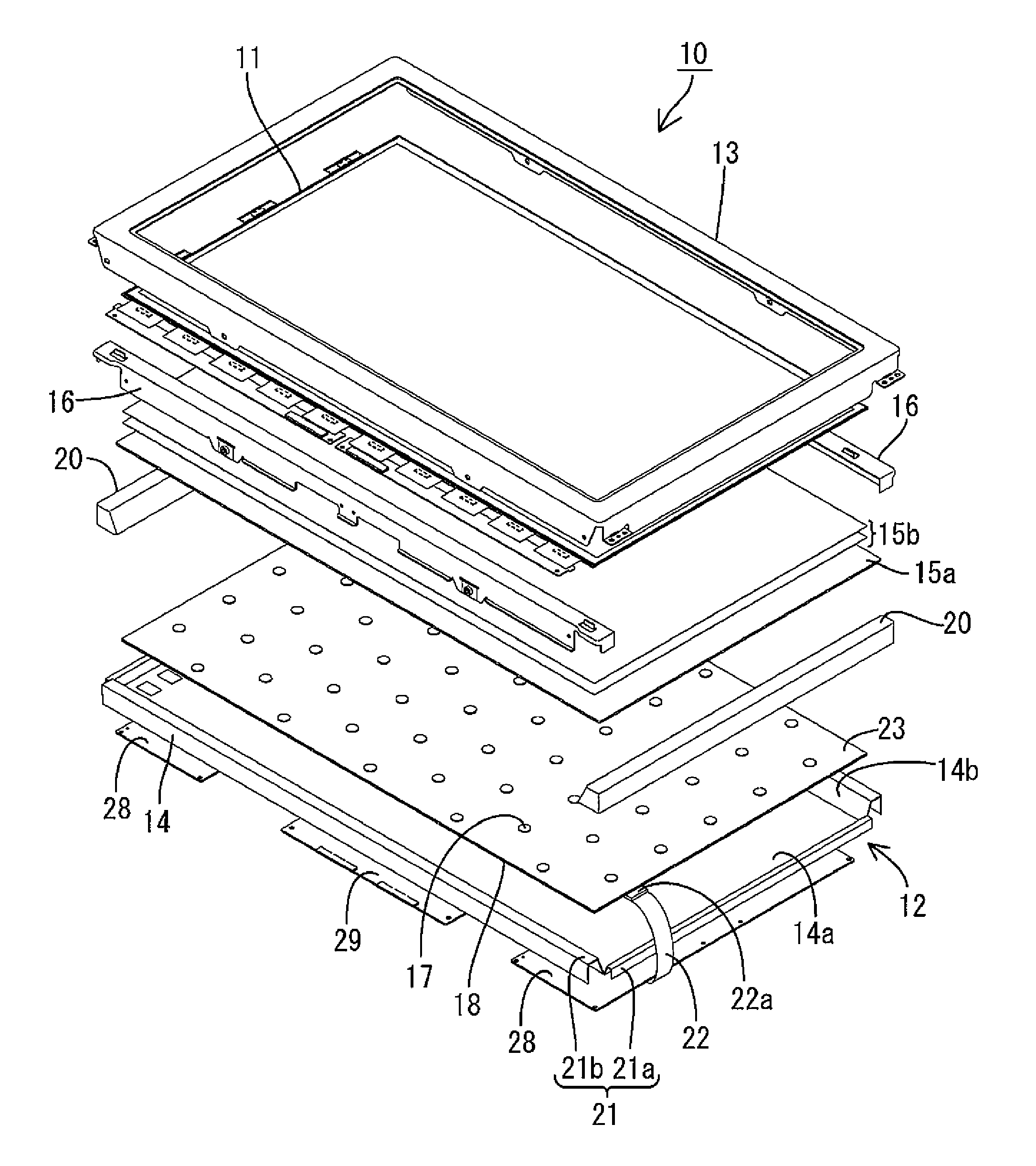

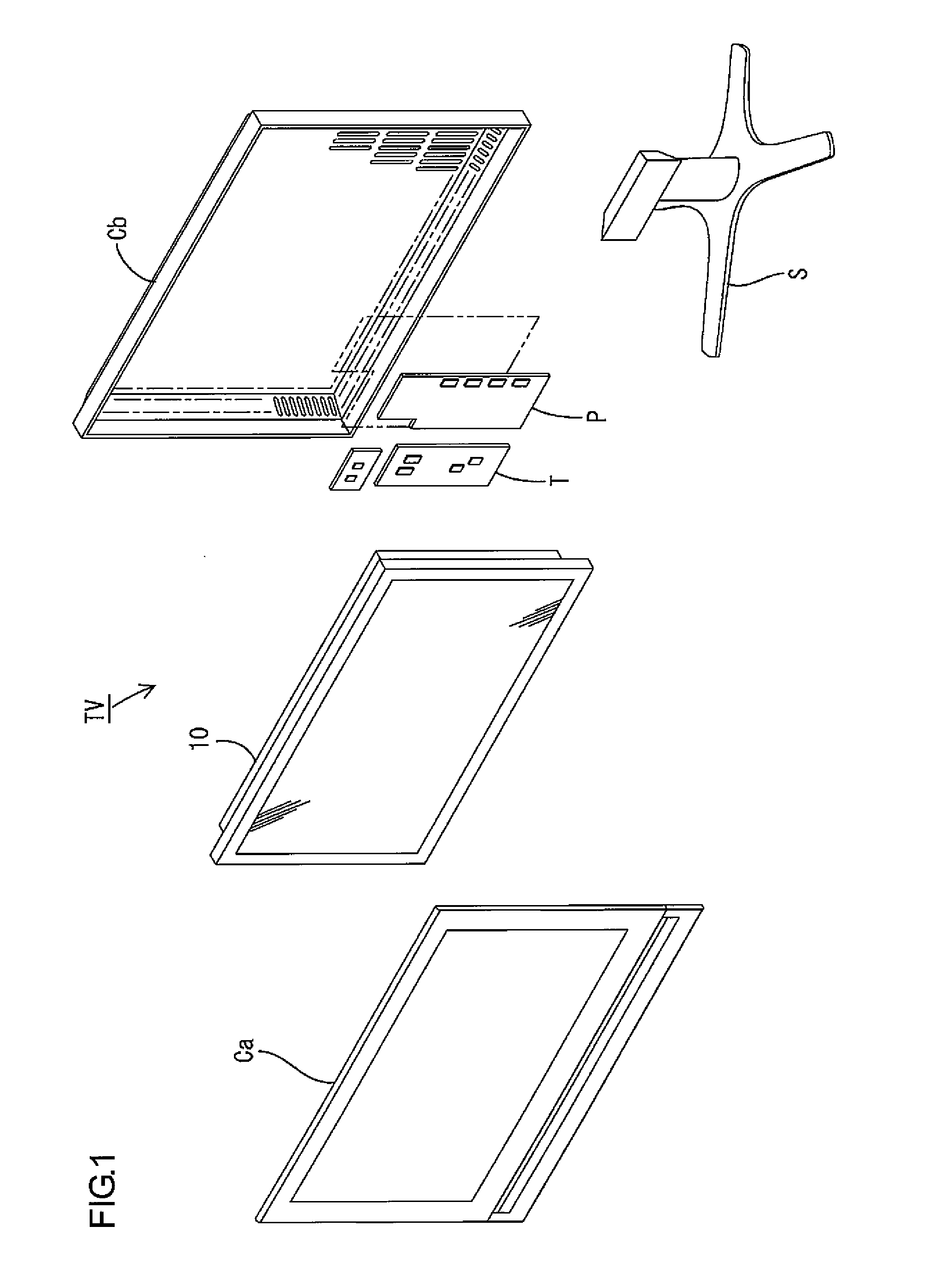

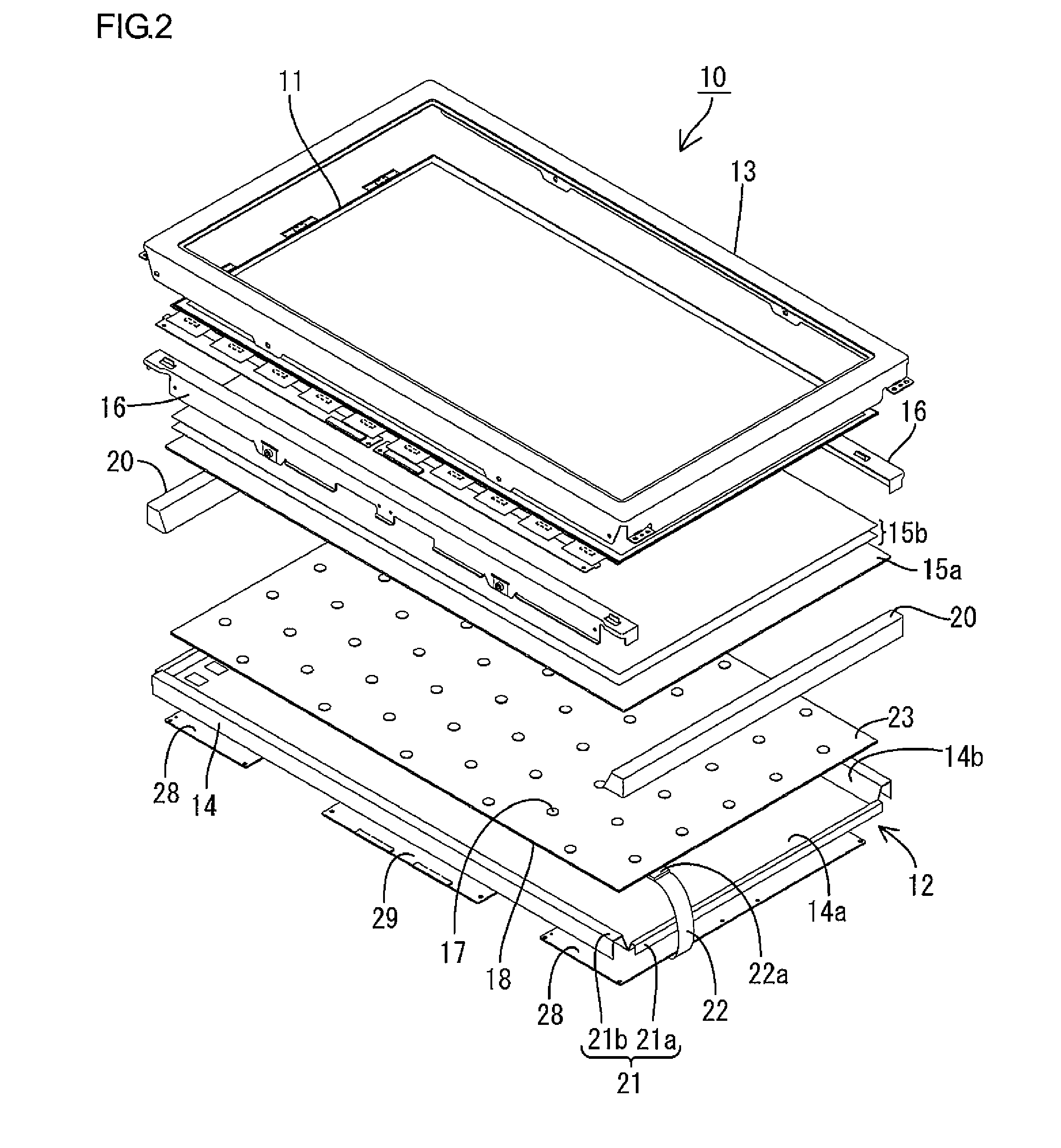

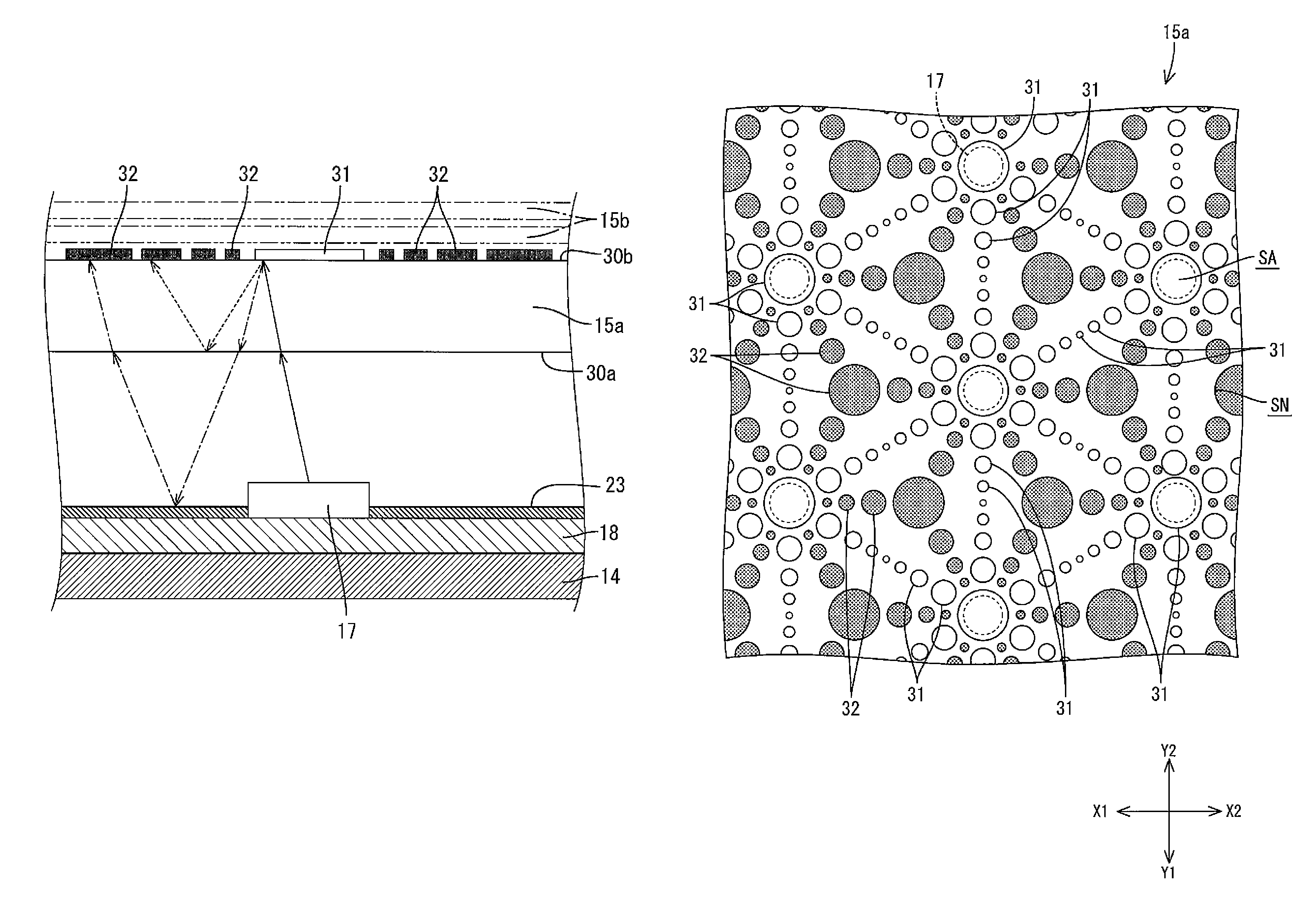

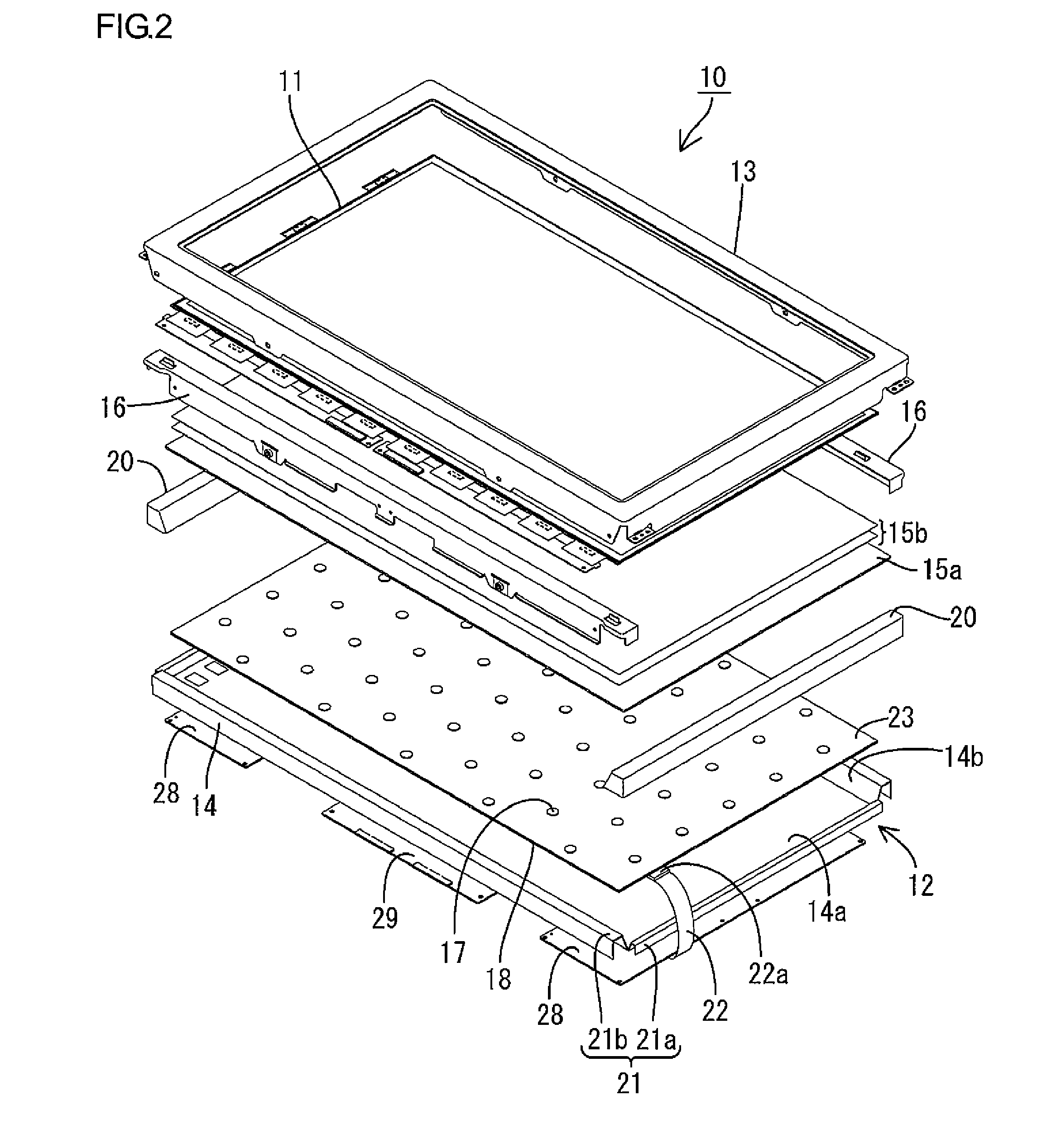

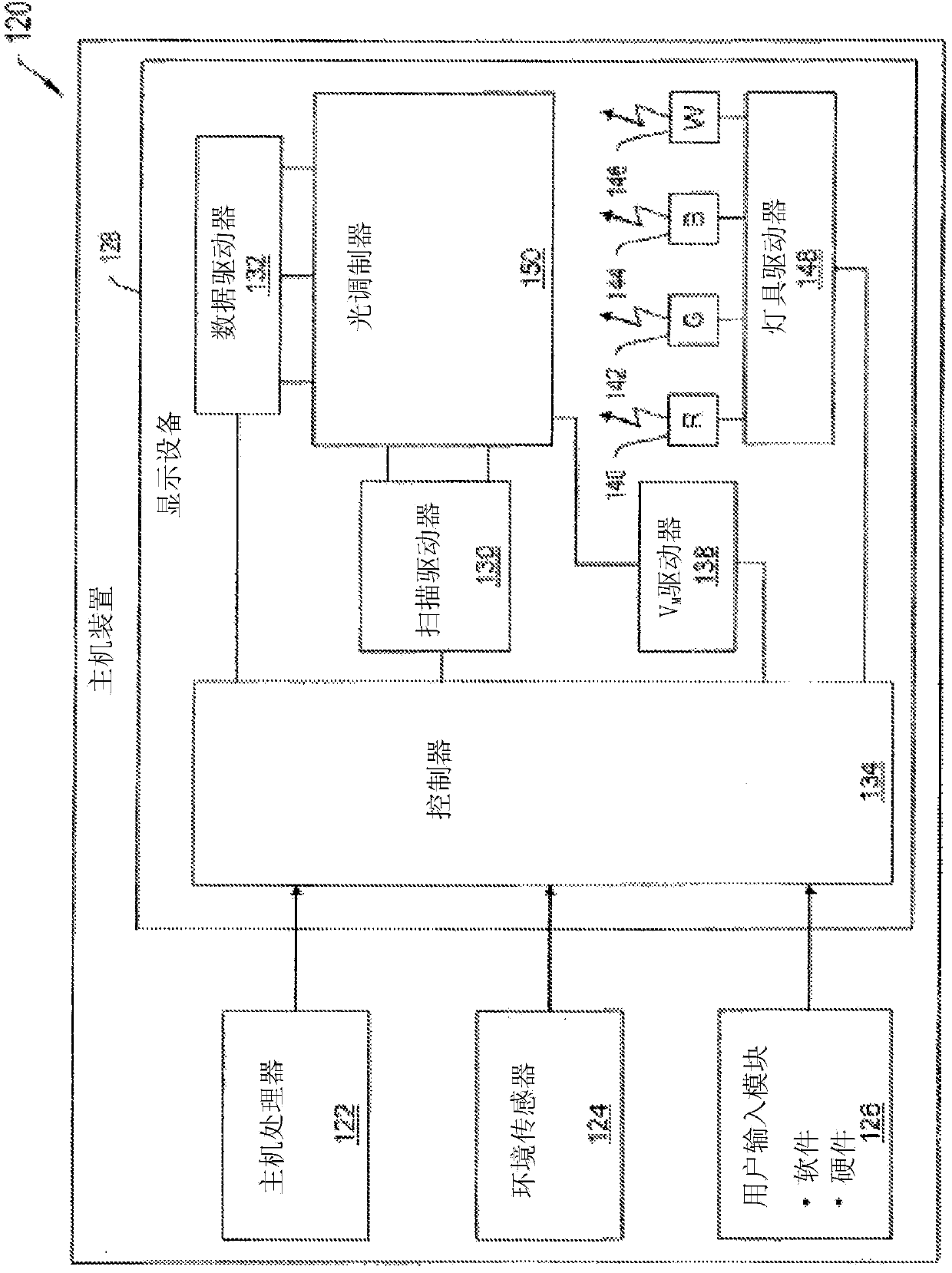

Lighting device, display device and television receiver

ActiveUS20110205448A1Uniform brightnessCompensate brightnessTelevision system detailsPoint-like light sourceTelevision receiversDisplay device

A lighting device 12 includes at least one point light source 17, an optical member 15a provided on a light output side of the lighting device 12 from the point light source 17. The optical member 15a is formed of a member having a substantially uniform light reflectance. A first light reflecting portion 31 is formed on a portion of the optical member 15a that overlaps the point light source 17, and the first light reflecting portion 31 reflects light from the point light source 17. A second light reflecting portion 30a, 23 is provided to reflect the light that is reflected by the first light reflecting portion 31 to be directed to the first light reflecting portion 31.

Owner:SHARP KK

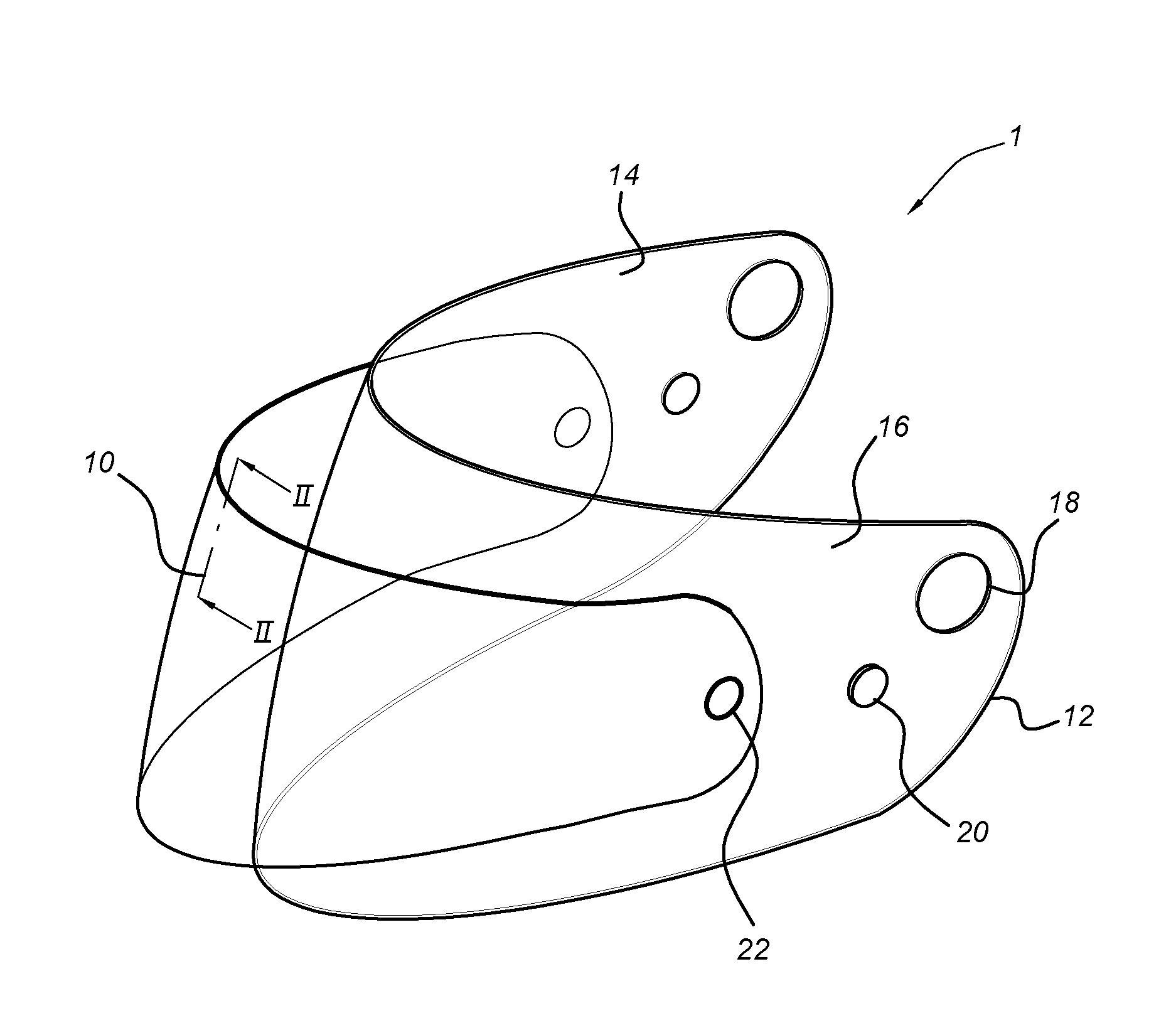

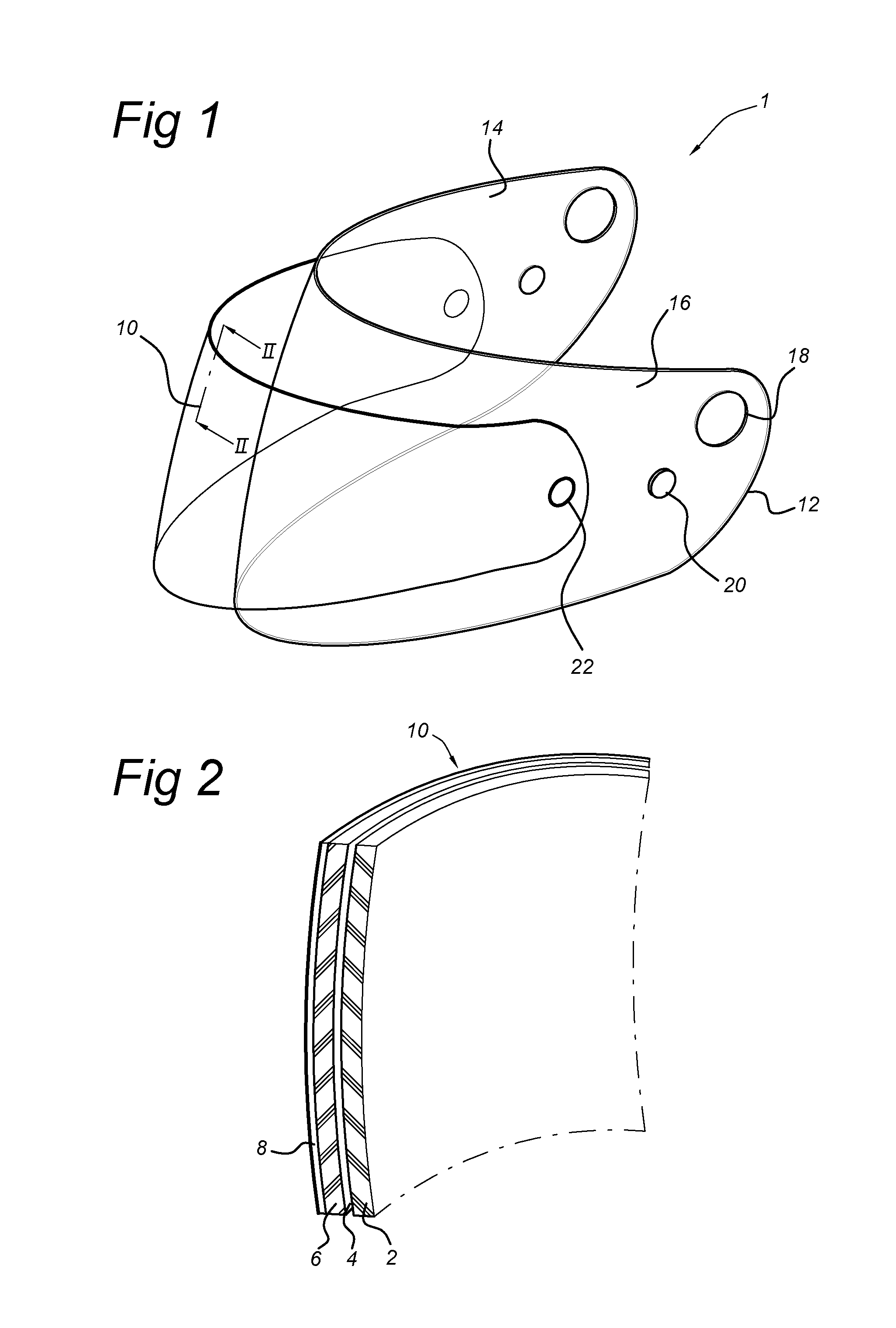

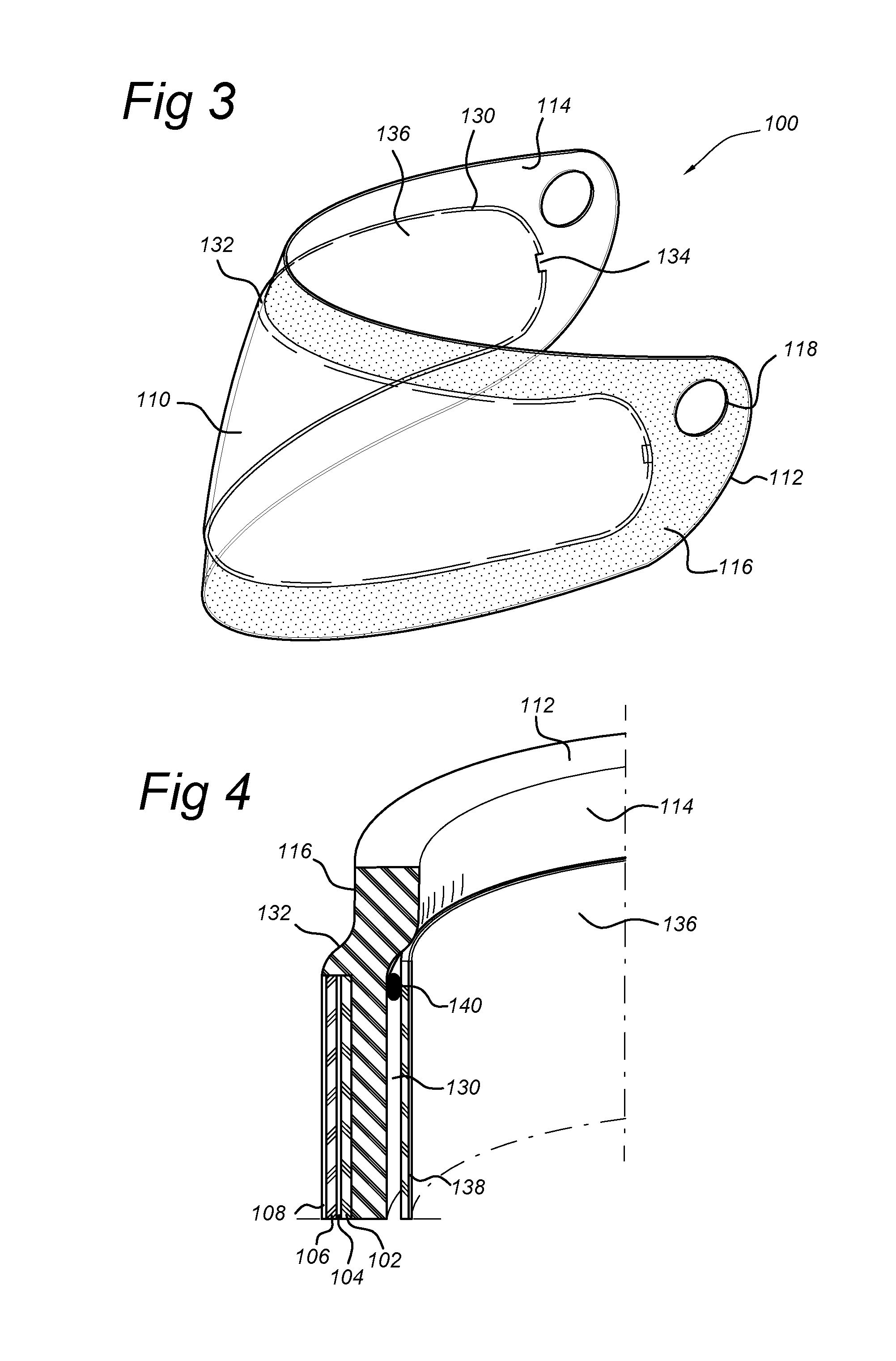

Visor and method of manufacture

InactiveUS20140259321A1Excellent engineering property and ease of manufactureImprove impact resistanceOptical articlesHatsPlastic materialsUltraviolet

A visor for a helmet or the like has a curved, transparent shield with an inner surface and an outer surface. The shield is provided with attachment elements for connecting the visor to the helmet and further includes a viewing region having a photochromatic insert at its outer surface, capable of responding to incident light. The shield is formed of a first plastic material provided with an amount of UV stabilizing additives, the UV stabilizing additives protecting the first plastic material from degradation by UV radiation during use, and the insert includes a second plastic material without UV stabilizing additives or having substantially less UV stabilizing additives than the first plastic material. A manufacturing process for producing a visor with a functional insert region is also disclosed.

Owner:PINLOCK PATENT

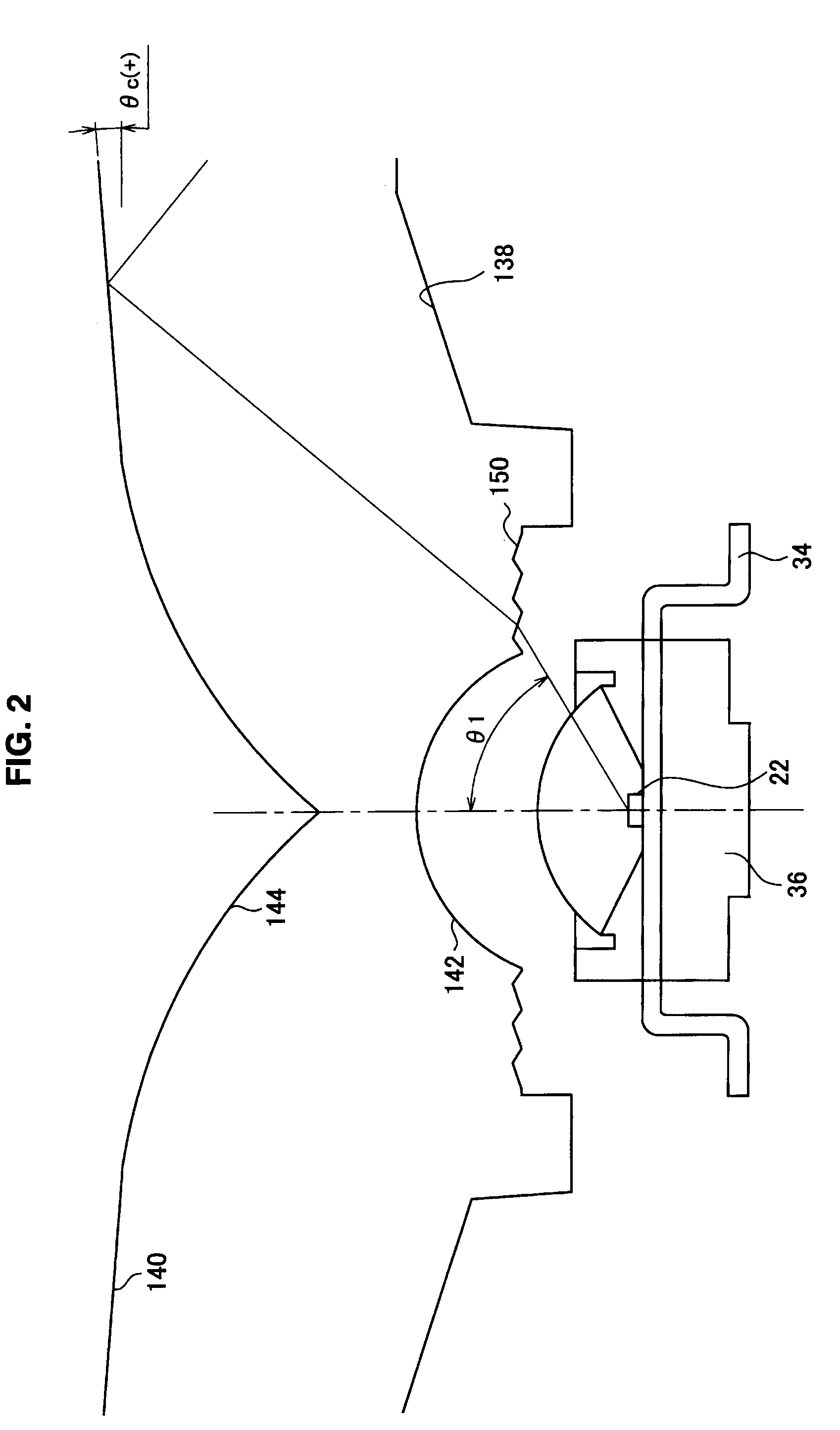

Emission device, surface light source device and display

InactiveUS7866844B2Improve efficiencyLocally bright portions are prevented more effectivelyMechanical apparatusPoint-like light sourceLight fluxOptical axis

A light flux control member has a back face provided with a first recess portion and ventilation grooves. Output light of the light emitting element arranged as to correspond to the first recess portion enters into the light flux control member via the first recess portion and ventilation grooves being emitted from a light control emission face of the light flux control member after inner-propagation. Refraction of incident light to second recess portions formed in the ventilation grooves hardly generate inner-propagation light which has travelling directions near to a direction of reference optical axis L. This avoids emission from the light control emission face from providing a ring-like bright part. In addition, heat emitted from the light emitting element can be released at a high efficiency because a space in the first recess portion communicates with the outside of the light flux control member.

Owner:ENPLAS CORP

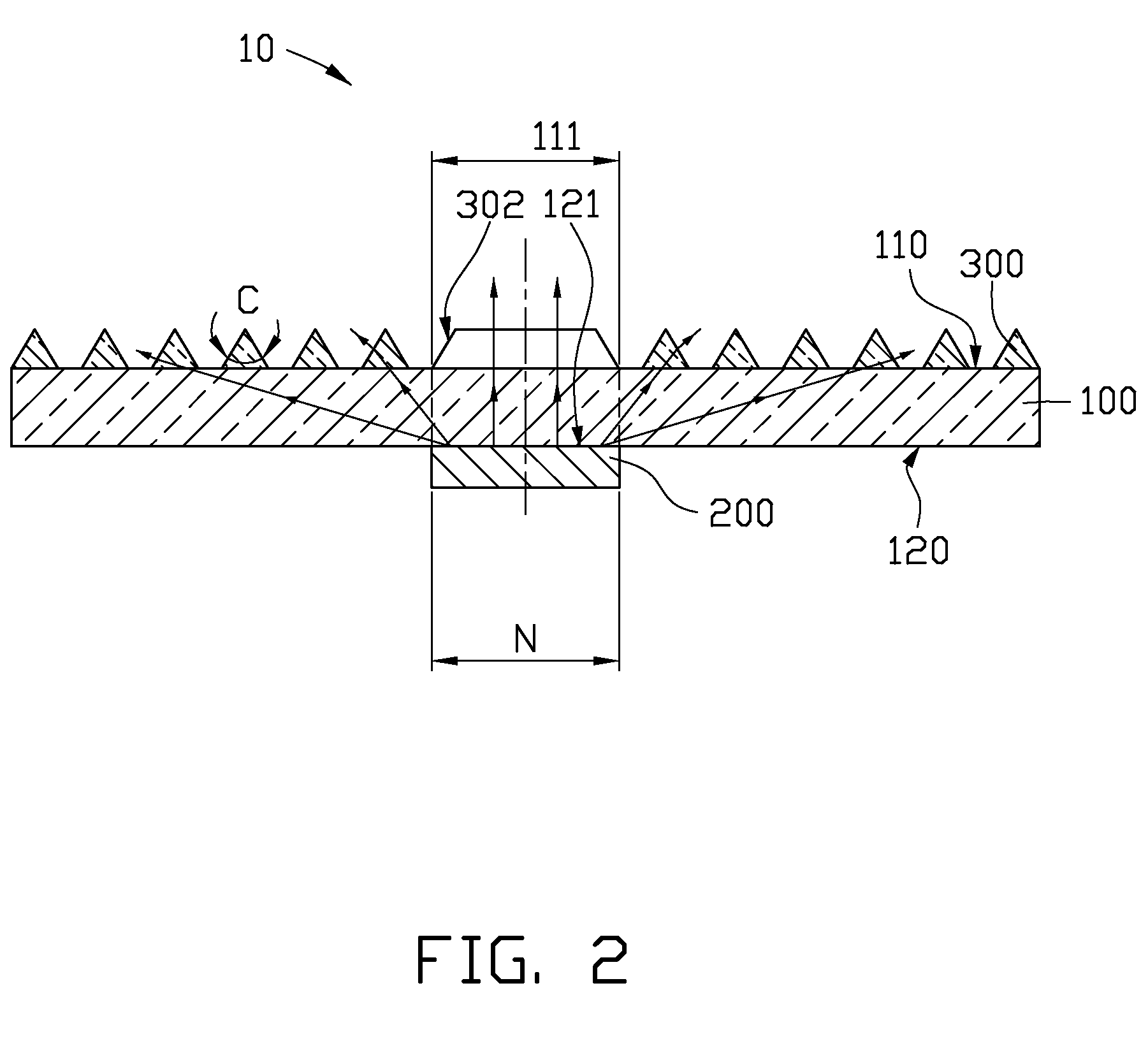

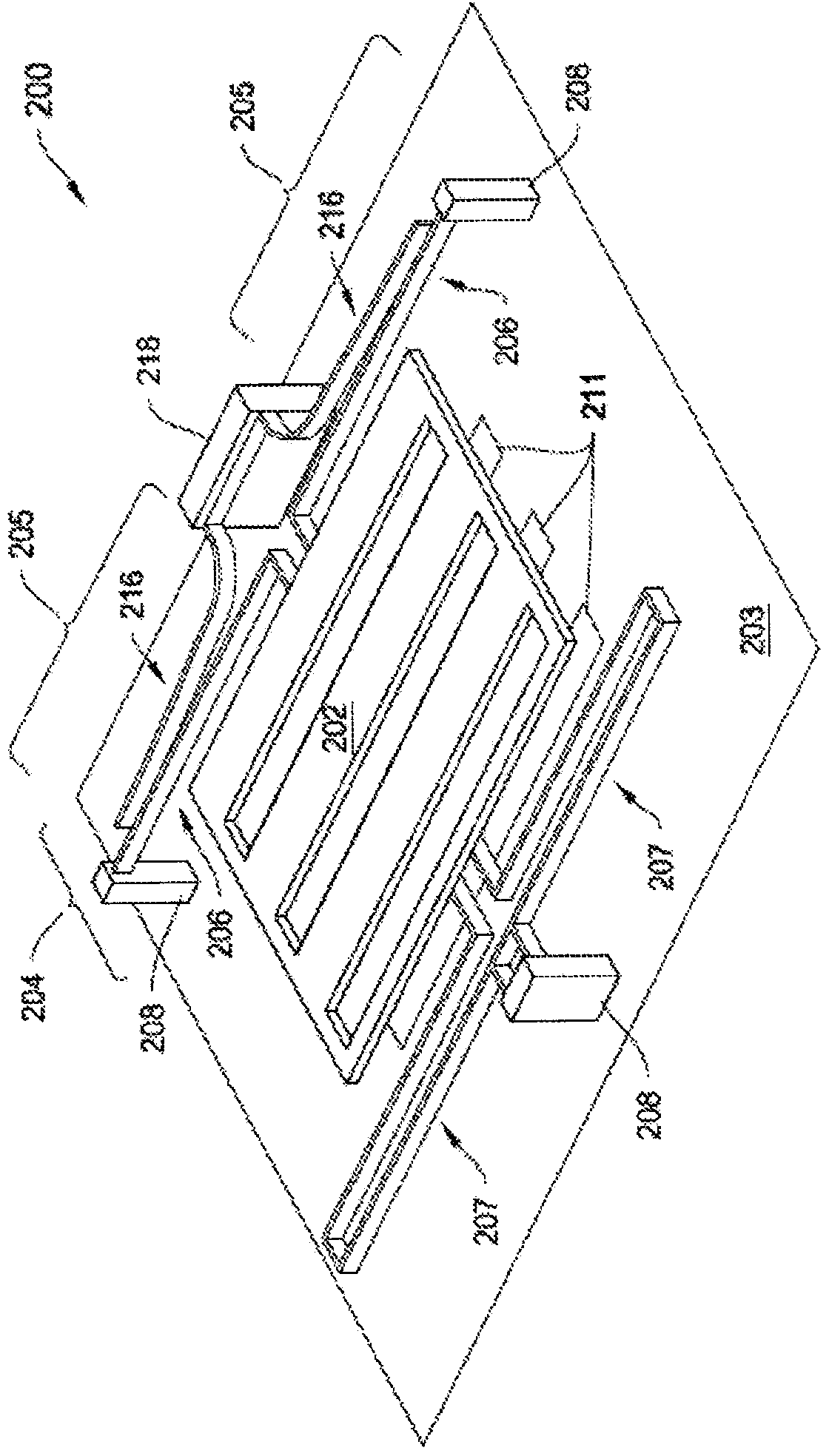

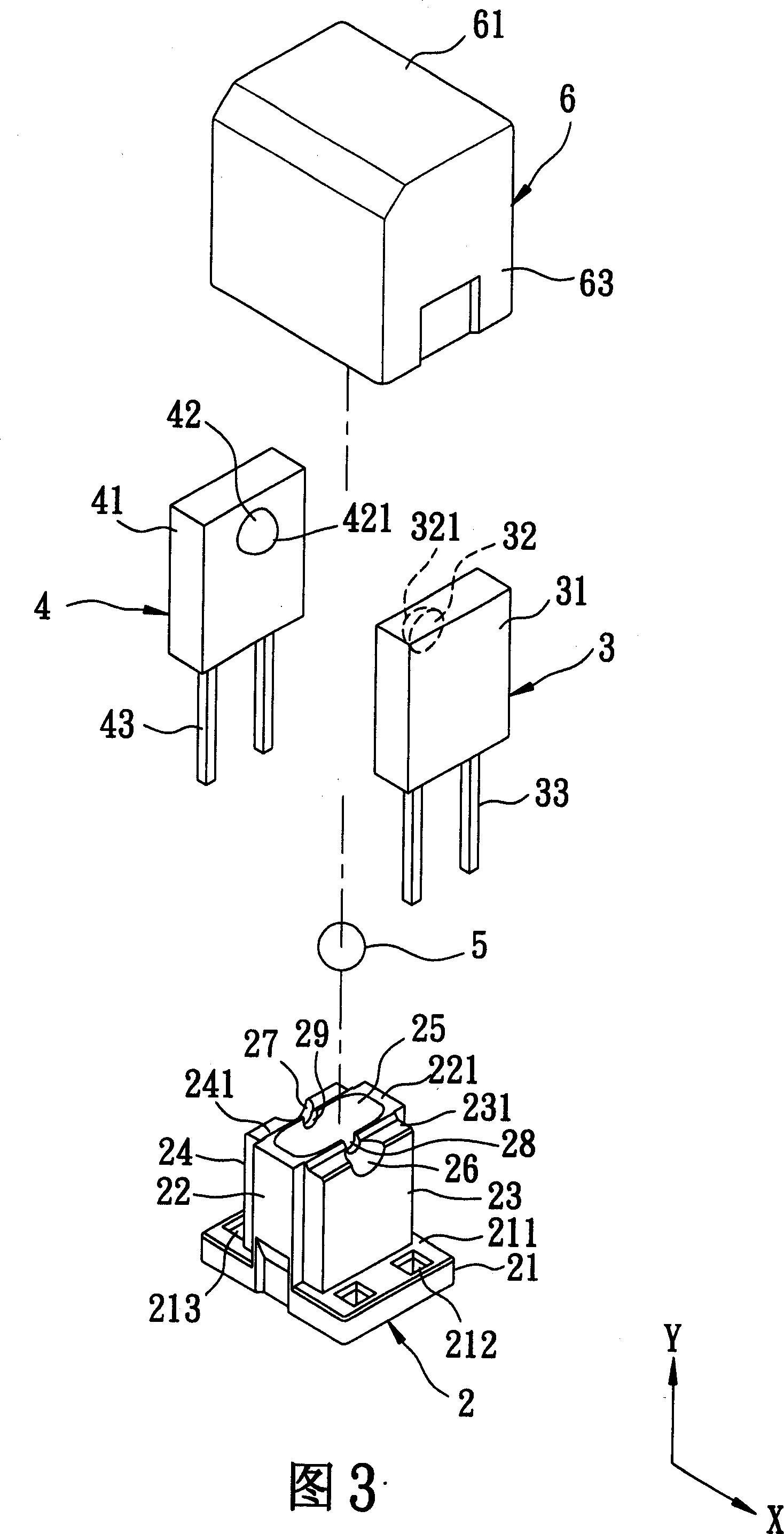

Light source device

InactiveUS7806580B2Reduce brightnessAvoid refractionPlanar light sourcesPoint-like light sourceOptoelectronicsLight source

A light source device includes a light conduction, a light source and a light diffusion component. The light conduction component has a first surface and a second surface opposite to the first surface. The second surface has a light input portion. The first surface has a light output portion substantially coaxial with the light input portion and having two opposite longitudinal ends and two opposite lateral ends. The light source is configured to emit lights to the light input portion. The first light diffusion component is positioned on the first surface, and includes row light diffusion components and column light diffusion components substantially perpendicular to the row light diffusion components. The row light diffusion components are positioned at the longitudinal ends of the light output portion. The column light diffusion components are positioned at the lateral ends of the light output portion.

Owner:HON HAI PRECISION IND CO LTD

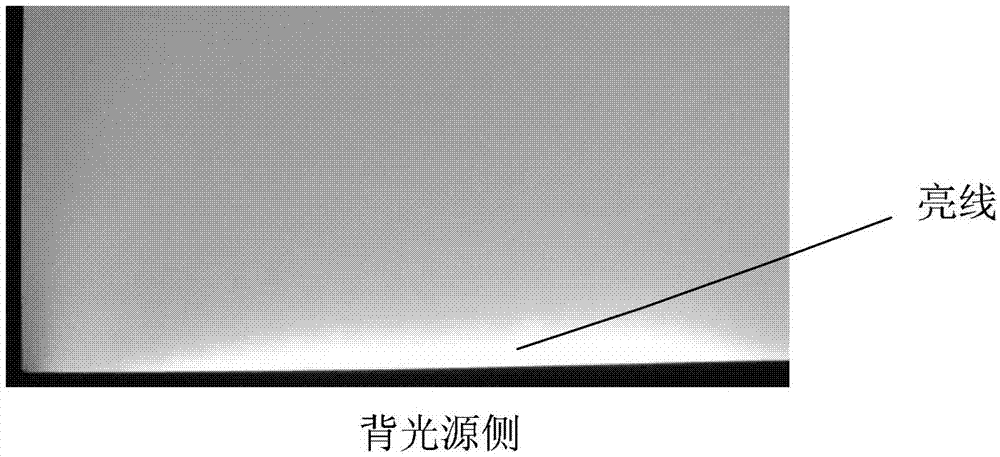

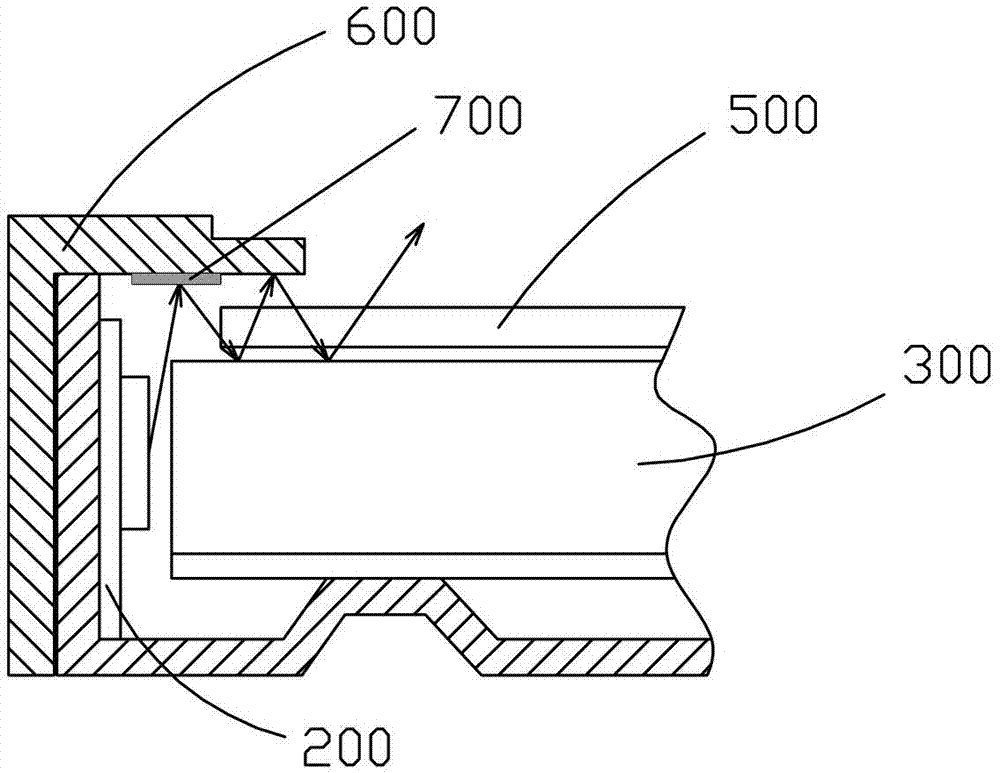

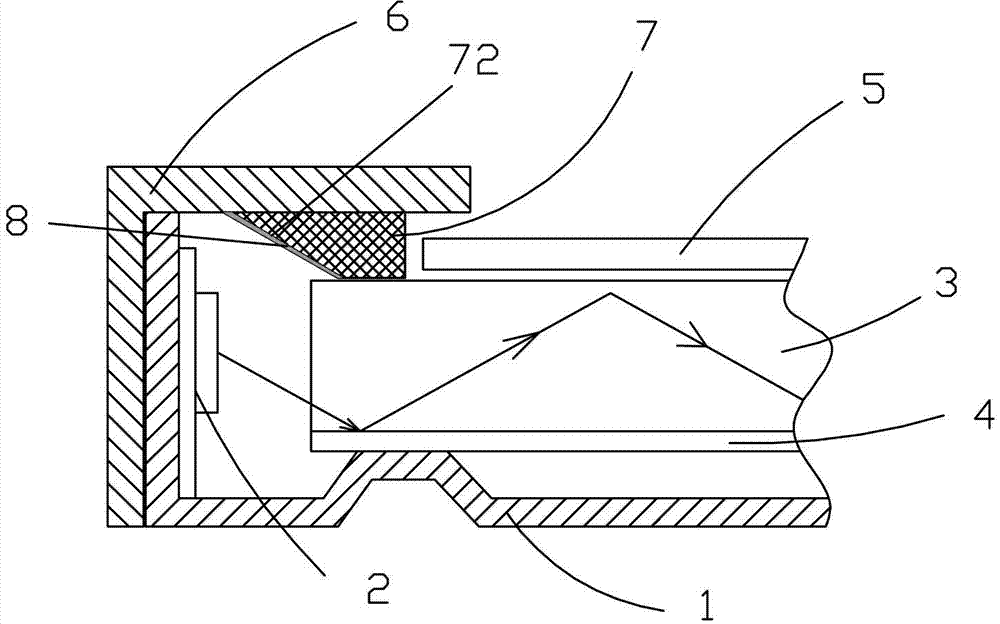

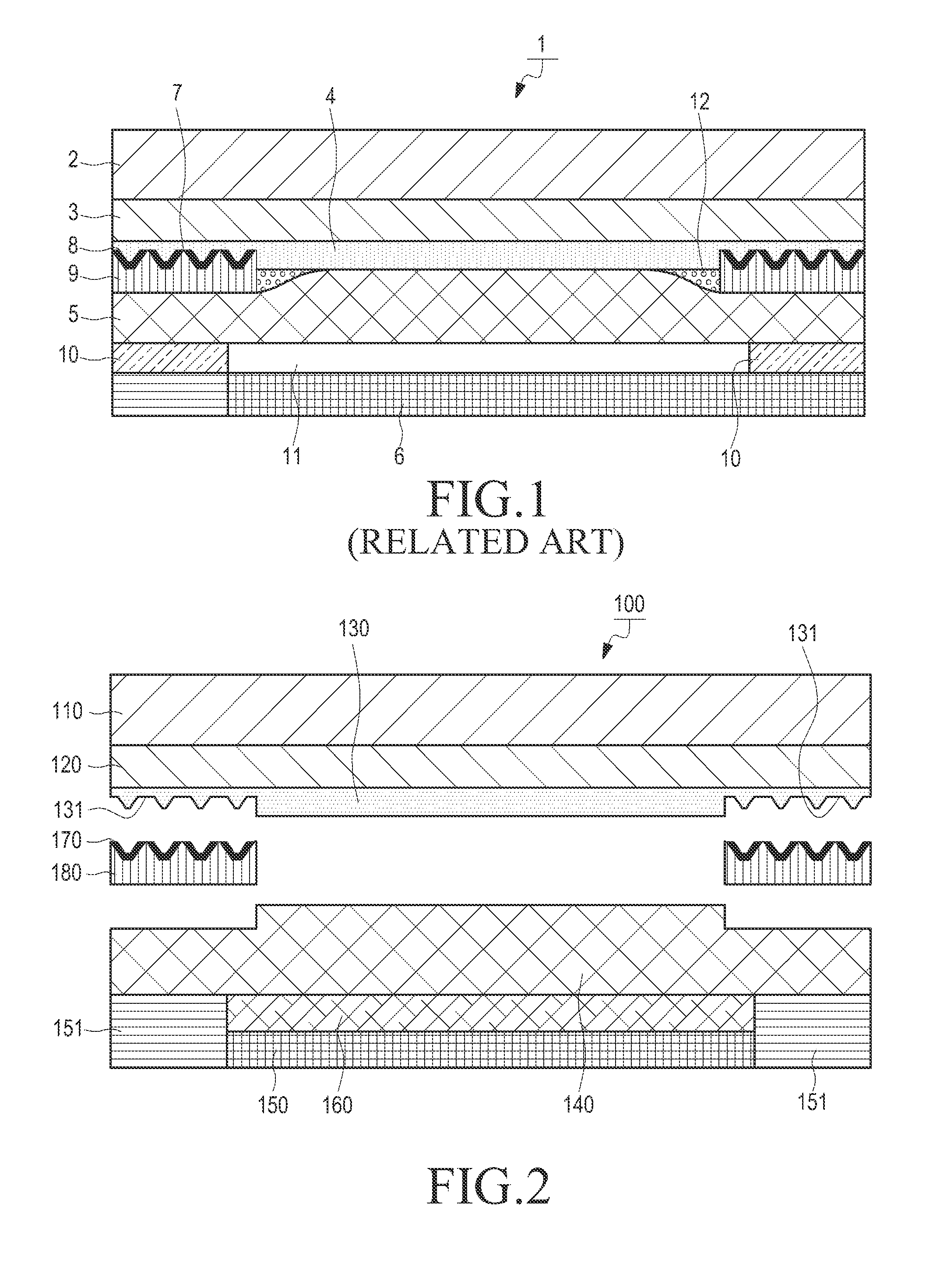

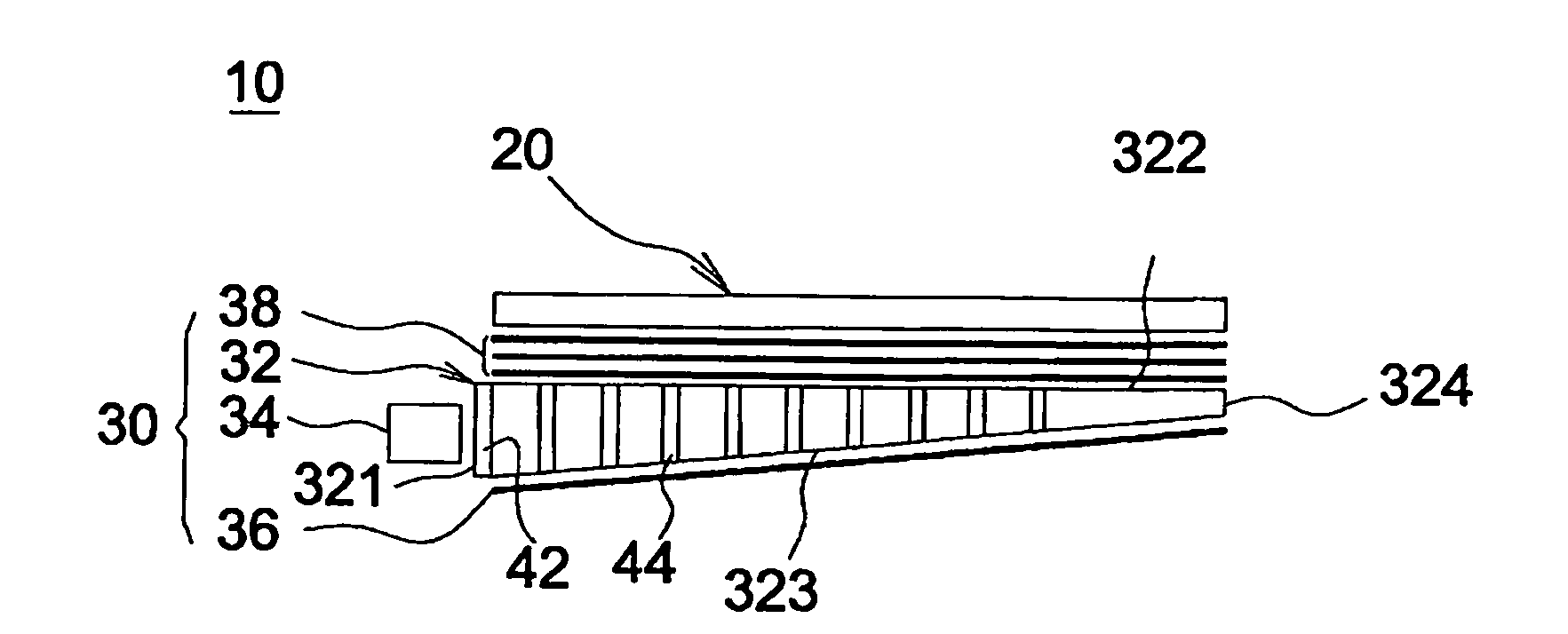

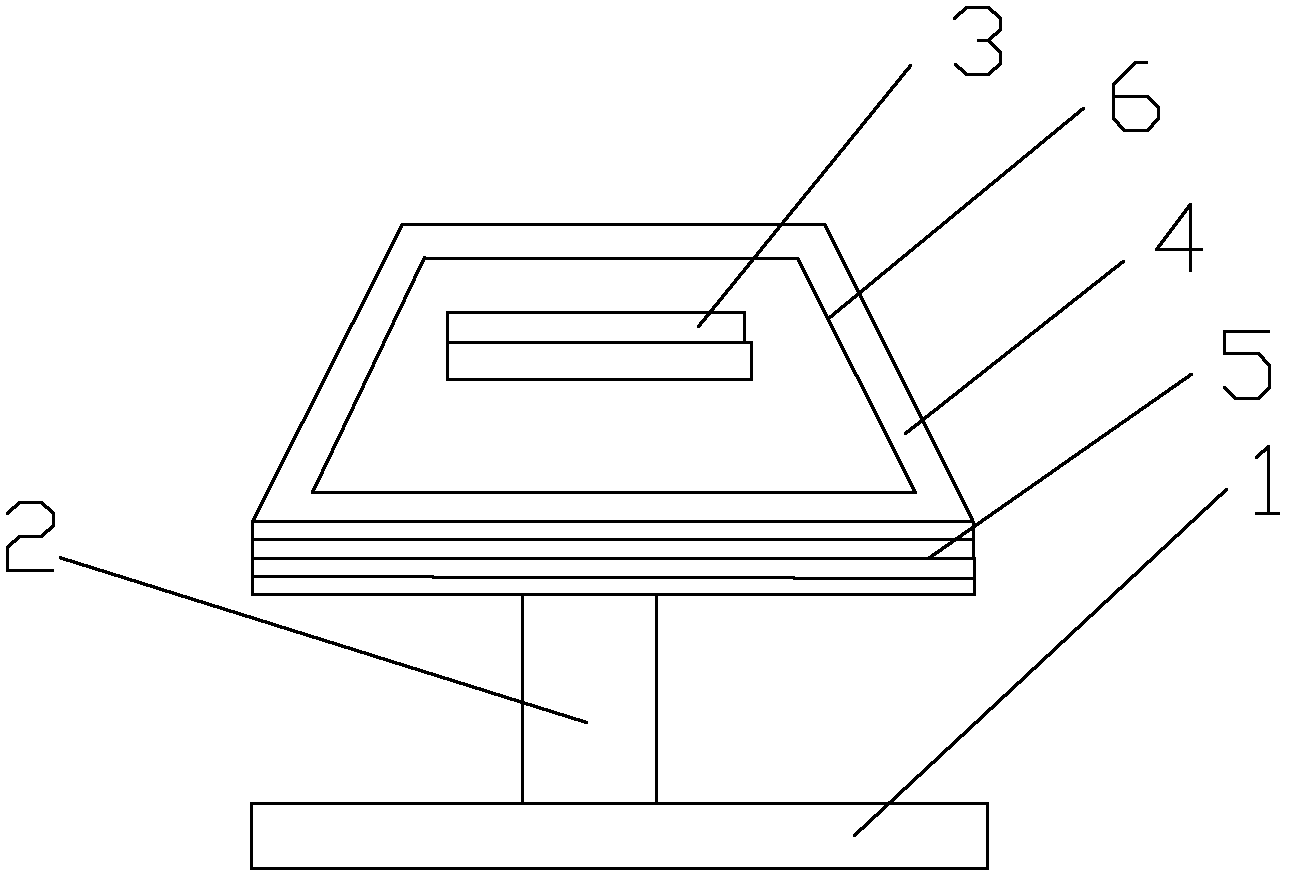

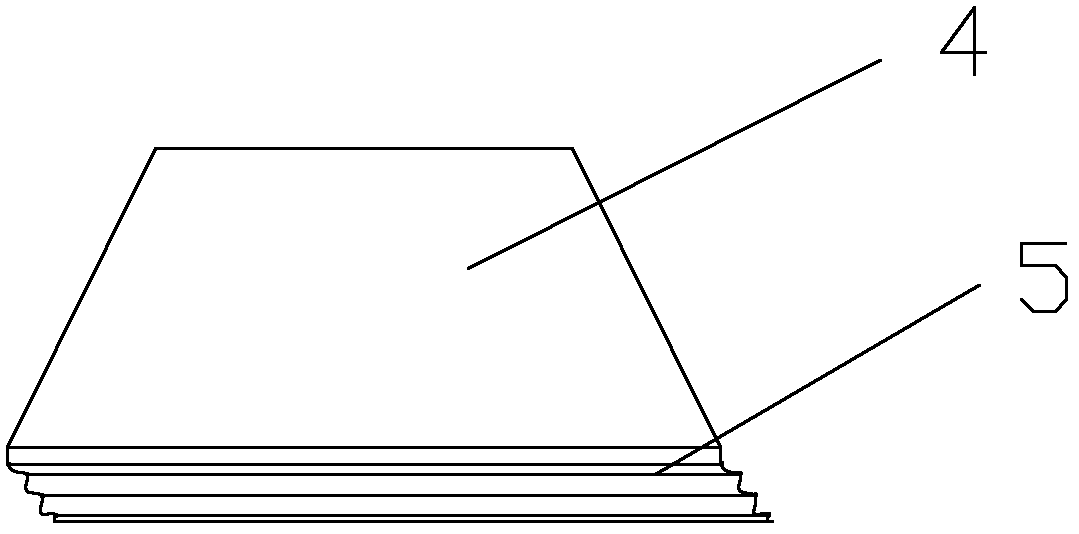

Backlight module

ActiveCN102767762AAvoid brightness lossIncrease profitPoint-like light sourcePlanar/plate-like light guidesCoupling efficiencyBackplane

The invention provides a backlight module. The backlight module comprises a back board, a backlight source, a guide plate, a light guide plate, a reflective piece, an optical membrane set, a rubber frame and a baffle wall, wherein the backlight source is arranged in the back board; the light guide plate is arranged in the back board and is opposite to the backlight source; the reflective piece is arranged between the guide plate and the back board; the optical membrane set is arranged on the guide plate; the rubber frame is arranged on the back board; the baffle wall is arranged between the light guide plate and the rubber frame and is opposite to the backlight source; the trapezoidal baffle wall is provided with a bevel close to the backlight source; the bevel is provided with a reflective layer; and light incident to the baffle wall is reflected to the light guide plate by arranging the baffle wall with the reflective layer in a position opposite to the backlight source between the rubber frame and the light guide plate, so that the light is prevented from being refracted from a gap between the optical membrane set and the light guide plate to form a bright line, thereby the bright line problem of an incident side in a side incident backlight module is solved well. The backlight module provided by the invention has higher light coupling efficiency; and meanwhile, with the adoption of the backlight module, the brightness of the light guide plate is improved, brightness loss of light emitted by an LED (light emitting diode) light source is avoided, and the utilization ratio of the LED light source is improved.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

Emission device, surface light source device and display

InactiveUS20090225550A1Avoid appearanceHigh efficiencyMechanical apparatusPoint-like light sourceLight fluxOptoelectronics

A light flux control member has a back face provided with a first recess portion and ventilation grooves. Output light of the light emitting element arranged as to correspond to the first recess portion enters into the light flux control member via the first recess portion and ventilation grooves being emitted from a light control emission face of the light flux control member after inner-propagation. Refraction of incident light to second recess portions formed in the ventilation grooves hardly generate inner-propagation light which has travelling directions near to a direction of reference optical axis L. This avoids emission from the light control emission face from providing a ring-like bright part. In addition, heat emitted from the light emitting element can be released at a high efficiency because a space in the first recess portion communicates with the outside of the light flux control member.

Owner:ENPLAS

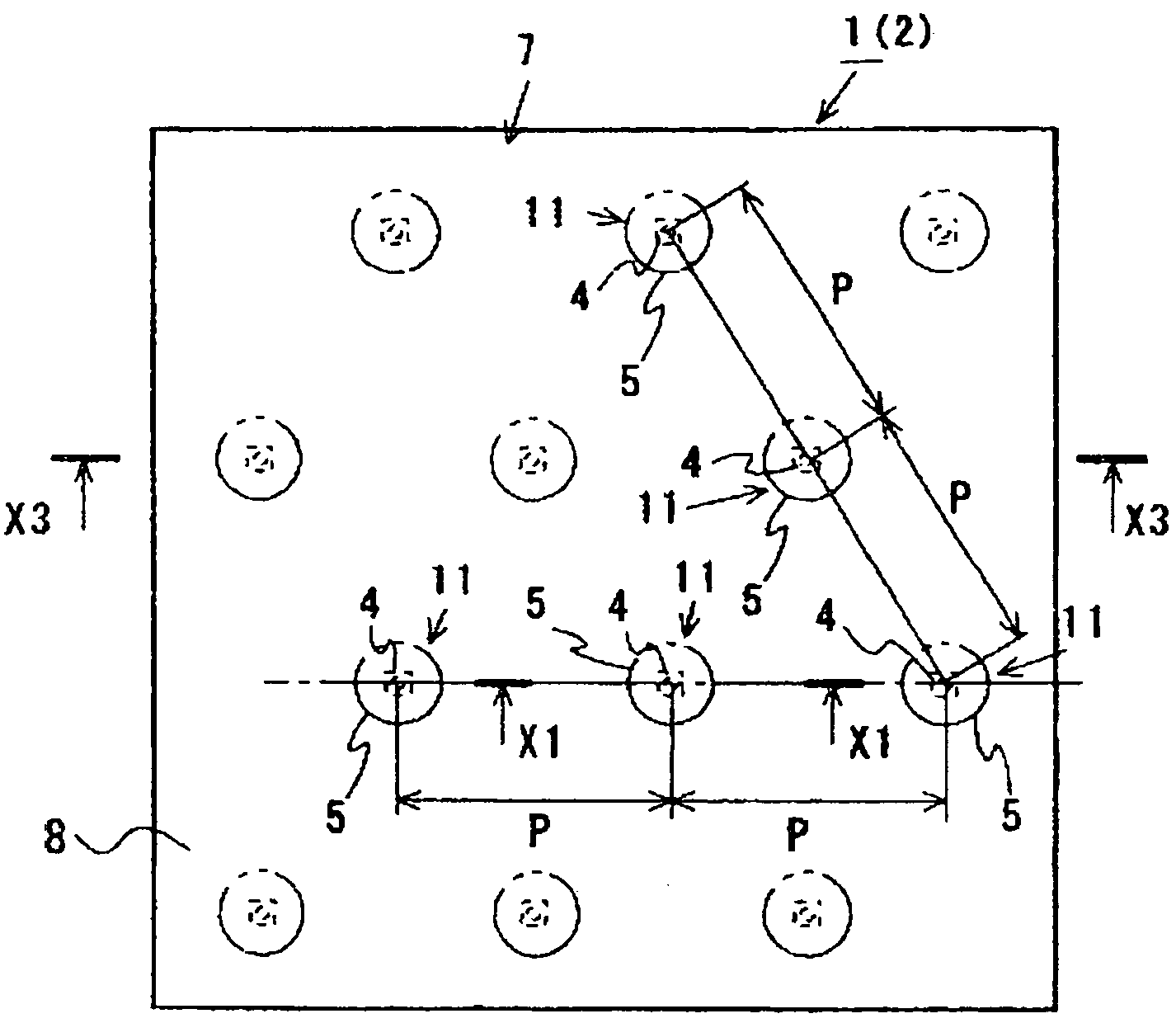

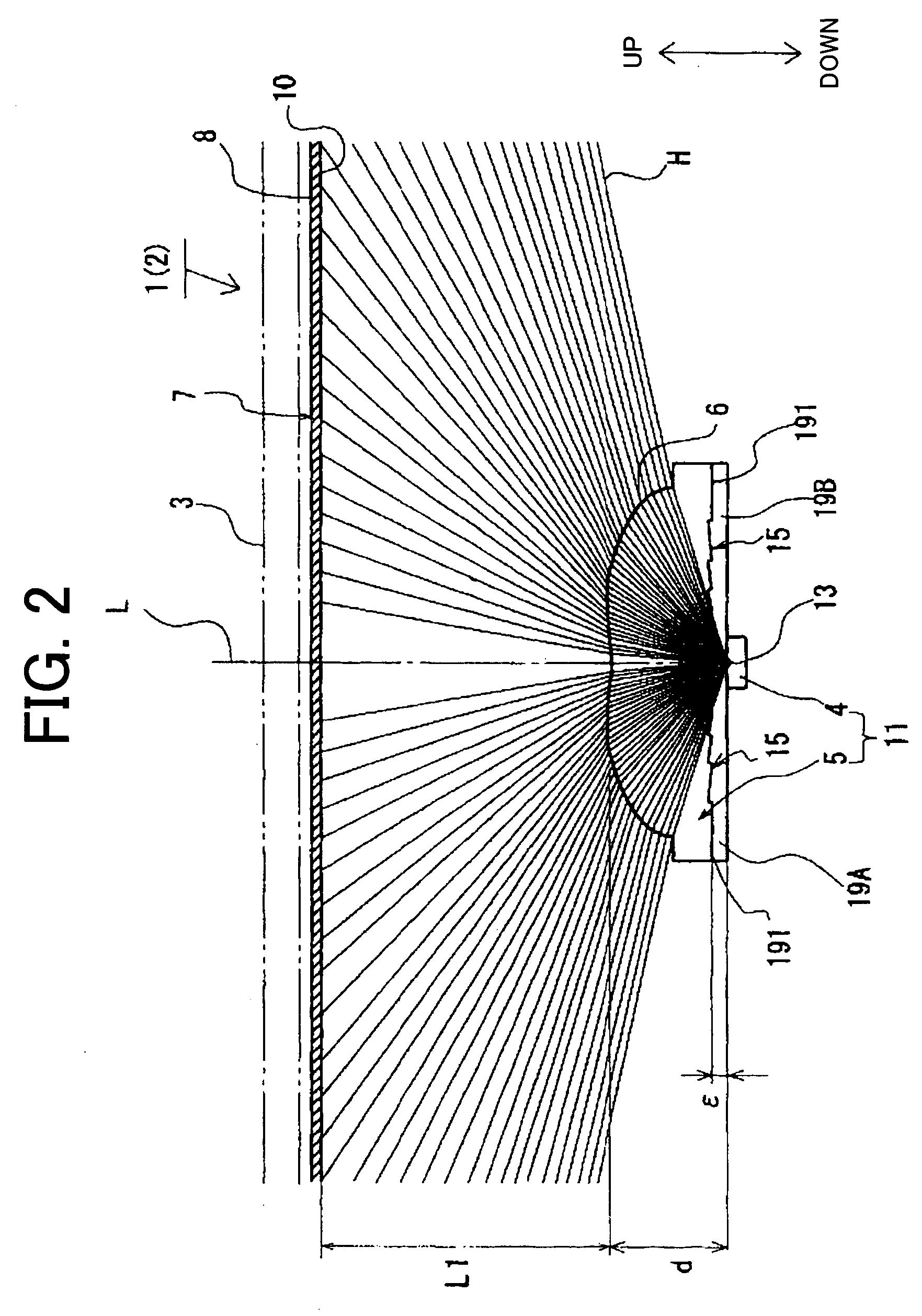

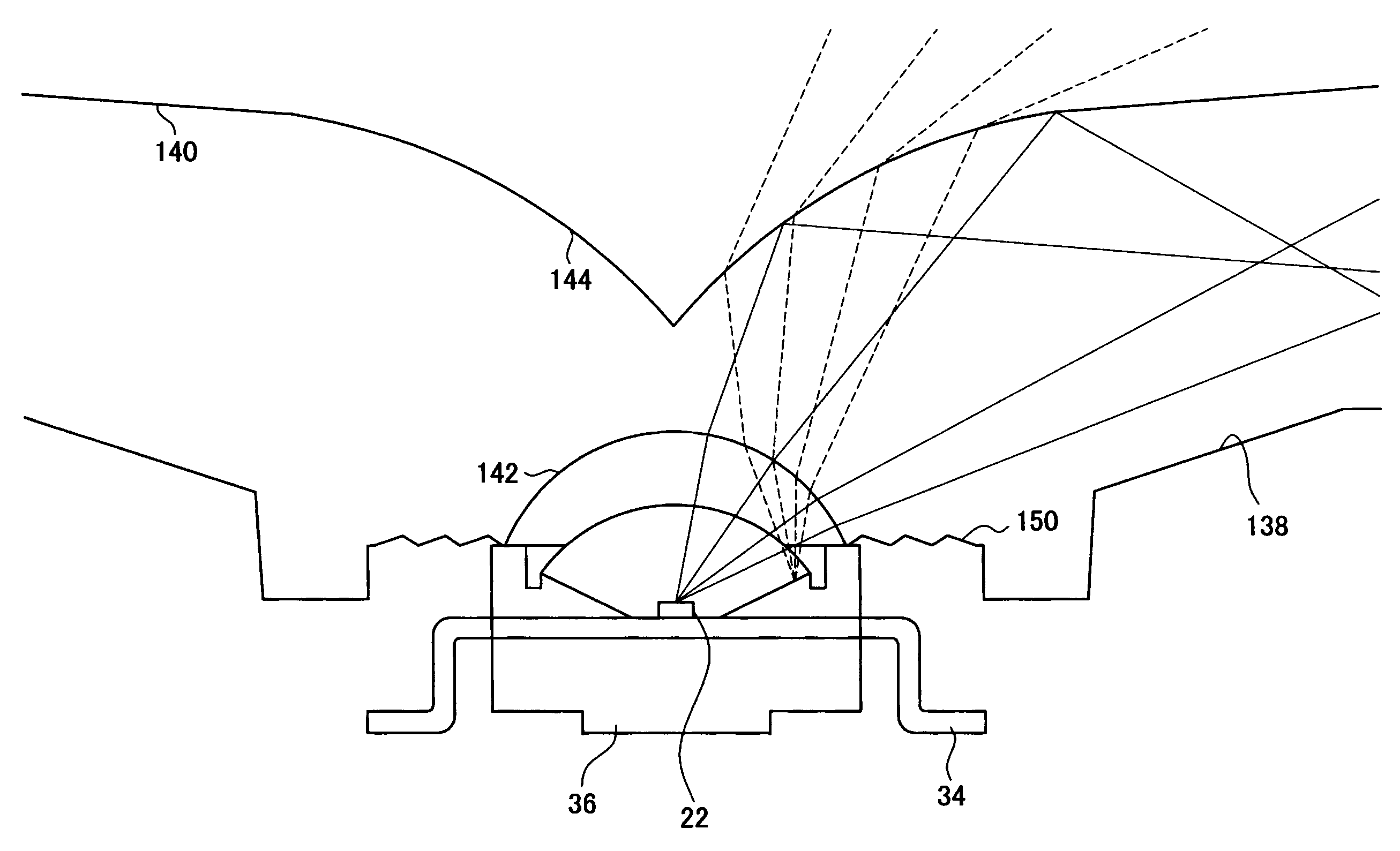

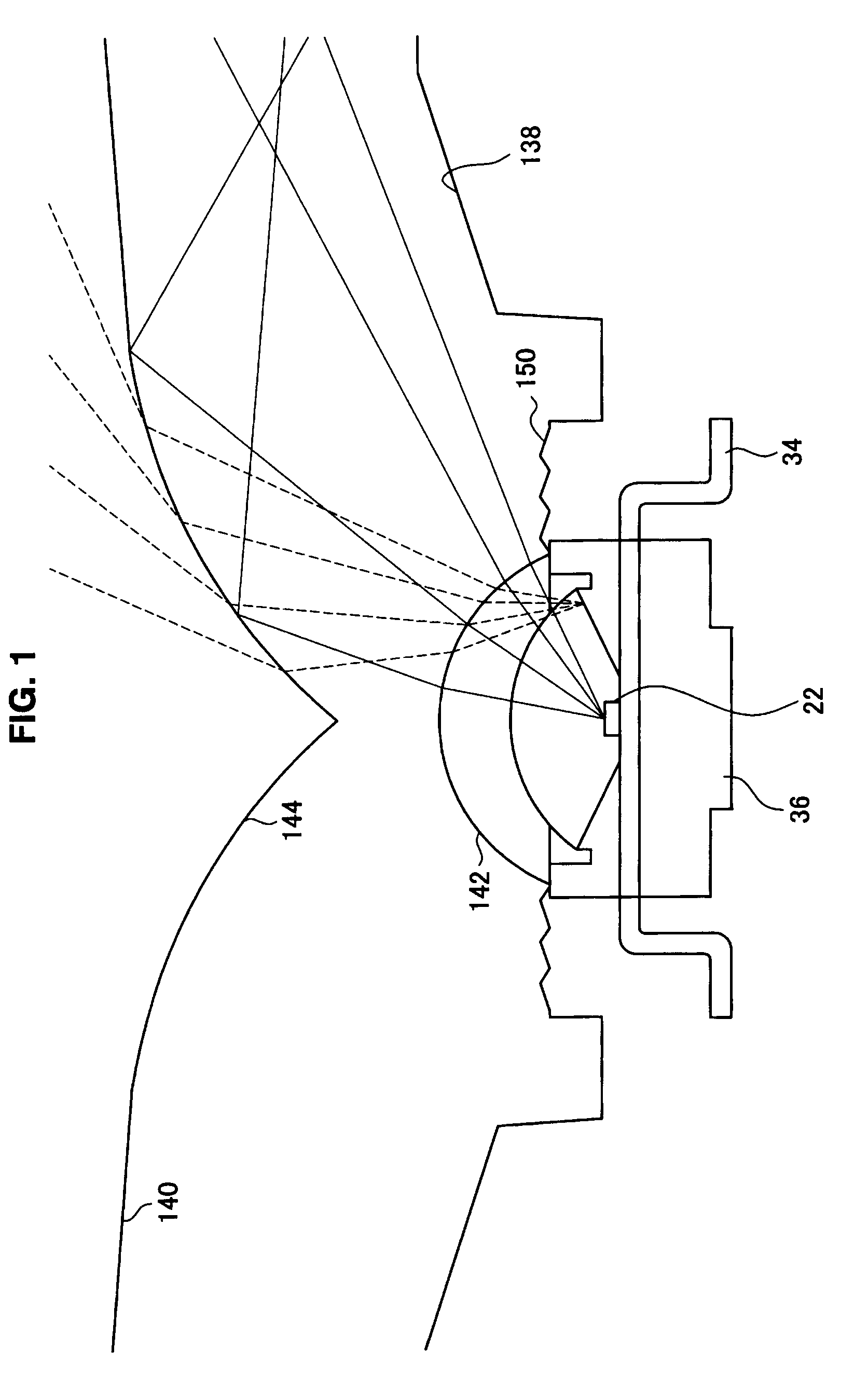

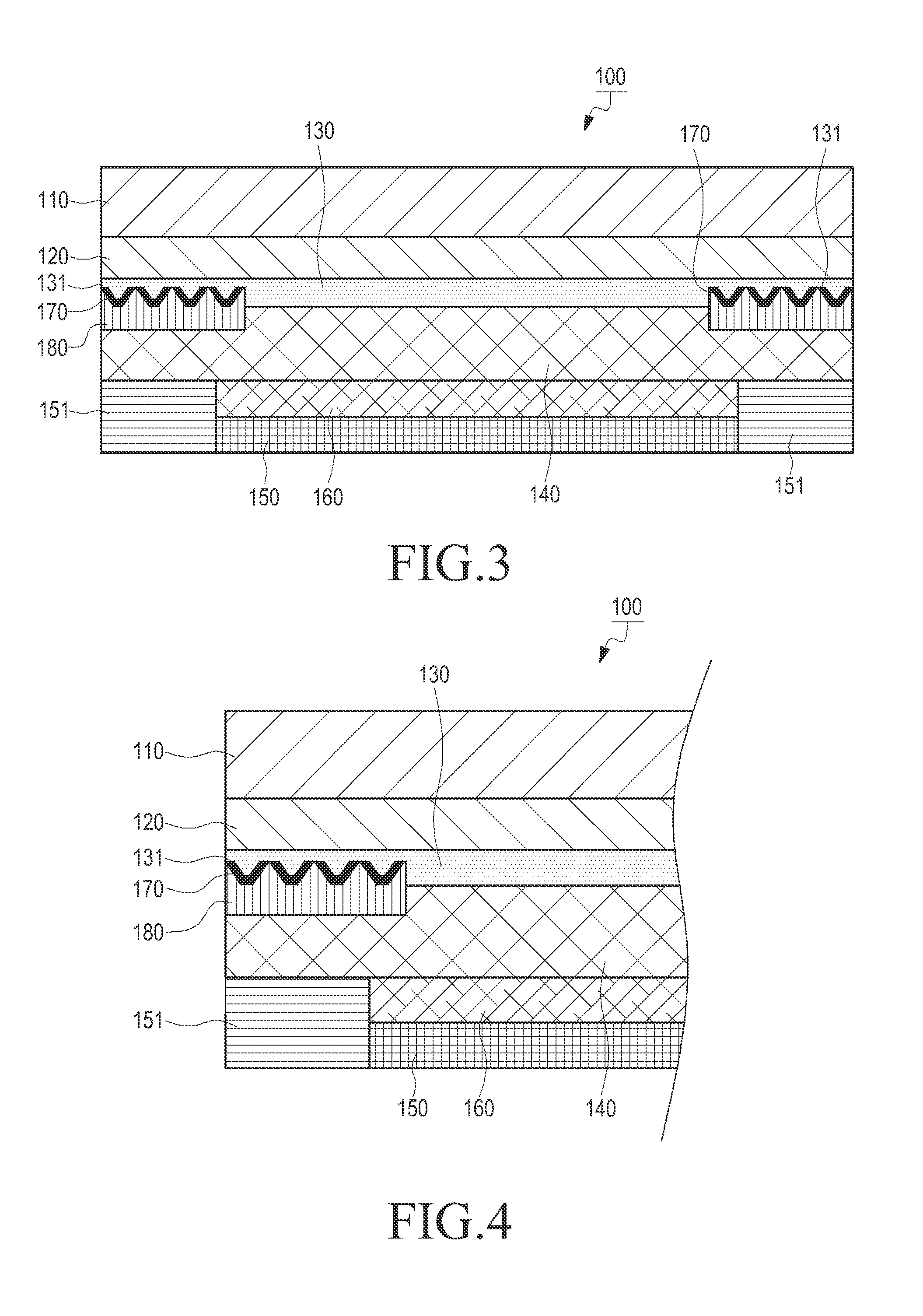

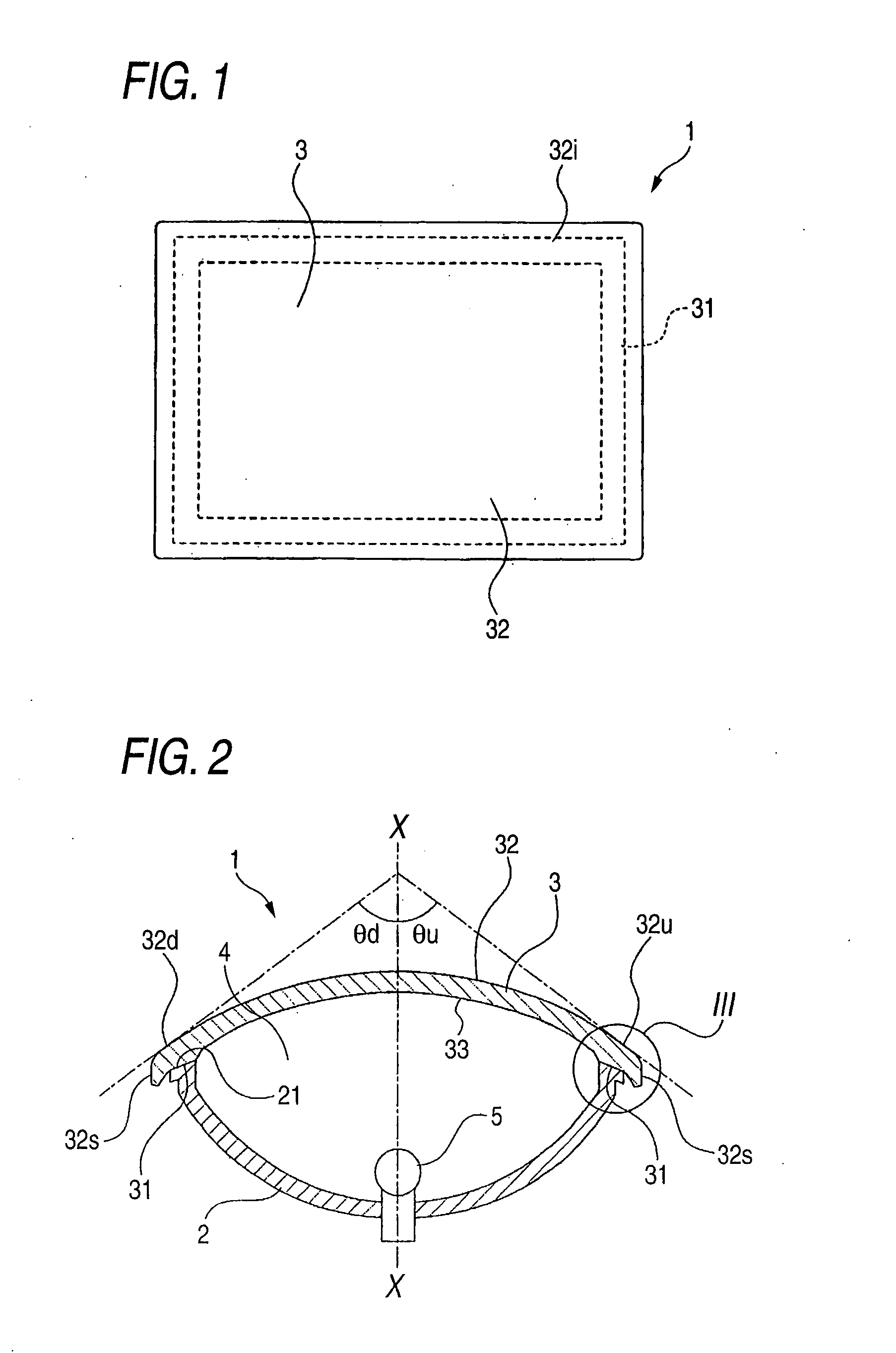

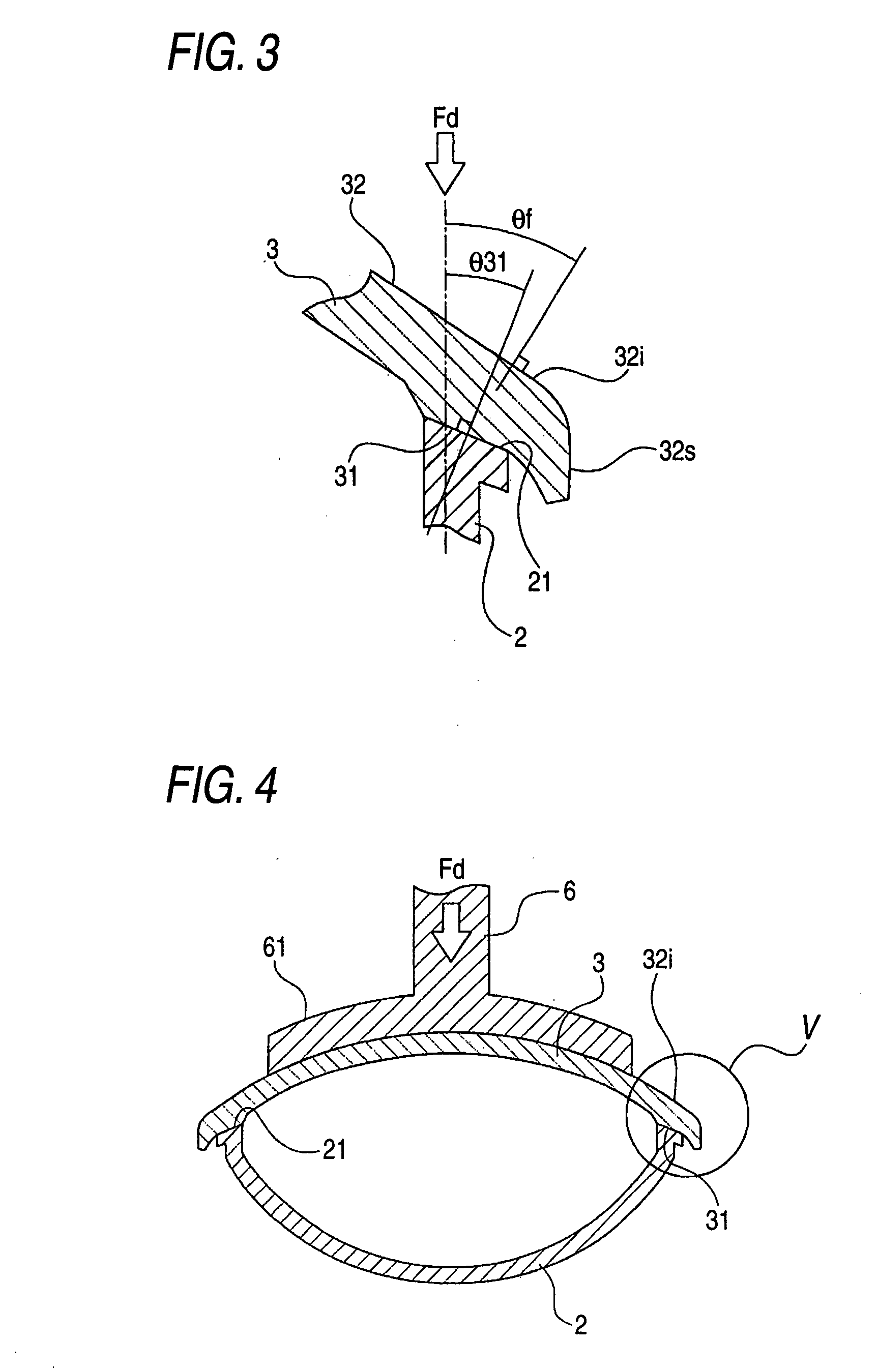

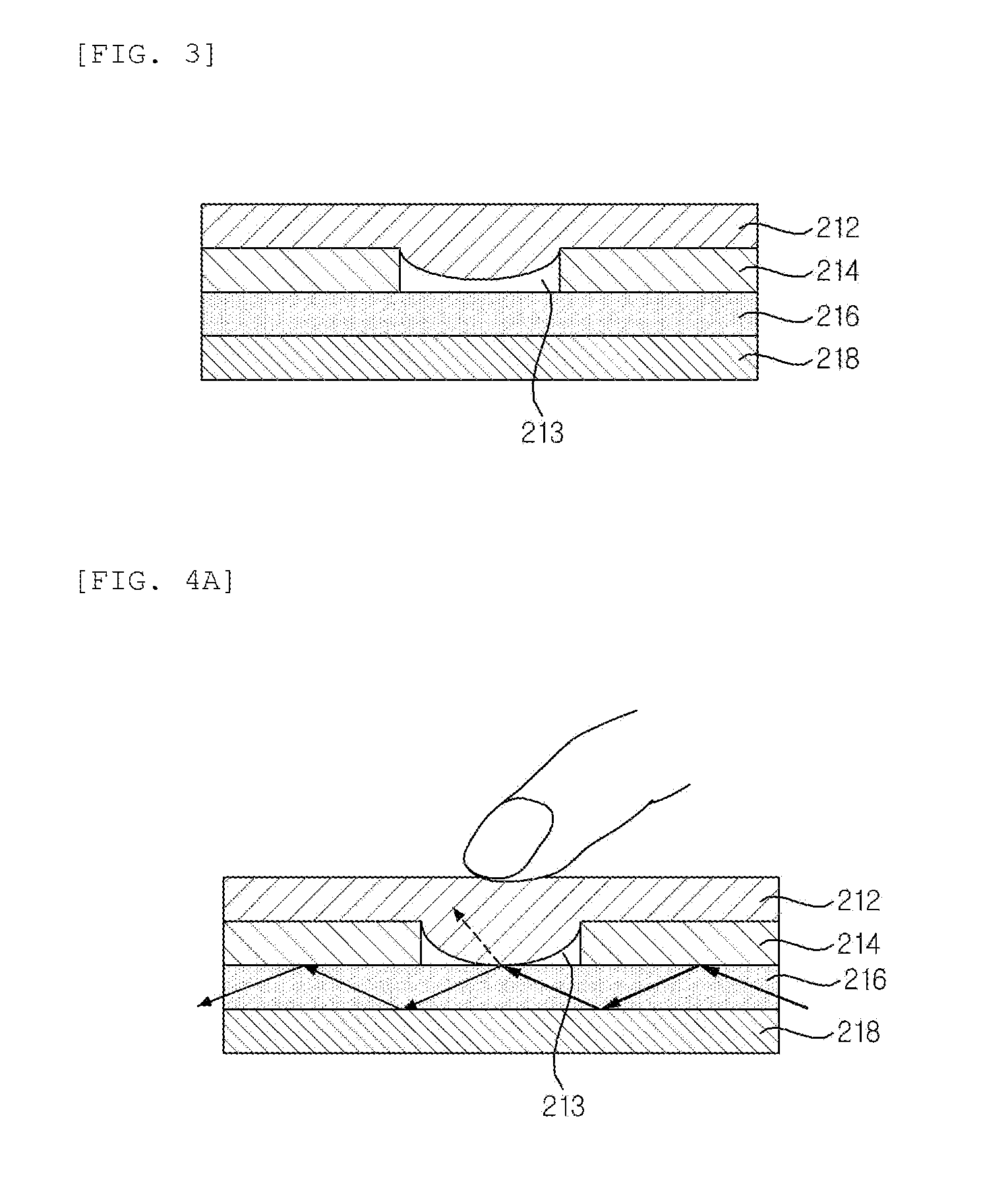

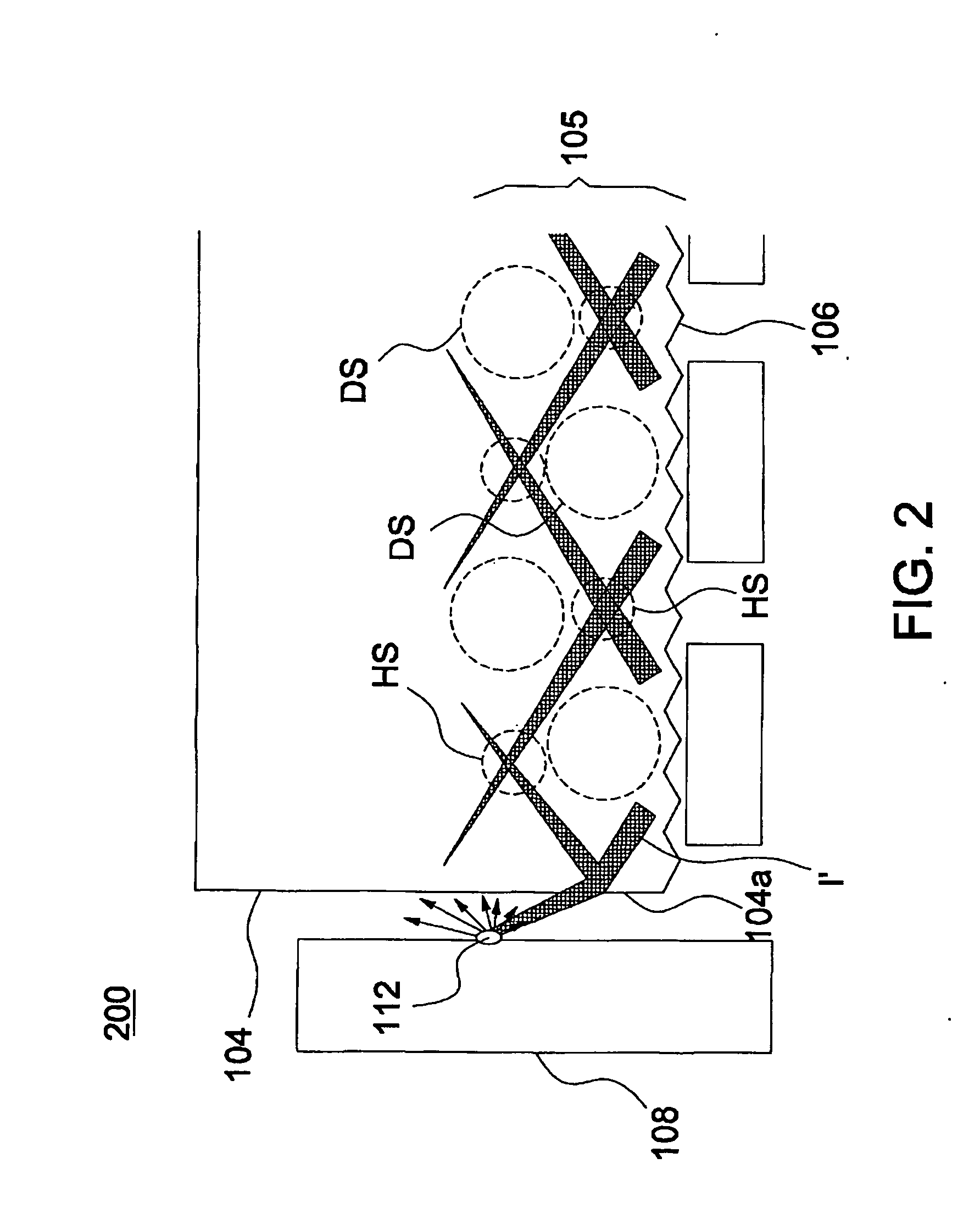

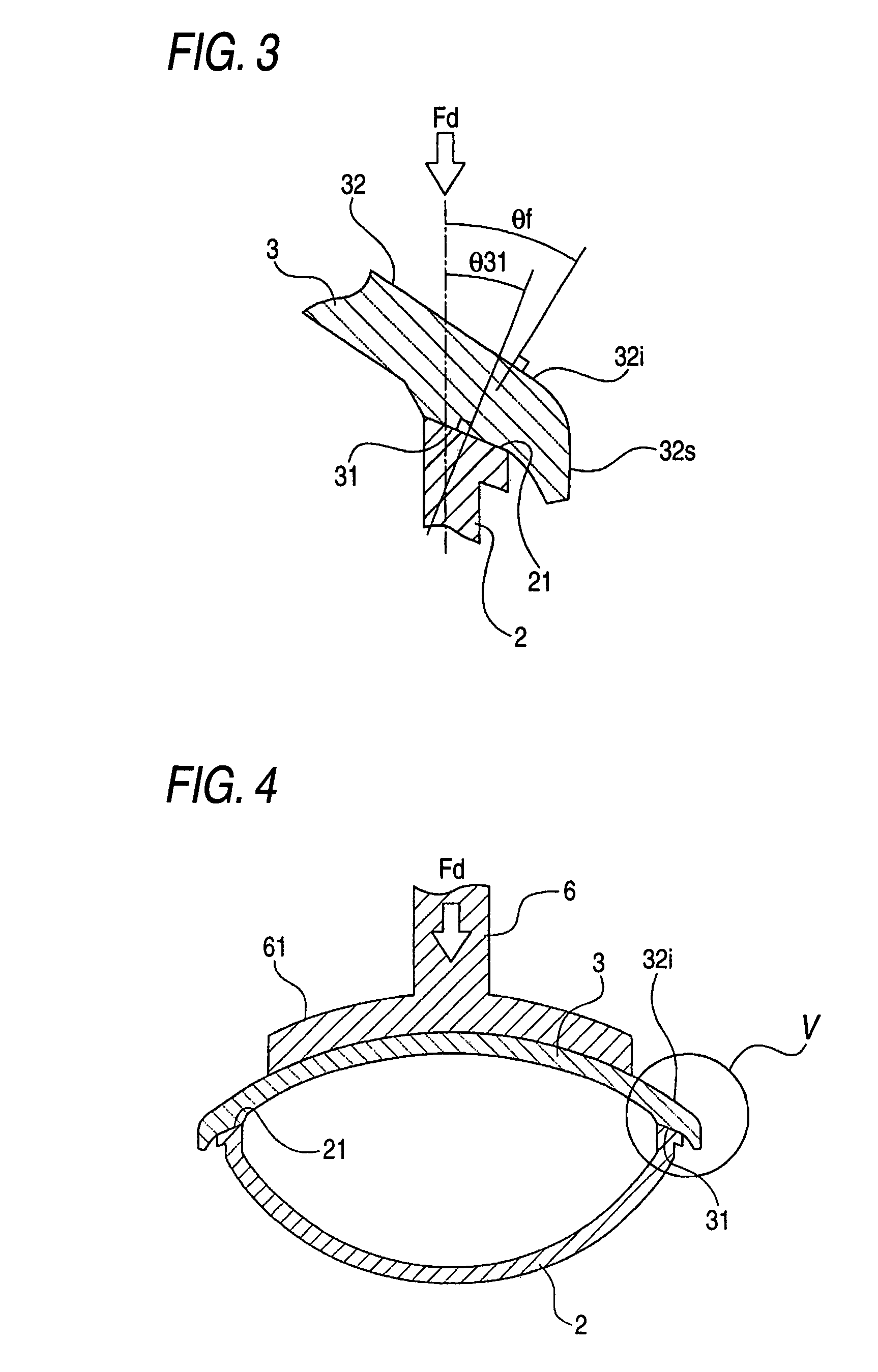

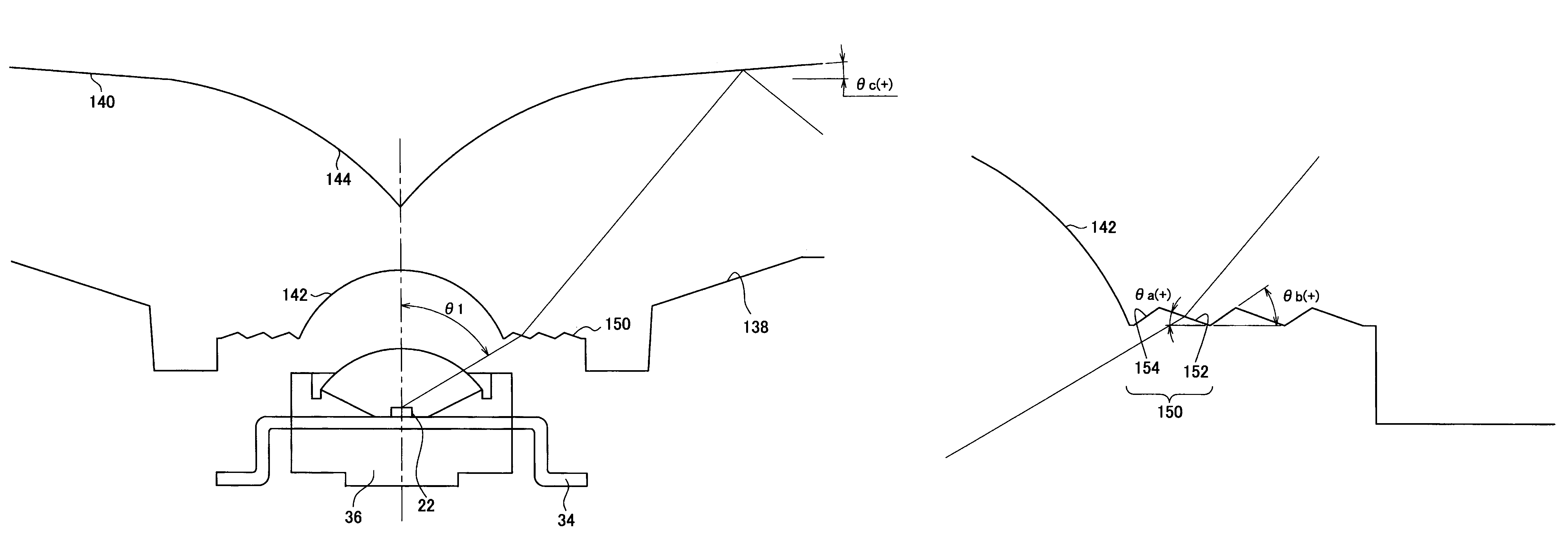

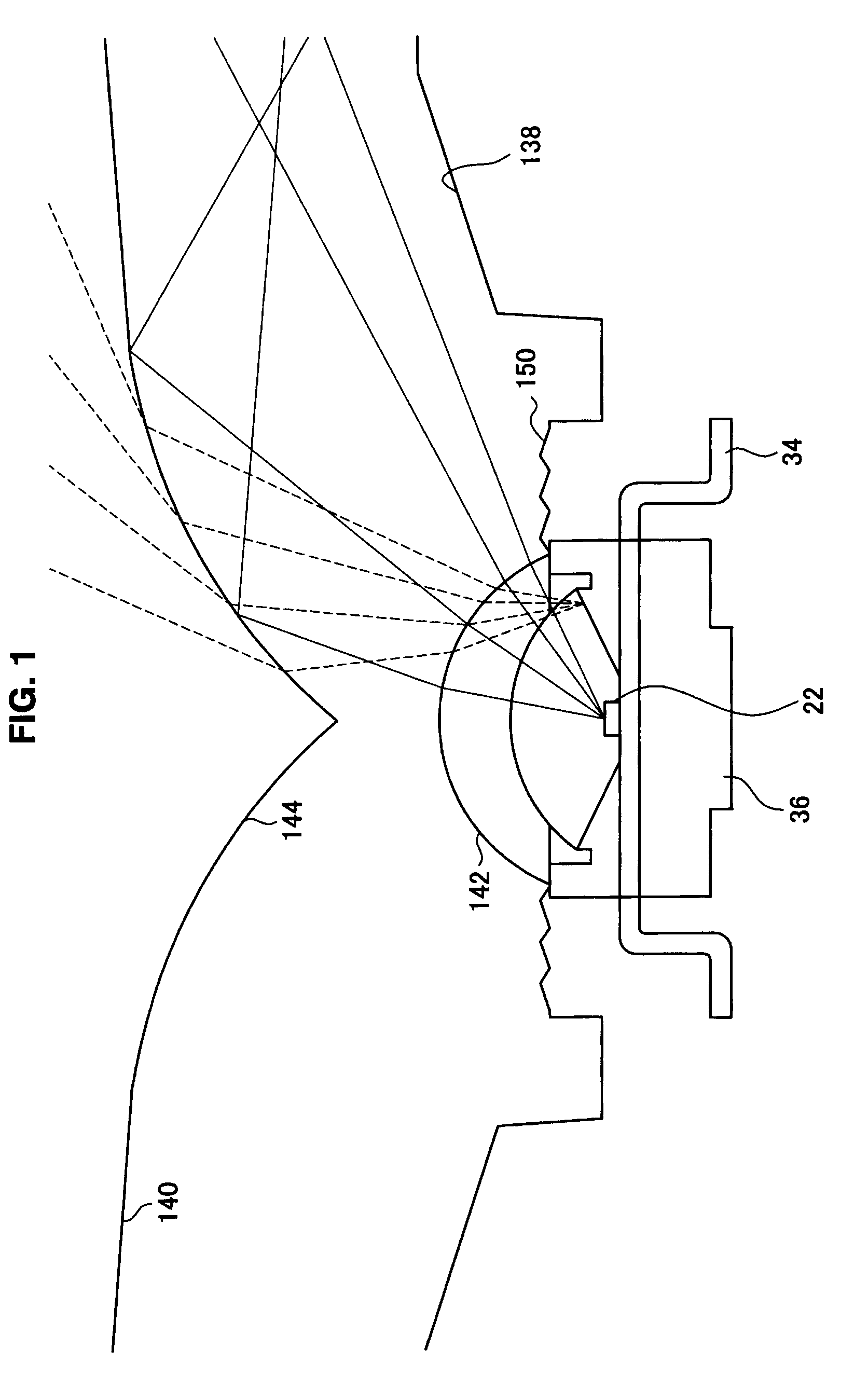

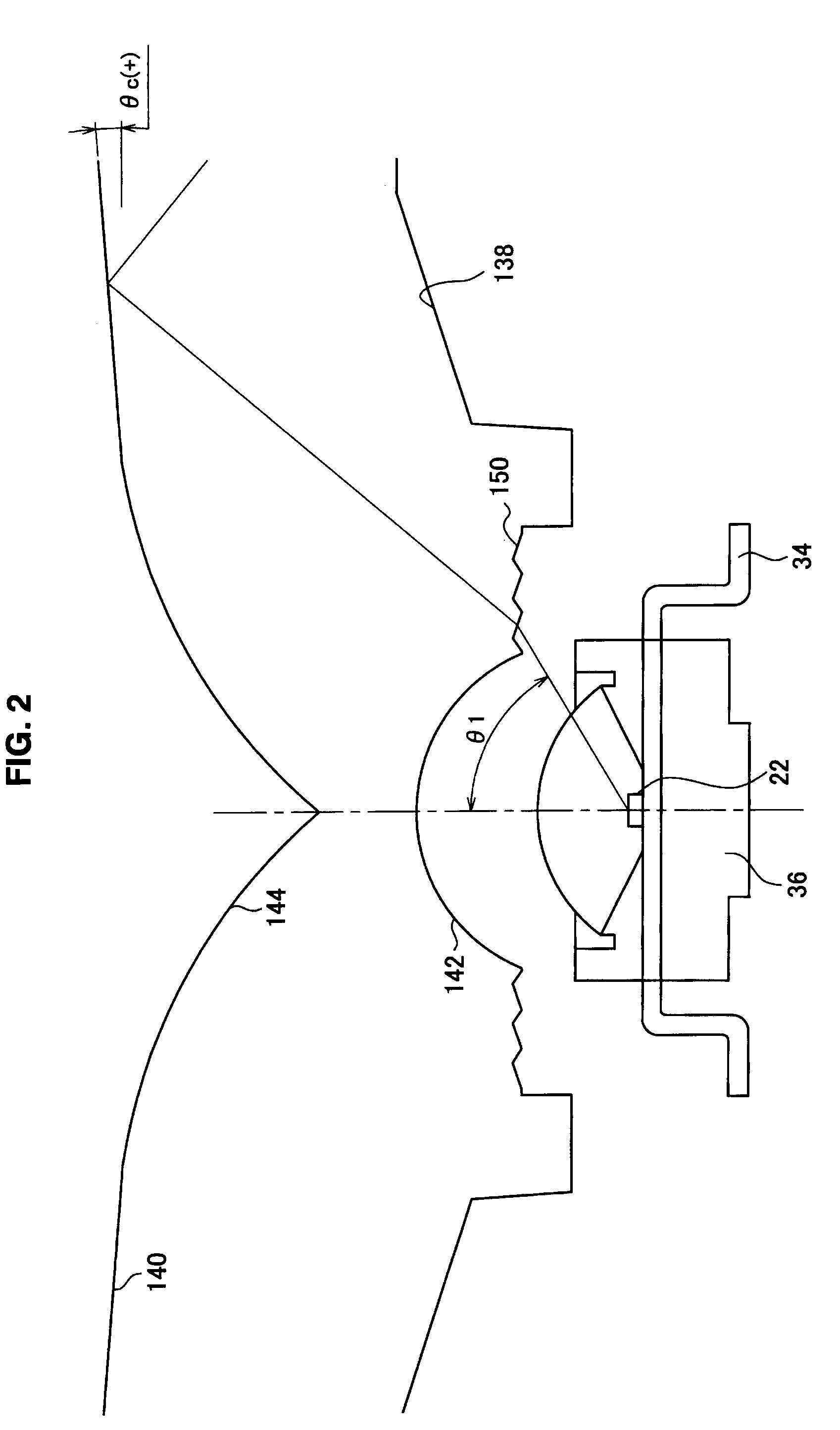

Light Emitting Apparatus and Image Displaying Apparatus

ActiveUS20100195315A1Suppress mutationAvoid refractionNon-electric lightingPoint-like light sourceLight guideOptical axis

A light emitting apparatus is provided which includes a plurality of light sources for emitting a light, and a light guide plate having a substantially plate shape orthogonal to the optical axis direction of the light source, which includes a light incident face into which a light exited from the light source is incident and a light exit face from which the light incident from the light incident face is exited. Irregularities each made of a first slope forming an angle θa with the plane of the light incident face and a second slope forming an angle θb with the plane of the light incident face are continuously formed on the light incident face.

Owner:SATURN LICENSING LLC

Lighting device, display device and television receiver

ActiveUS8430519B2Low costSave powerTelevision system detailsPoint-like light sourceTelevision receiversDisplay device

Owner:SHARP KK

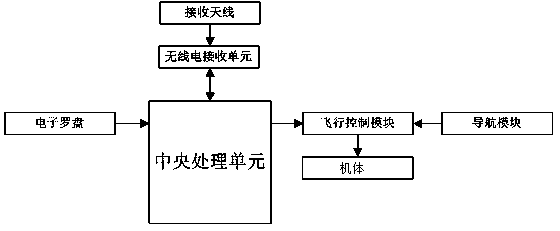

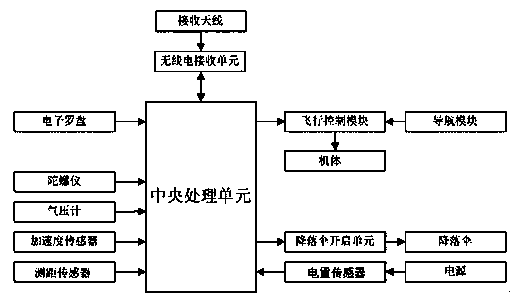

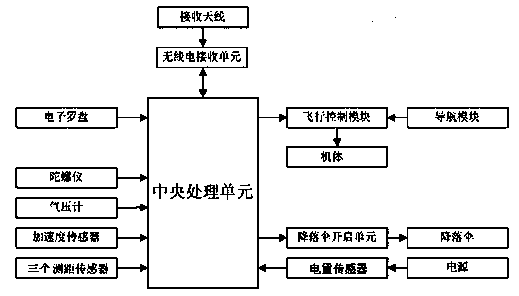

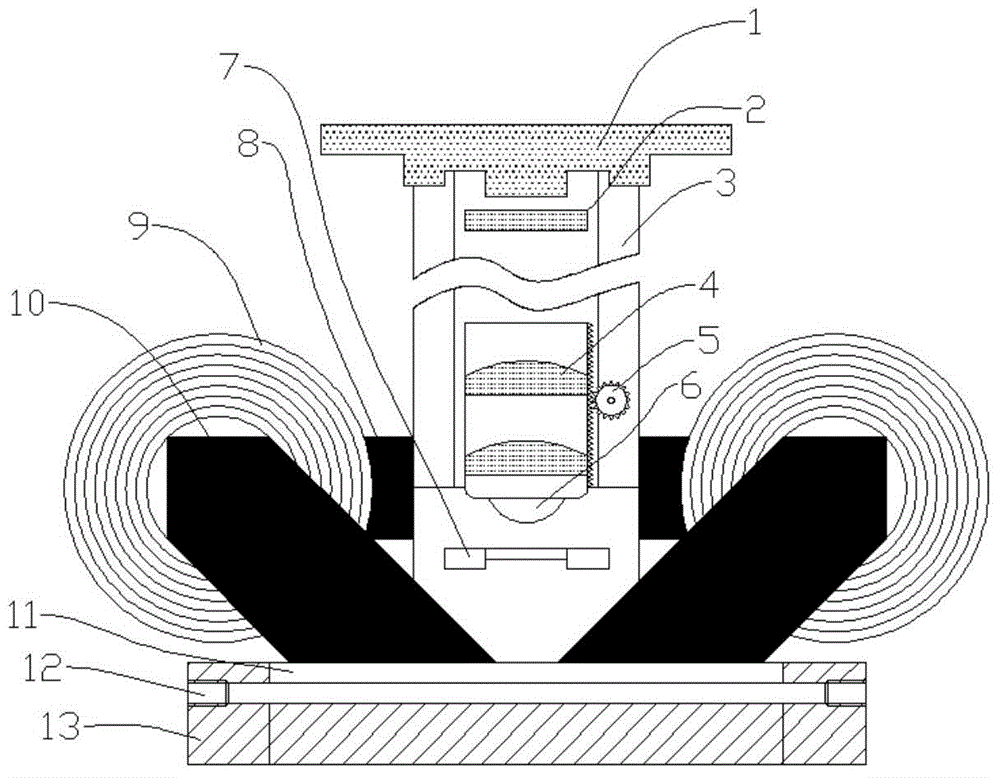

Aerial radio monitoring intelligent robot

ActiveCN104316900AEasy to operateReduce riskBeacon systems using radio wavesPosition fixationFlight control modesMarine navigation

The invention discloses an aerial radio monitoring intelligent robot. A receiving antenna, an electronic compass, a radio monitoring receiving unit, a central processing unit, a flight control module and a navigation module are all installed on a robot body. The central processing unit is connected with the flight control module, the electronic compass and the radio monitoring receiving unit. The navigation module is connected with the flight control module. The receiving antenna is connected with the radio monitoring receiving unit. The central processing unit firstly measures the direction of a radio signal source, then controls the robot body to fly through the flight control unit according to a direction measurement result and finally calculates the position of the radio signal source according to data further monitored on a flight track. According to the aerial radio monitoring intelligent robot, the navigation module is connected with the flight control module, and in-chip transmission is conducted on position information, so that pose correction instantaneity is improved, the error rate is reduced, influences of more modules are avoided, the safety of an aircraft is guaranteed, and the fault probability is reduced.

Owner:CHENG DU DIAN ZHEN TECH +1

Touch panel having improved visibility and method of manufacturing the same

ActiveUS20130223016A1Increase awarenessHigh light transmittanceLaminationLamination apparatusVisibilityUltraviolet

A touch panel having improved visibility is provided. The touch panel includes a window part, at least one ultraviolet (UV) resin layer attached to a bottom surface of the window part, and a display part including a touch sensor film module attached to a bottom surface of the at least one UV resin layer such that the UV resin layer prevents refractions and reflections of light.

Owner:SAMSUNG ELECTRONICS CO LTD

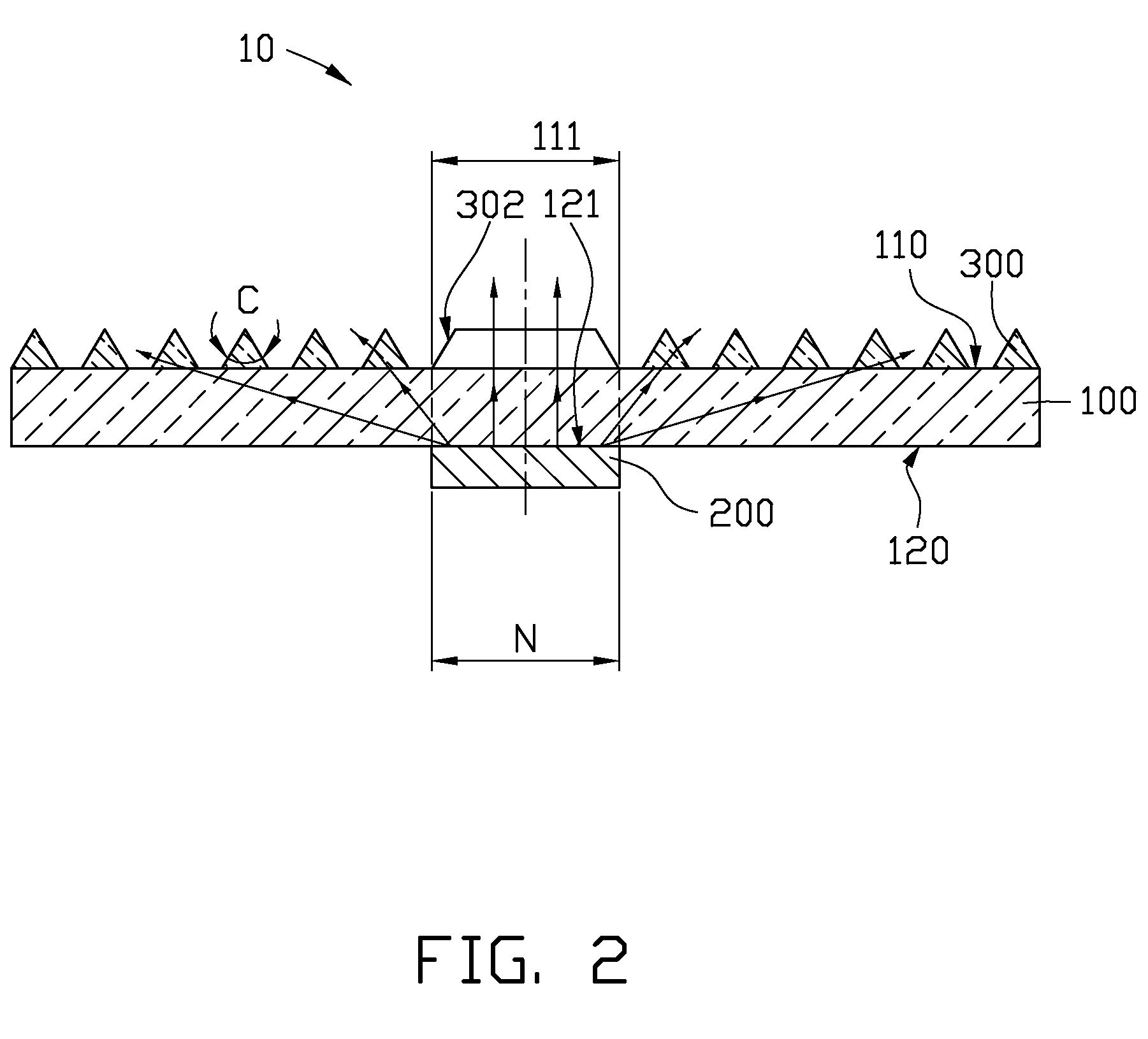

Light source device

InactiveUS20090323329A1Reduce brightnessAvoid refractionPlanar light sourcesPoint-like light sourceOptoelectronicsLight source

A light source device includes a light conduction, a light source and a light diffusion component. The light conduction component has a first surface and a second surface opposite to the first surface. The second surface has a light input portion. The first surface has a light output portion substantially coaxial with the light input portion and having two opposite longitudinal ends and two opposite lateral ends. The light source is configured to emit lights to the light input portion. The first light diffusion component is positioned on the first surface, and includes row light diffusion components and column light diffusion components substantially perpendicular to the row light diffusion components. The row light diffusion components are positioned at the longitudinal ends of the light output portion. The column light diffusion components are positioned at the lateral ends of the light output portion.

Owner:HON HAI PRECISION IND CO LTD

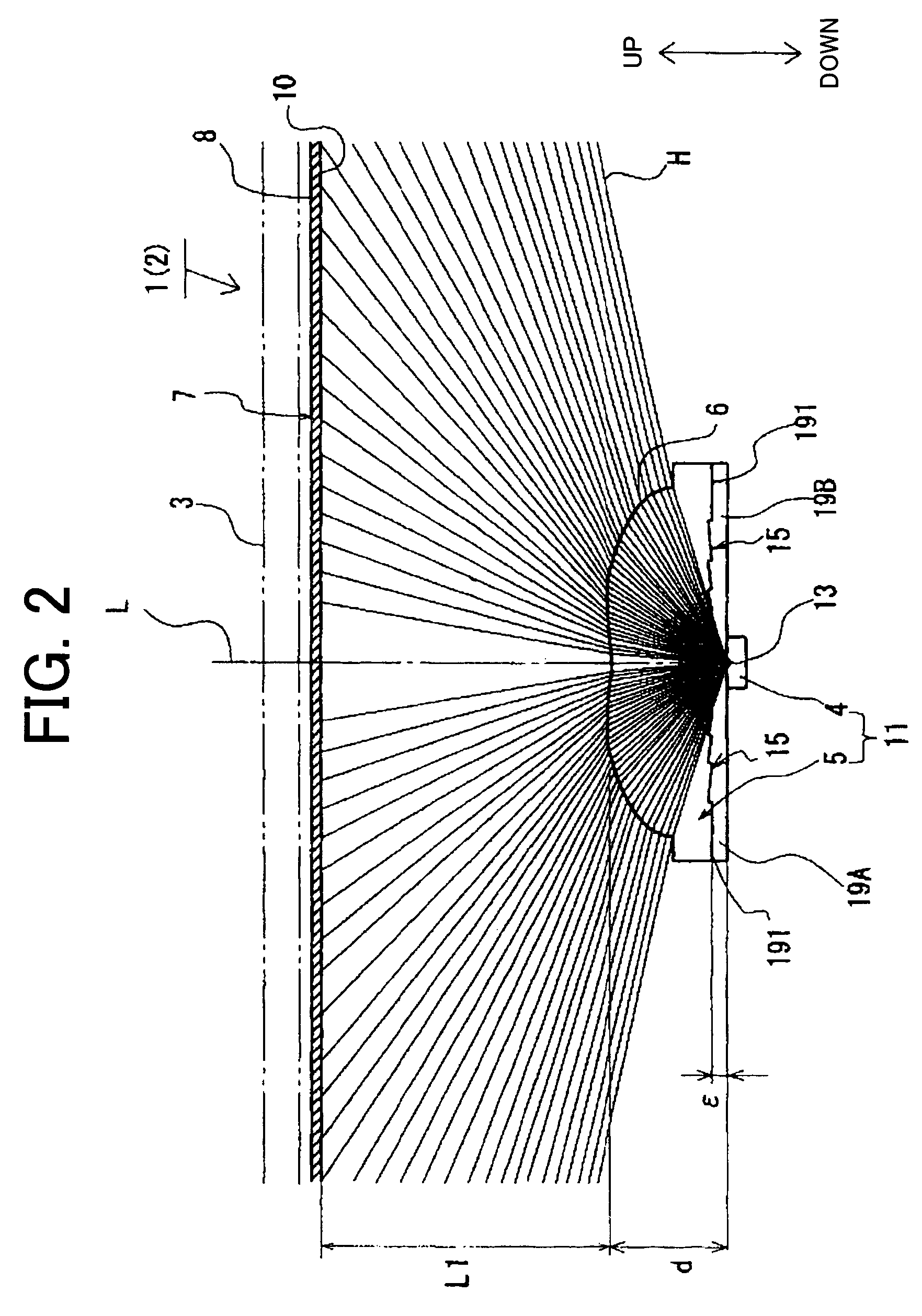

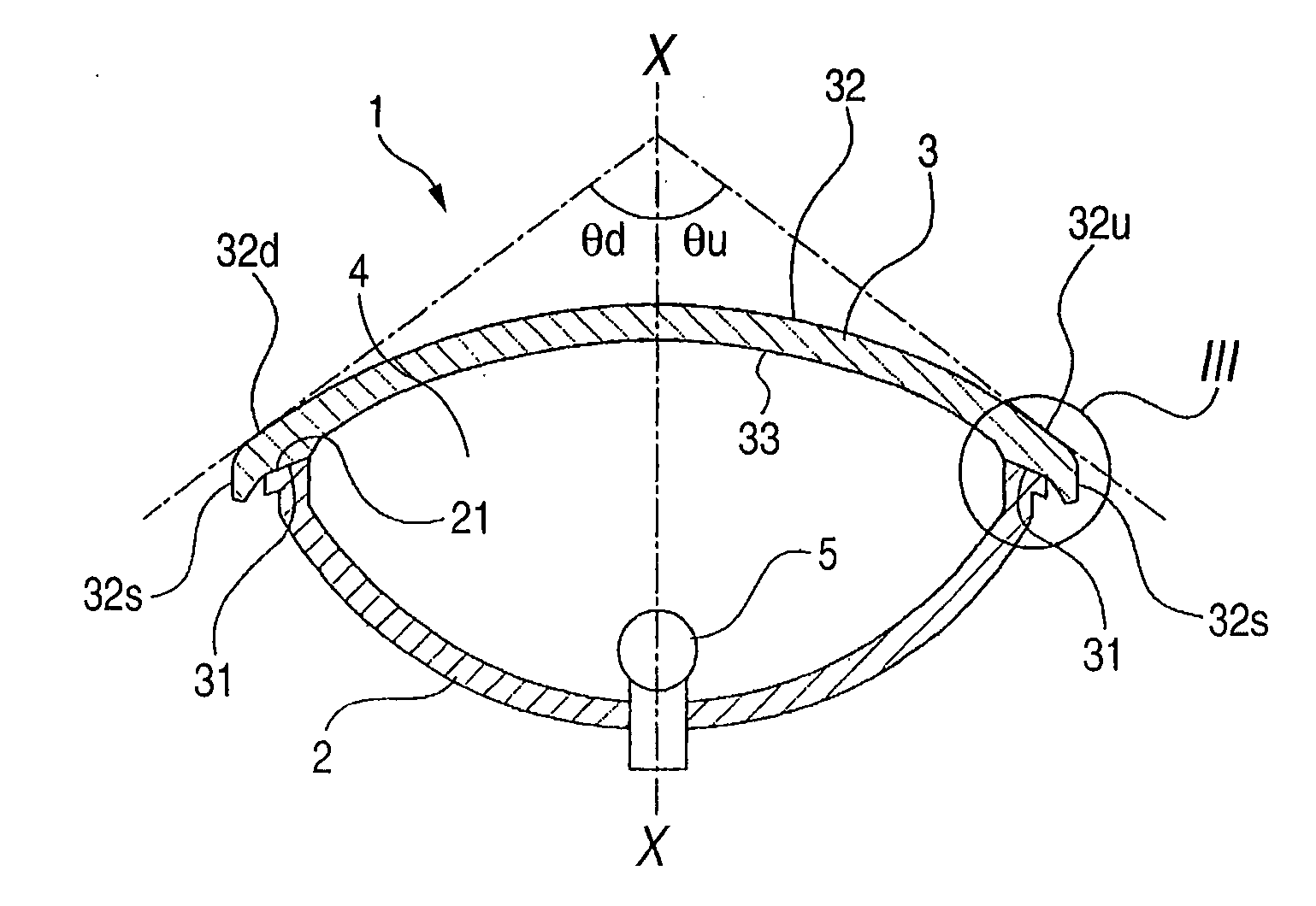

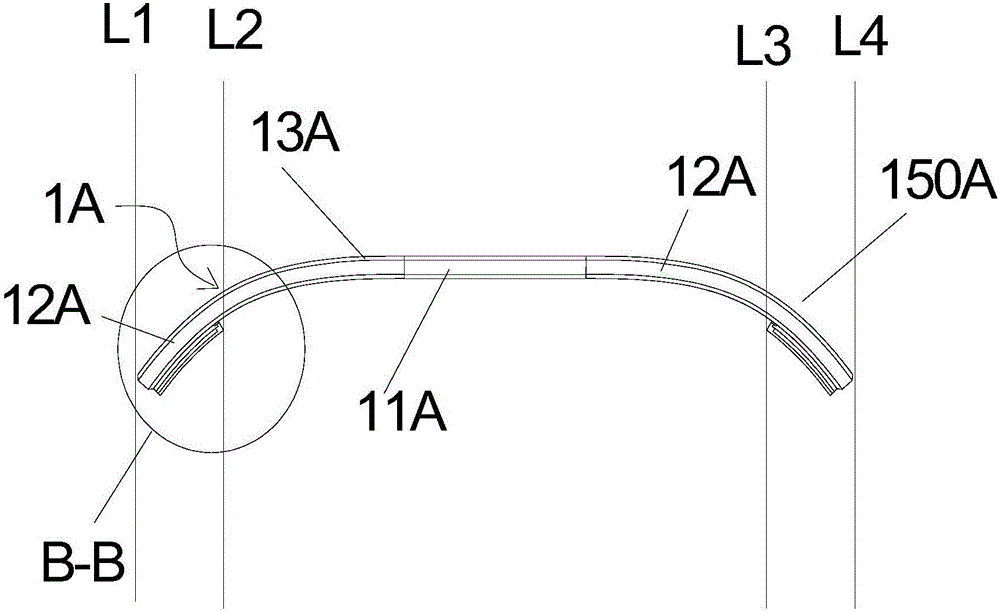

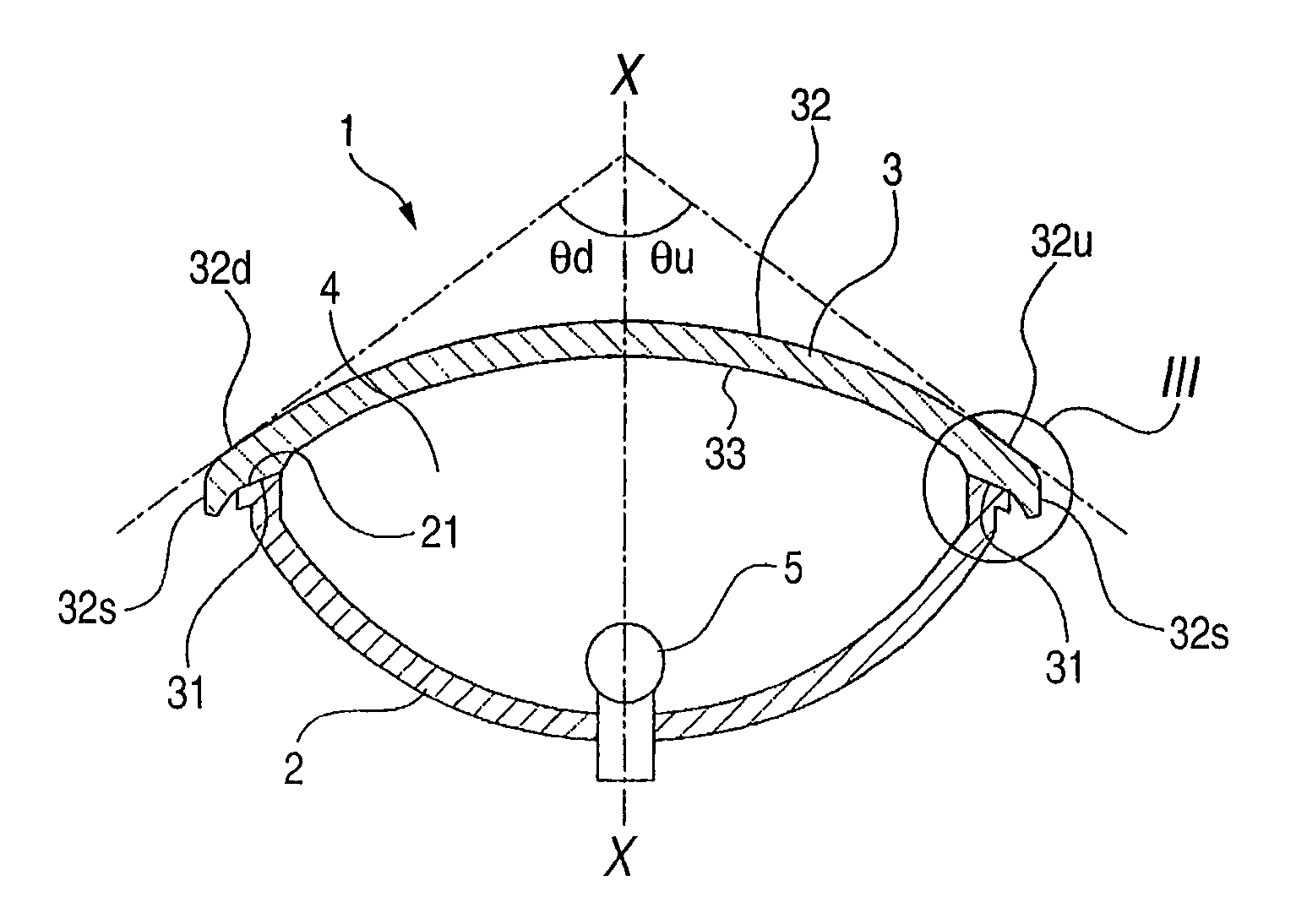

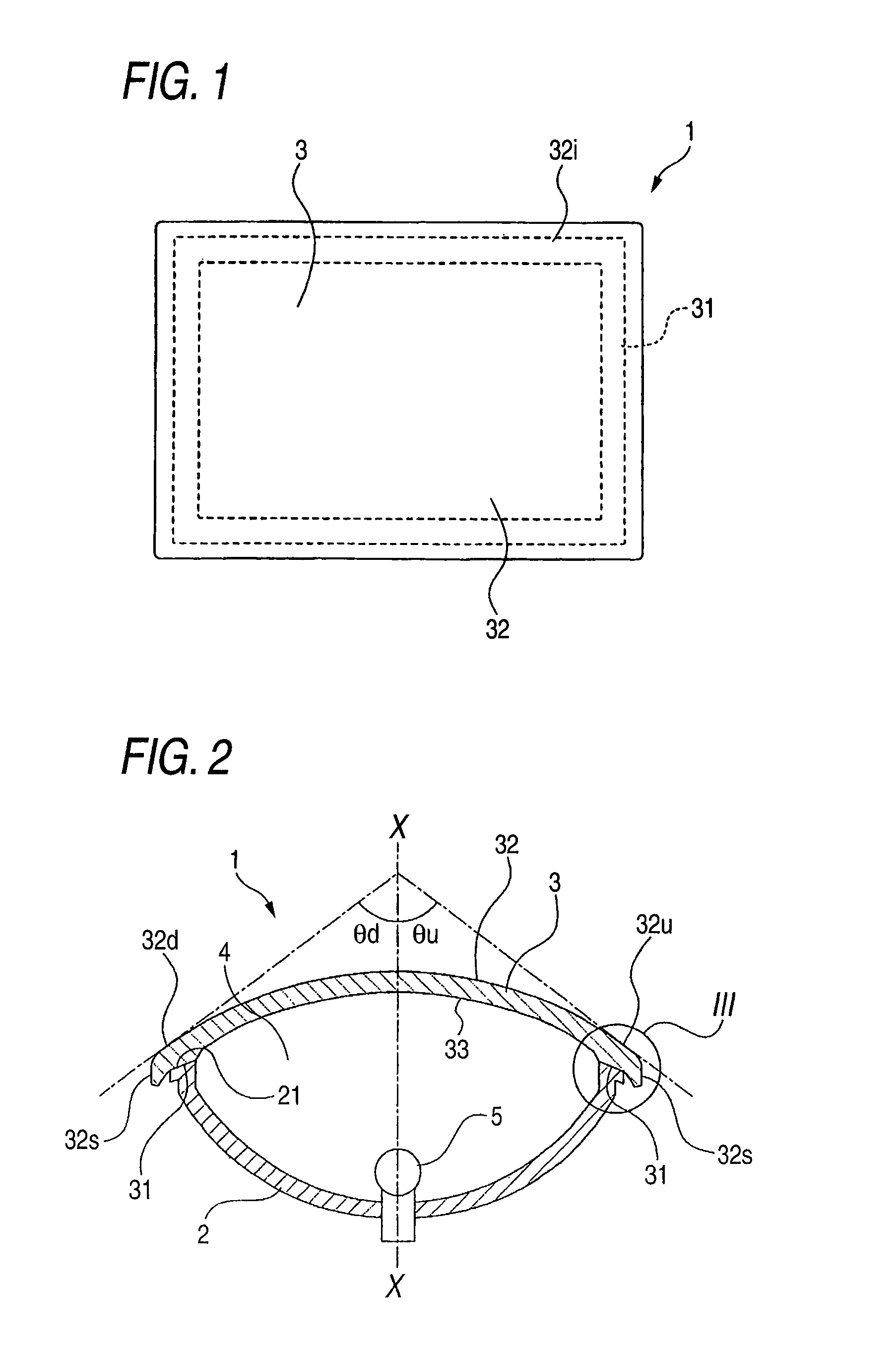

Vehicle lamp and method of manufacturing vehicle lamp

InactiveUS20070295719A1Avoid problemsAvoid refractionOptical articlesOptical signallingEngineeringReference line

A vehicle lamp includes a housing and a transparent cover, which is joined to the housing by a light ray welding. A front face of the transparent cover is curved and a rear face of the transparent cover includes a welding face portion formed along a circumferential portion thereof. In at least one section of the transparent cover, respective end portions of the front face corresponding to the welding face portion are inclined in different directions, and an angle of the welding face portion with respect to a reference line, which passes through the transparent cover and forms equal angles with respect to the respective end portions of the front face, is closer to a right angle than the angle of each of the end portions of the front face with respect to the reference line.

Owner:KOITO MFG CO LTD

Image capturing device

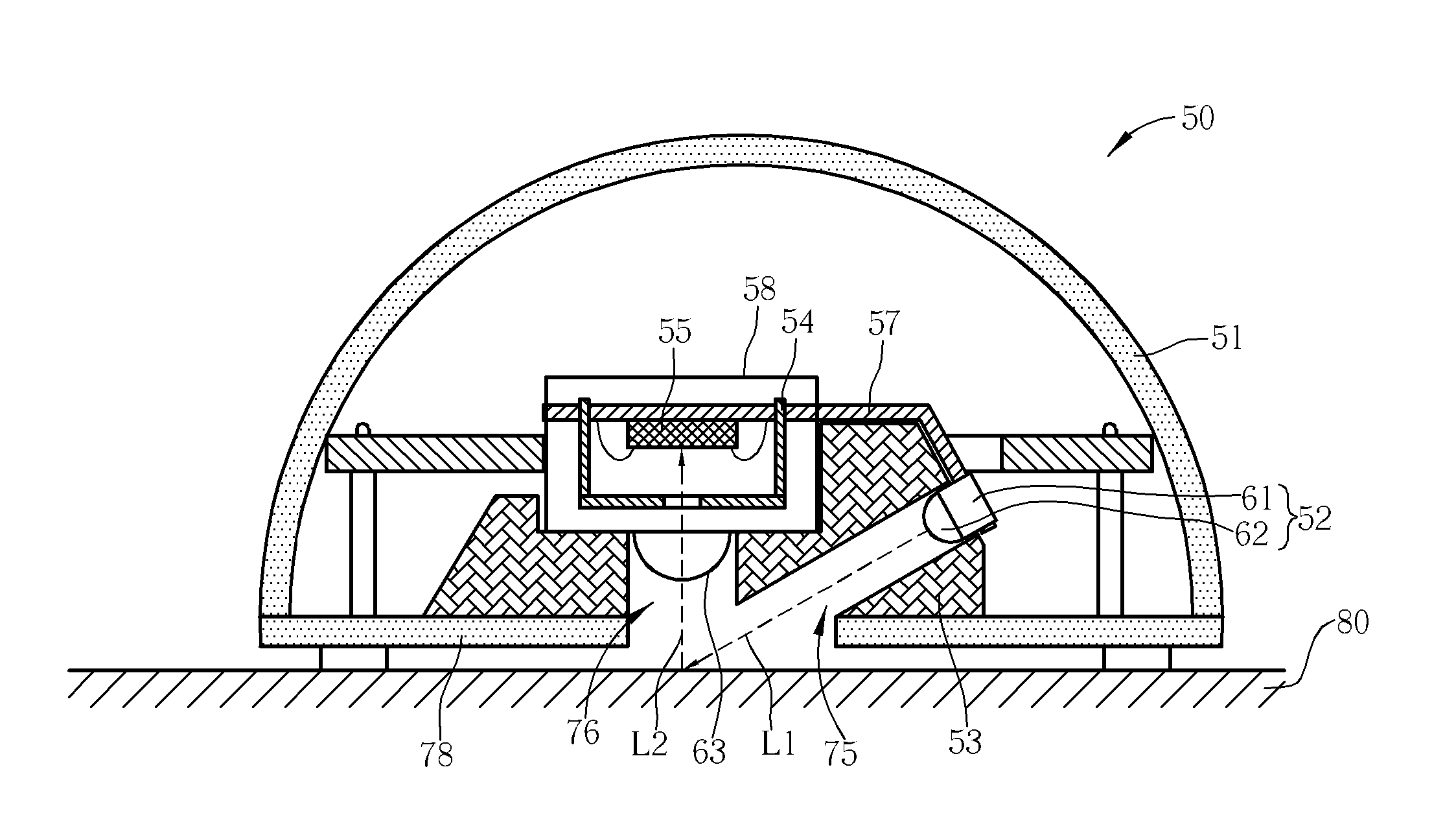

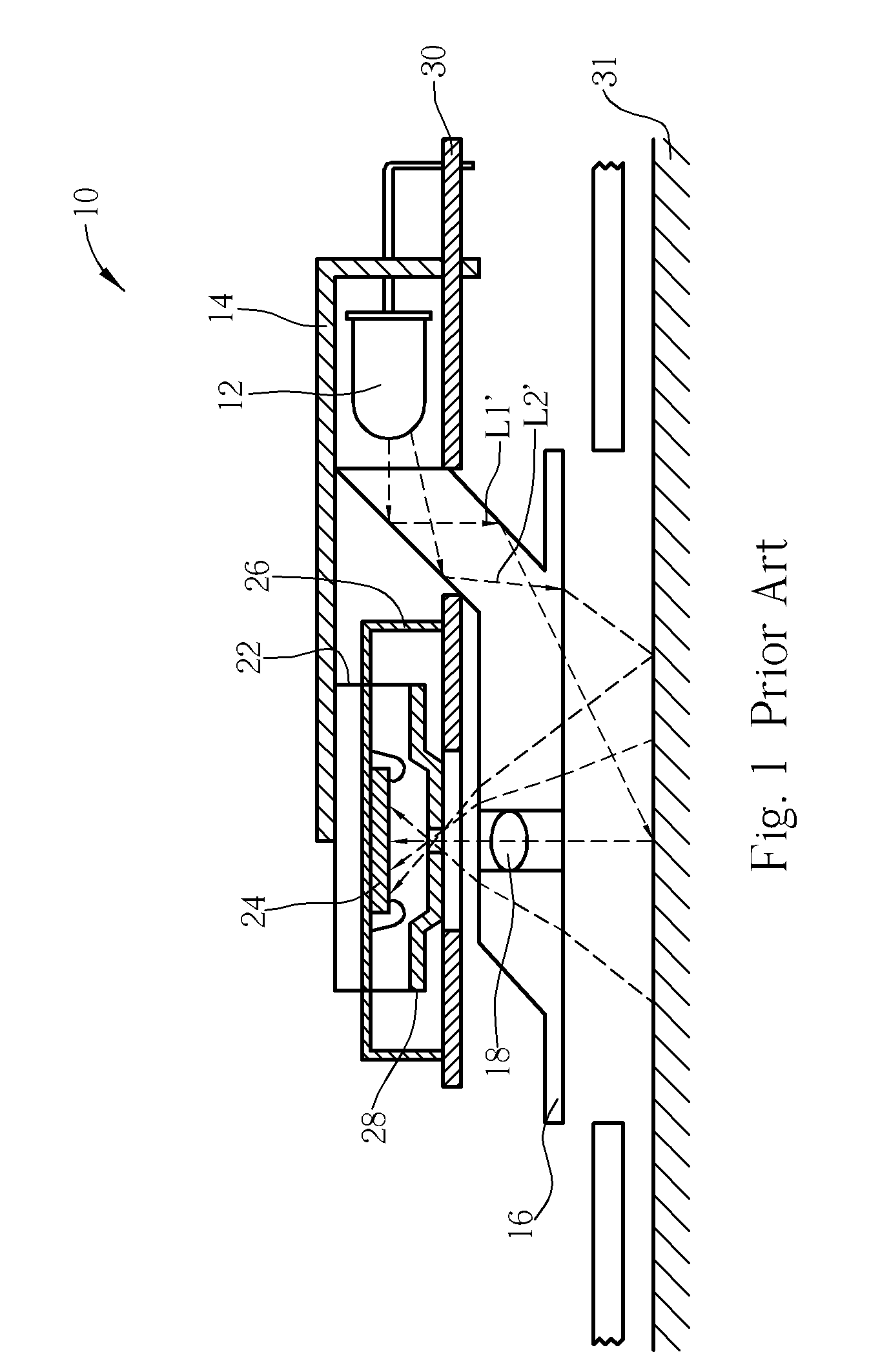

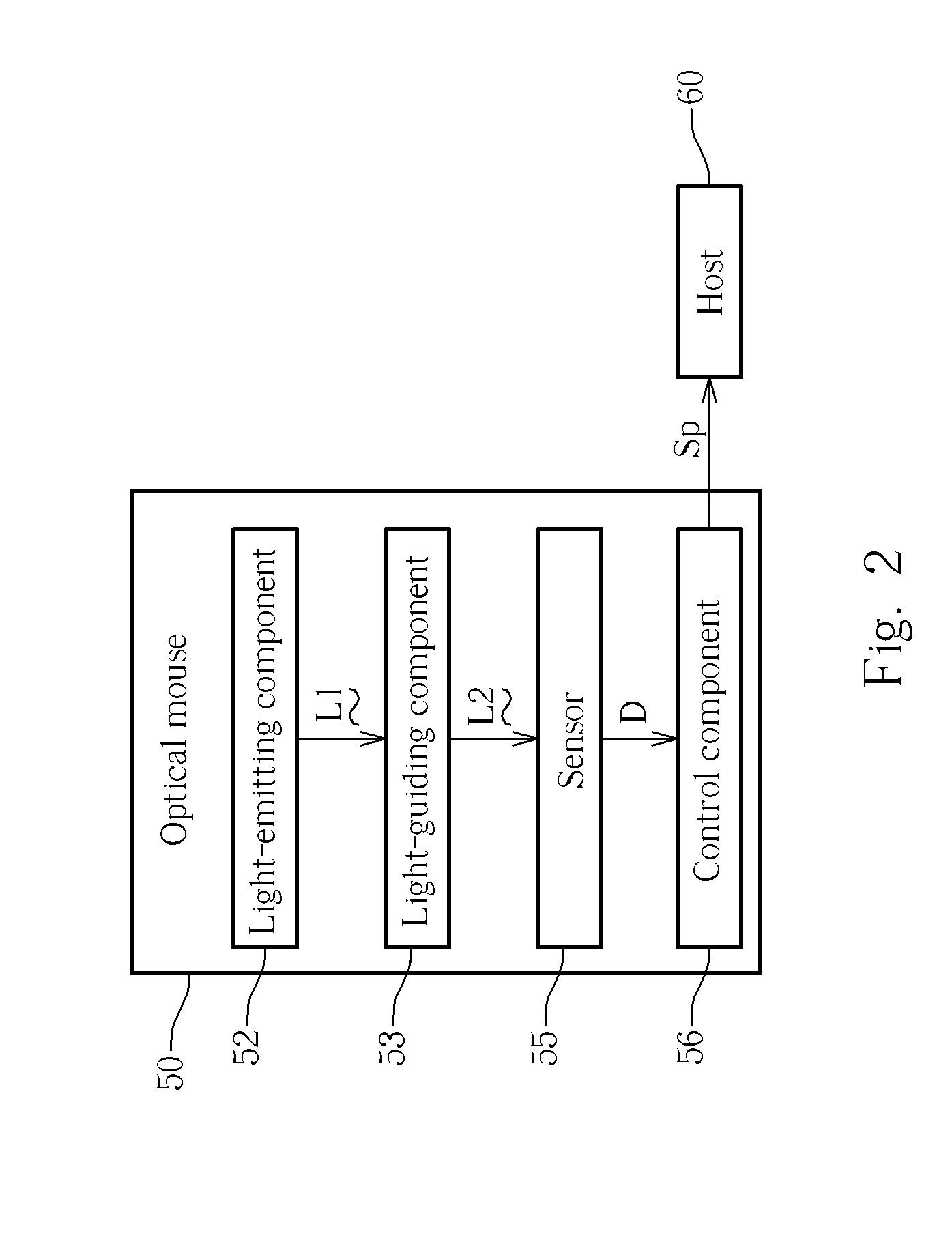

InactiveUS20070008285A1Intensity of light not be weakenedImprove image qualityCharacter and pattern recognitionCathode-ray tube indicatorsLight guideComputer science

An image capturing device is disclosed. The image capturing device includes: a light-emitting component for generating a light ray; a light-guiding component for providing a first straight light-guiding path to guide the light ray generated by the light-emitting component toward a surface; and a sensor for sensing the light ray reflected by the surface to detect a movement of the image capturing device on the surface.

Owner:LITE ON TECH CORP

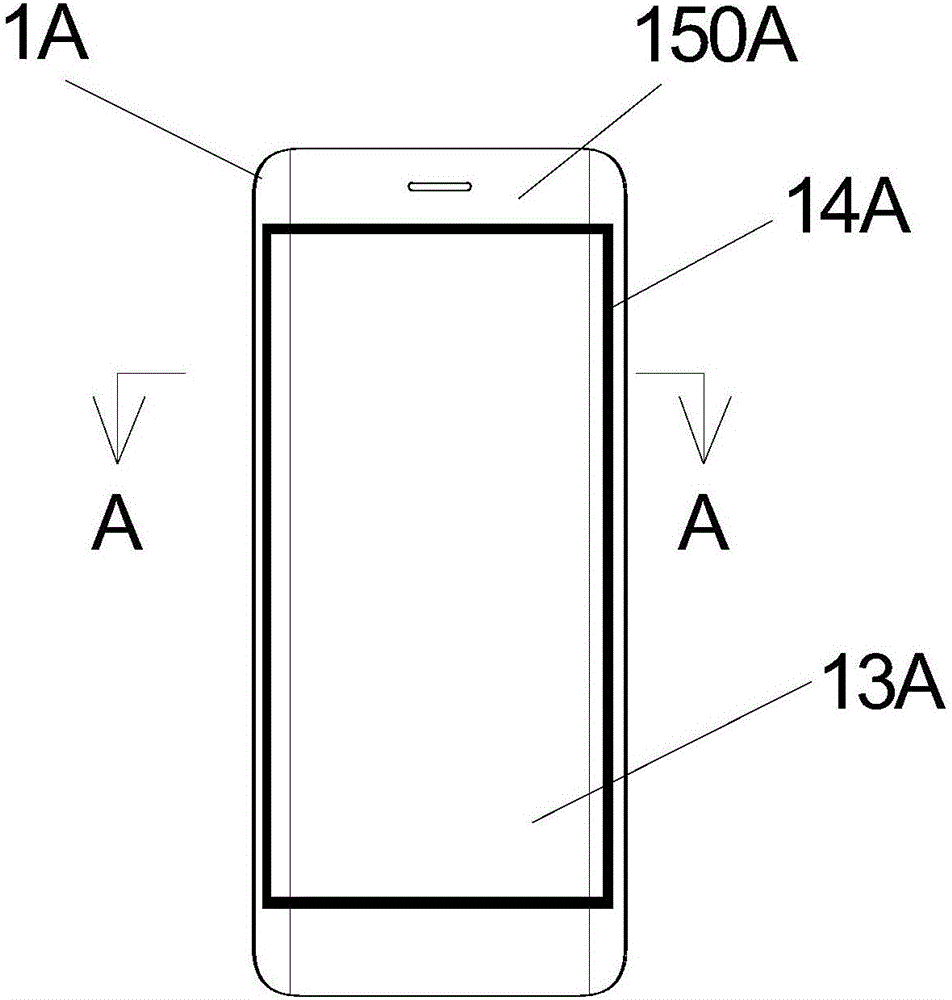

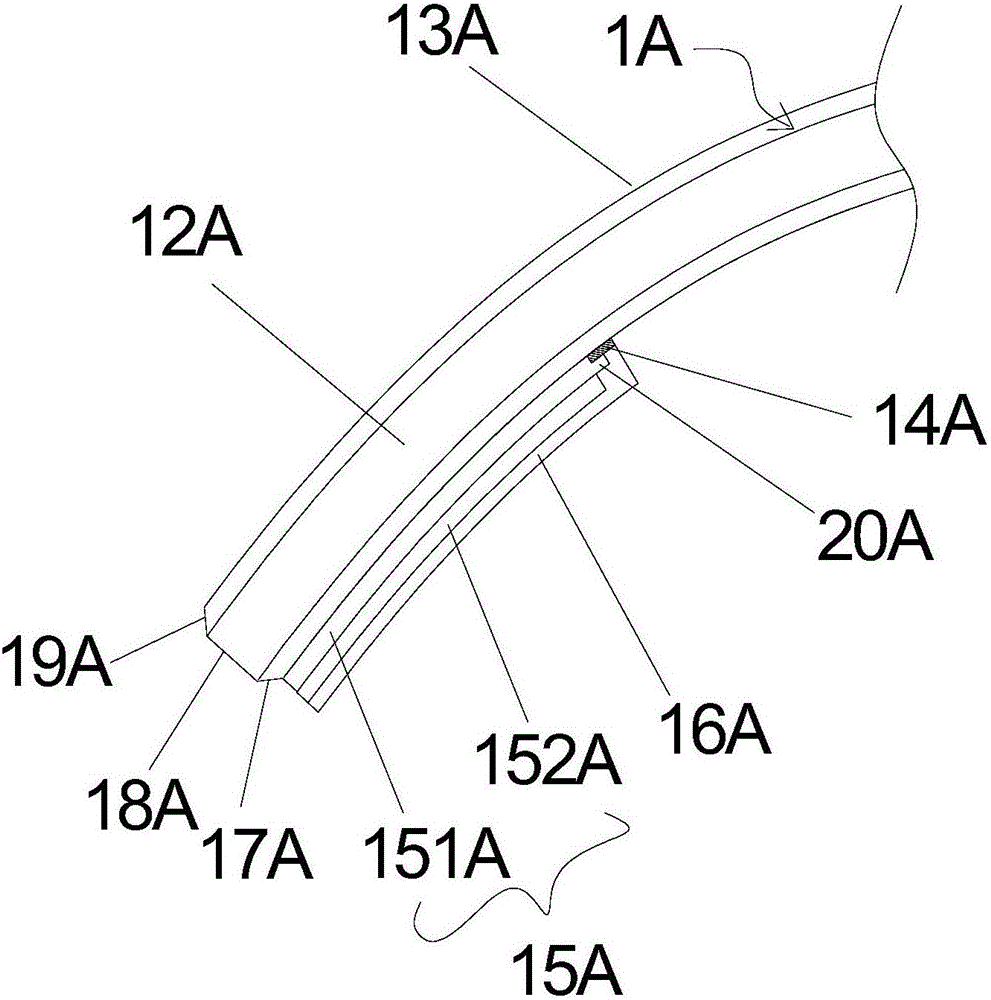

3D (Three-dimensional) glass cover plate for mobile terminal and manufacturing method thereof

ActiveCN106774650AAvoid refractionAvoid reflectionsDigital data processing detailsCoatingsGlass coverPrinting ink

The invention relates to a 3D (Three-dimensional) glass cover plate for a mobile terminal and a manufacturing method thereof. The 3D glass cover plate for the mobile terminal comprises a glass cover plate body (1) and a printing ink covering part (2) which is arranged at the bottom surface (15) of the glass cover plate body (1); the glass cover plate body (1) comprises a flat panel part (11) and a 3D bending part (12) which is positioned on the edge; a transparent visible area (13) is enclosed in the centre of the printing ink covering part (2); the glass cover plate body (1) comprises a top surface (14), a bottom surface (15) and side surfaces (16) which are used for connecting the top surface (14) and the bottom surface (15); the printing ink covering part (2) extend to the side surfaces (16) to cover part or the whole of the side surfaces (16). According to the 3D glass cover plate for the mobile terminal, the chromatic aberration between an inner chamfer surface and a vertical lifting surface between the transparent visible area, and a decorating ring of the mobile terminal or a middle frame is avoided; a thorough problem is solved. The manufacturing method for the 3D glass cover plate for the mobile terminal provided by the invention is wide in application range; the problem about a mass production process of the 3D glass cover plate with four bent surfaces is solved.

Owner:VIVO MOBILE COMM CO LTD

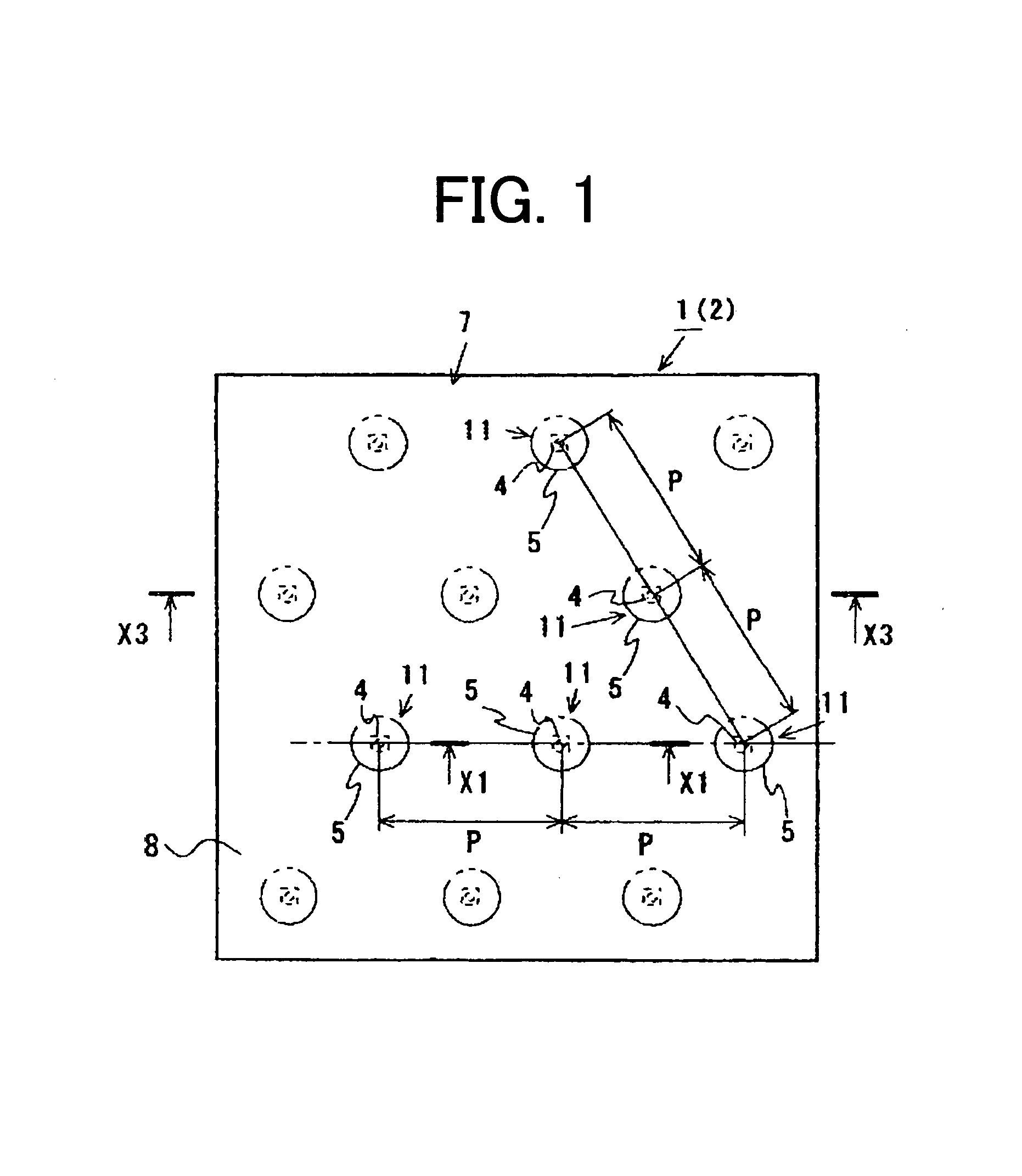

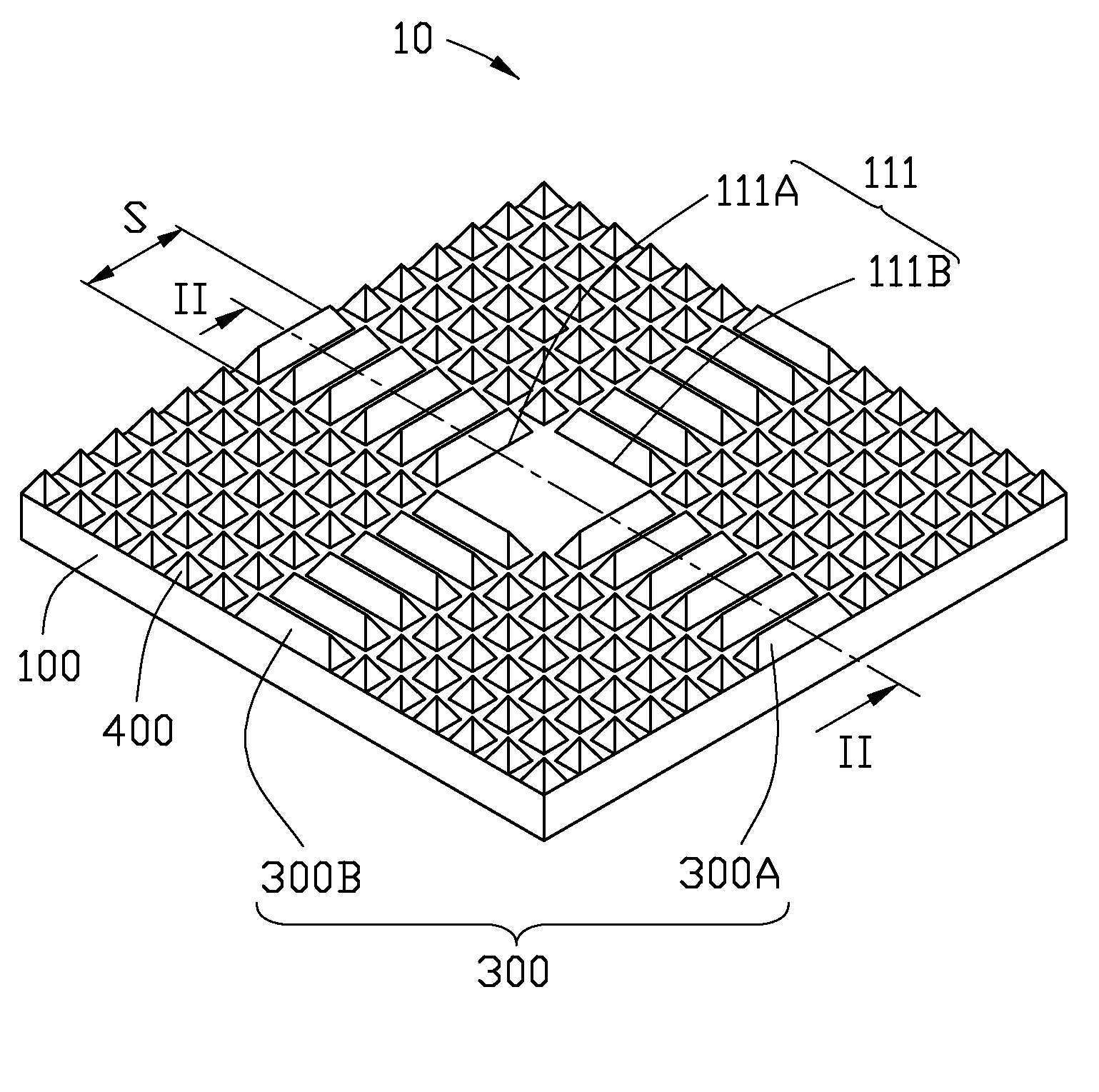

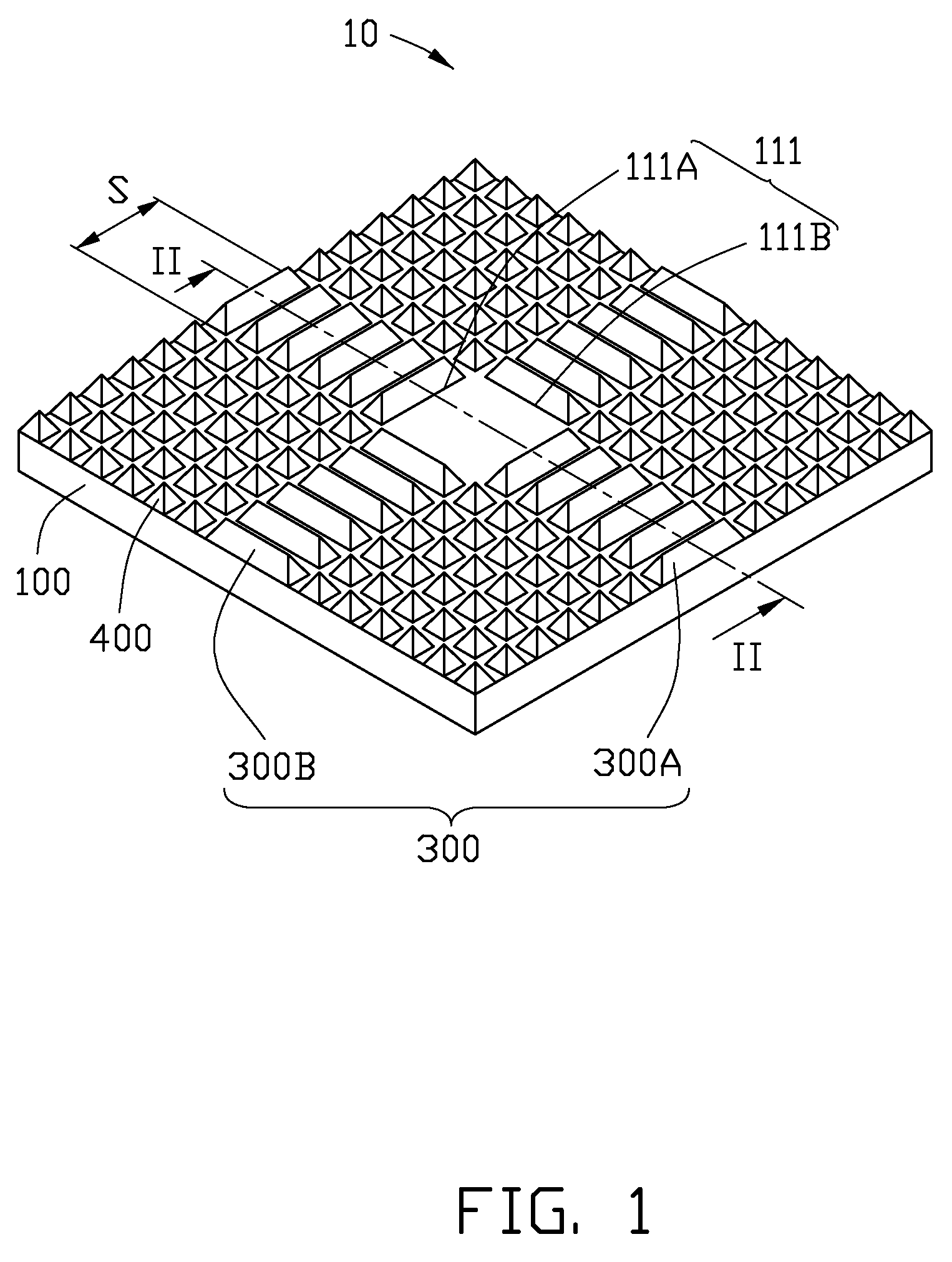

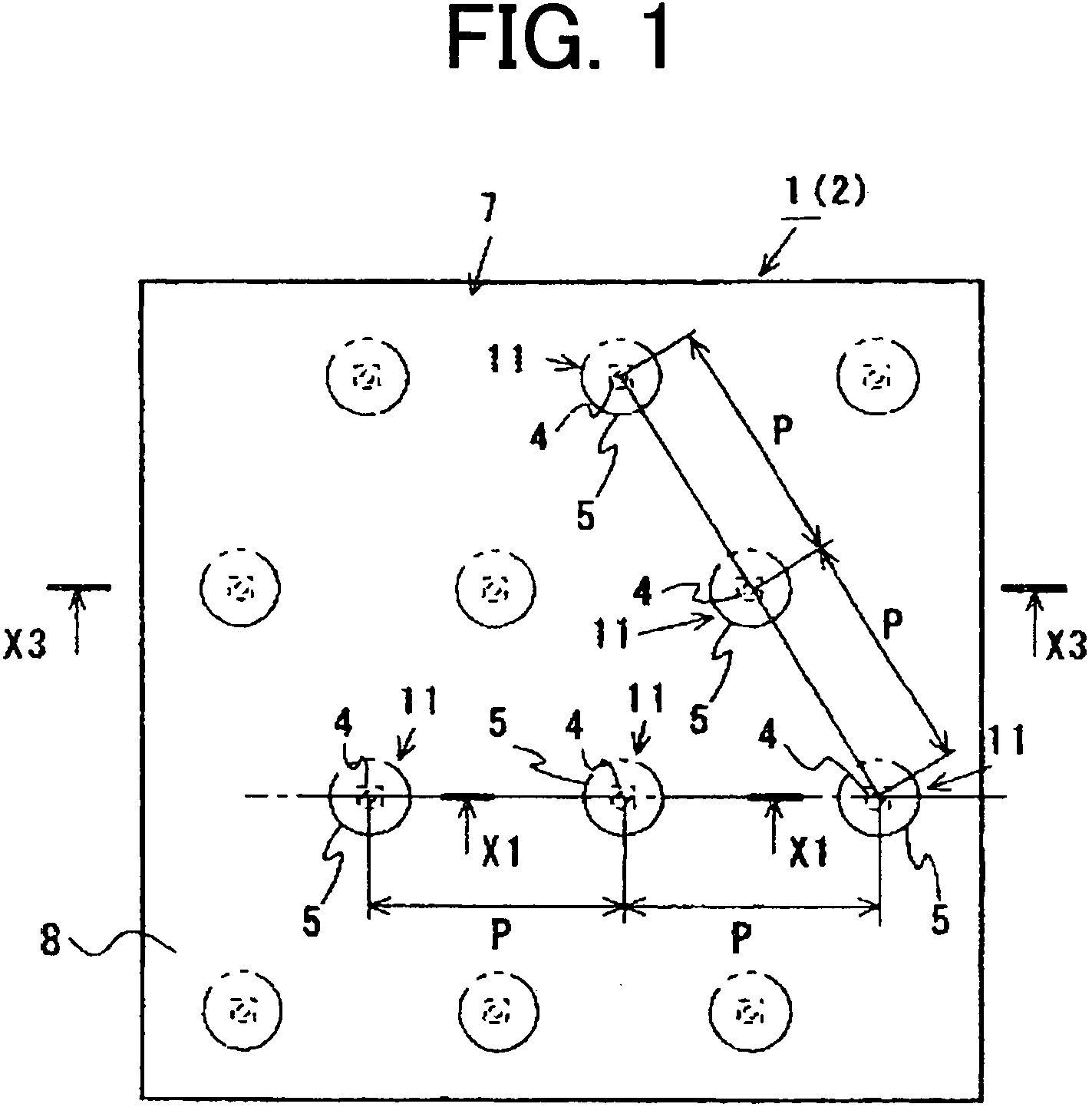

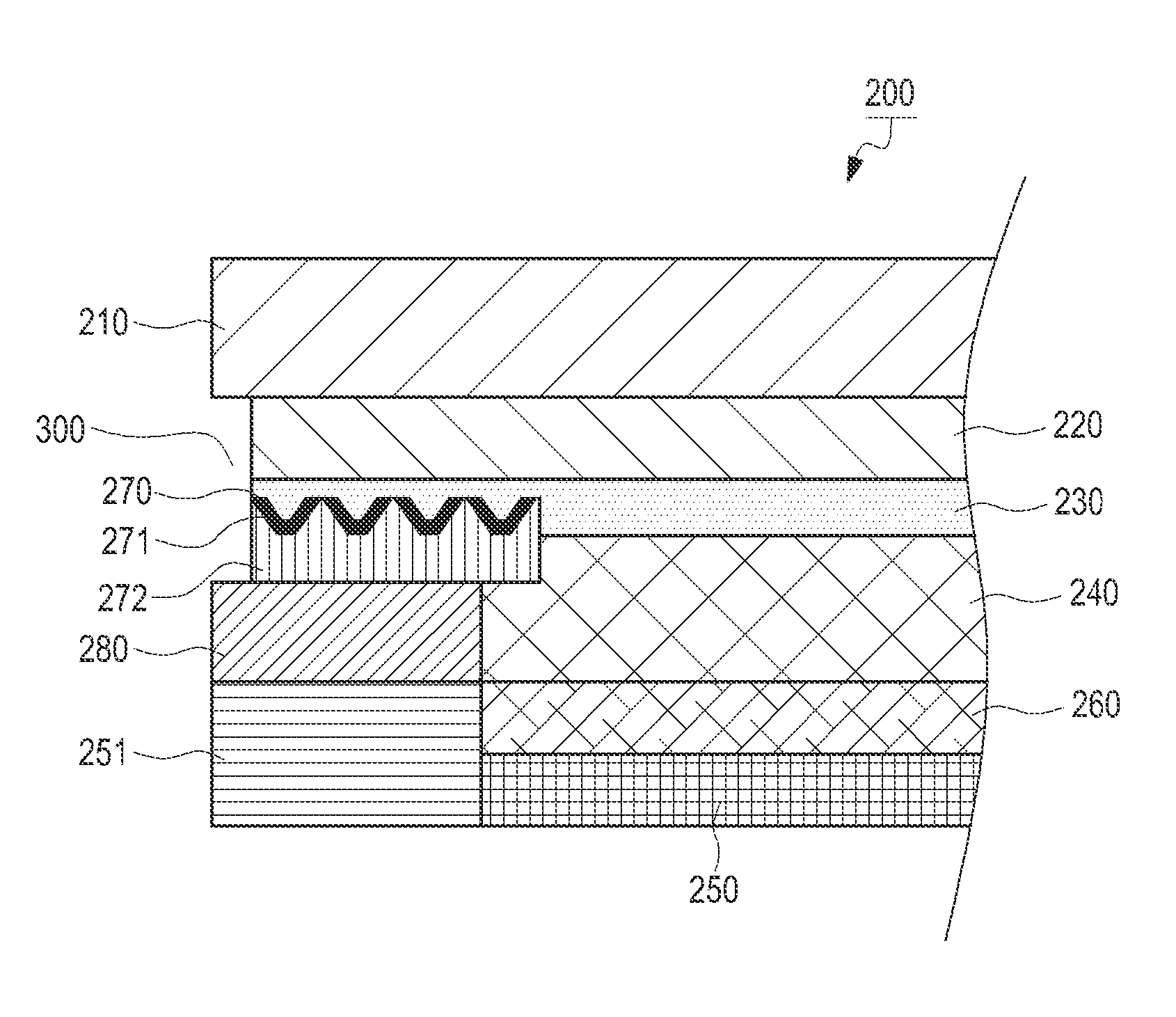

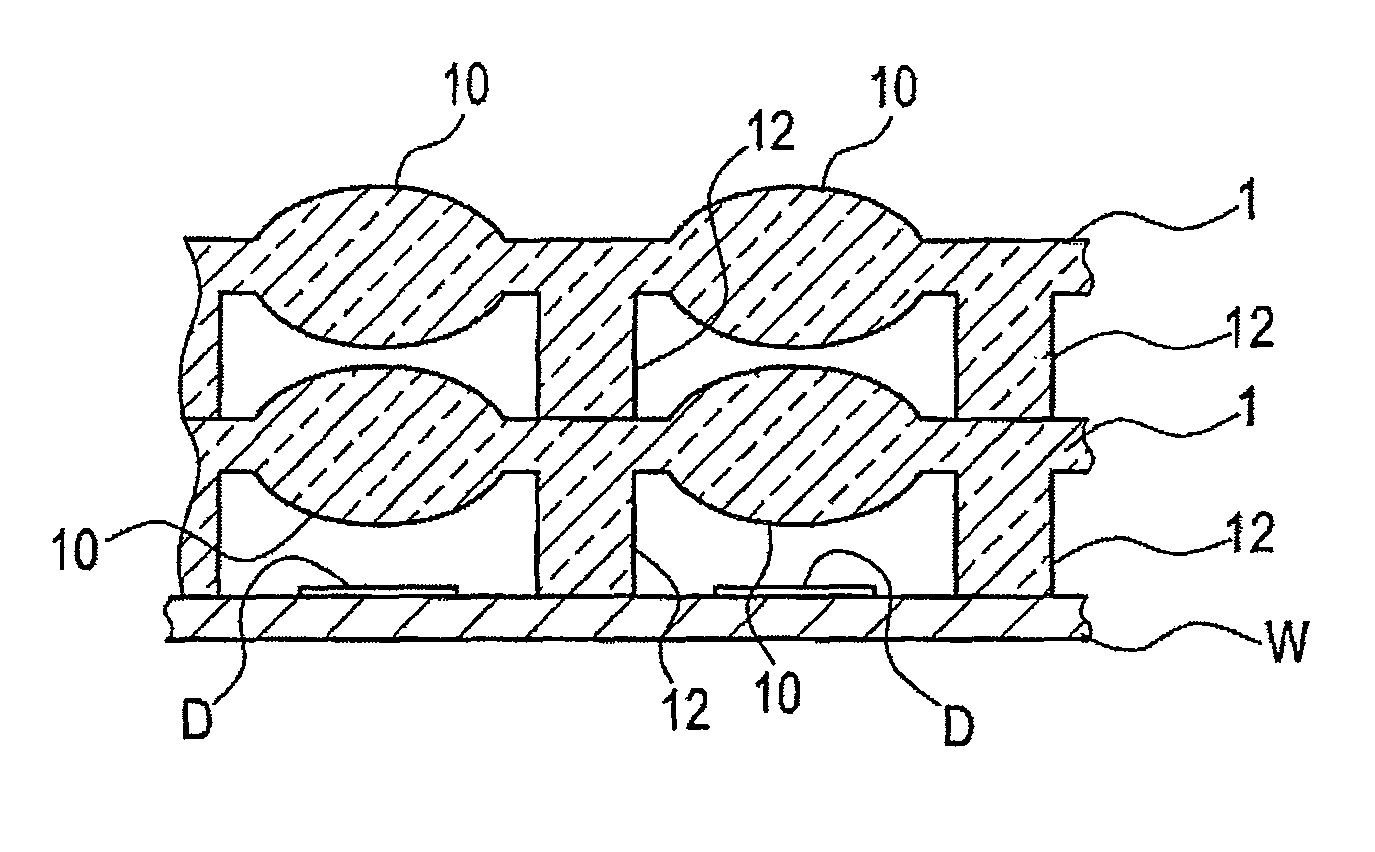

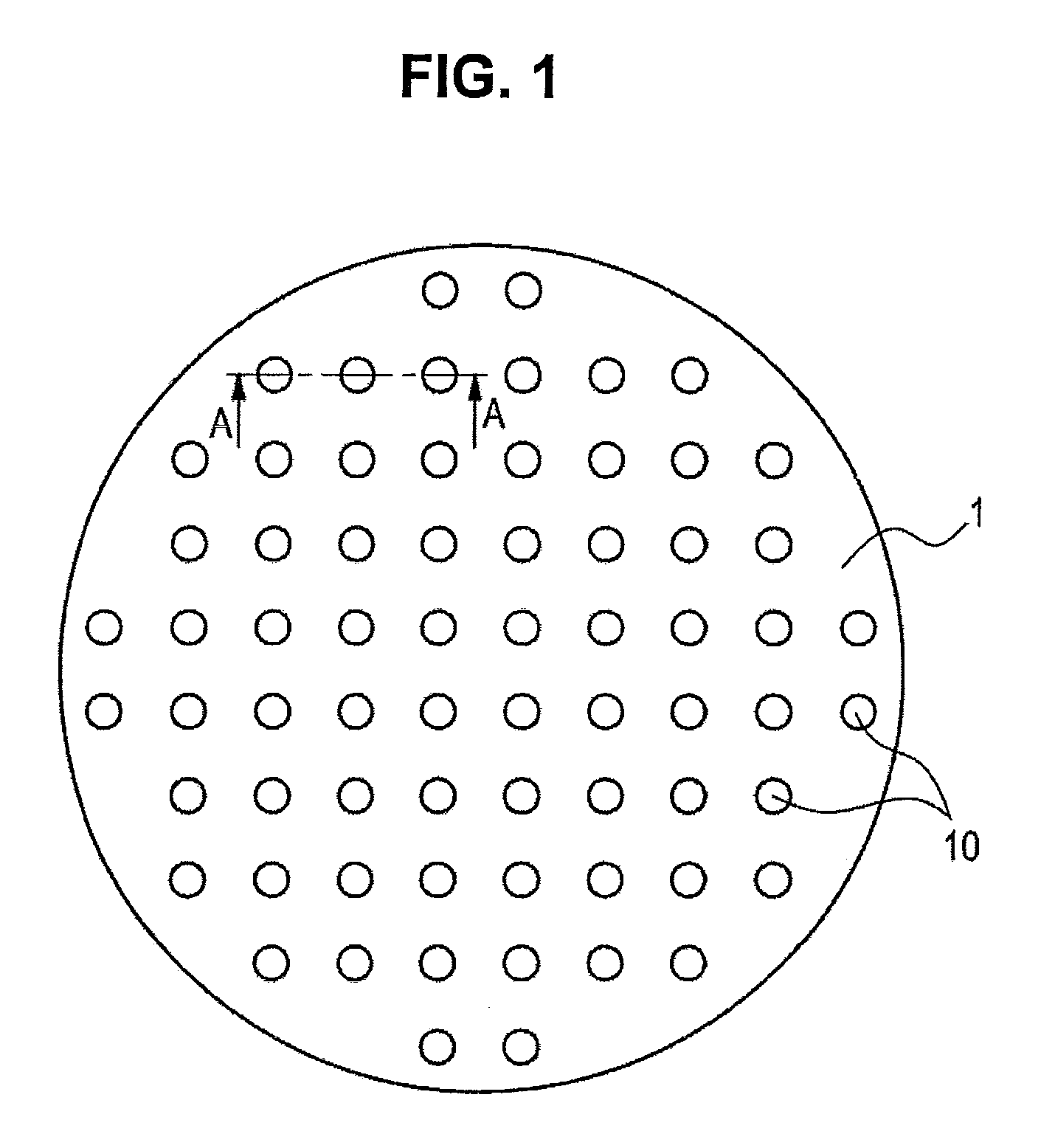

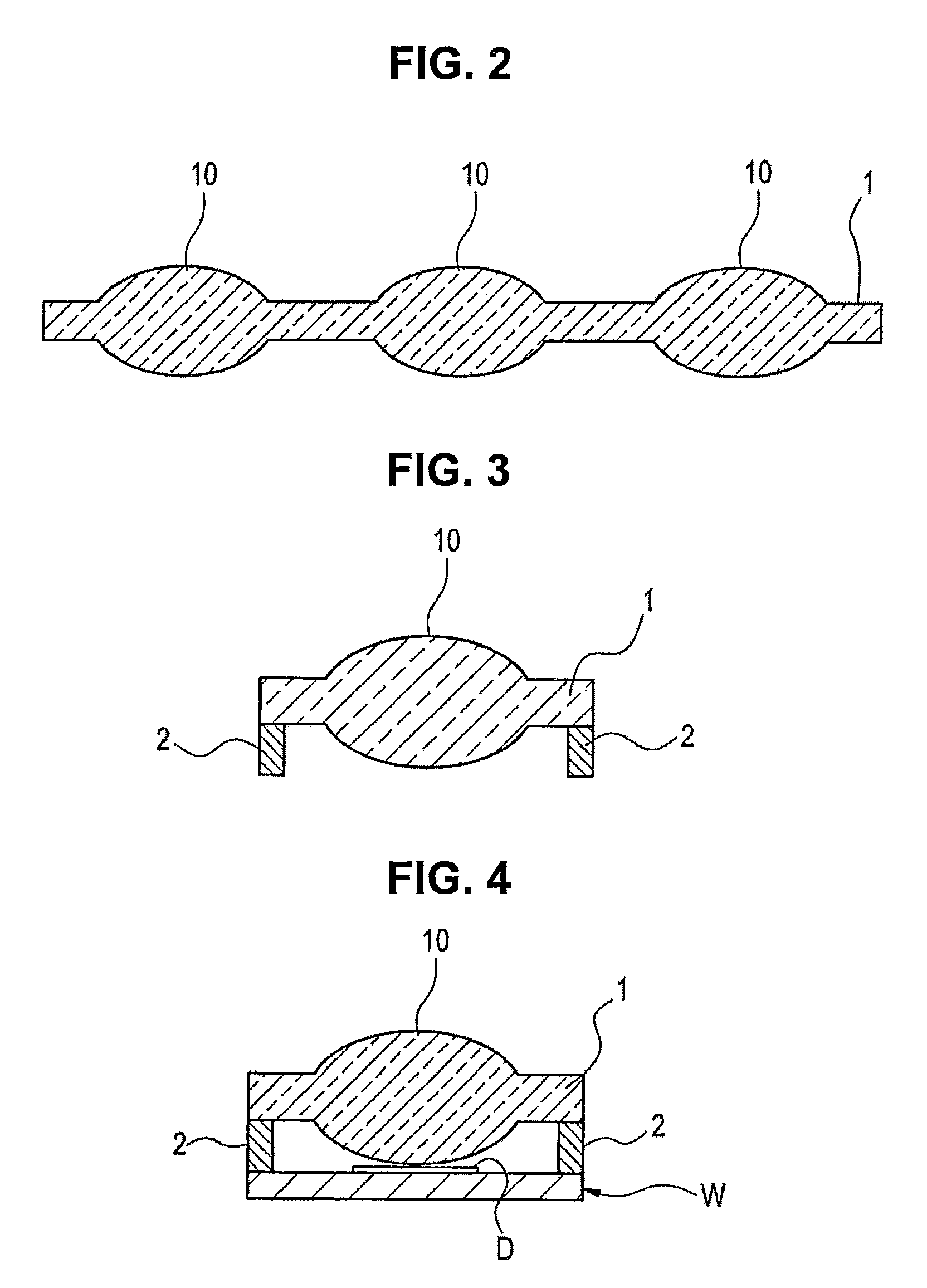

Wafer-level lens array, method of manufacturing wafer-level lens array, lens module and imaging unit

InactiveUS8542309B2Avoid position deviationSimple designTelevision system detailsTelevision system scanning detailsComputer moduleOptoelectronics

Disclosed are a wafer-level lens array, a method of manufacturing a wafer-level lens array, a lens module, and an imaging unit that can prevent the influence of, for example, the shrinkage of a forming material, prevent the positional deviation between lenses when the wafer-level lens arrays overlap each other or when the wafer-level lens array overlaps an imaging element array, and be easily designed.A method of manufacturing a wafer-level lens array including a substrate unit and a plurality of lens units that is arranged on the substrate unit includes: forming the substrate unit; and integrally forming the lens units that are made of a resin having substantially the same optical characteristics as a material forming the substrate unit with the substrate unit.

Owner:FUJIFILM CORP

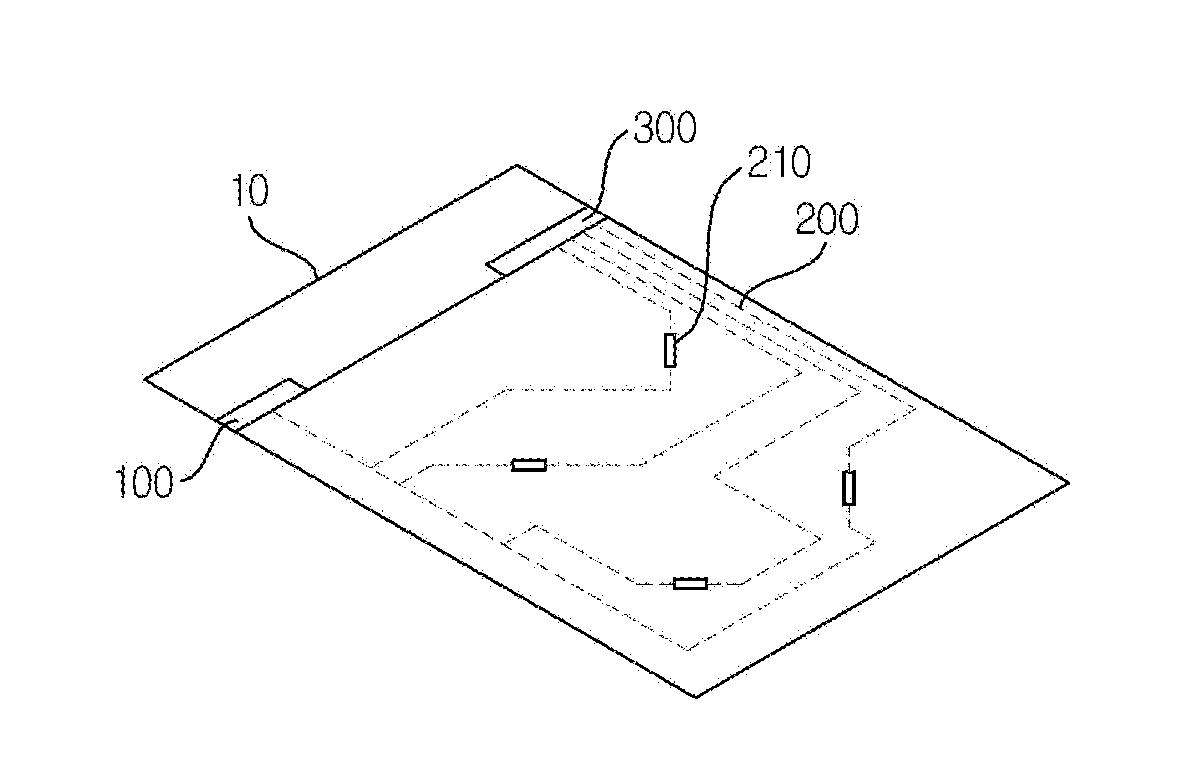

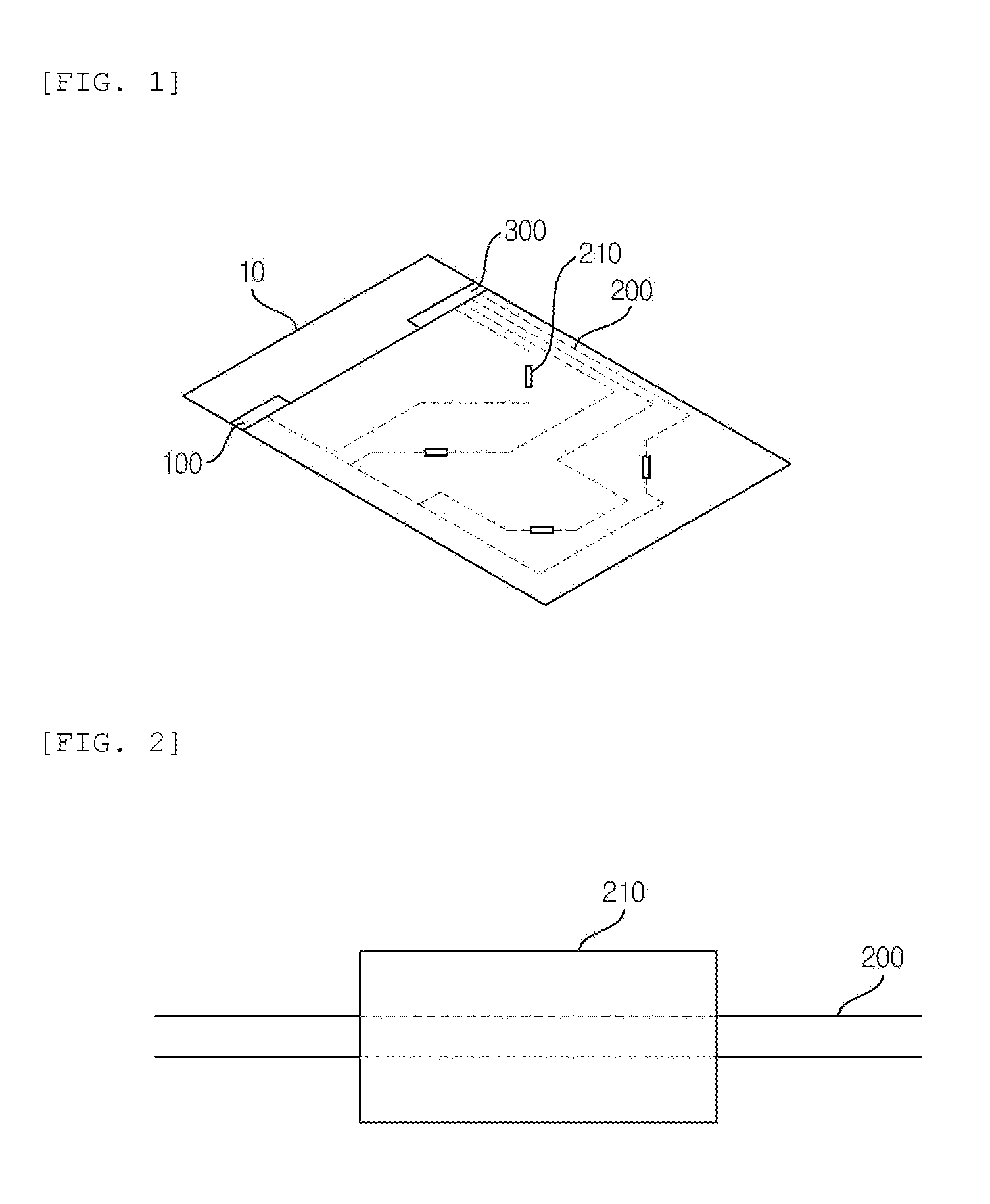

Pressure sensor and apparatus for sensing pressure and touch screen including the same

InactiveUS20130194237A1Increase direct pressure measurement effectDirect effectForce measurement by measuring optical property variationApparatus for force/torque/work measurementEngineeringTouchscreen

Disclosed is a film or a panel that may measure pressure while interacting with an electronic device. A pressure sensor according to the present invention includes: a light source unit to generate light; an optical waveguide to transfer, to a light receiving unit, the light that is generated by the light source unit; and the light receiving unit to receive the light that is transferred through the optical waveguide. The optical waveguide includes a pressure sensing unit to adjust the quantity of light that is transferred through the optical waveguide based on a pressure. The light receiving unit senses the pressure based on the change in the quantity of light that is generated by the light source unit and is transferred through the optical waveguide.

Owner:ELECTRONICS & TELECOMM RES INST

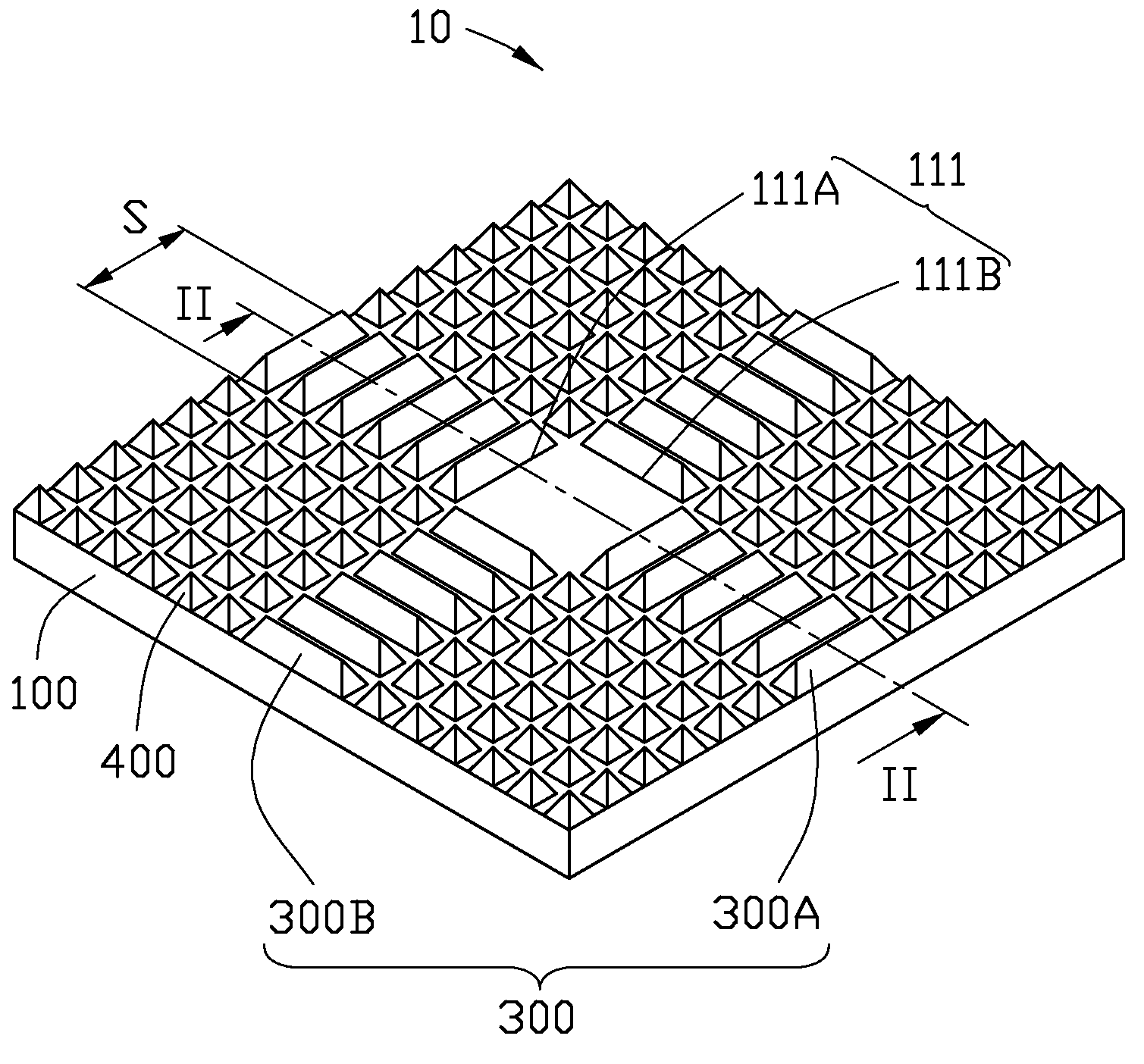

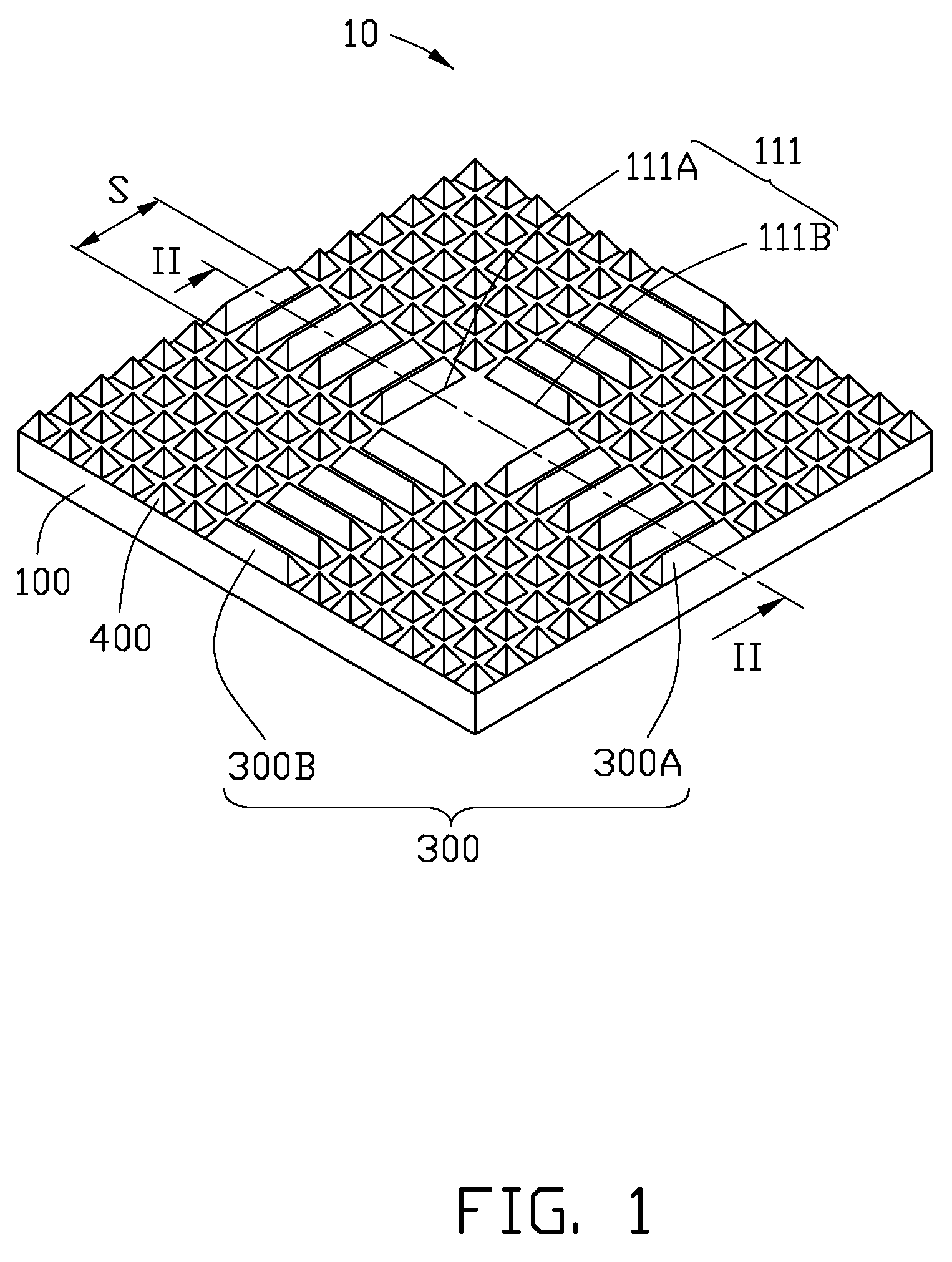

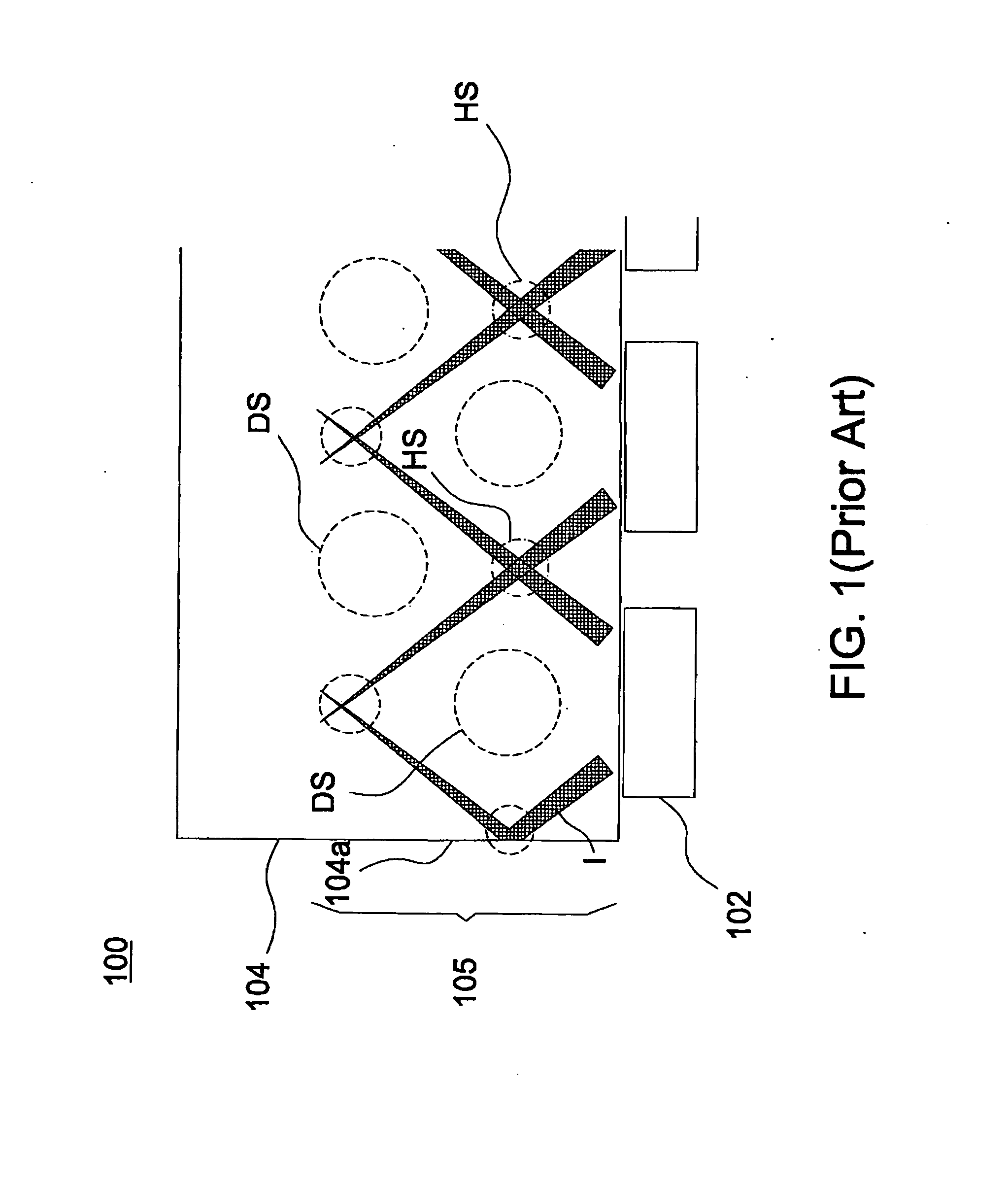

Backlight module and liquid crystal display

InactiveUS20100103345A1Good light utilization efficiencyAvoiding generating the side hot spot in the backlight modulePlanar/plate-like light guidesIlluminated signsPoint light sourceLiquid-crystal display

A backlight module includes at least one point light source and a light guide plate. The light guide plate includes a light emitting surface, a bottom surface, a light incident surface, a first side surface, a second side surface, a first microstructure, and a second microstructure. The bottom surface is opposite to the light emitting surface, the light incident surface connects the light emitting surface and the bottom surface, the point light source is disposed adjacent to the light incident surface, and the first microstructure is formed on the light incident surface. The first side surface is opposite to the light incident surface and connects the light emitting surface and the bottom surface, and the second side surface connects the light emitting surface, the bottom surface, the light incident surface, and the first side surface. The second microstructure is formed on the second side surface.

Owner:CORETRONIC

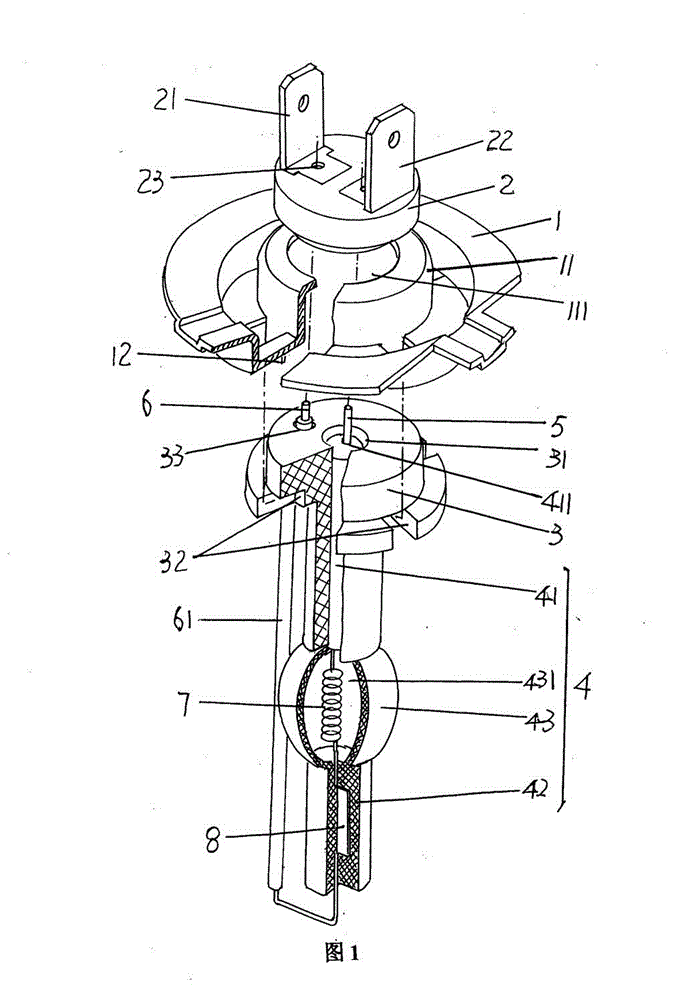

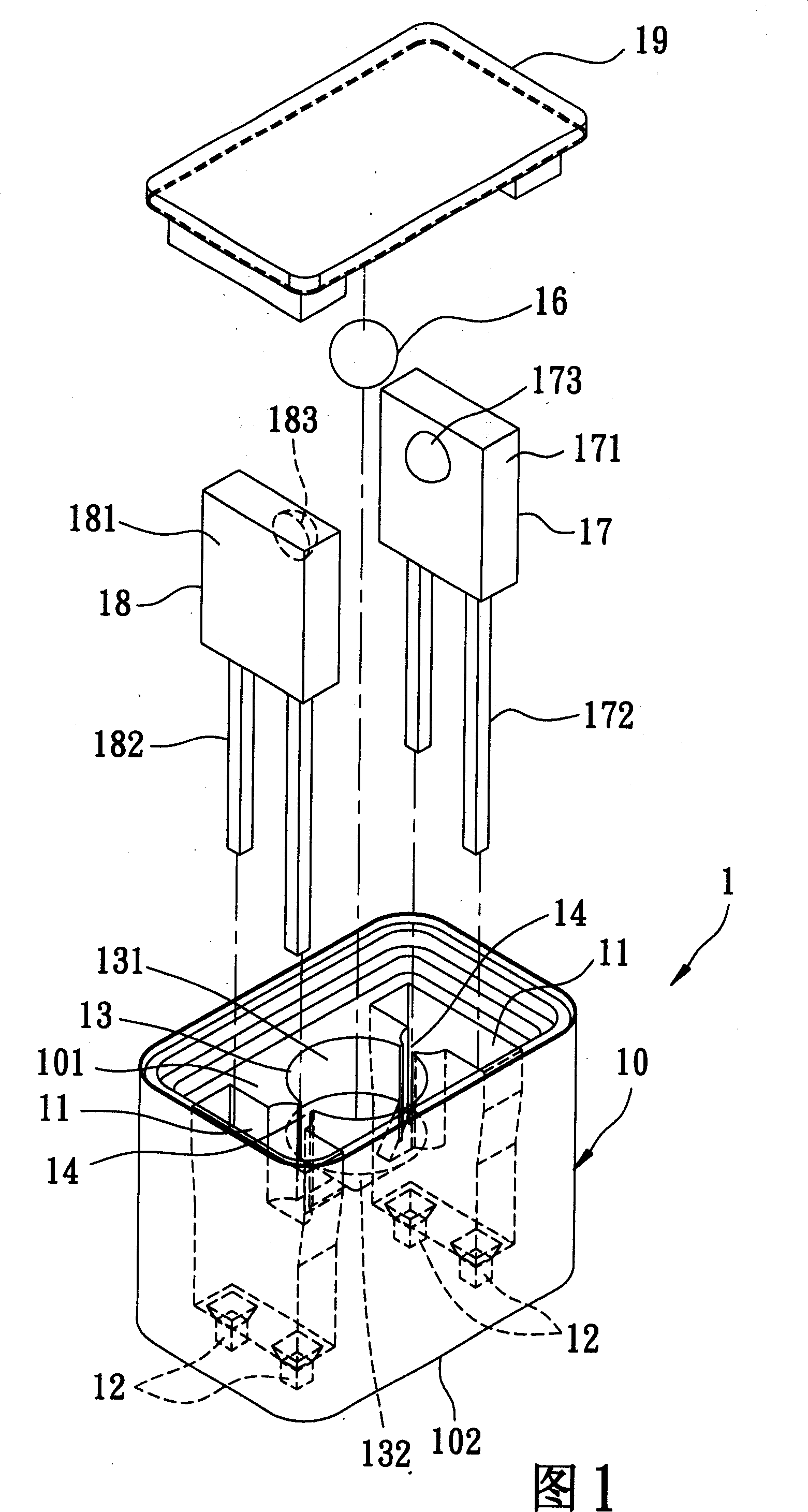

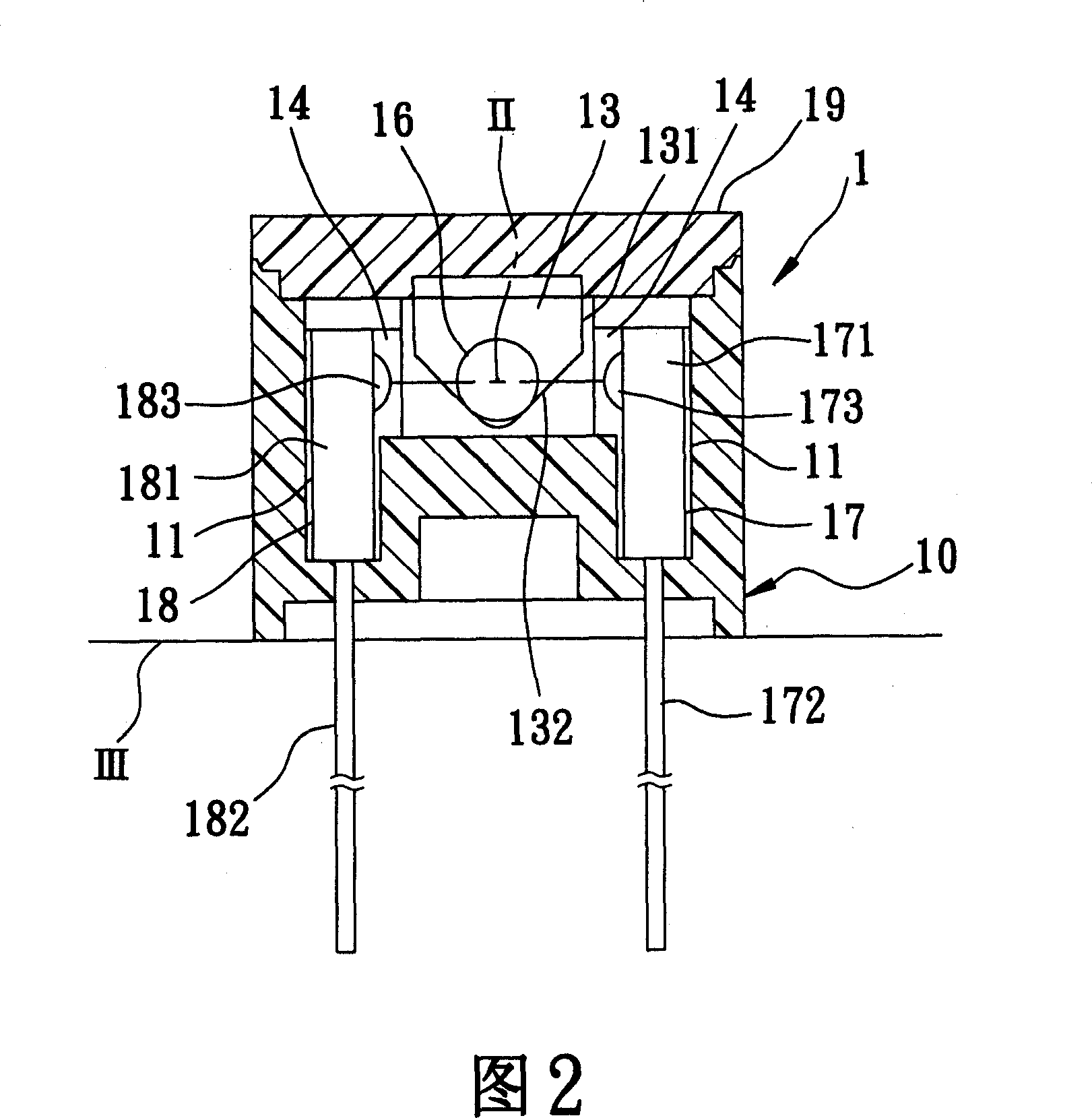

Xenon lamp

ActiveCN102287778BOptimize the connection methodEasy to installLighting support devicesElectric circuit arrangementsEngineeringMechanical engineering

The invention relates to a xenon lamp, and belongs to the technical field of light source parts. The xenon lamp provided by the invention comprises a lamp holder, an insulation receptacle, a tube face, a strip lamp, a negative pole wire, a positive pole wire, an electron-tube heater, and a molybdenum slice, wherein the centre of the lamp holder is provided with a receptacle installation boss, andthe middle of the receptacle installation boss is provided with a tube face cavity; a first conducting pin and a second conducting pin are fixed on the insulation receptacle, and the middle of the tube face is provided with a core tube hole; the strip lamp is composed of a first core tube, a second core tube and a discharge tube, the first core tube is positioned in the core tube hole, and the discharge tube is formed between the first core tube and the core tube; one end of the positive pole wire is located on the tube face and connected with the first conducting pin, and the other end of the positive pole wire is connected with one end of the molybdenum slice; the molybdenum slice is packaged in the second core tube, and the other end of the molybdenum slice is connected with one end ofthe electron-tube heater; and the electron-tube heater is positioned at the interior of the discharge cavity of the discharge tube, the other end of the electron-tube heater is connected with one endof the negative pole wire, and the other end of the negative pole wire is connected with the second conducting pin. The xenon lamp provided by the invention has the advantages that the installation is convenient, the ideal economical efficiency is reflected, and the refraction phenomenon is avoided.

Owner:常熟林芝电子技术有限公司

Vehicle lamp housing with transparent cover welded thereon, and method

InactiveUS7815354B2Avoid problemsAvoid refractionLamination ancillary operationsVehicle interior lightingEngineering

A method of manufacturing a vehicle lamp includes providing a housing having a front opening and a transparent cover having a curved front face and a rear face having a welding face portion. The welding face portion of the transparent cover is placed in a closely contacting state with respect to the housing and the transparent cover is joined with the housing so as to close the front opening of the housing by irradiating a welding light ray toward the welding face portion through the transparent cover. The placing includes applying a pressing force against the housing to the transparent cover in a predetermined direction such that an angle of the welding face portion of the transparent cover with respect to the predetermined direction is closer to a right angle than an angle of the front face of the transparent cover corresponding to the welding surface with respect to the predetermined direction.

Owner:KOITO MFG CO LTD

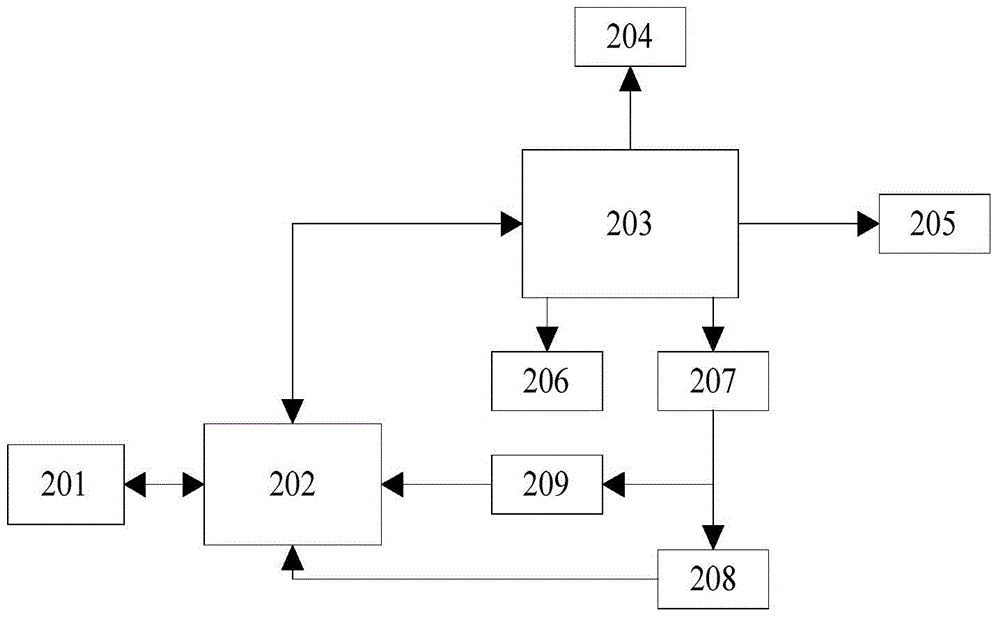

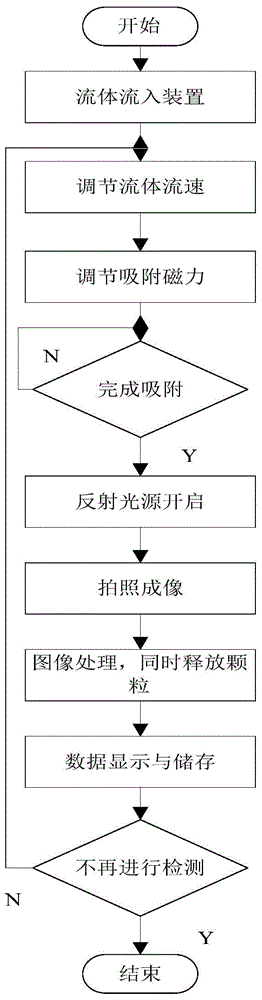

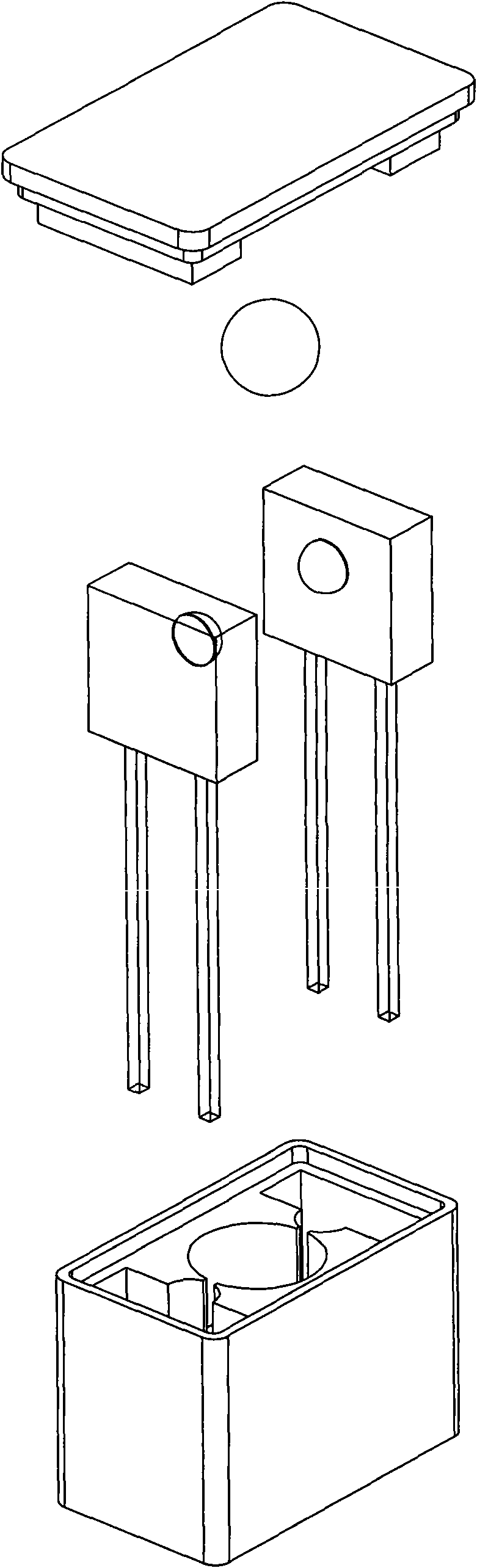

Device and method for detecting fluid magnetic particles

ActiveCN104949904AAvoid light reflectionAvoid refractionParticle size analysisIndividual particle analysisElectricityImaging processing

The invention relates to a device and a method for detecting fluid magnetic particles. The device comprises an imaging module, an adsorption module, a control module, a light transmission piece and an image processing module, wherein the imaging module, the adsorption module and the light transmission piece are arranged on the same side of a runner; the adsorption module is electrically connected with the control module; the light transmission piece is fixed on the upper surface of the runner and is positioned in the center of the light path of the imaging module; the light transmission piece is positioned in a magnetic field generated by electrifying the adsorption module; the particles are adsorbed to the lower side of the light transmission piece by virtue of the adsorption module; the image processing module is respectively and electrically connected with the imaging module and the control module; the particle image signal output by the imaging module is processed and then uploaded to the control module; and the image signal is subjected to image analyzing and processing by virtue of the control module, so as to acquire the physical property data of the particles. The influence of bubbles in fluid on the imaging of the magnetic particles is eliminated, the magnetic particles in the fluid are detected, and the number, shape, texture and size of the magnetic particles in the fluid can be obtained.

Owner:GUANGZHOU MECHANICAL ENG RES INST

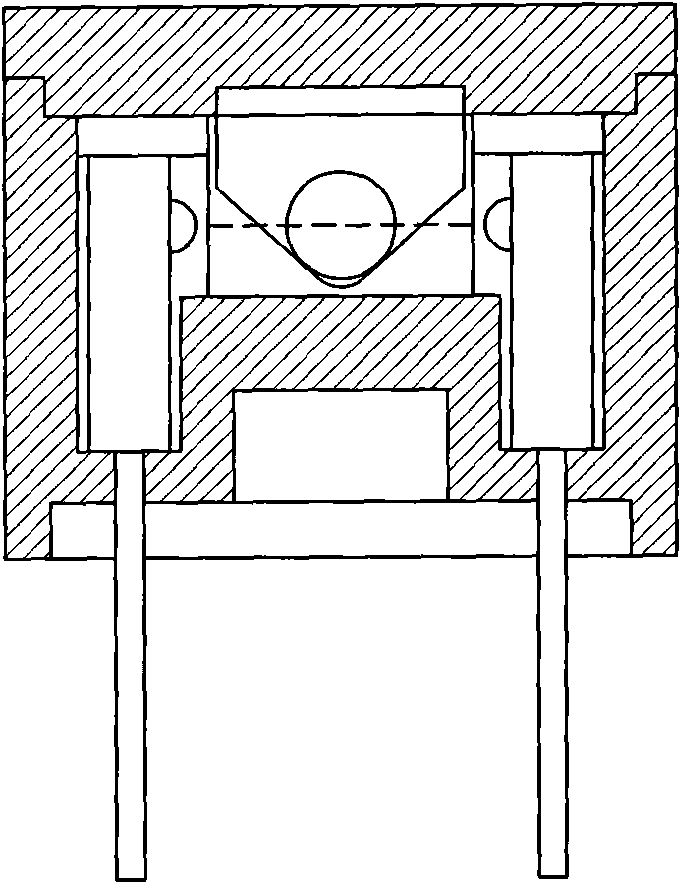

Ball inductive switch

InactiveCN101783668ATransitions scroll smoothlySimple structureElectronic switchingLight beamDirect communication

The invention relates to a ball inductive switch which comprises a shell, a ball, a transmitter and a receiver, wherein an accommodating chamber, a transmitting chamber and a receiving chamber are arranged in the shell; light beams sent from the transmitter are transmitted to the receiver after passing through the accommodating chamber to form a direct communication path; the inner wall of the accommodating chamber is provided with recessed berths. When a ball is sunk in any one berth, the ball is in a stable balance state. The inner wall of the accommodating chamber is provided with three berths which respectively are a first berth, a second berth and a third berth. The first berth and the second berth are respectively a pit. The pit bottom of the first berth is provided with a transmitting port, and the pit bottom of the second berth is provided with a receiving port. The communication path passes through the transmitting port and the receiving port. When the ball rolls into the first berth or the second berth, the ball blocks the communication path; when the third berth is positioned between the first berth and the second berth, and is a circular channel surrounding the communication path. When the ball rolls into the third berth, the ball deviates from the communication path. The invention has the advantages of simple structure, stable signal and good communication.

Owner:朱成辉

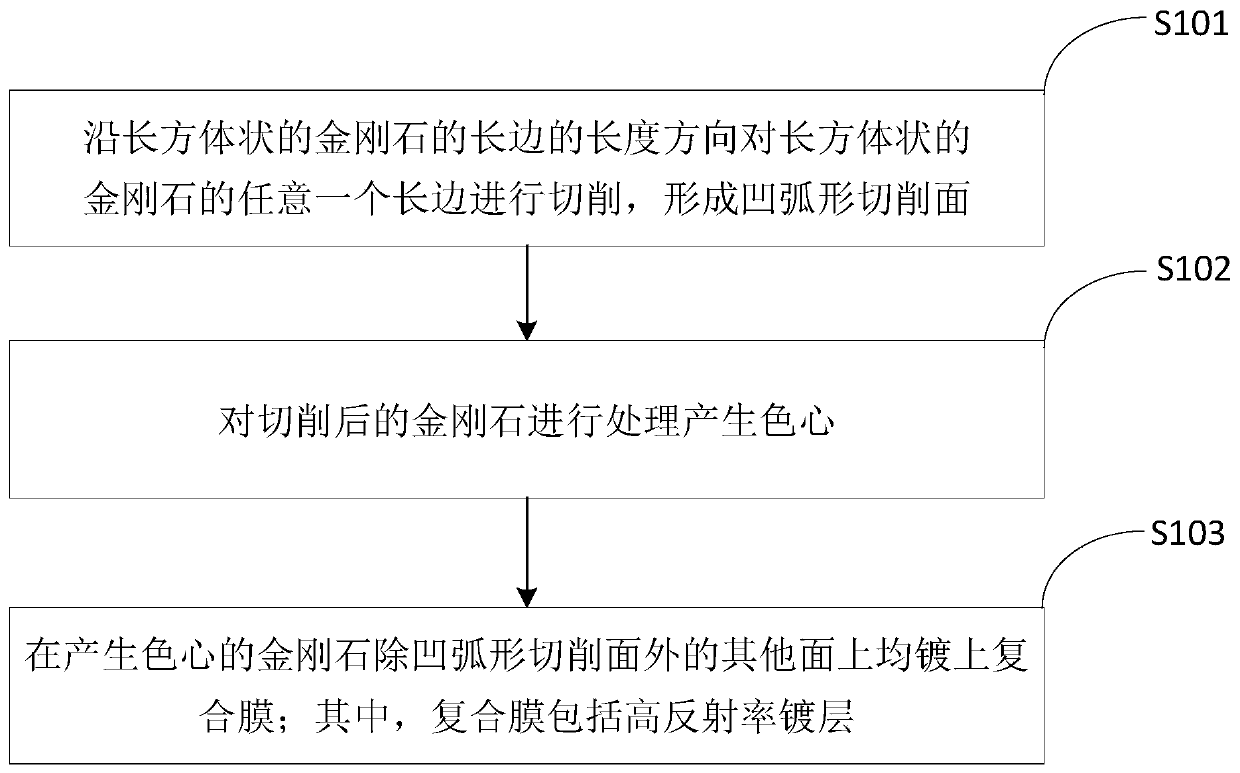

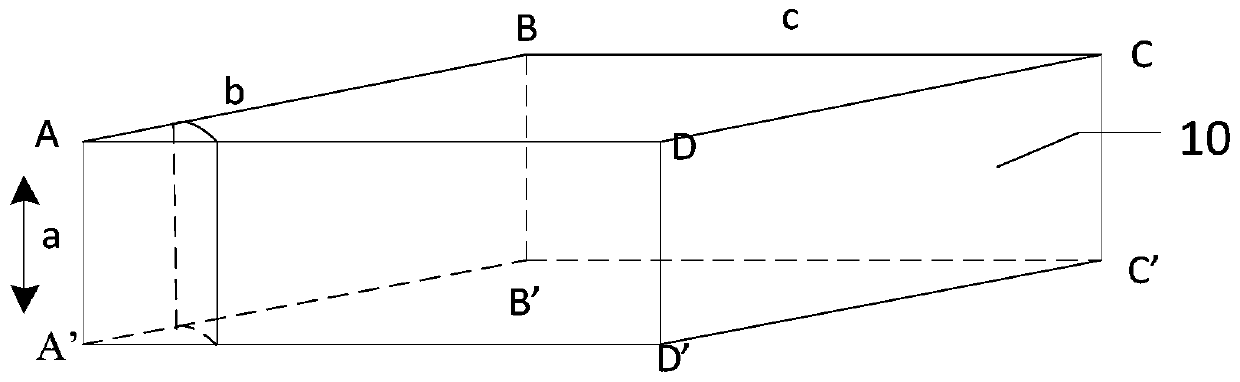

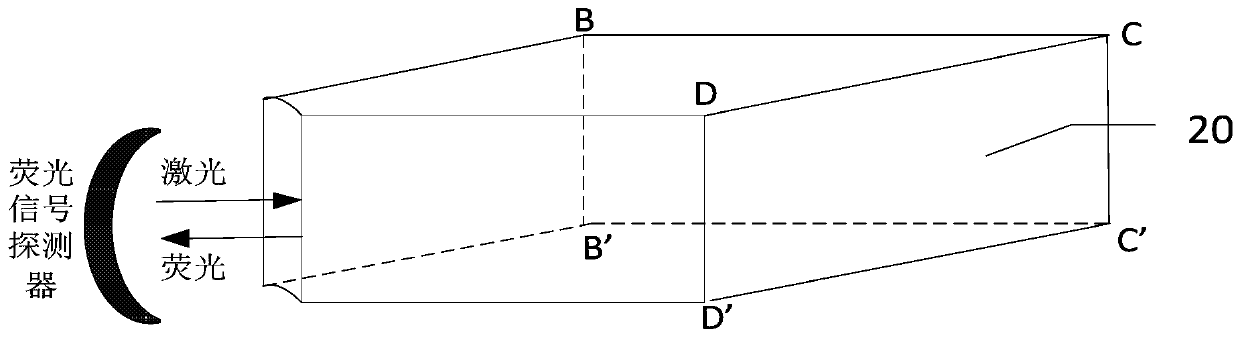

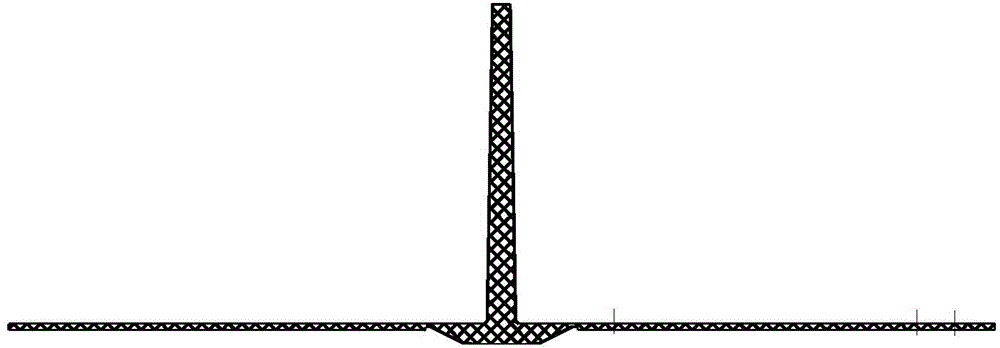

Color center diamond preparation method and color center diamond

ActiveCN110395727AIncrease the optical pathImprove collection efficiencyDiamondLaser beam welding apparatusColour centreFluorescent light

The invention is applicable to the technical field of color center diamond preparation and provides a color center diamond preparation method and a color center diamond. The method comprises the following steps: cutting any shortest side of a cuboid diamond along a length direction of the shortest side of the cuboid diamond so as to form a concave arc-shaped cut section; treating the cut diamond to form a color center; and plating surfaces except the concave arc-shaped cut section of the diamond with the color center by a composite membrane, wherein the composite membrane comprises a high-reflection plating layer. Laser enters from the concave arc-shaped cut section, so that the optical path length of the laser can be increased. Meanwhile, the composite membrane has a high reflection rate,the laser and fluorescent light can be prevented from being refracted outside the diamond, so that the fluorescent light collection rate and the laser emission efficiency can be improved.

Owner:THE 13TH RES INST OF CHINA ELECTRONICS TECH GRP CORP

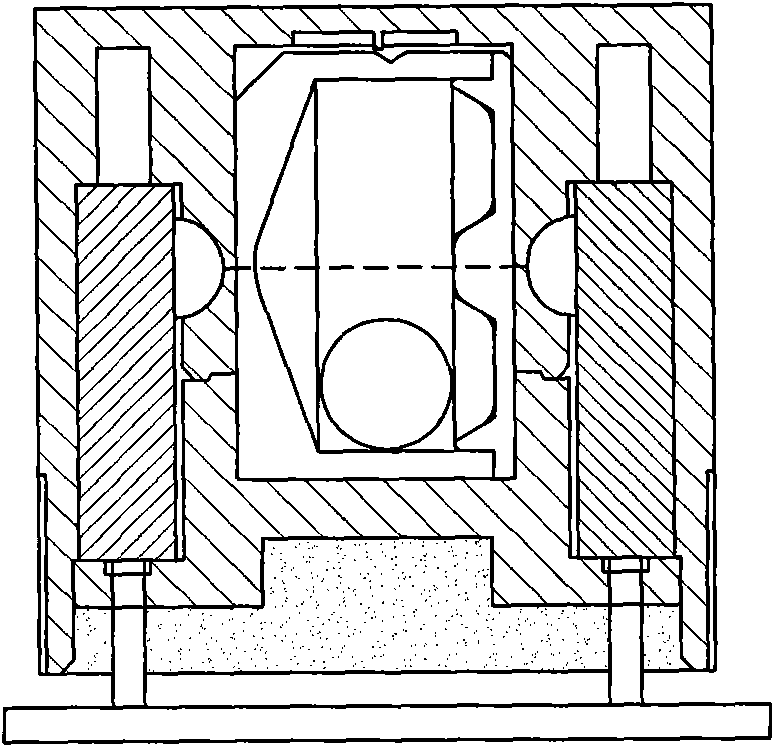

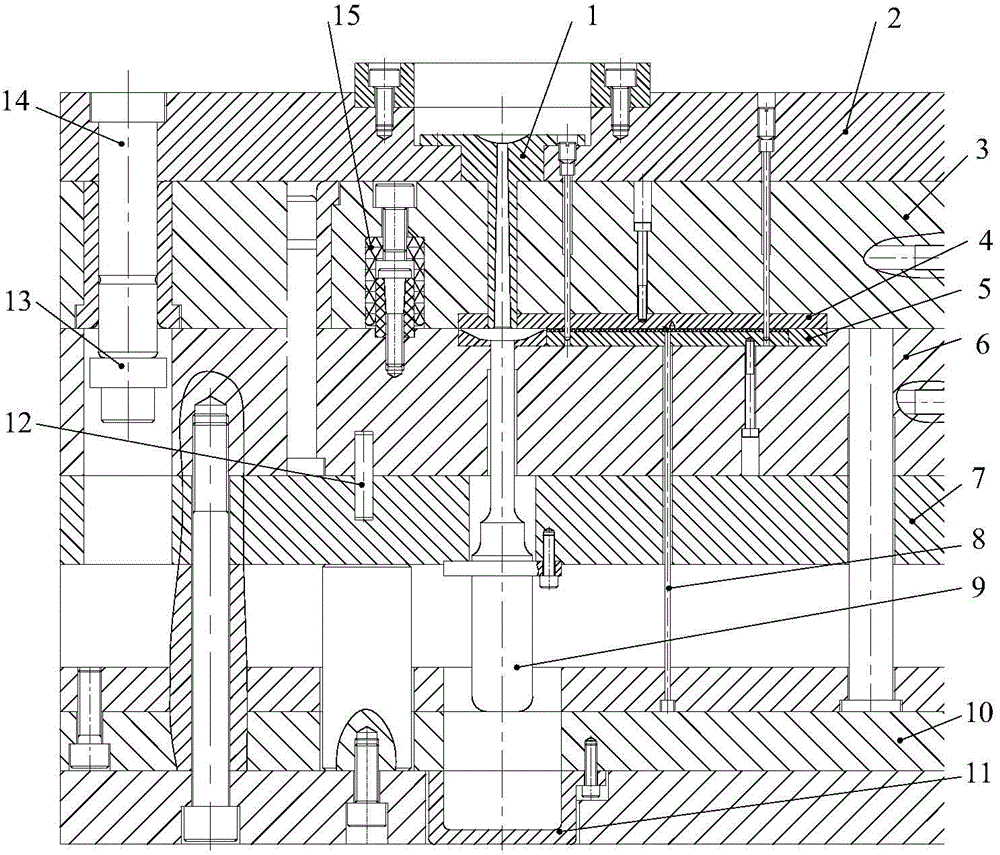

Injection mold with ultrasonic waves directly acting on polymer melt

The invention discloses an injection mold with ultrasonic waves directly acting on a polymer melt, and belongs to the field of injection molding. An ultrasonic vibrator is arranged at the tail end of a main runner and on the moving side of a mold, and is connected with a moving mold plate or a moving mold cushion plate through screws by virtue of a flange plate at a nodal surface, and an amplitude variation rod is in clearance fit with the moving mold plate. The flange plate of the ultrasonic vibrator and the amplitude variation rod are made of a piece of titanium alloy material, and the outer circles of the flange plate of the ultrasonic vibrator and the amplitude variation rod are concentric. The flange plate of the ultrasonic vibrator is positioned by virtue of a counter bored hole in the mold plate, so that the ultrasonic vibrator and the amplitude variation rod are accurately centered. The frequency of the applied ultrasonic waves is 15-30 kHz, the power is 100-500 W, the ultrasonic waves act in the stages of injection and pressure maintaining, and the general working time is 2s-20s. The ultrasonic amplitude variation rod directly faces the main runner, so that the ultrasonic waves act on the melt for enough time, the transfer efficiency of the ultrasonic waves is improved, energy loss is avoided, and a new platform is provided for researching the influence of ultrasonic waves on the molding quality of an injection molding product.

Owner:DALIAN UNIV OF TECH

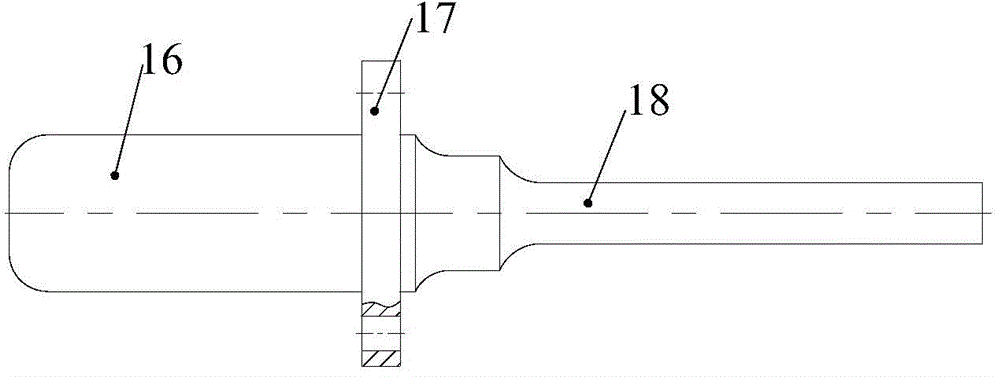

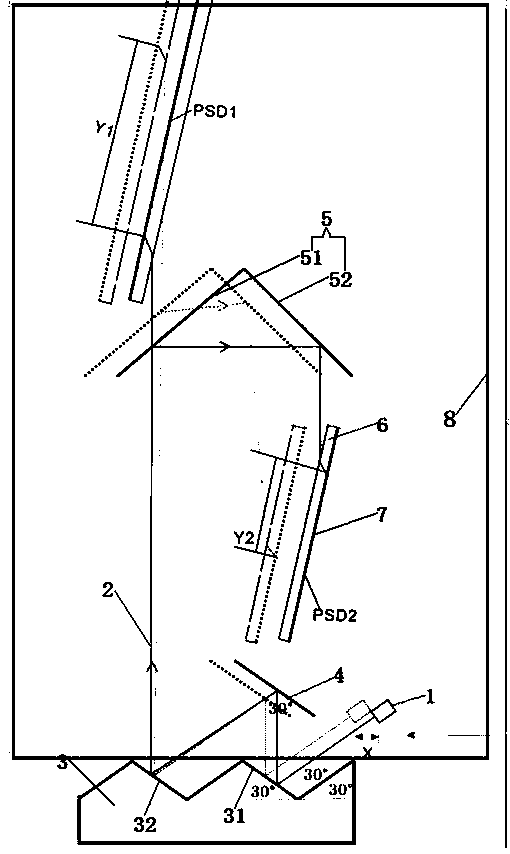

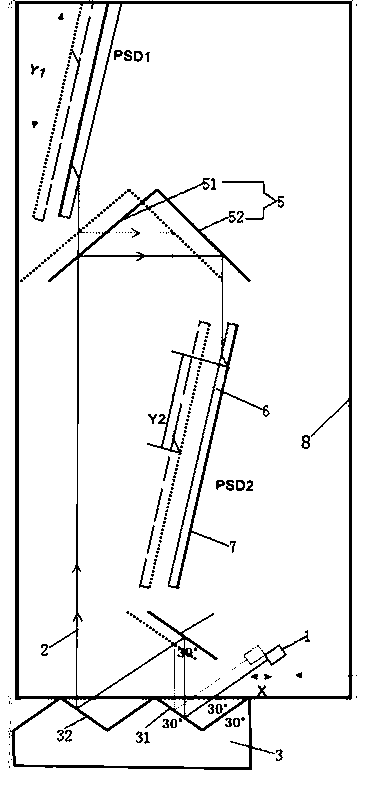

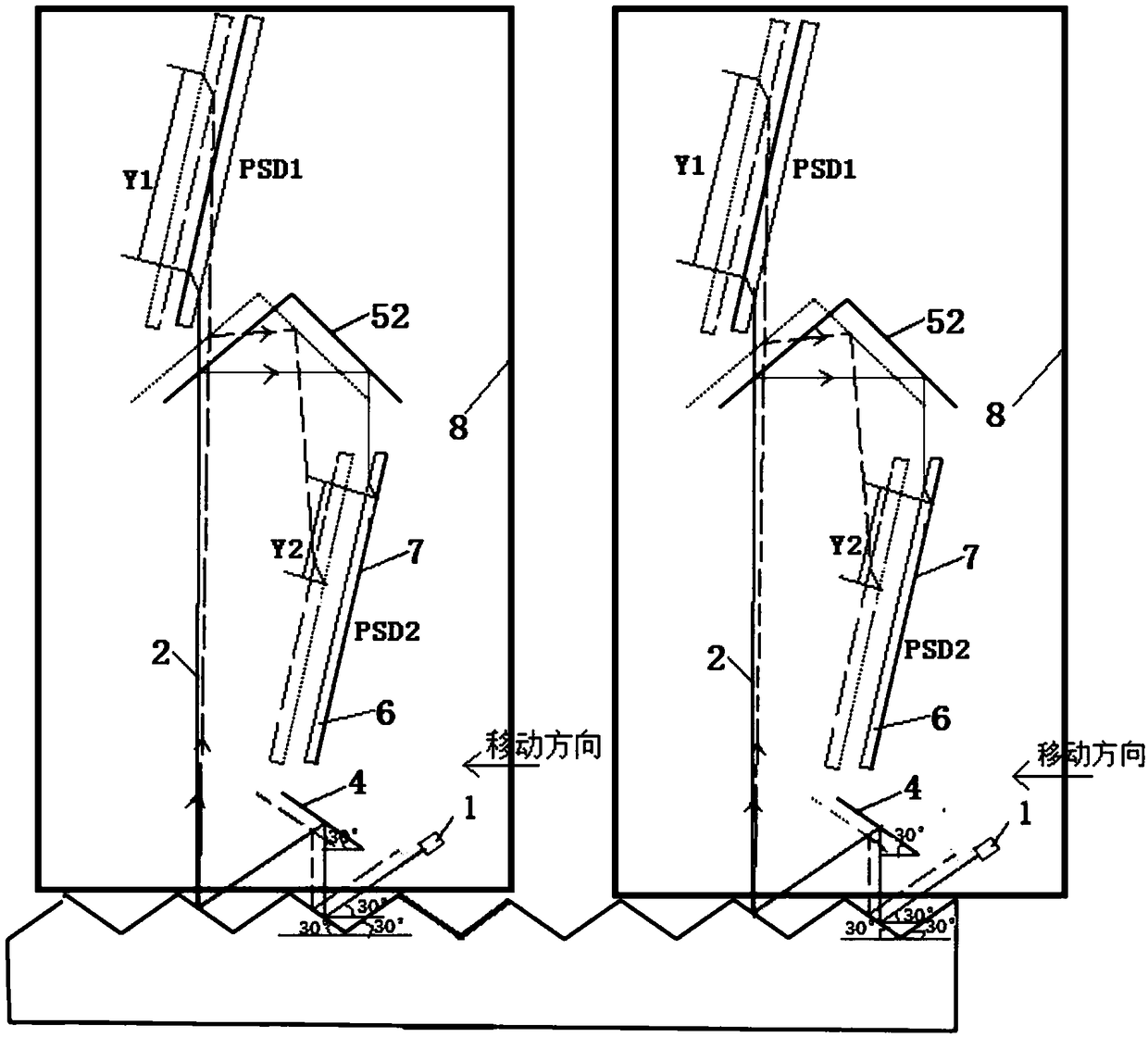

Novel displacement sensor with refractors and measuring method thereof

PendingCN109443219AHigh magnificationHigh measurement accuracyUsing optical meansPhotovoltaic detectorsOptoelectronics

The invention provides a novel displacement sensor with refractors and a measuring method thereof. The novel displacement sensor with the refractor comprises the components of a reflector which is used for receiving a laser beam that is reflected from a first reflecting surface of a triangular wave reflector, makes the laser beam be reflected to a second reflecting surface of the triangle wave reflector in a measuring process in which the laser beam is incident into the same first reflecting surface; and a spectroscope set which comprises a spectroscope and a light reflector, wherein the spectroscope and the light reflector are arranged in a certain included angle therebetween, and furthermore the laser beam which is reflected by the second reflecting surface of the triangle wave reflectoris incident to the spectroscope. Partial laser beam is reflected by the spectroscope and the light reflector and is incident to one refractor and is refracted and incident to a photoelectric detector, and the other partial laser beam is transmitted through the spectroscope and is incident into the other refractor for refraction and incidence into the photoelectric detector. According to the displacement sensor, through arranging the refractors, the measuring precision of the displacement sensor can be improved.

Owner:BEIFANG UNIV OF NATITIES

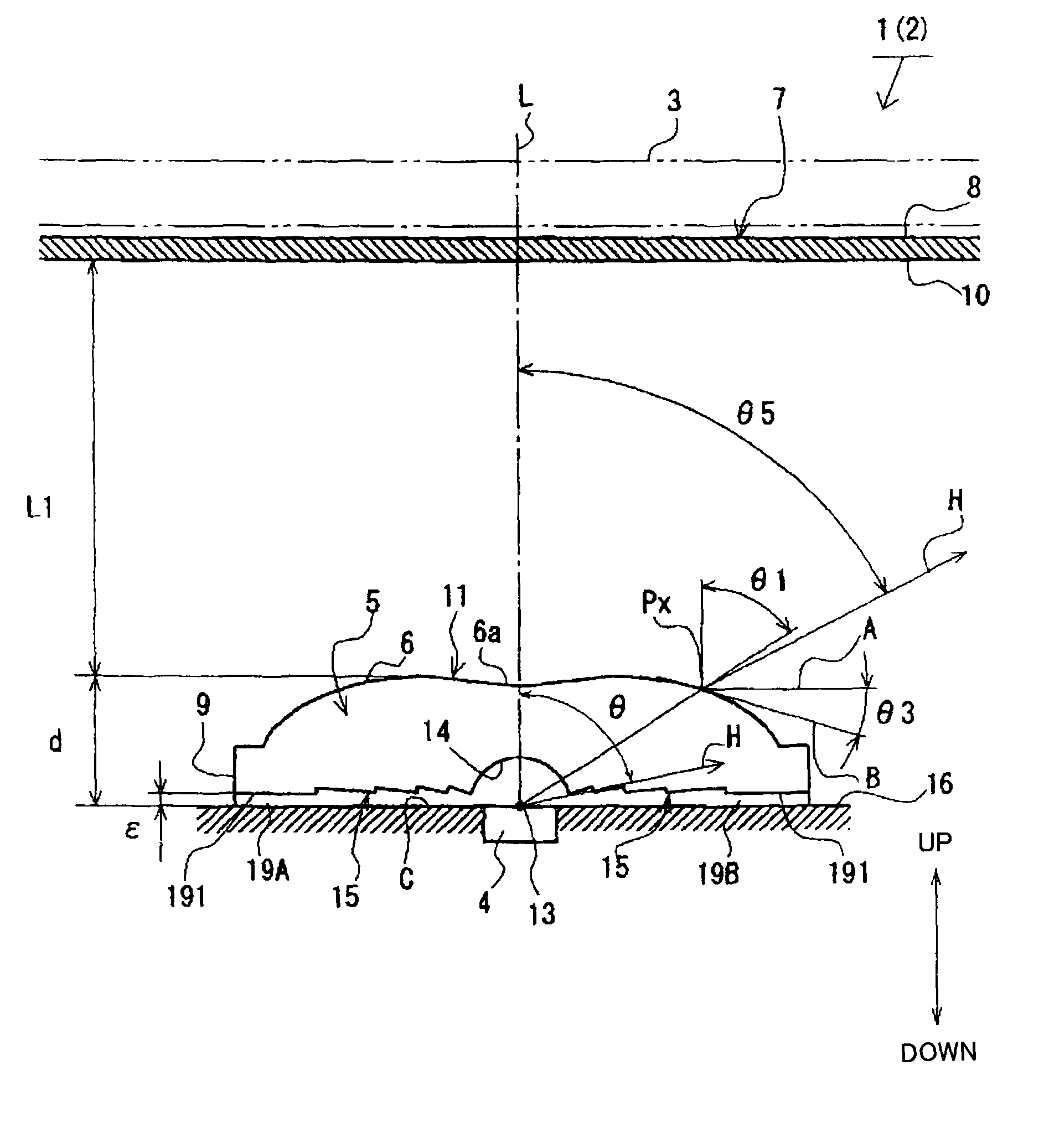

Light emitting apparatus and image displaying apparatus

ActiveUS8177378B2Suppress mutationAvoid refractionNon-electric lightingPoint-like light sourceOptical axisLight guide

A light emitting apparatus is provided which includes a plurality of light sources for emitting a light, and a light guide plate having a substantially plate shape orthogonal to the optical axis direction of the light source, which includes a light incident face into which a light exited from the light source is incident and a light exit face from which the light incident from the light incident face is exited. Irregularities each made of a first slope forming an angle θa with the plane of the light incident face and a second slope forming an angle θb with the plane of the light incident face are continuously formed on the light incident face.

Owner:SATURN LICENSING LLC

Light-adjustable desk lamp

InactiveCN102840500AAvoid refractionAvoid lossNon-electric lightingPoint-like light sourceEngineeringEnergy consumption

The invention discloses a light-adjustable desk lamp which comprises a lamp stand, a lamp bracket and a lamp cap, wherein the lamp bracket is connected with the lamp stand, the lamp cap is arranged at the other end of the lamp bracket, the lamp cap is provided with a lampshade, and the lower end of the lampshade is provided with a light shield. When the light-adjustable desk lamp is used, the light shield can be folded, compressed and opened through pulling, so that the scattering of light can be prevented and the focus point can be adjusted as required; and a reflector is arranged in the lampshade, so that a situation that light is refracted and scattered in the lampshade can be prevented, thereby further reducing the energy consumption and saving the energy.

Owner:NANTONG TIANHUA HERUI TECH VENTURES

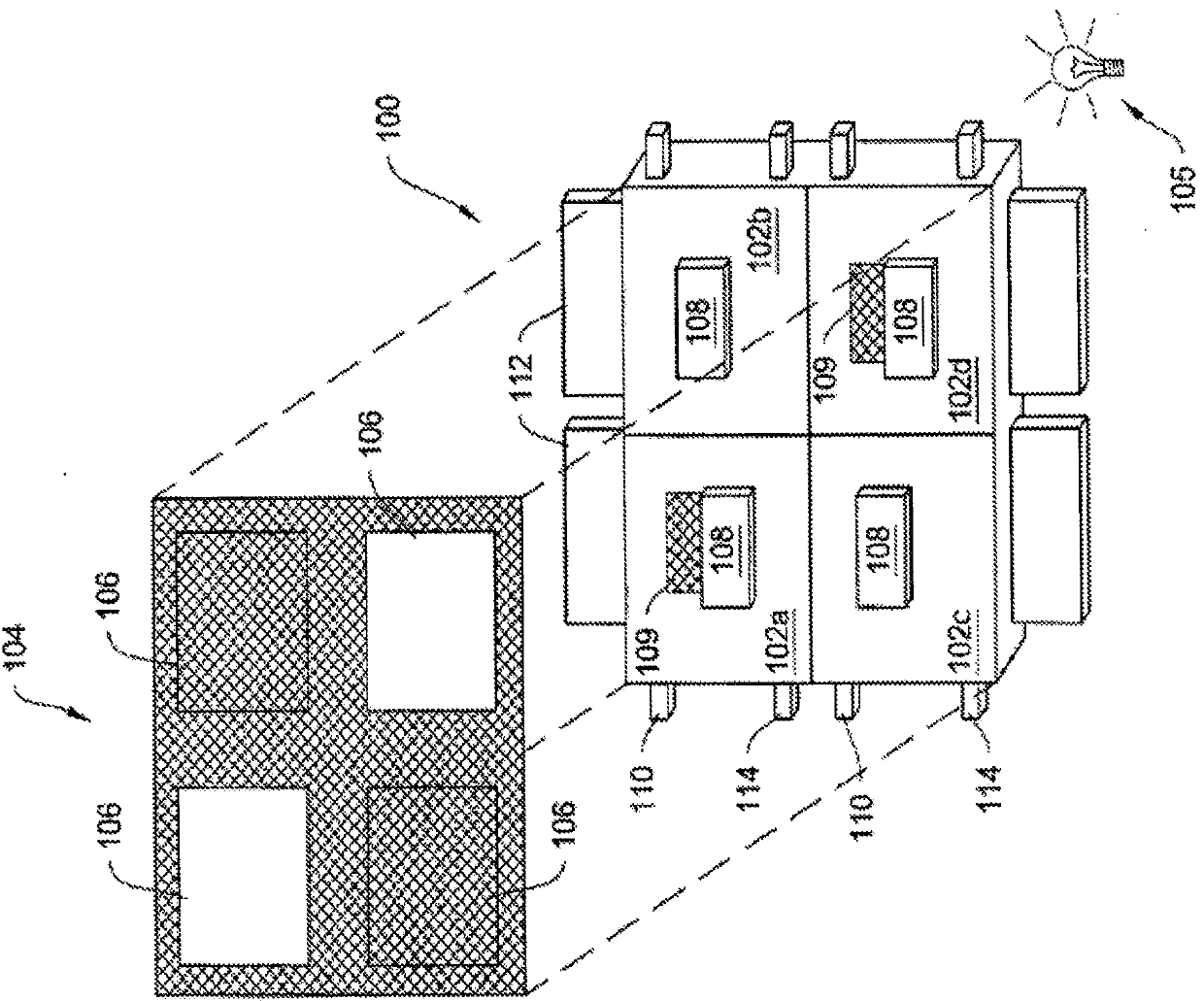

Displays having self-aligned apertures and methods of making the same

InactiveCN103797399AAvoid reflectionsAvoid refractionStatic indicating devicesPhotosensitive materials for photomechanical apparatusDisplay deviceAbsorption layer

Owner:PIXTRONIX INC

Ball switch

The invention relates to a ball bearing switch that comprises a base, a emitter, a receiver, a ball bearing, and a outer cover which covers said subassembly. The base includes a bottom block, a center block, a first bearing block, a second bearing block are extended from the bottom block, a containing groove which is set on the center block to contain the ball bearing, a emitting head which is set on the first bearing block and the second bearing block to bear the emitter, a first bearing surface, a second bearing surface of a receiving head, and the first channel, the second channel which link the two bearing surface. The outer cover includes a first pressing block, a second pressing block and a stopper which prevents light beam to be reflected which are pressed on the emitter and the receiver. So, the invention can prevent light beam to be reflected and scattered effectively, and without fault operation.

Owner:ONCQUE CORP

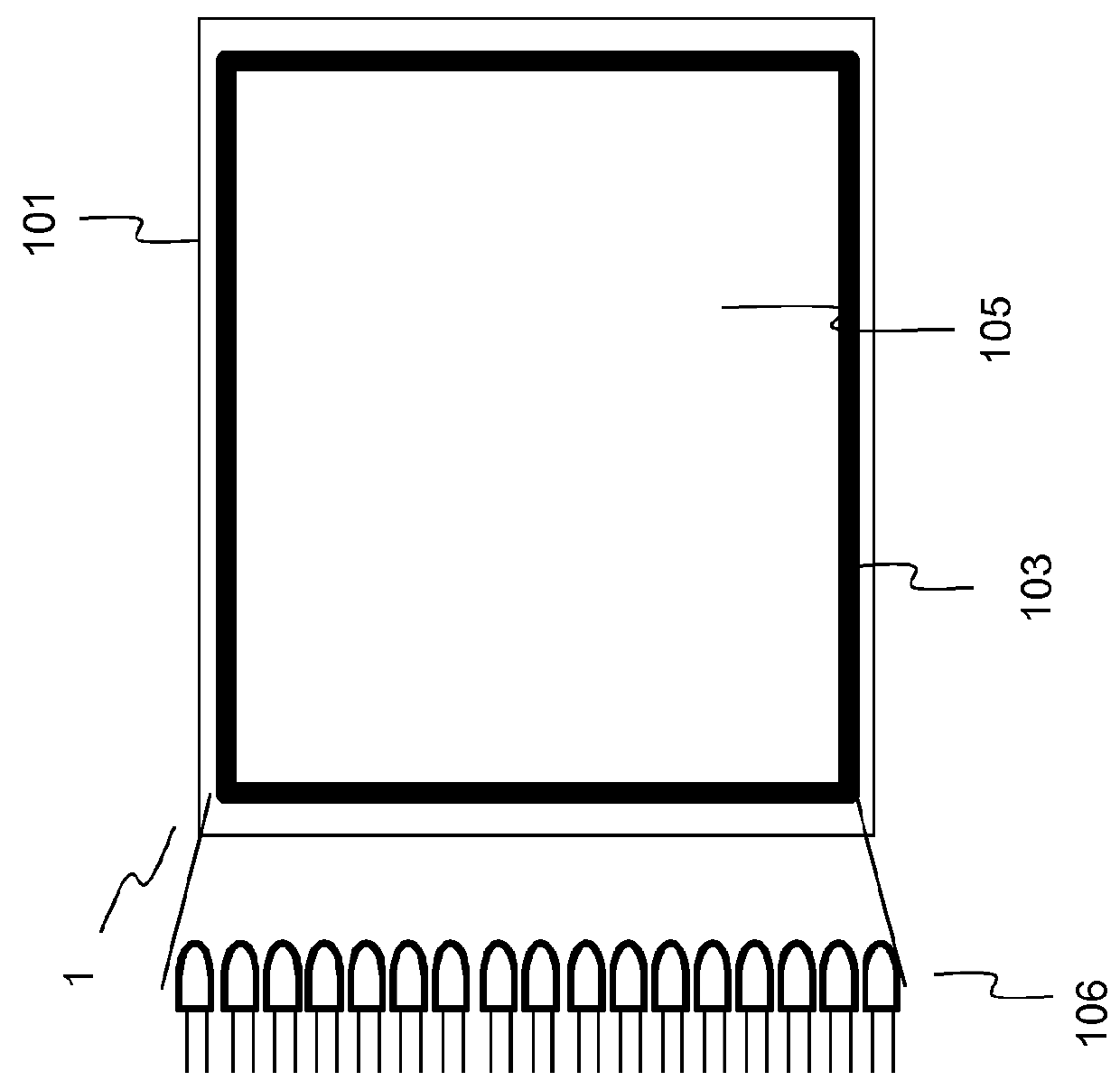

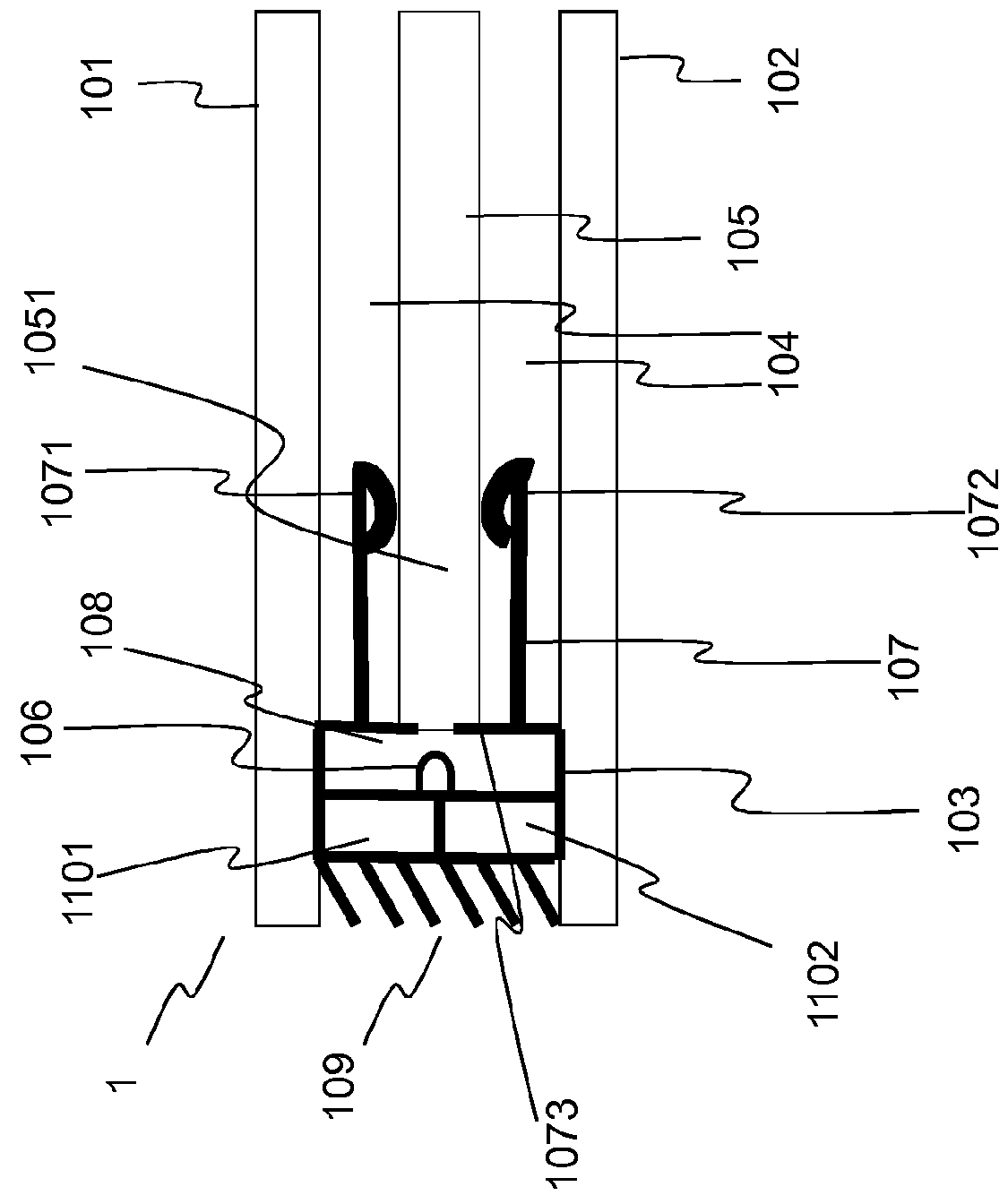

LED illuminated glass insulating panel

ActiveUS9250382B2Reduce decreaseOverall aesthetics of the illuminated panel are improved or are keptMechanical apparatusPoint-like light sourceEffect lightEngineering

A glass lighting panel (1), comprising: a first glass substrate (101), a second glass substrate (102), a spacer profile (103) at the periphery of the glass panel (1) between the first and the second glass substrate, the spacer being used to maintain an intermediate space (104) between the first and second glass substrates, According to the invention, the panel comprises: an intermediate organic glass substrate (105), at least one light source (106). According to the invention, the spacer profile (103) comprises: means (107) to maintain the intermediate organic glass substrate (105) in the intermediate space (104) between the first and the second glass substrates, means (108) to lodge the at least one light source (106) so as the at least one light source emits light into the intermediate organic glass substrate (105) predominantly along a plane of the panel. According to the invention, at least part of the intermediate organic glass substrate (105) is arranged to deflect the light out of the plane of the panel and through at least one of the first and second glass substrates to provide a diffused light output.

Owner:AGC GLASS EUROPE SA

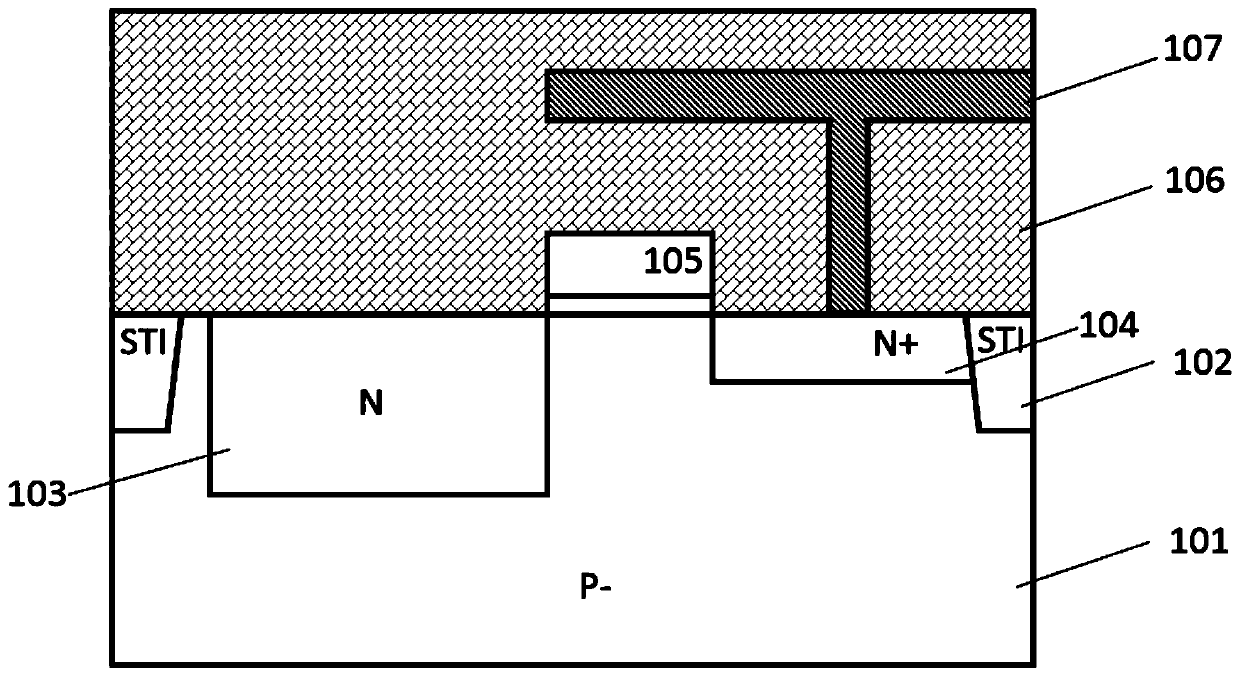

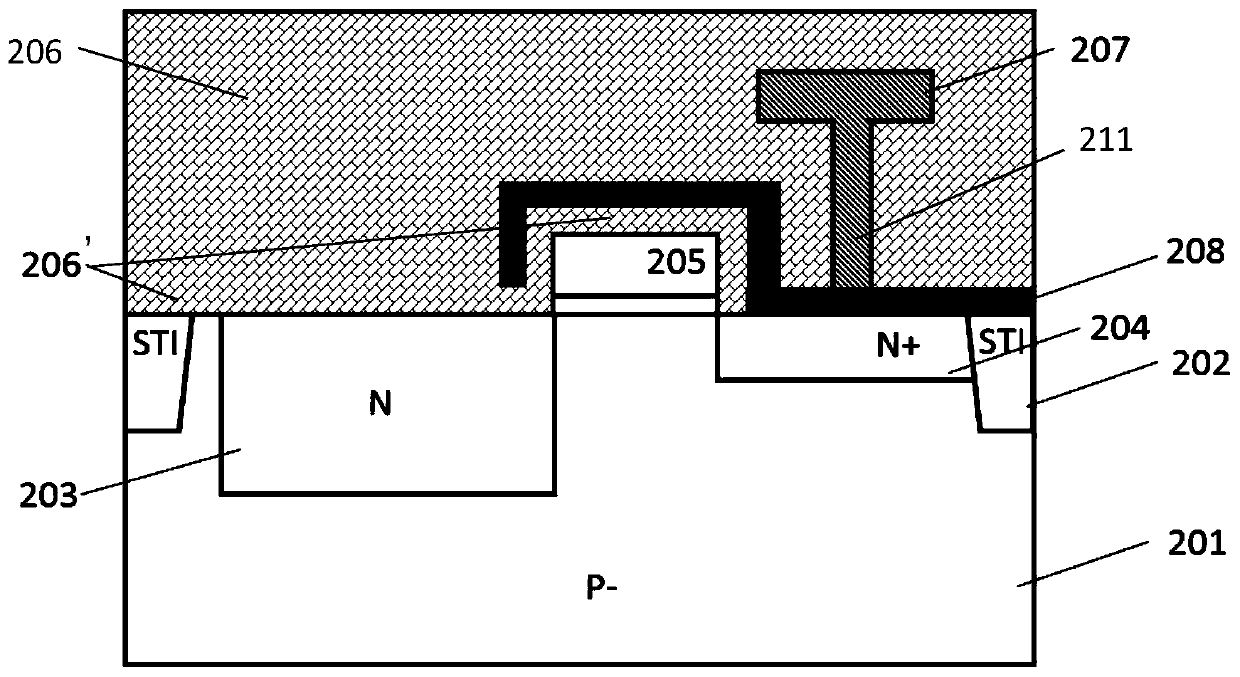

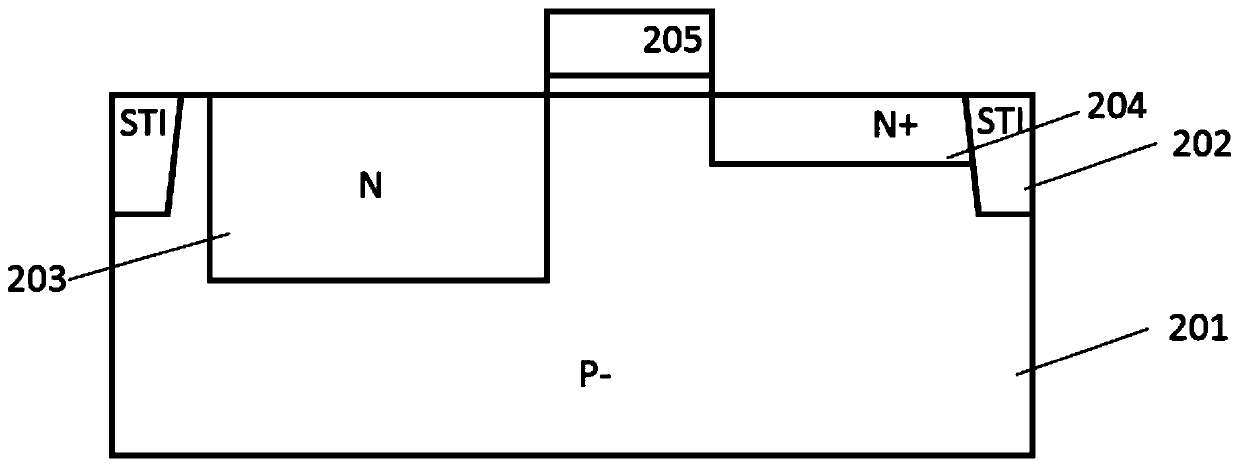

Global shutter image sensor unit and preparation method thereof

PendingCN111463225AGood technical effectGood light blocking effectSolid-state devicesDiodeBlock layerMetal interconnect

The invention discloses a global shutter image sensor unit. The global shutter image sensor unit comprises a substrate, and a shallow slot isolation region, a transmission transistor gate, a photodiode and a floating diffusion region which are arranged on the substrate, and a conductive light blocking layer arranged above the substrate, wherein the conductive light blocking layer is adjacently located above the floating diffusion region and completely covers the floating diffusion region, a lower surface of the conductive light blocking layer is connected with an upper surface of the floatingdiffusion region, and an upper surface of the conductive light blocking layer is connected with a metal interconnection layer arranged above the substrate. The global shutter image sensor unit is advantaged in that through a lightproof silicide conductive light blocking layer arranged above a storage node capacitor of the floating diffusion region, the floating diffusion region is effectively prevented from being influenced by illumination, and the parasitic light response of the global shutter image sensor unit is reduced.

Owner:上海微阱电子科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com