Xenon lamp

A xenon lamp and lamp holder technology, applied in the field of xenon lamps, can solve the problems of affecting the luminous effect and the unreasonable structure of the discharge tube, and achieve the effect of avoiding the phenomenon of refraction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

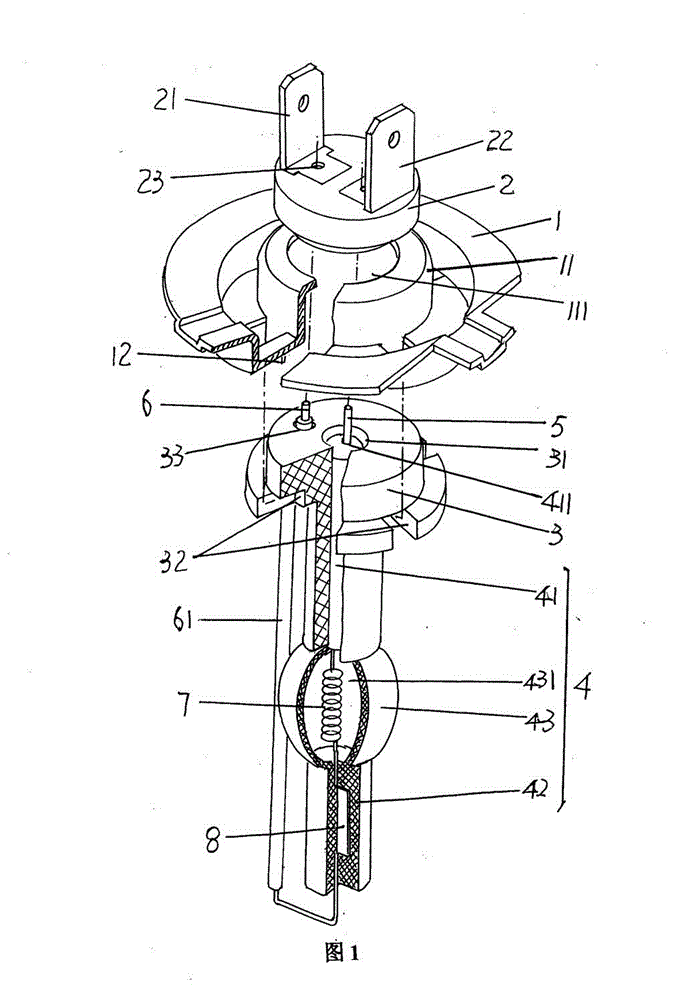

[0018] please see figure 1 , provides a generally disc-shaped lamp holder 1 preferably molded using a metal material, that is, stamped, for the current figure 1 The position state shown is taken as an example. In the center of the lamp holder 1 and on the upward side, there is a socket configuration boss 11 protruding from the plane (upper plane) of the lamp holder 1, and the boss 11 is arranged on the socket. The center of the tube is formed with a through lamp tube socket cavity 111 . And on the side of the lamp holder 1 facing the lamp holder 3 , that is, on the side facing downward of the lamp holder 1 and surrounding the opening of the lamp holder cavity 111 , a set of fixing buckle feet 12 extend at equal intervals. In this embodiment, the number of a group of fixed buckle feet 12 is 3, and each interval is 60° based on the circumferential direction of the lamp socket cavity 111, but the number of fixed buckle feet 12 is not affected by this embodiment. Quantity r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com