Injection mold with ultrasonic waves directly acting on polymer melt

An ultrasonic and polymer technology, applied in the field of injection molding, can solve the problems of product appearance quality, high ultrasonic transmission efficiency, and reduced energy transmission efficiency, and achieve the effects of improving transmission efficiency, low processing cost, and improving fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

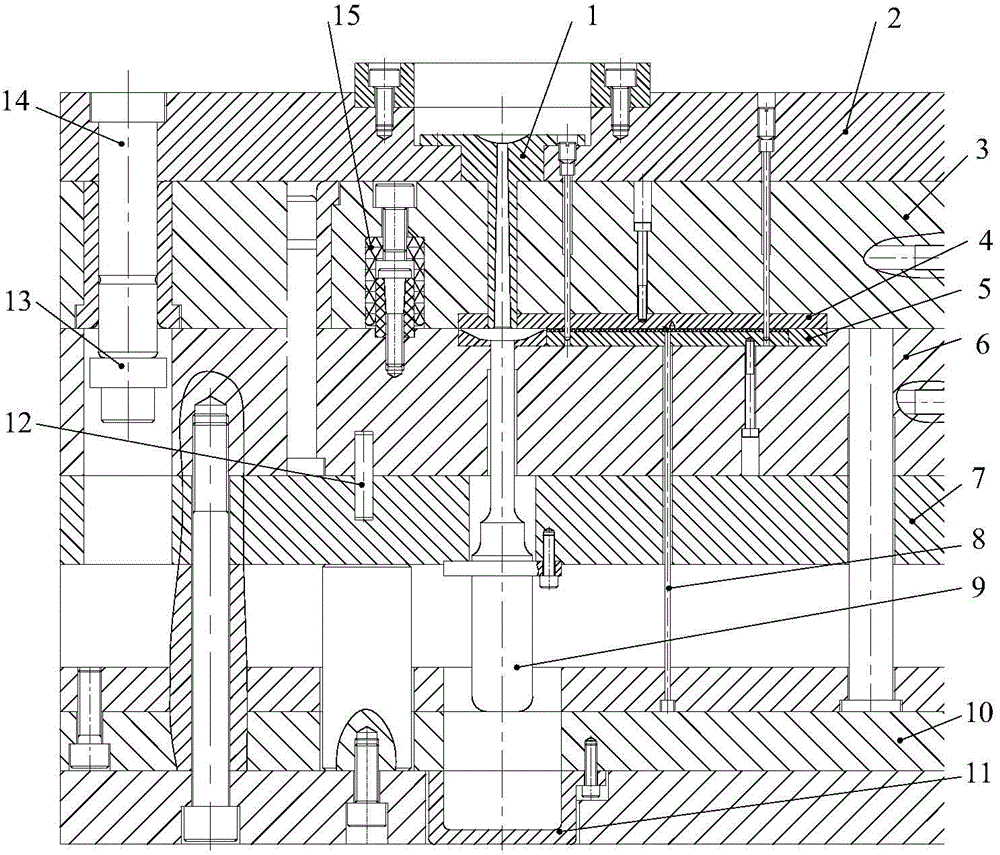

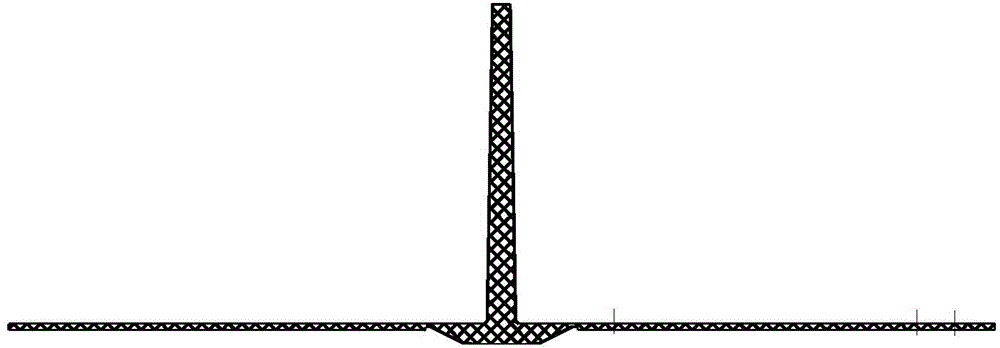

[0017] The ultrasonic-assisted injection mold of the invention is used to study the influence of ultrasonic action on the molding quality of injection-molded products. The injection molding mold of the present invention is used to form a microfluidic chip with a liquid reservoir as shown in FIG. 3 .

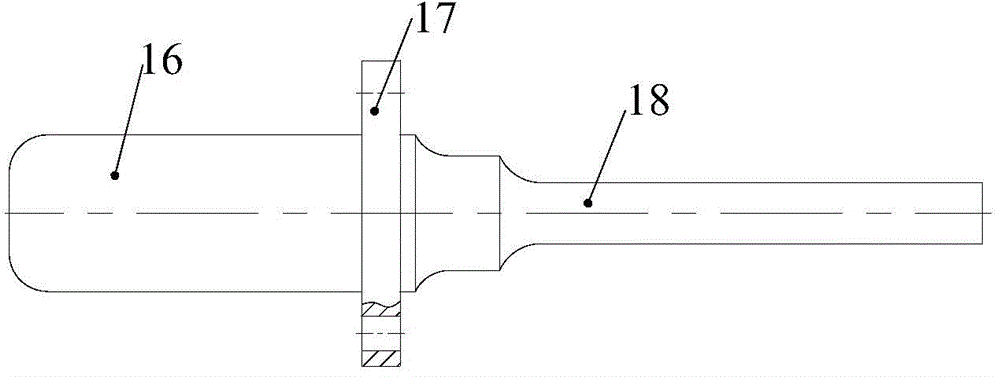

[0018] Such as figure 1 As shown, the ultrasonic vibrator 9 used in the ultrasonic assisted forming of the present invention is fixed on the movable mold backing plate 7 by screws through the flange plate 17 at the nodal surface, the end of the ultrasonic horn is matched with the corresponding hole of the movable mold, and the movable template 6 and The movable mold backing plate 7 is positioned by the positioning pin 12, and the movable mold backing plate 7 is processed with a counterbore that matches the vibrator flange 17. This metho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com