Touch control base plate and preparation method thereof, and display device

A substrate and touch technology, applied in the direction of instruments, digital data processing, data processing input/output process, etc., can solve the problems of affecting the display effect, inconvenient use of users, large difference in refractive index, etc., and achieve the disappearing effect Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

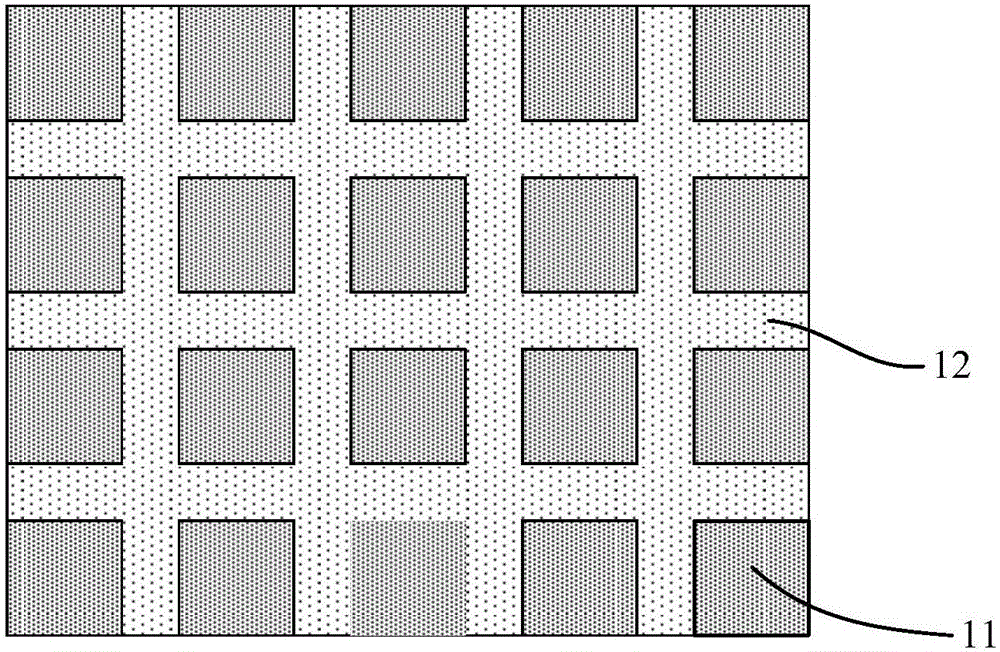

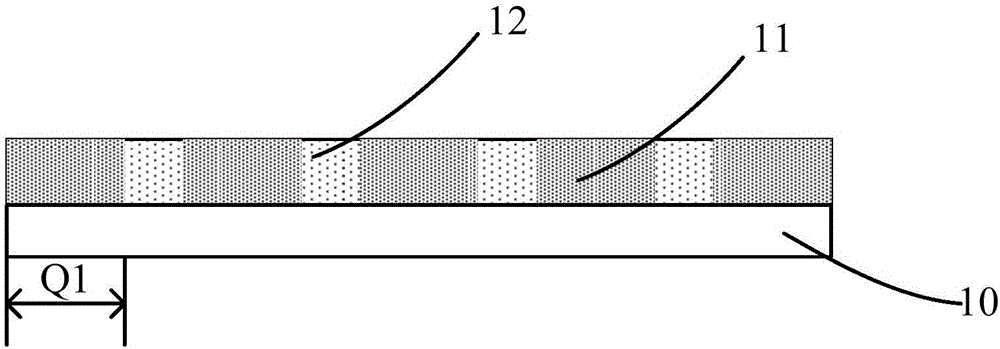

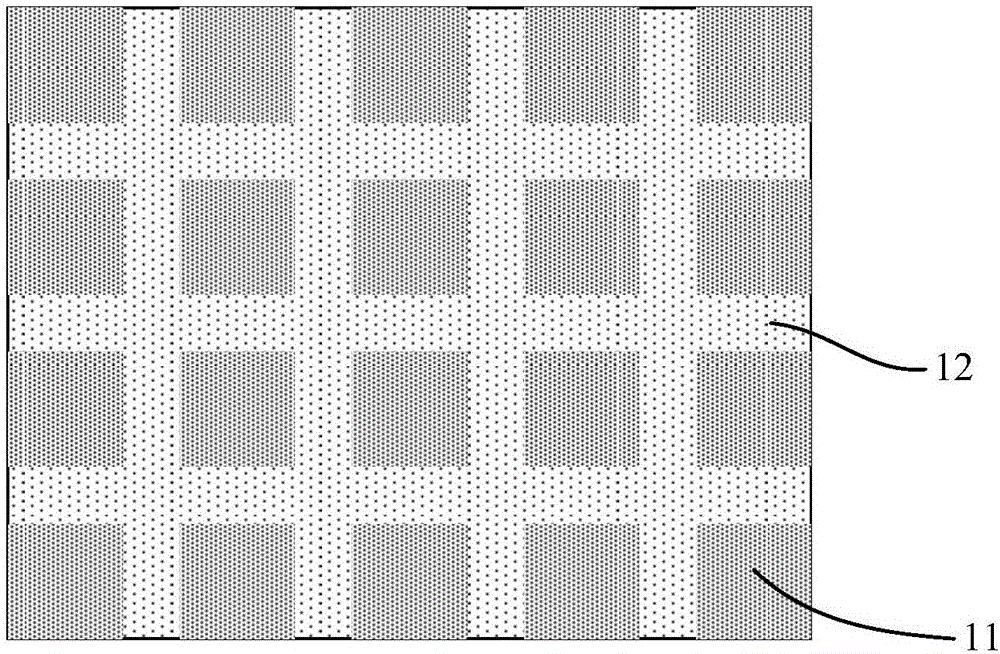

[0032] combine figure 1 As shown, this embodiment provides a touch control substrate, including a base 10 and a plurality of touch electrode blocks 11 disposed on the base 10, that is, the touch control substrate is a self-capacitive touch control substrate. In particular, a filling block 12 is provided between each touch electrode block 11 of the touch control substrate of this embodiment, and the material of the filling block 12 has a refractive index n 3 , the refractive index n of the material of the substrate 10 1 , the refractive index of the material of the touch electrode block 11 is n 2 , and|n 2 -n 3 |2 -n 1 |.

[0033] In the existing touch substrates, the substrate 10 is usually made of glass, and its refractive index is quite different from that of the touch electrode block 11, which makes the etched lines more obvious and affects the user's viewing effect. However, in this embodiment, a filling block 12 is provided between each touch electrode block 11, and...

Embodiment 2

[0040] This embodiment provides a method for preparing a touch substrate, which can be used to prepare the touch substrate in Embodiment 1. The preparation method includes: a step of forming a touch electrode block 11 on a substrate 10; a step of forming a filling block 12 between any two adjacent forests of the touch electrode blocks 11; wherein, the filling block 12 The refractive index of the material is n 3 , the refractive index of the material of the substrate 10 n 1 , the refractive index of the material of the touch electrode block 11 is n 2 , and|n 2 -n 3 |2 -n 1 |.

[0041] In the existing touch substrates, the substrate 10 is usually made of glass, and its refractive index is quite different from that of the touch electrode block 11, which makes the etched lines more obvious and affects the user's viewing effect. However, in this embodiment, a filling block 12 is provided between each touch electrode block 11, and the material of the filling block 12 has a ref...

Embodiment 3

[0054] This embodiment provides a display device, which includes the touch substrate in Embodiment 1.

[0055] Since the display device in this embodiment includes the touch substrate in Embodiment 1, that is, a filling block 12 is provided between each touch electrode block 11, and the material of the filling block 12 has a refractive index n 3 , the refractive index n of the material of the substrate 10 1 , the refractive index of the material of the touch electrode block 11 is n 2 , and the relationship between these three materials satisfies |n 2 -n 3 |2 -n 1 |, that is, the difference between the refractive index of the material of the filling block 12 and the material of the touch electrode block 11 is smaller than the difference between the refractive index of the material of the base 10 and the material of the touch electrode block 11, and the refractive index of the material determines its reflection Therefore, the reflectivity of the material of the filling block...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com