Patents

Literature

37results about How to "Good shadow removal effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

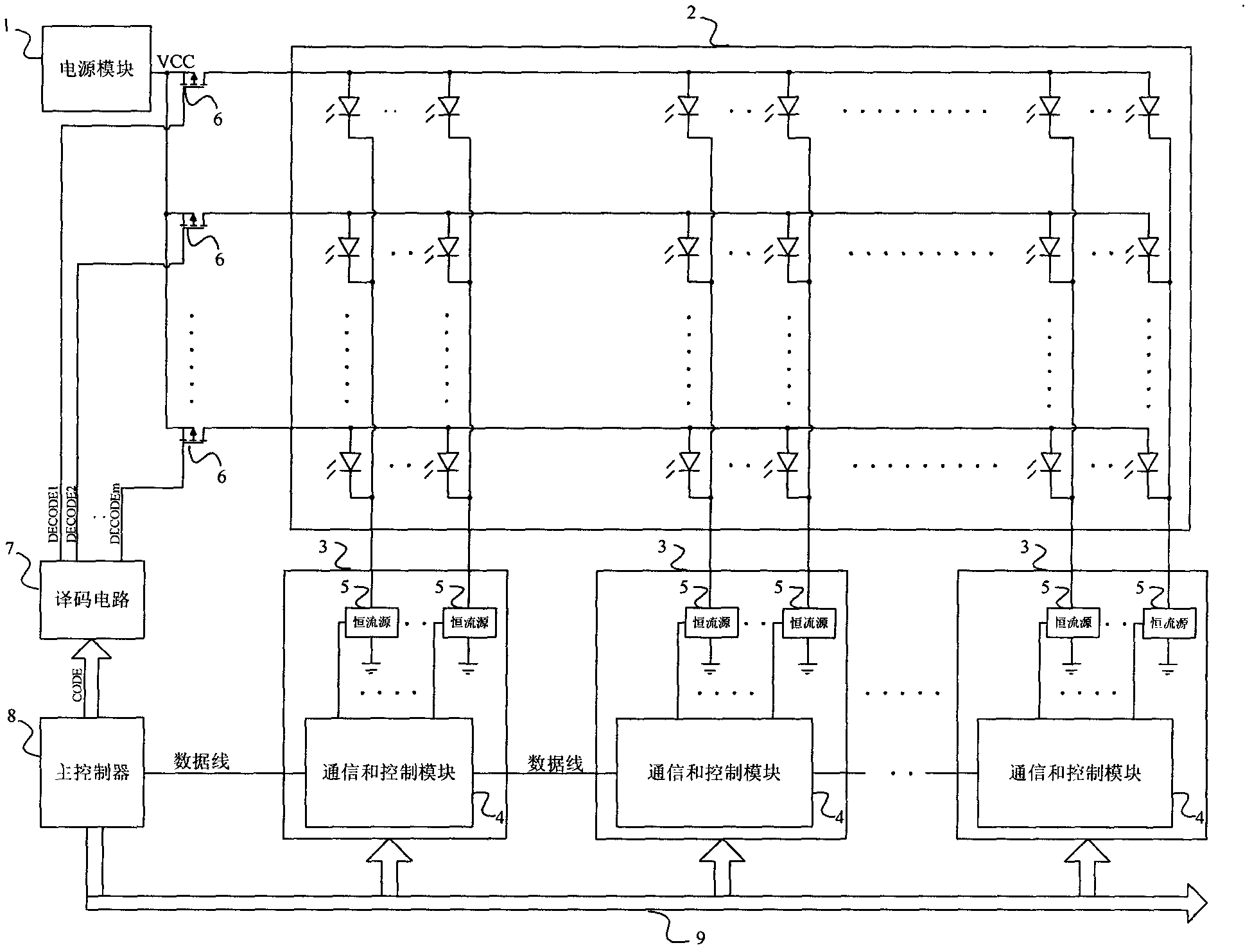

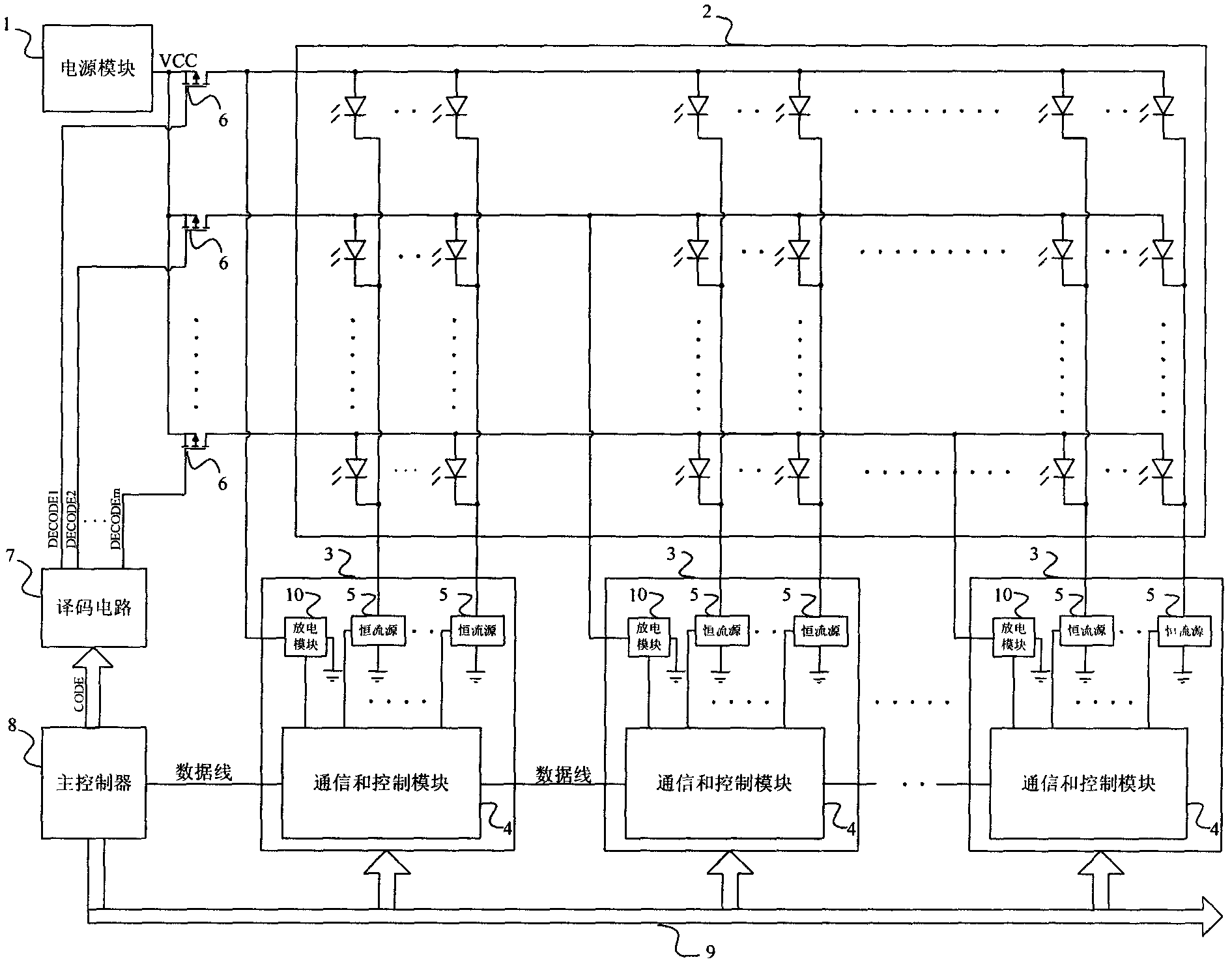

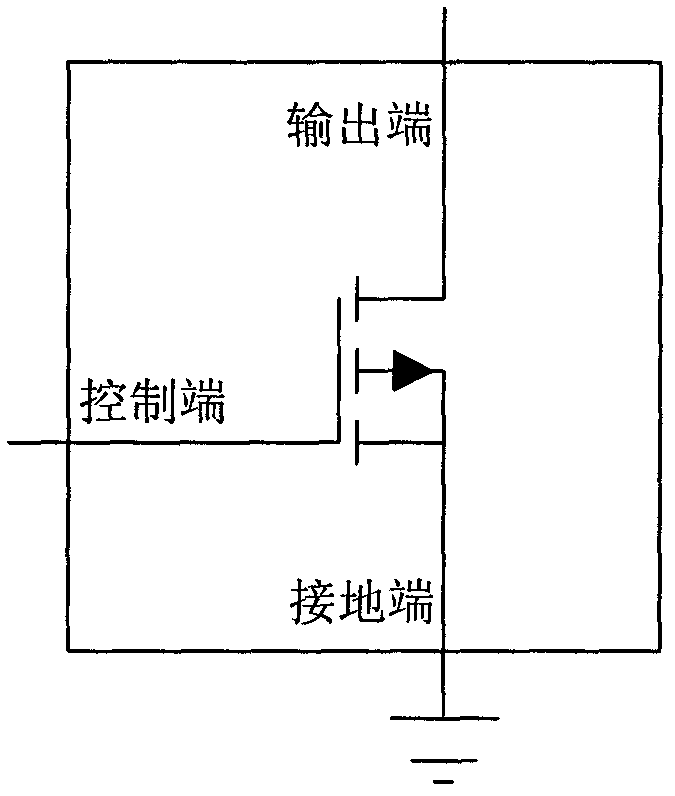

LED (light-emitted diode) display system capable of eliminating dynamic LED display ghost

The invention relates to an LED (light-emitted diode) display system capable of eliminating dynamic LED display ghost includes a power supply module, an LED array, M switch tubes, a decoding circuit, multiple constant-current driving circuits and a main controller, wherein each constant-current driving circuit is provided with a discharge module, the main controller sends discharge control signals to communication and control modules of all constant-current driving circuits through a control bus when LED lines are being switched in the LED array during the dynamic displaying time, and the discharge module of each constant-current driving circuit discharges a spurious charge at the second end of each cut-off PMOS switch tube from an output port of the discharge module to the system. Superior ghost removing effect can be realized only through a minor hardware modification in the traditional LED display system and the system of the invention has strong practicability.

Owner:杭州士兰控股有限公司

Blanking manufacturing method of capacitance touch screen

InactiveCN103699286AImprove visual enjoymentChanging the vanishing structureInput/output processes for data processingCapacitanceIndium tin oxide

The invention belongs to the technical field of capacitance touch screens, particularly relates to a blanking manufacturing method of a capacitance touch screen. The method includes adopting vacuum magnetic-control continuous plating to deposit a silica film on a glass substrate to serve as a bottom layer; depositing an indium tin oxide film on the silica film through magnetic-control sputtering to serve as an electroconductive film layer; plating a silicon nitride film on the indium tin oxide film to serve as a blanking layer. Indium tin oxide is arranged on the glass substrate, sheet resistance value of indium tin oxide can be easily controlled to be within a preset range, and parameters of the silicon nitriode film are adjusted according to sheet resistance of indium tin oxide and film forming effect, so that lines on indium tin oxide are enabled to be nonobvious, excellent blanking effect is realized, visual enjoyment of a user is improved, the problem that the capacitance touch screen cannot balance the sheet resistance value of indium tin oxide and the blanking effect, and the capacitance touch screen meets market requirements and is high in market competitiveness.

Owner:SHENZHEN LEAGUER OPTRONICS

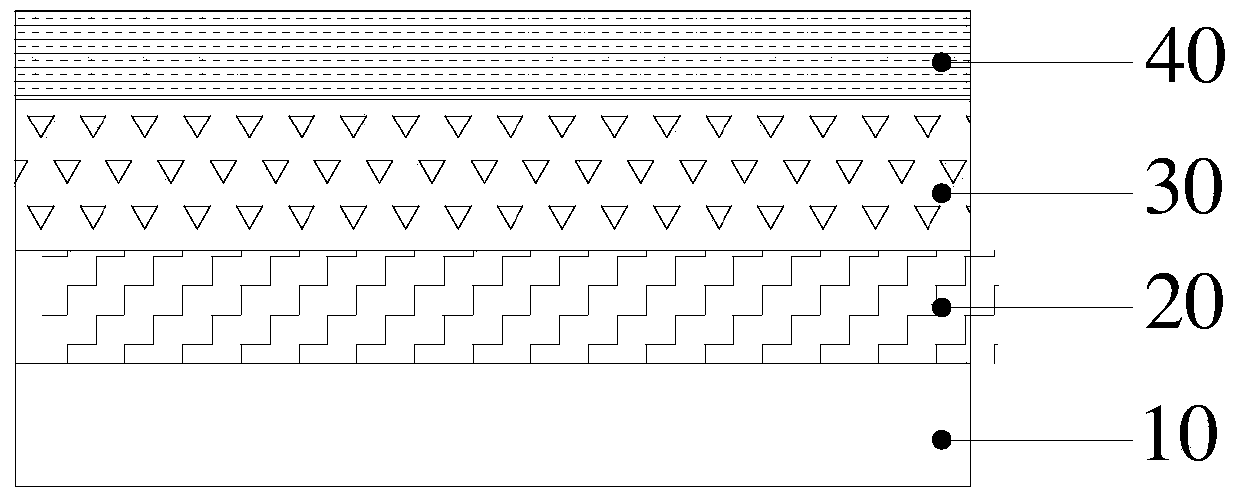

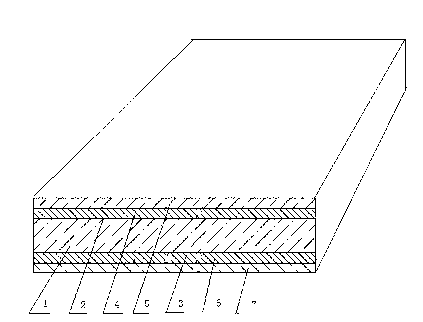

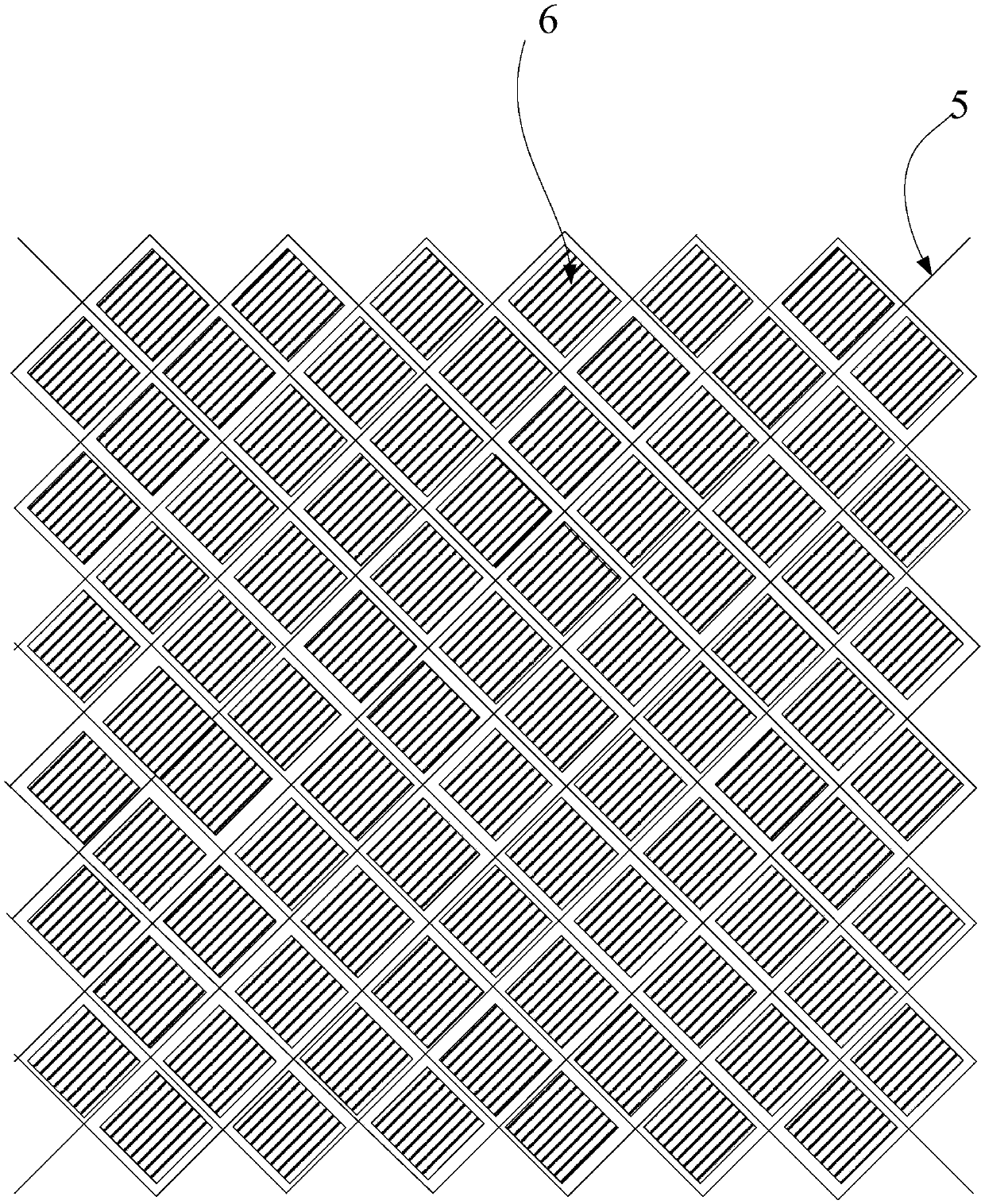

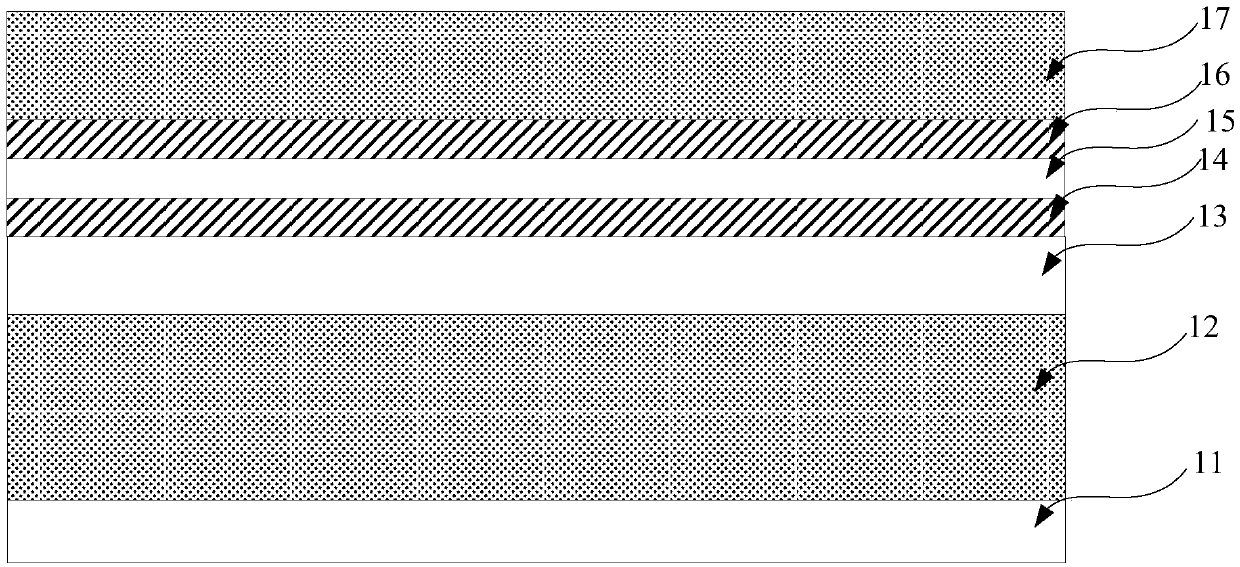

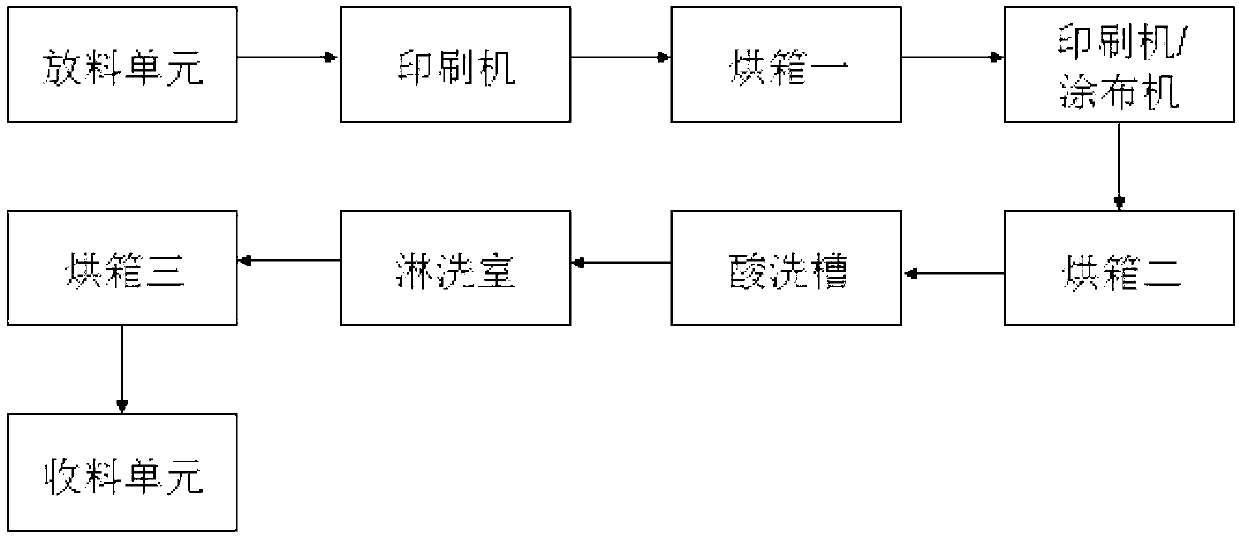

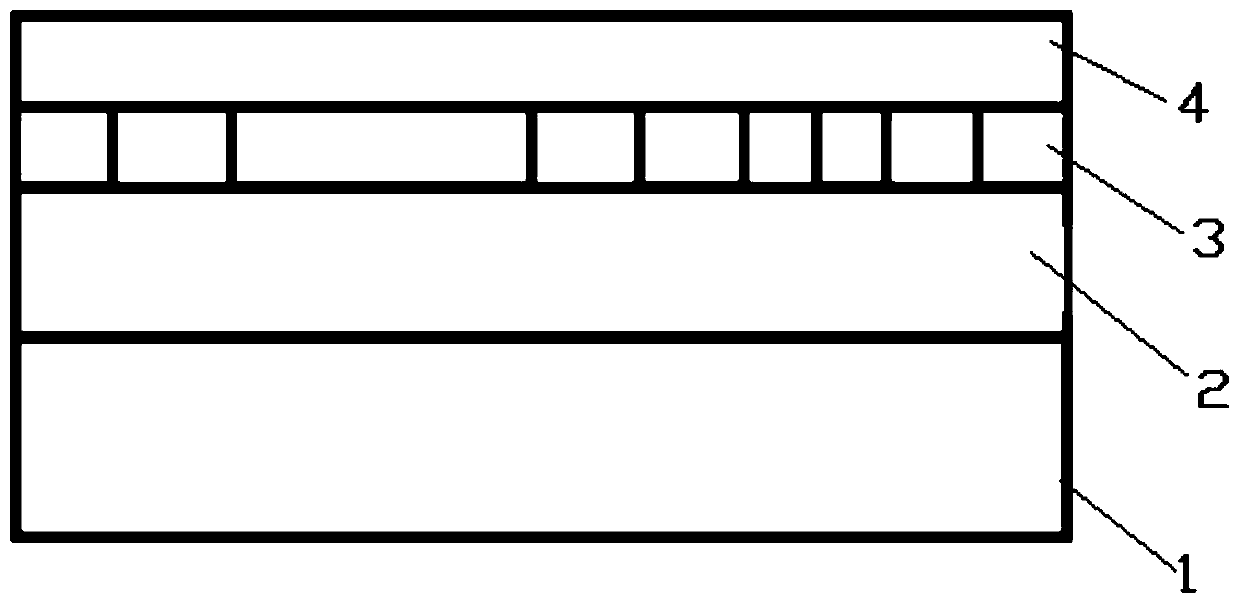

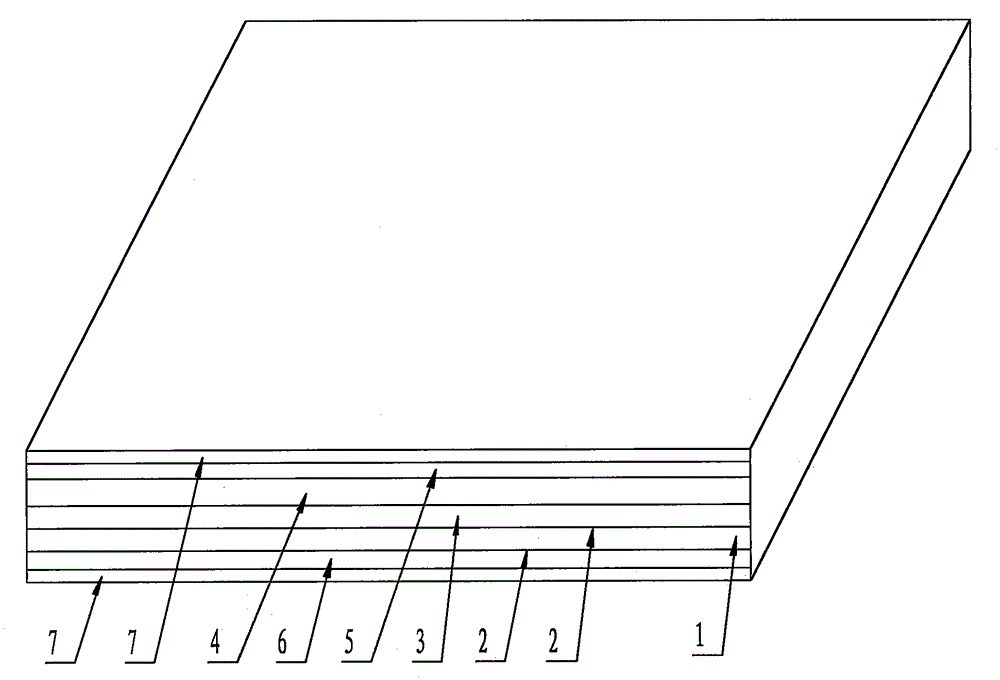

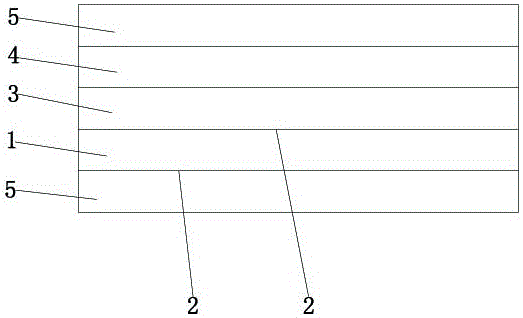

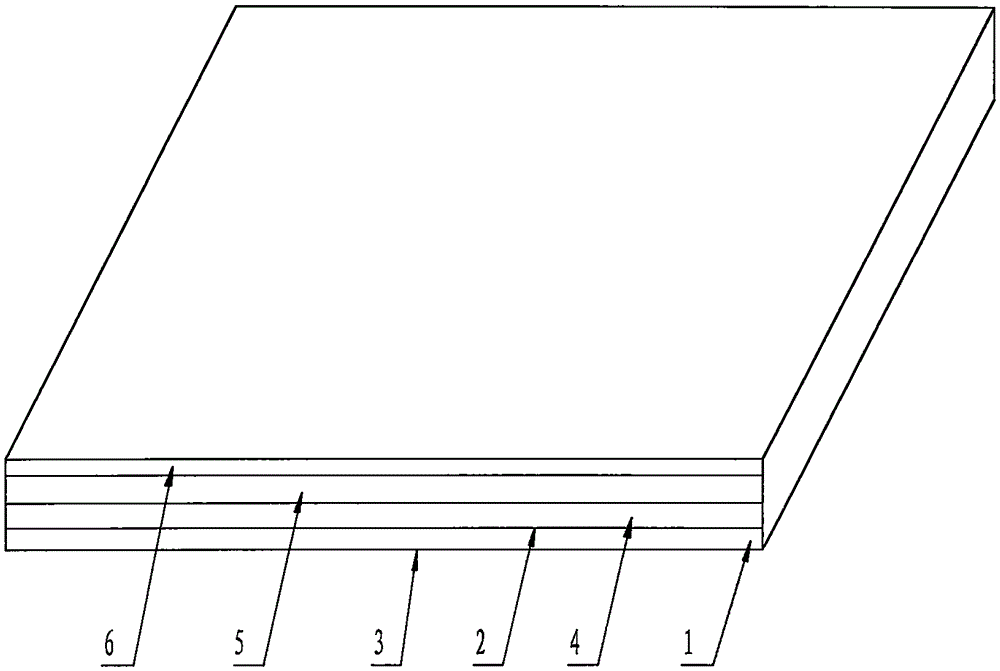

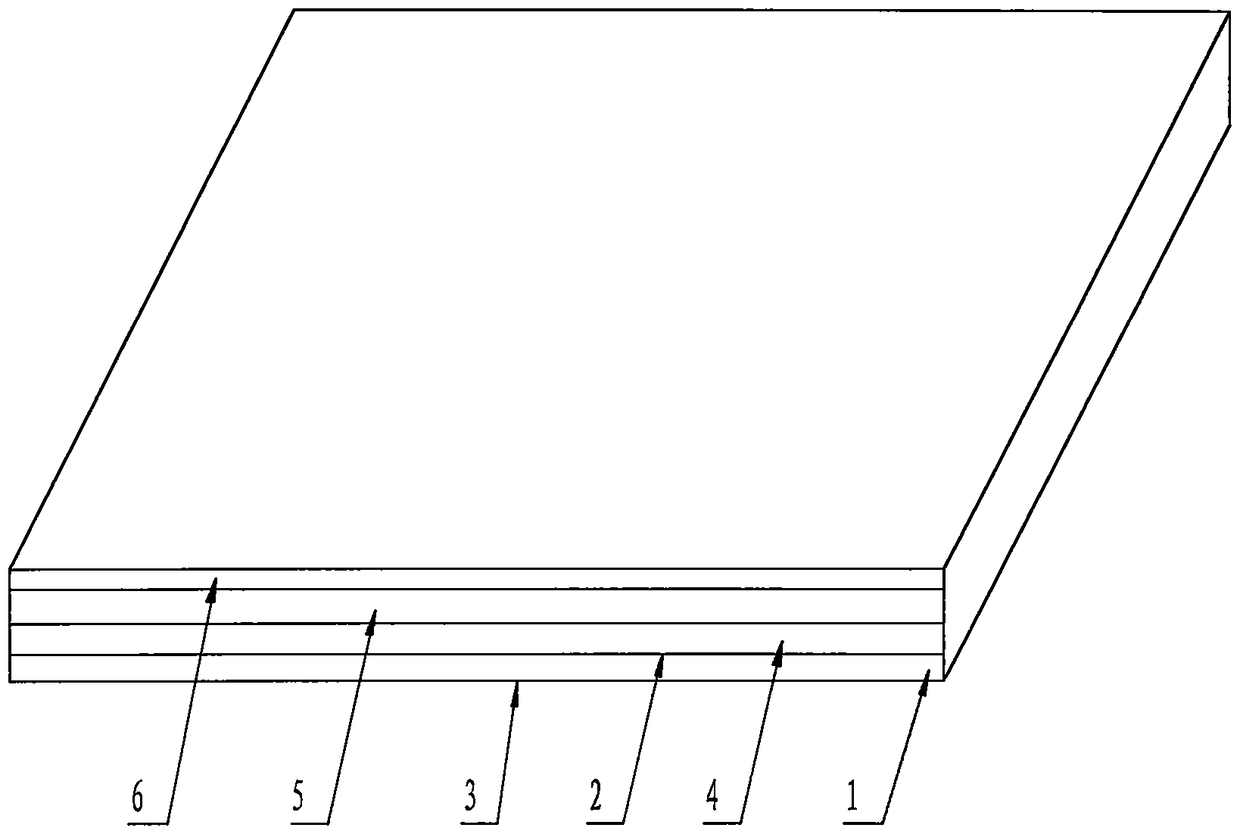

Method for machining double-sided coated glass for capacitive screen and double-sided coated glass

ActiveCN103218102AReduce energy consumptionImprove uniformityInput/output processes for data processingIndium tin oxideTransparent conducting film

The invention relates to the technical field of conductive glass, and discloses a method for machining a piece of double-sided coated glass for a capacitive screen and the double-sided coated glass. The double-sided coated glass is characterized in that a transparent conductive film I is arranged on a transparent passivation layer on a tin surface of a glass substrate; and a transparent conductive film II is arranged on a disapparation layer on an air surface. The machining method comprises the following steps of: firstly processing an original glass substrate, sputtering the disapparation layer (6) and the transparent passivation layer (4) onto the glass substrate, and then sputtering an indium tin oxide conductive film respectively on the transparent dissapparation layer and the transparent passivation layer of the glass substrate. Due to the adoption of the method, an indium tin oxide conductive film etching circuit can be prevented from being etched by an acid solution in a production process, and a good electromagnetic shielding, electrostatic protection or disapparation effect can be realized. The double-sided coated glass can completely substitute traditional conductive glass, the double-sided coated glass for the capacitive screen, which is low in energy consumption, high in uniformity and low in cost, can be provided for downstream customers.

Owner:LUOYANG KANGYAO ELECTRONICS

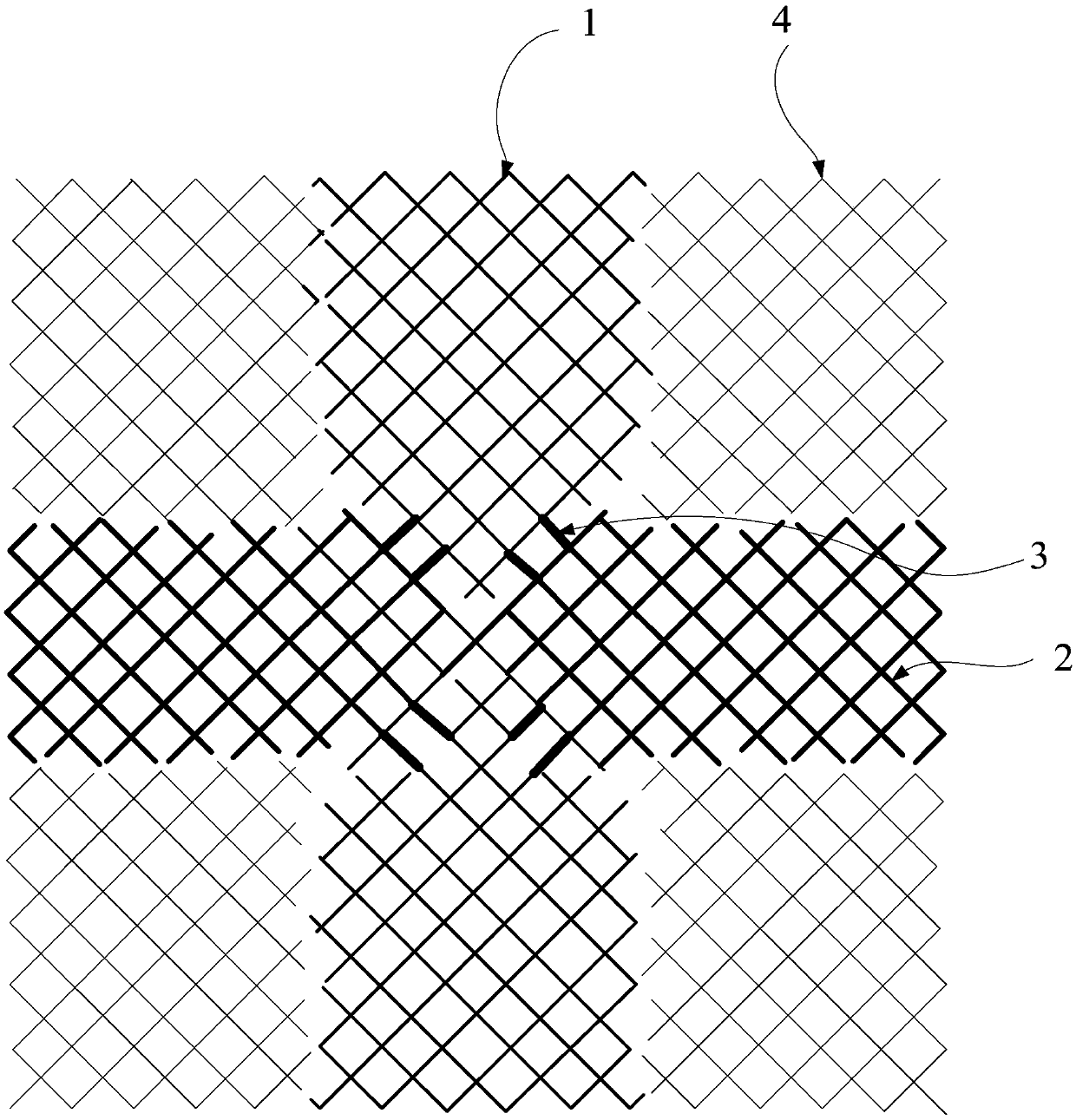

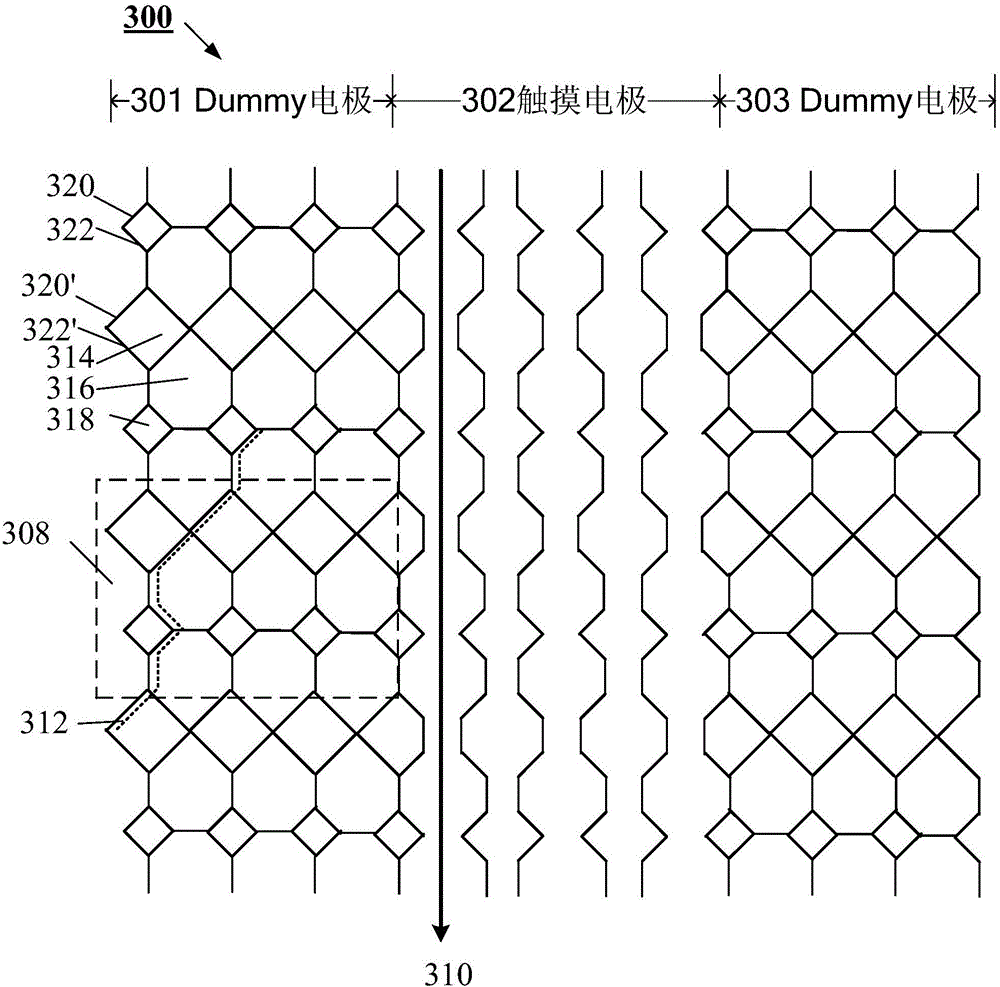

Touch substrate and fabrication method thereof, and touch display apparatus

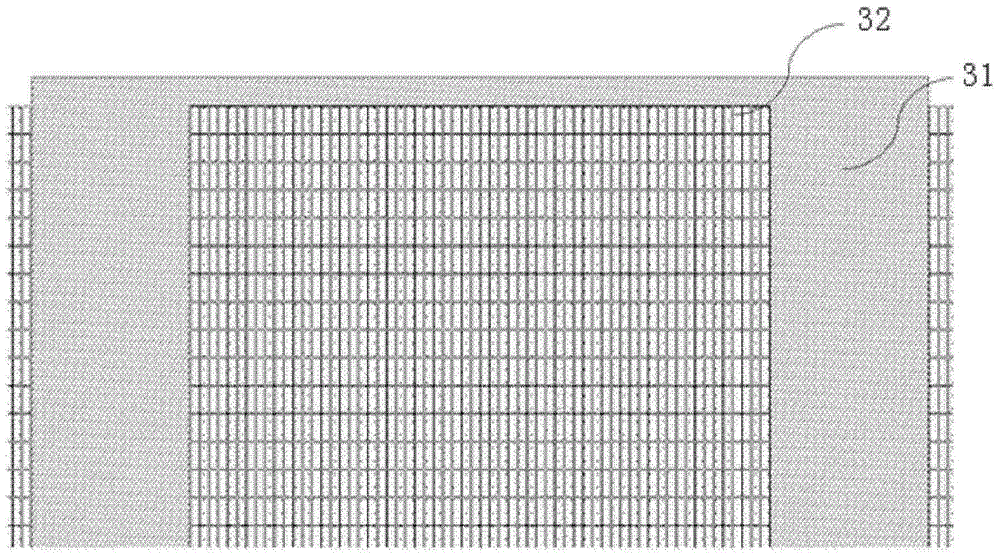

PendingCN108681414AImprove ductilityAvoid breakingInput/output processes for data processingHuman–computer interactionMetal grid

The invention provides a touch substrate and a fabrication method thereof, and a touch display apparatus, and belongs to the technical field of display. The touch substrate comprises a substrate, andfirst and second touch electrodes located on the substrate and arranged crossly in an insulated manner; a virtual electrode is arranged in a region between the first touch electrode and the second touch electrode; the virtual electrode is insulated from the first touch electrode and the second touch electrode; and the virtual electrode, the first touch electrode and the second touch electrode arearranged in a same-layer and same-material manner, and adopt metal grids of the same patterns. Through the technical scheme, the touch substrate has a certain curvature and has a relatively good shadow elimination effect.

Owner:BOE TECH GRP CO LTD +1

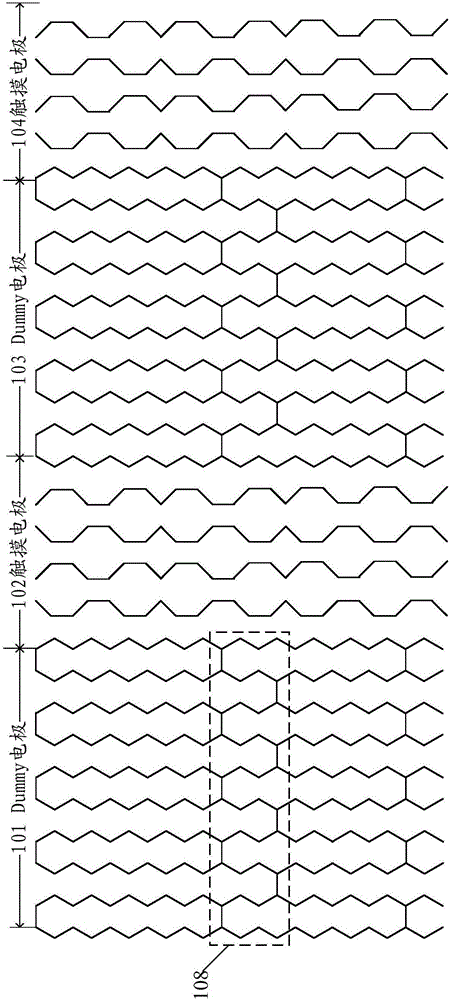

Electrode structure and manufacturing method thereof, touch panel and touch display device

ActiveCN106020527AImprove experienceIncrease graininessInput/output processes for data processingElectricityDisplay device

The invention discloses an electrode structure. The electrode structure includes: a plurality of first electrodes for sending an electrical signal; and a plurality of second electrodes which do not send the electrical signal; the first electrodes and the second electrodes are in mutual electrical isolation; the second electrodes and the first electrodes are arranged alternatively; each second electrode includes a plurality of electrically-isolated electrodes; some isolated edges which are not perpendicular to an extension direction of the first electrodes, of the plurality of electrically-isolated electrodes can be connected into an inclined connection line relative to the extension direction. In addition, the invention discloses a manufacturing method of the electrode structure, a touch panel, and a touch display device. The electrode structure can effectively improve the granular sensation, has a good shadow elimination effect, and can improve the user experience.

Owner:BOE TECH GRP CO LTD +1

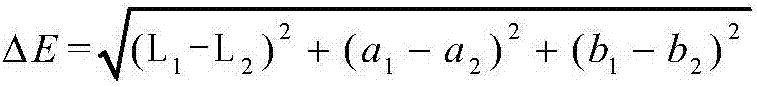

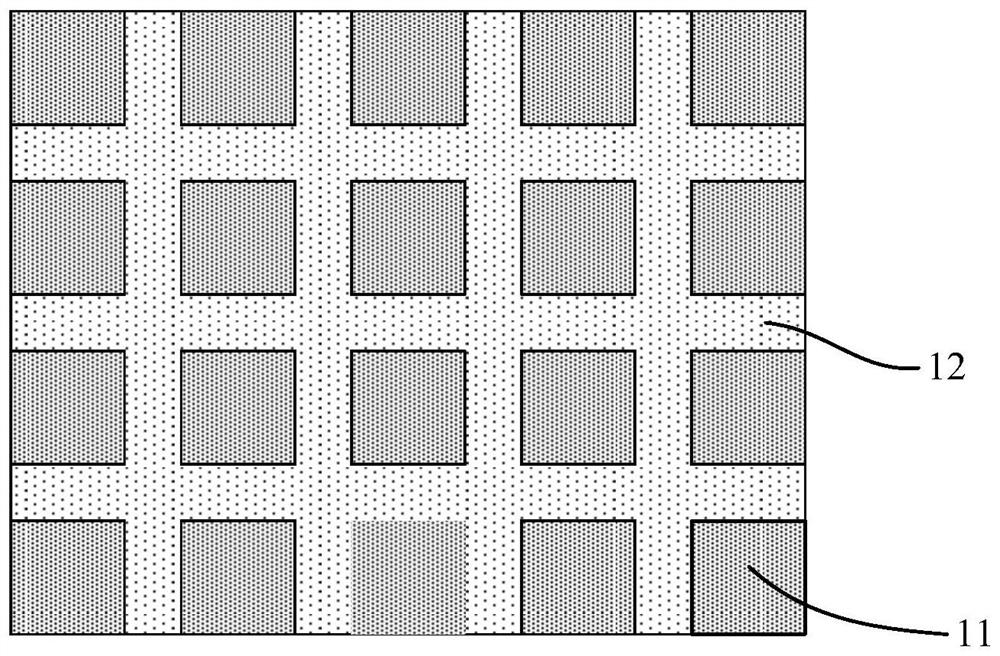

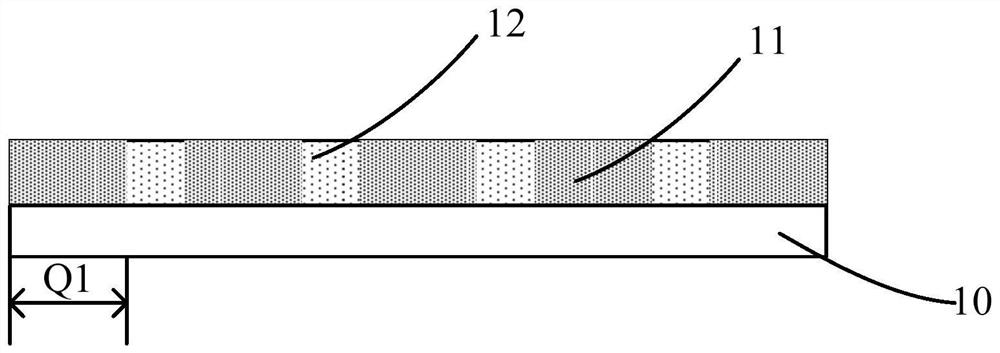

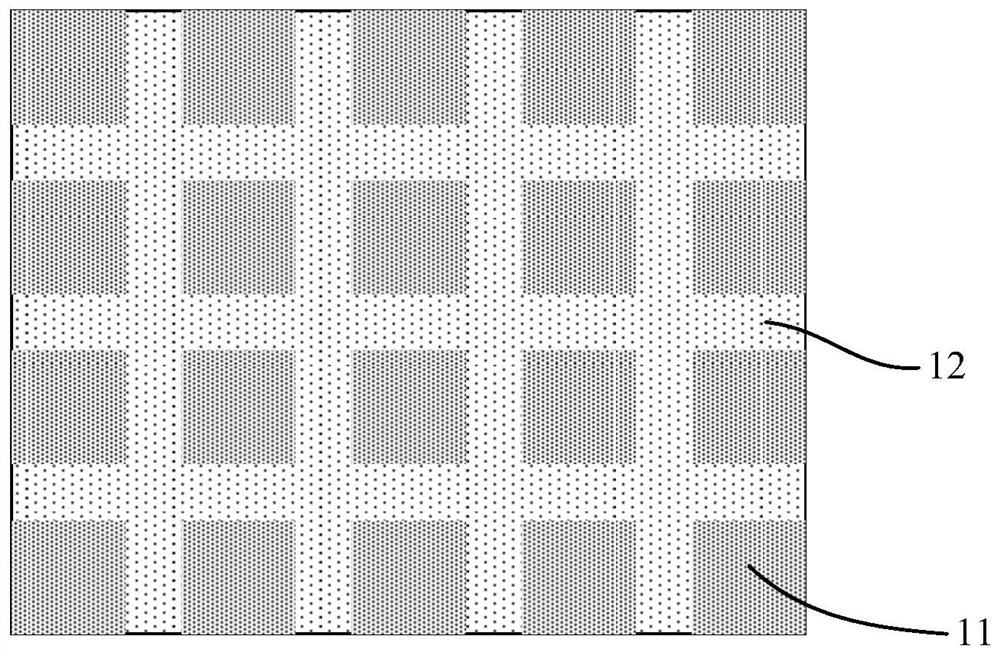

Chromatism-free patterning carbon nanotube transparent conductive film and preparation method thereof

ActiveCN103280255AImprove conductivityHigh light transmittanceConductive layers on insulating-supportsCable/conductor manufactureTransmittanceElectric properties

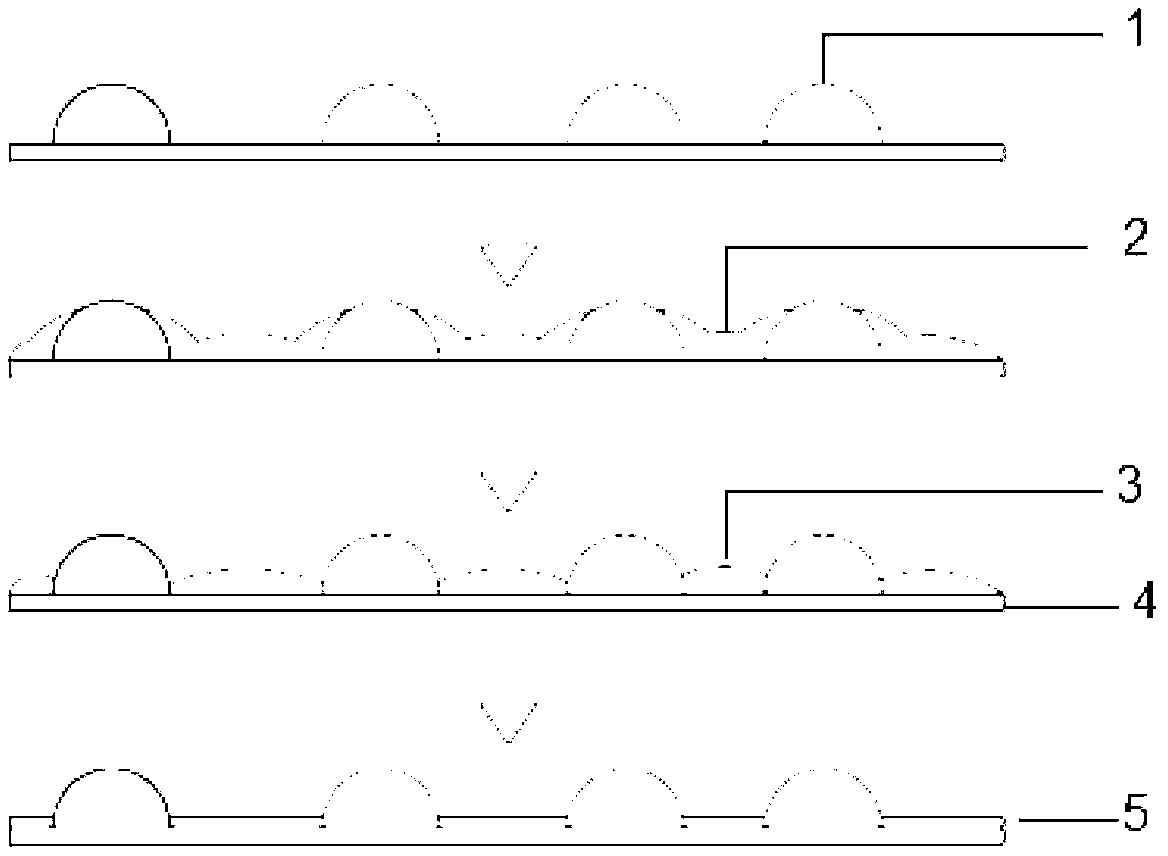

The invention discloses a chromatism-free patterning carbon nanotube transparent conductive film and a preparation method of the chromatism-free patterning carbon nanotube transparent conductive film. The chromatism-free patterning carbon nanotube transparent conductive film comprises a transparent substrate, a patterning carbon nanotube film which is at least distributed in a visible area on the surface of the transparent substrate, and a patterning insulating material layer distributed on the surface of the transparent substrate, the insulating material layer and the carbon nanotube film are staggered and complemented at least in the visible area, and the light transmittance of the insulating material layer and the light transmittance of the carbon nanotube film are also fundamentally consistent. The preparation method includes the steps of forming the patterning insulating material layer on the surface of the transparent substrate, and forming the patterning carbon nanotube film at least in the visible area on the surface of the transparent substrate. Preferably, the insulating material layer can be mainly made of hydrophobic insulating material, and paint can be further mixed. According to the chromatism-free patterning carbon nanotube transparent conductive film and the preparation method of the chromatism-free patterning carbon nanotube transparent conductive film, high-efficiency, large-area and continual preparation of the chromatism-free patterning carbon nanotube transparent conductive film can be achieved, the technology is easy and controllable, needed equipment is simple, cost is low, optical and electric properties of products are good, and the chromatism-free patterning carbon nanotube transparent conductive film has wide application prospects.

Owner:SUZHOU HANANO MATERIALS TECH LTD

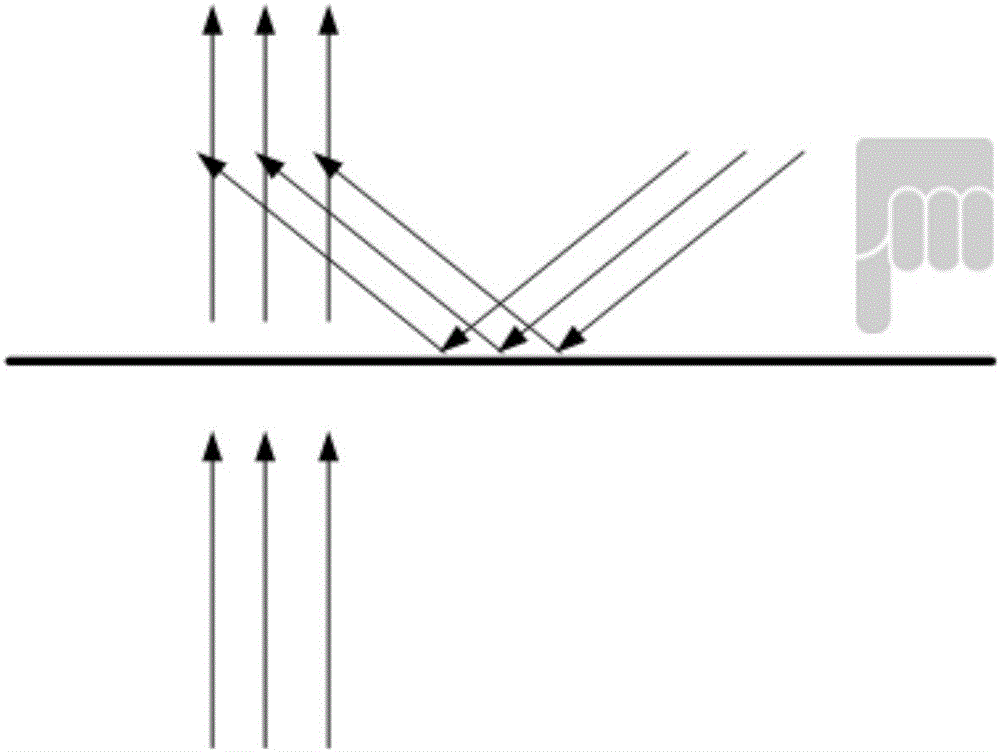

Touch screen and touch display panel

InactiveCN106125988AGuaranteed light transmittanceReduce instabilityInput/output processes for data processingOptoelectronicsFilm material

The invention belongs to the technical field of display and particularly relates to a touch screen and a touch display panel. The touch screen comprises a substrate and a sensor located above the substrate and further comprises a one-way light transmitting film, wherein the one-way light transmitting film is arranged between the substrate and the sensor or is arranged on the side, away from the sensor, of the substrate, so that the light from the side, close to the sensor, of the one-way light transmitting film is totally reflected, and the light is transmitted from the side, deviating from the sensor, of the one-way light transmitting film. The touch screen can decrease unstable factors in an existing OGS shadow-eliminating production process by adding one layer of one-way light transmitting film material, and the shadow-eliminating effect of invisible touch electrode patterns of an OG S sensor is achieved, or the light transmitting rate of the touch screen is ensured by further increasing one antireflection layer, the touch screen is simple in film layer structure, a preparation process is stable.

Owner:BOE TECH GRP CO LTD +1

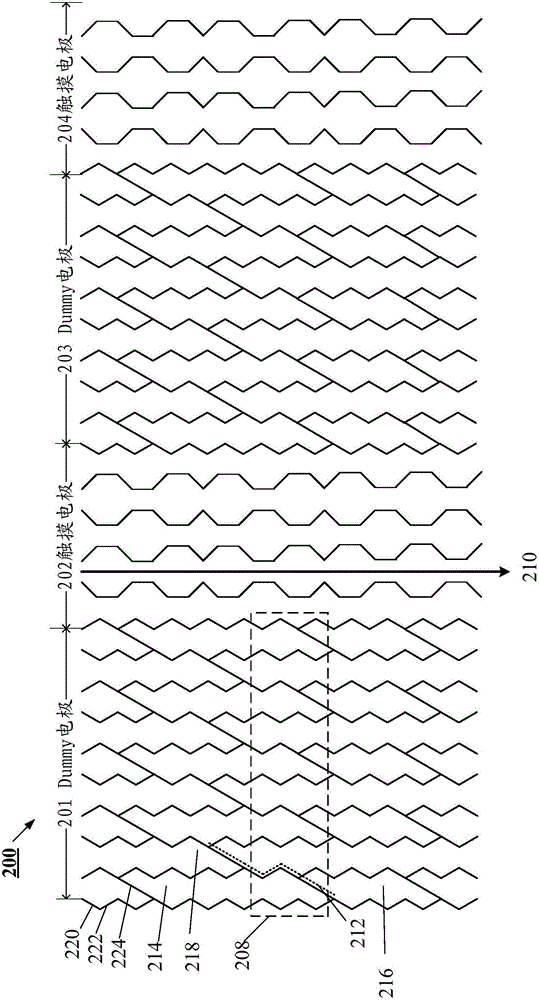

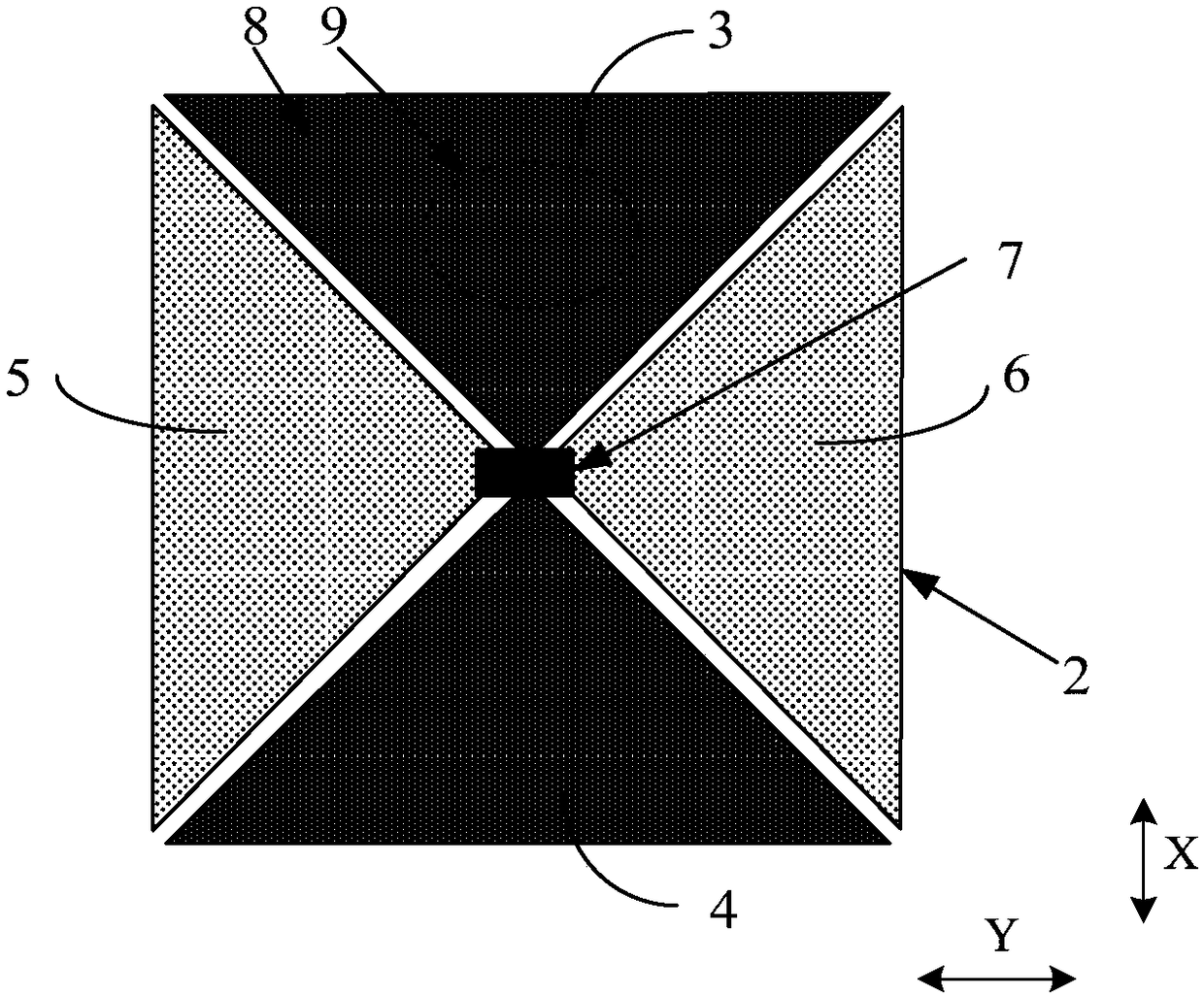

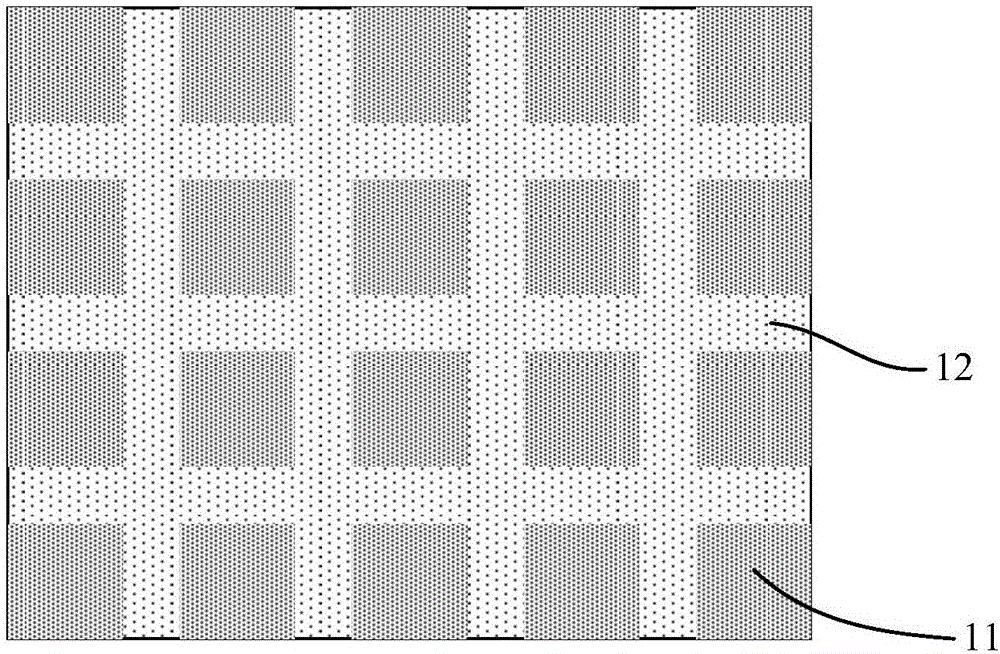

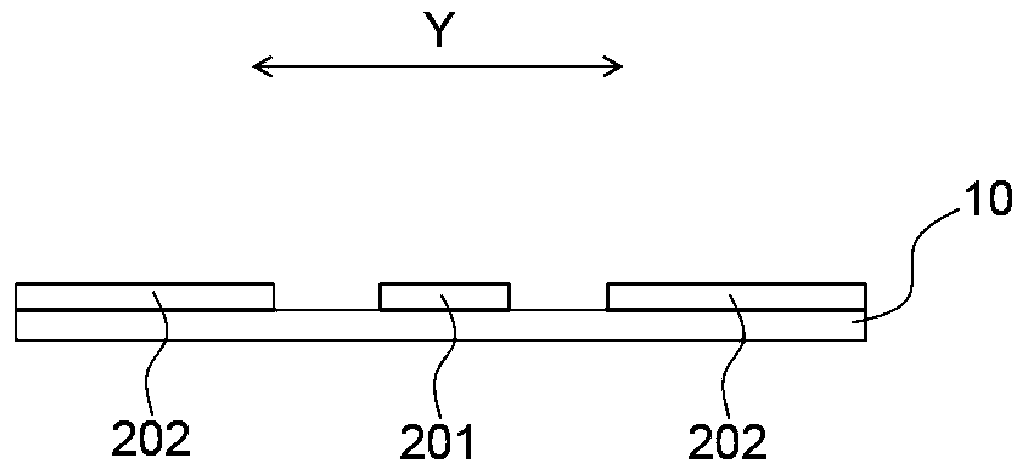

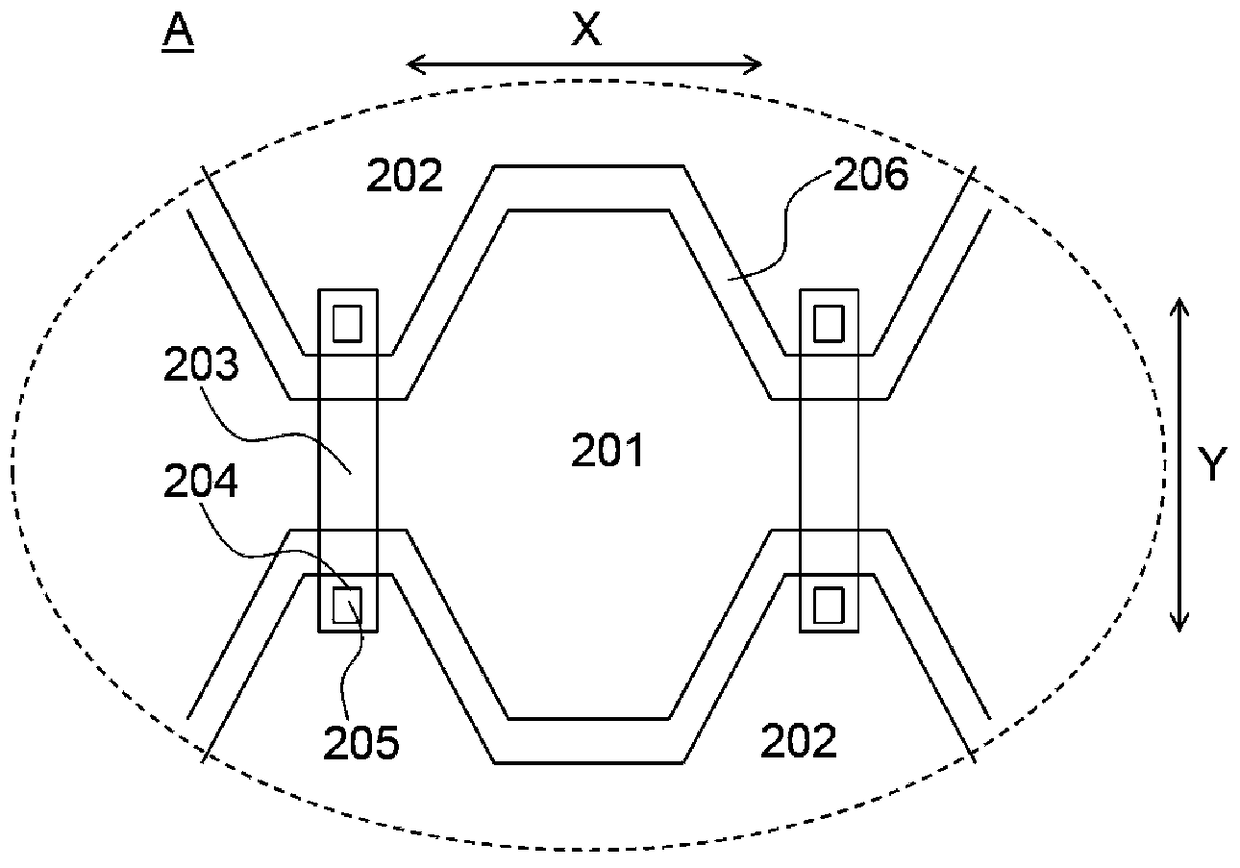

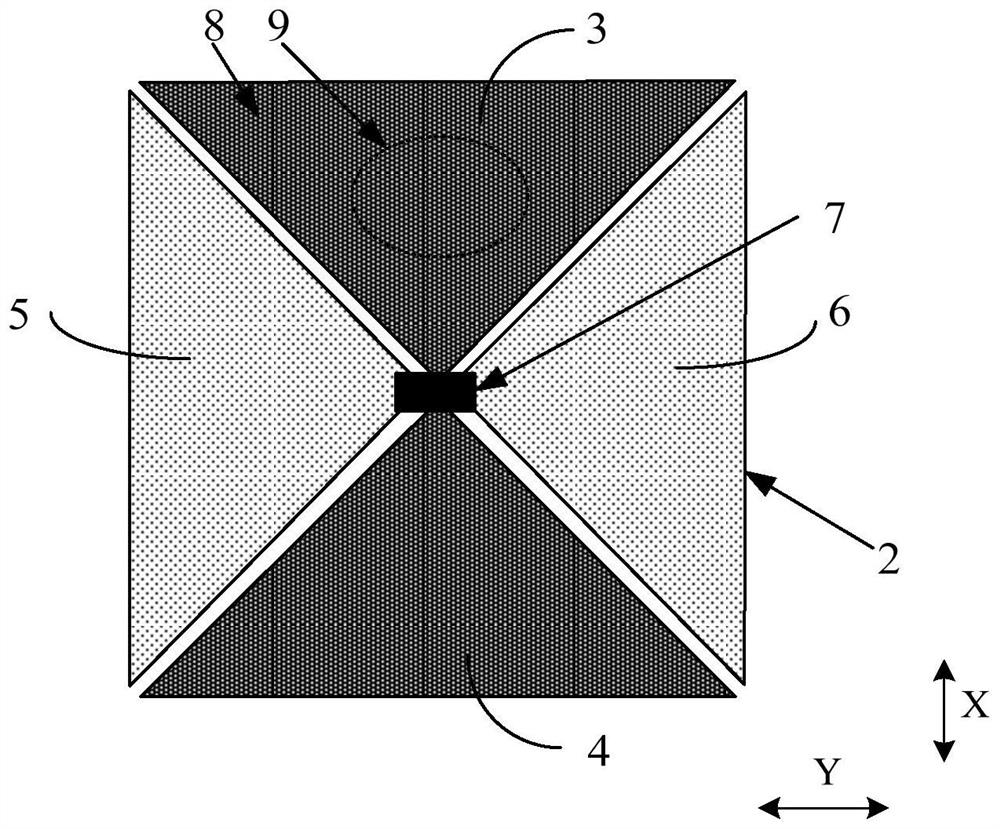

Touch unit, mutual capacitive touch screen and touch display apparatus

ActiveCN108628483AGood shadow removal effectPrevent moiréInput/output processes for data processingHuman–computer interactionElectrode

The invention discloses a touch unit, a mutual capacitive touch screen and a touch display apparatus. The touch unit comprises a substrate and first and second touch electrodes located on the substrate and crossly arranged; the first touch electrode comprises a first sub-electrode and a second sub-electrode; the first sub-electrode and the second sub-electrode are arranged in a first direction andelectrically connected; the first sub-electrode at least comprises a first stripline electrode; the second sub-electrode at least comprises a second stripline electrode; and an extension direction ofthe first stripline electrode and an extension direction of the second stripline electrode are not on the same straight line. The touch unit provided by the invention not only has a relatively good shadow elimination effect but also can effectively avoid the occurrence of moire.

Owner:BOE TECH GRP CO LTD +1

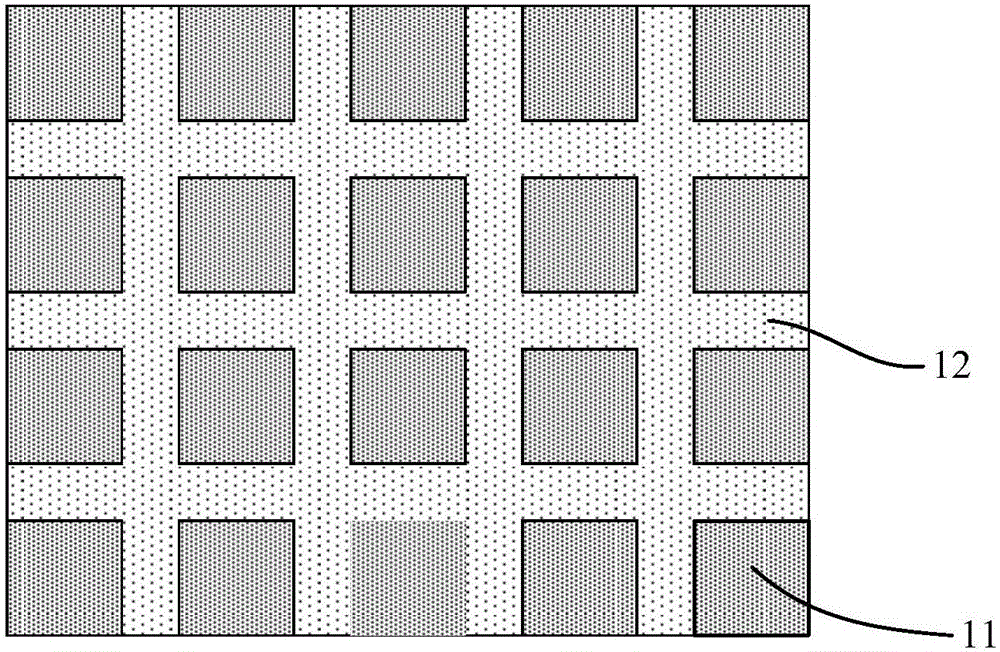

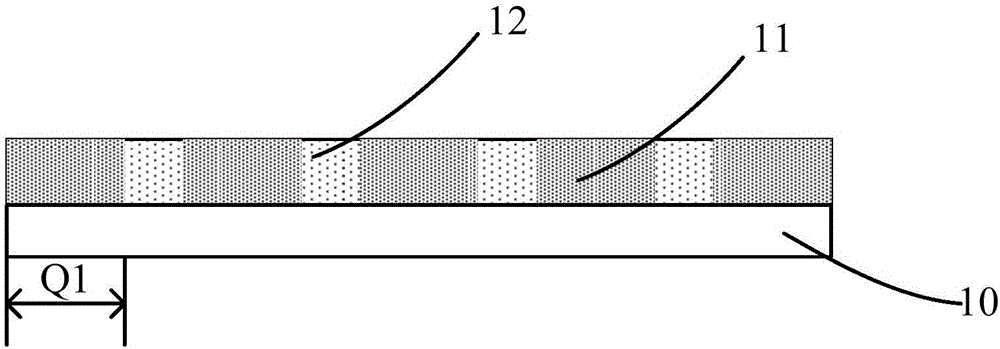

Touch control base plate and preparation method thereof, and display device

ActiveCN106775167AGood shadow removal effectInput/output processes for data processingReflectivityRefractive index

The invention provides a touch control base plate and a preparation method thereof, and a display device, and belongs to the field of display technologies. The touch control base plate provided by the invention comprises a substrate, a plurality of touch control electrode blocks arranged on the substrate, and filling blocks respectively positioned between any two adjacent touch control electrode blocks, wherein a refractive index of material of the filling blocks is n3, the refractive index of the material of the substrate is n1, the refractive index of the material of the touch control electrode blocks is n2, and the absolute value of n2-n3 is less than that of n2-n1. According to the base plate provided by the invention, the filling blocks are arranged between the touch control electrode blocks, and the absolute value of n2-n3 is less than that of n2-n1, that is to say a difference between the refractive indexes of the materials of the filling block and the touch control electrode block is less than that between the refractive indexes of the materials of the substrate and the touch control electrode blocks, meanwhile reflectivity of the material is decided by the refractive index thereof, so that the reflectivity of the material of the filling blocks and the reflectivity of the material of the touch control electrode blocks have little difference, and thus the touch control base plate provided by the invention is good in shadow eliminating effect.

Owner:BOE TECH GRP CO LTD +1

Touch display panel and touch display device

InactiveCN104536620AGood shadow removal effectImprove visual effectsInput/output processes for data processingDisplay deviceComputer science

Owner:BOE TECH GRP CO LTD +1

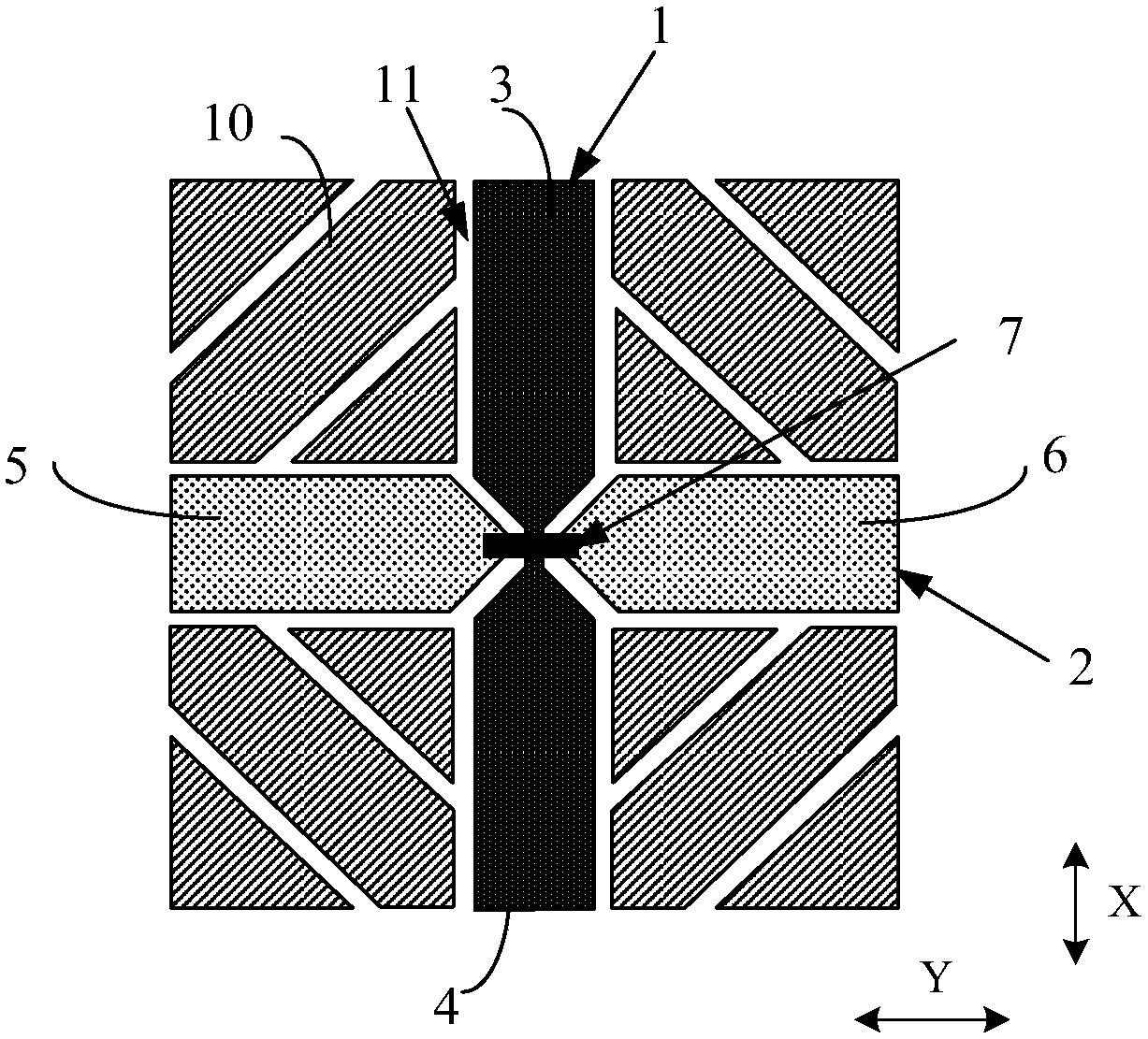

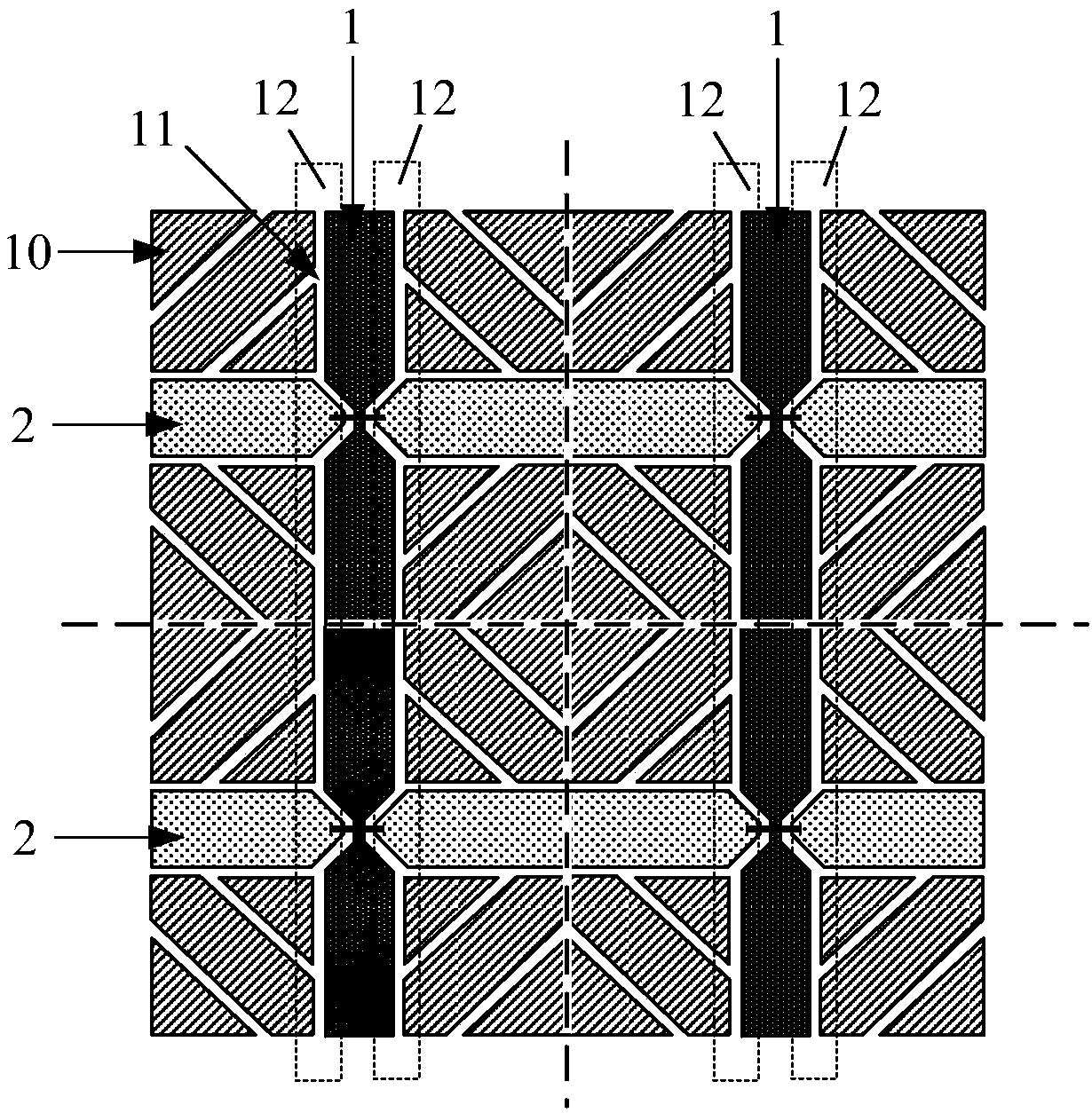

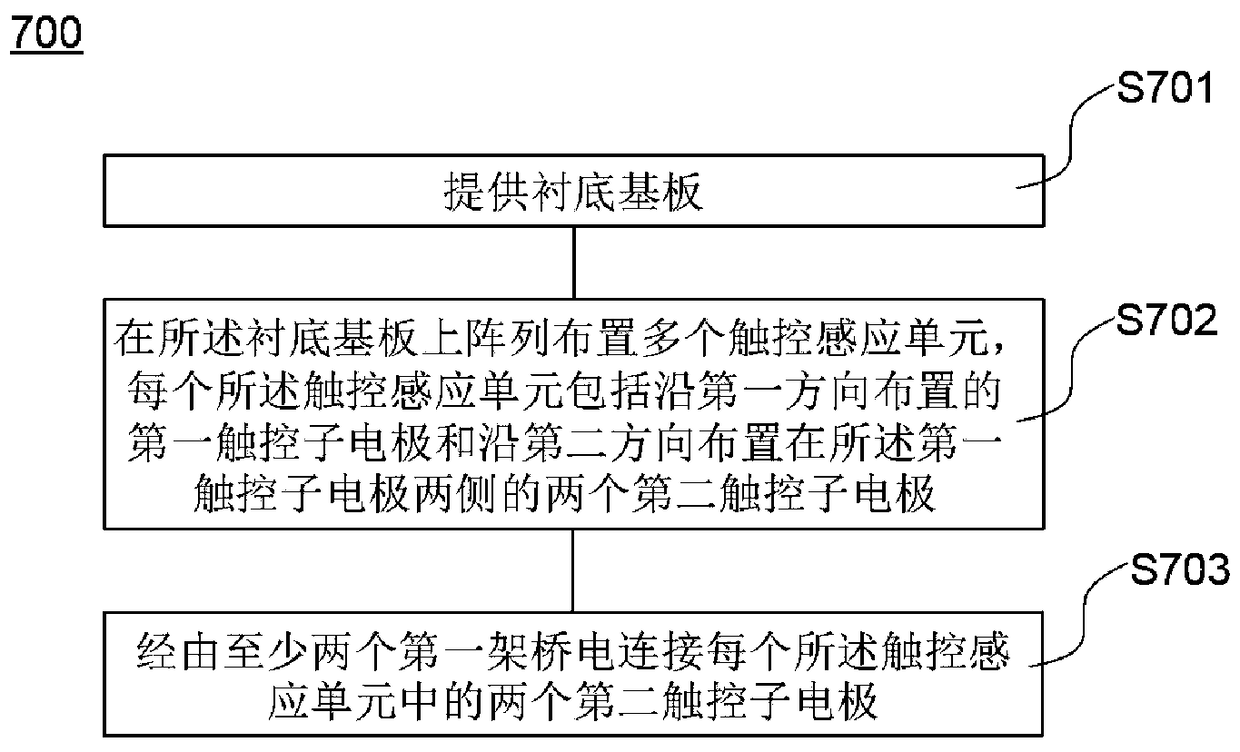

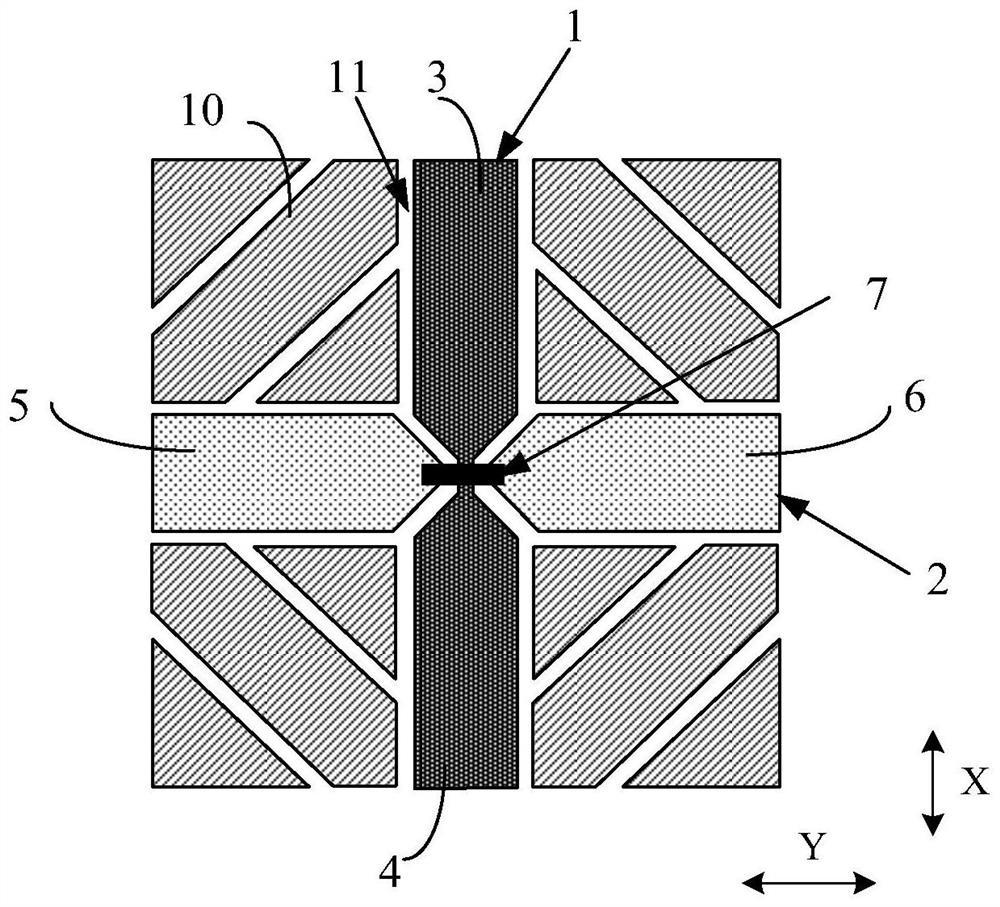

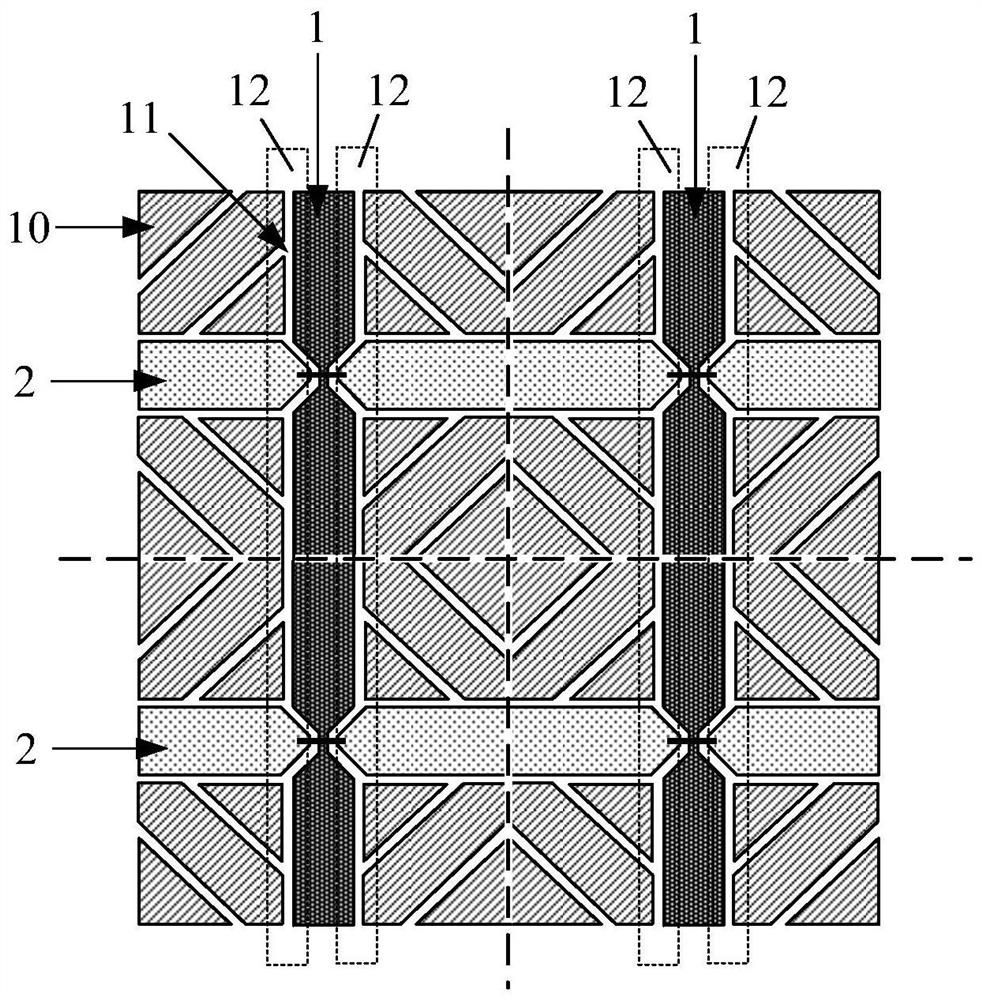

Touch control panel and manufacturing method thereof, and touch control display device

PendingCN109426373AGood shadow removal effectImprove stress relief effectDigital data processing detailsInput/output processes for data processingTouch SensesDisplay device

The embodiment of the invention provides a touch control panel, a touch control display device and a manufacturing method of the touch control panel, which improves the image elimination effect of thetouch control panel and increases the capability of releasing stress. The touch panel comprises a substrate base plate; a plurality of touch sensing units arranged in an array on the substrate, eachof the touch sensing units including a first touch sub-electrode arranged in a first direction and two second touch sub-electrodes arranged on both sides of the first touch sub-electrode in a second direction, wherein two second touch sub-electrodes in each of the touch sensing units are electrically connected via at least two first bridges.

Owner:BOE TECH GRP CO LTD +1

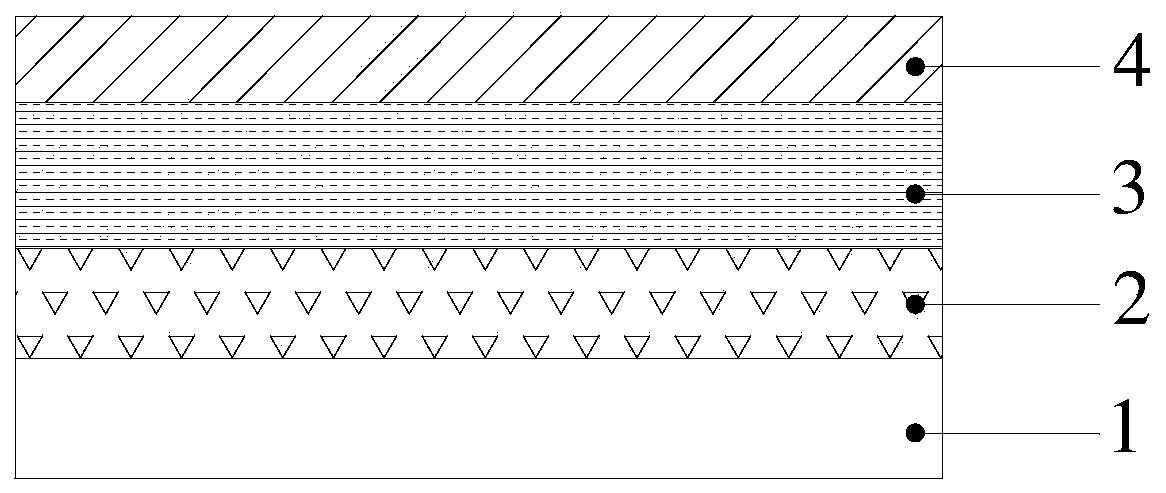

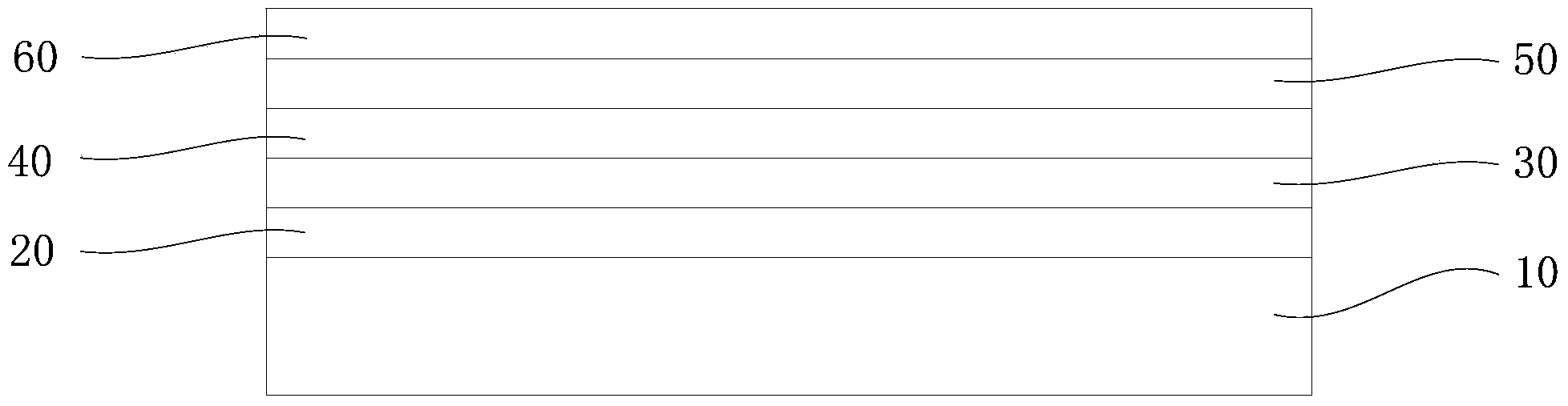

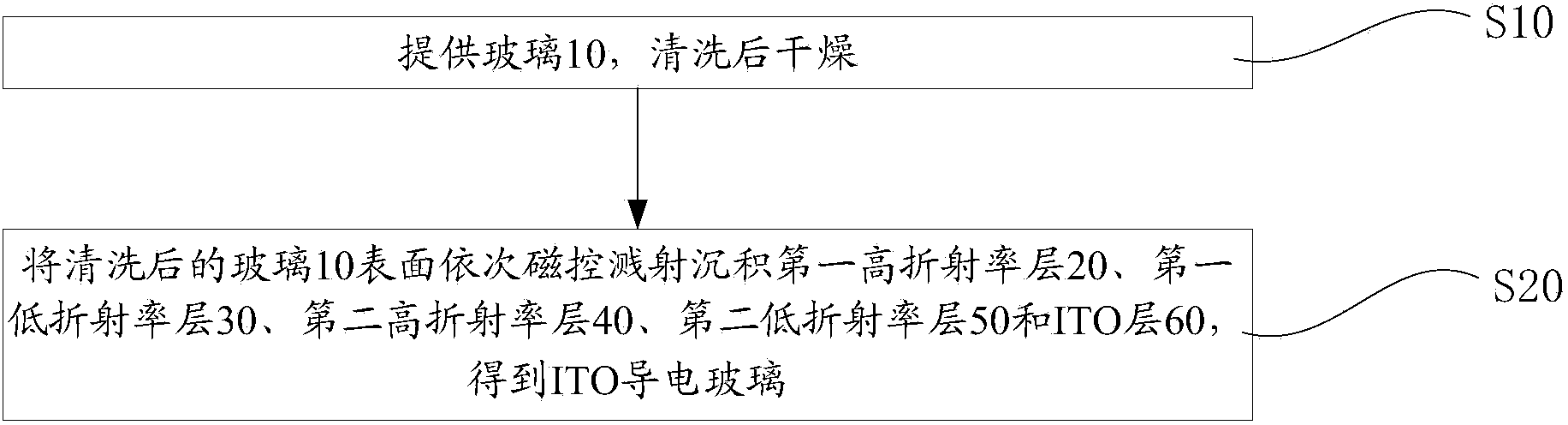

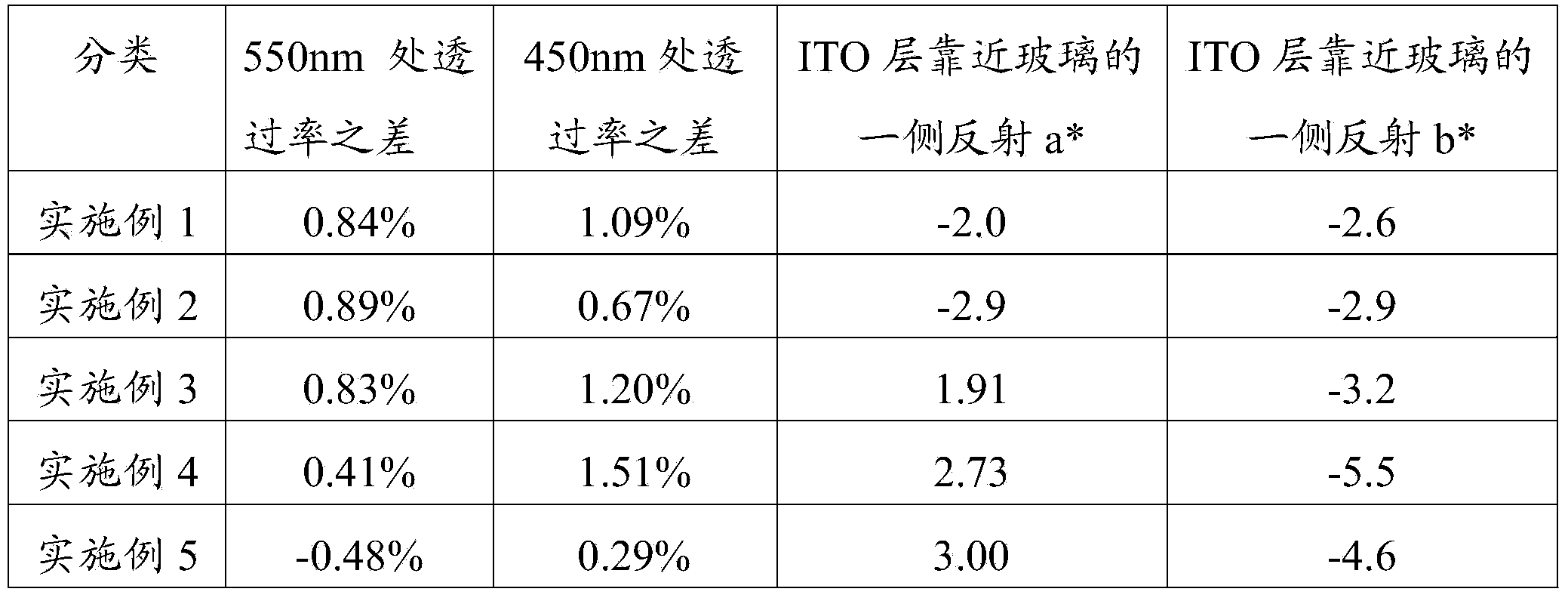

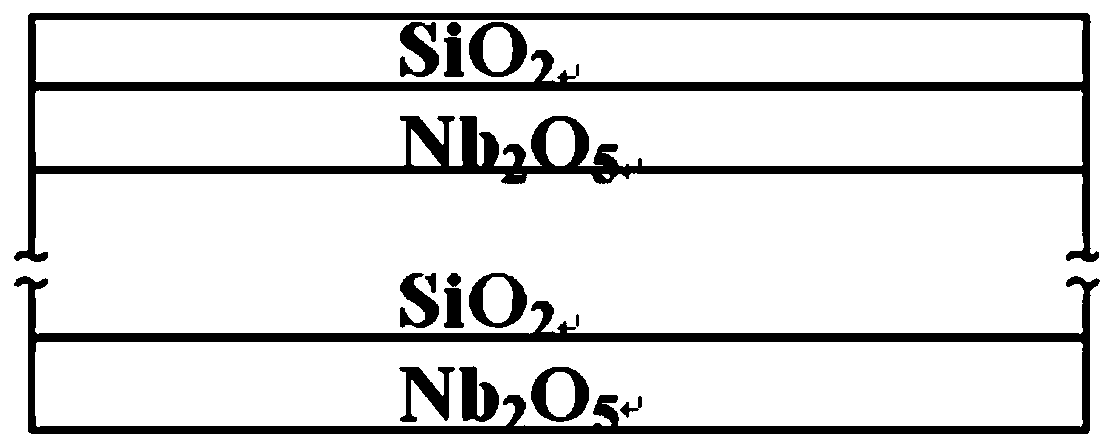

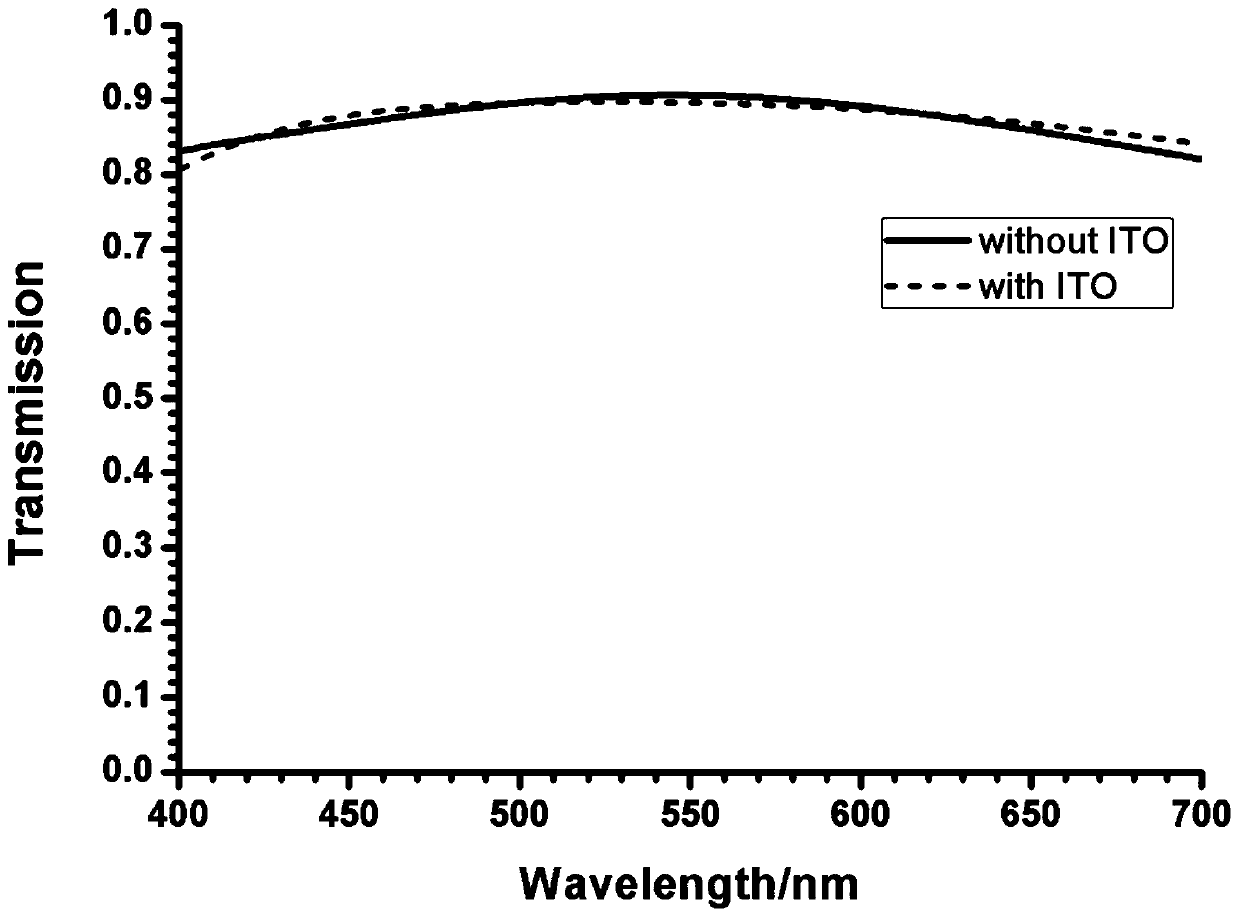

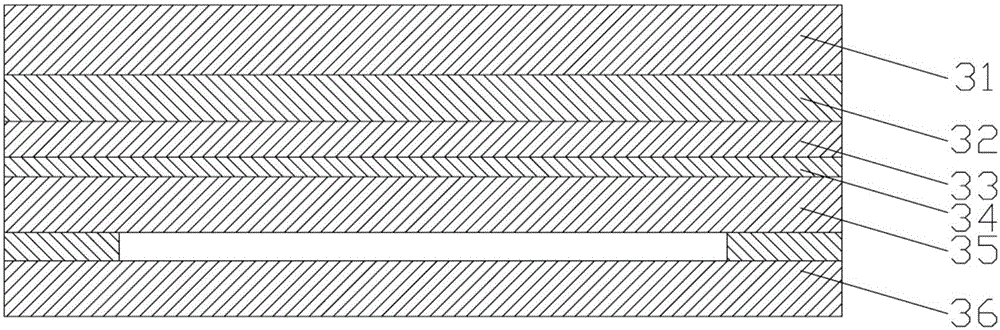

ITO conducting glass and preparation method thereof

InactiveCN104166490AImprove transmittanceGuaranteed compactnessInput/output processes for data processingElectrical resistance and conductanceRefractive index

The invention discloses a piece of colorless low-resistance ITO conducting glass for medium-and-large-sized capacitive touch screens. The ITO conducting glass comprises a glass body, a first high-refractive-index layer, a first low-refractive-index layer, a second high-refractive-index layer, a second low-refractive-index layer and an ITO layer, wherein the glass body, the first high-refractive-index layer, the first low-refractive-index layer, the second high-refractive-index layer, the second low-refractive-index layer and the ITO layer are stacked in sequence; the first high-refractive-index layer and the second high-refractive-index layer are both made of TiO2 or ZrO2 or Si3N4; the first low-refractive-index layer and the second low-refractive-index layer are both made of SiO2 or MgF2. According to the ITO conducting glass, a film layer structure with the combination of a low refractive index and a high refractive index is adopted to replace a traditional shallow elimination layer, so the ITO conducting glass can achieve shallow elimination when the area resistance is low (ranging from 10 ohms to 30 ohms); the ITO conducting glass also solves the problem that when Nb2O5 is adopted as high-refractive-index materials of traditional shallow elimination glass, the Nb2O5 reacts with alkali liquor in the subsequent processing process; meanwhile, the ITO color of the shallow elimination glass of the structure is light, so the shadow elimination effect is good, and the application requirements for large-sized capacitive touch screens can be met. The invention further discloses a preparation method of the ITO conducting glass.

Owner:YICHANG NANBO DISPLAY

Antireflection conductive film with matched refractive index and preparation method thereof

InactiveCN109704596AHigh hardnessGood shadow removal effectIndium tin oxideRefractive index matching

The invention discloses an antireflection conductive film with a matched refractive index. The antireflection conductive film is characterized by comprising a glass substrate; an antireflection film layer, an indium tin oxide (ITO) layer and a diamond protective layer are sequentially arranged on the glass substrate, wherein the ITO layer forms an electrode by etching; and the antireflection filmlayer is composed of multiple layers of alternately stacked SiO2 and Nb2O5 oxide dielectric films with different thickness. The invention further discloses a preparation process of the antireflectionconductive film with the matched refractive index. The invention provides the antireflection-indium tin oxide-diamond multilayer film with the matched refractive index and a preparation process thereof, advantages of index matching (IM) and ITO film layers with matched refractive indexes are combined with advantages of the diamond protection layer with good optical characteristics, and the antireflection conductive film can be used for photoelectric devices under various severe environment conditions, so that the usability of the photoelectric devices is improved, and the service life of the photoelectric devices is prolonged.

Owner:昆山福钻新材料科技有限公司

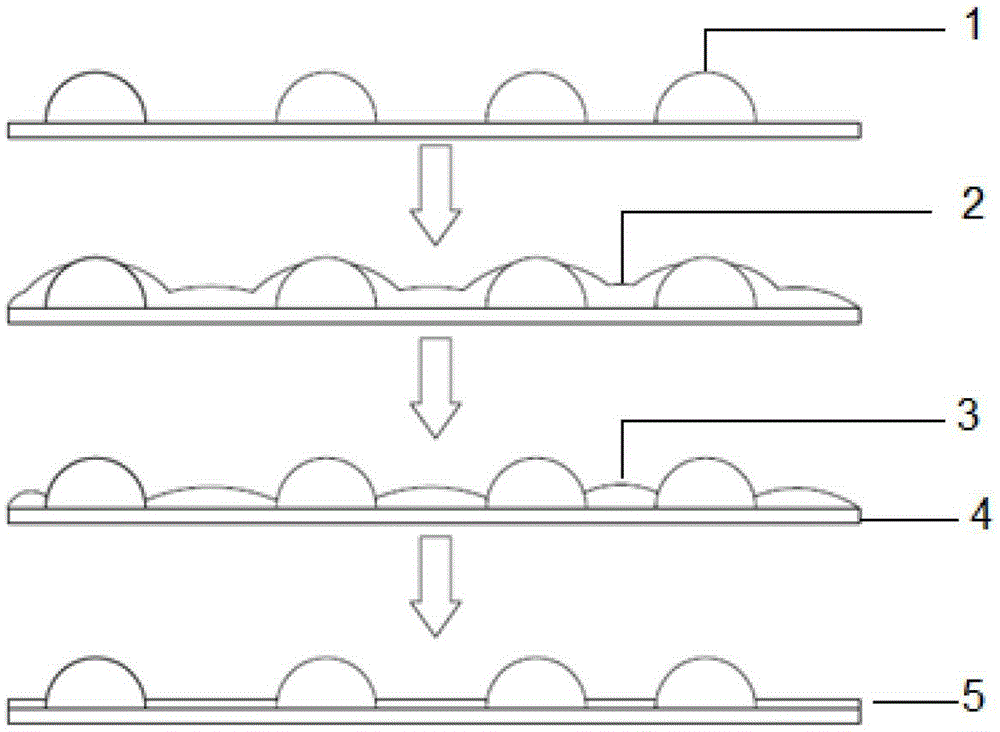

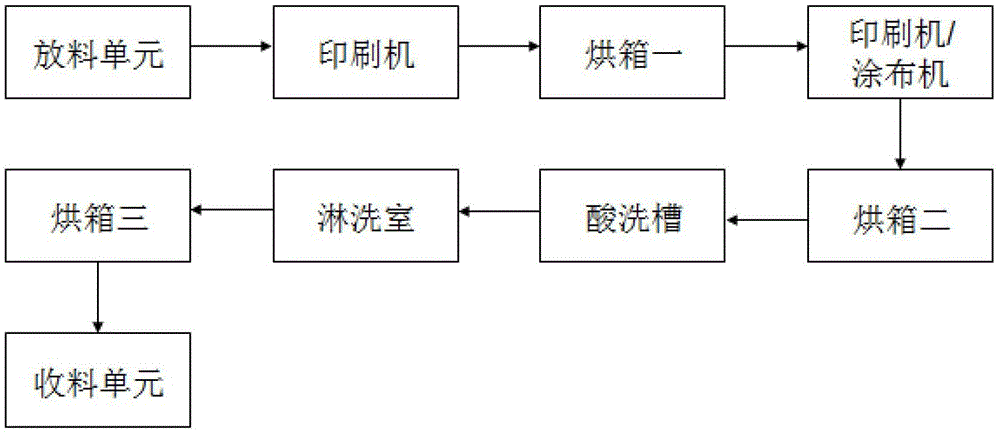

Processing method for single-sided shadow eliminating conductive glass of touch screen

A processing method for single-sided shadow eliminating conductive glass of a touch screen comprises following steps: step 1, a glass substrate is processed; step 2, an interference layer I, a transparent passivation layer, an interference layer II and a transparent layer are sputtered on the glass substrate; step 3, an ITO (indium tin oxide) film is sputtered on the glass substrate on the basis of sputtering in the step 2. The single-sided shadow eliminating conductive glass has good electromagnetic shielding, electrostatic protection and shadow eliminating functions and can completely replace the traditional conductive glass, and the conductive glass having low energy consumption, high uniformity and low cost and used for production of a capacitive touch screen is provided for down-stream customers.

Owner:LUOYANG KANGYAO ELECTRONICS

Method for processing touch screen conductive glass with double-side shadow elimination

InactiveCN106293227AReduce energy consumptionLow costGlass severing apparatusInput/output processes for data processingSputteringElectromagnetic shielding

The invention provides a method for processing touch screen conductive glass with double-side shadow elimination. The method comprises the following steps of step 1, processing an upper glass substrate and a lower glass substrate; step 2, sputtering a first upper transparent layer, an upper transparent passivation layer, a second upper transparent layer, a lower interference layer and a lower transparent passivation layer on the upper glass substrate and the lower glass substrate; and step 3, on the basis of the second step of sputtering, sputtering an upper interference layer, a lower transparent layer and an ITO film on the upper glass substrate and the lower glass substrate. The method for processing the touch screen conductive glass with the double-side shadow elimination provided by the invention has good effects in electromagnetic shielding, electrostatic protection and eliminating the shadow, can completely replace the existing traditional conductive glass, and provide the conductive glass used for producing a capacitive screen with low energy consumption, high uniformity and low cost for downstream customers.

Owner:LUOYANG KANGYAO ELECTRONICS

Single-face shadow eliminating conductive glass and processing method thereof

InactiveCN106042531ASimple structureGood electromagnetic shieldingLamination ancillary operationsVacuum evaporation coatingSputteringIndium tin oxide

The invention discloses single-face shadow eliminating conductive glass and a processing method thereof. The single-face shadow eliminating conductive glass comprises a glass substrate, tin surfaces, an interference layer, a transparent passivation layer and ITO (indium tin oxide) films. Upper and lower surfaces of the glass substrate are provided with the tin surfaces, the interference layer, the transparent passivation layer and one of the ITO films are arranged above the tin surface of the upper surface of the glass substrate sequentially from bottom to top, and the other ITO film is arranged below the tin surface of the lower surface of the glass substrate. The processing method of the single-face shadow eliminating conductive glass includes: step one, cleaning and heating the glass substrate, wherein a heating temperature is 40-60 DEG C; step two, forming the interference layer, the transparent passivation layer and the ITO film on the tin surface of the upper surface of the glass substrate by sputtering; step three, forming the other ITO film on the tin surface of the lower surface of the glass substrate by sputtering. The single-face shadow eliminating conductive glass has advantages of simple structure, low cost and effectiveness in electromagnetic shielding, electrostatic protection and shadow elimination.

Owner:东莞汇海光电科技实业有限公司

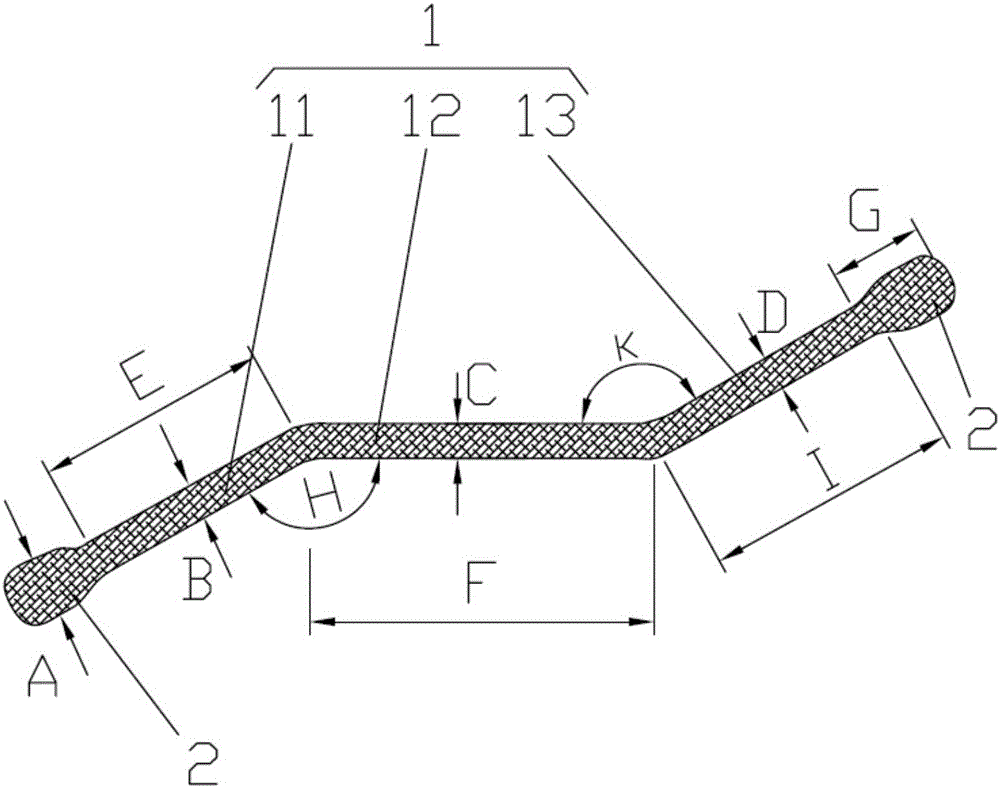

Metal bridge of touch structure and touch screen

InactiveCN105700760AAvoid occlusionImprove display qualityNon-linear opticsInput/output processes for data processingMedicineTouchscreen

The invention provides a metal bridge of a touch structure and a touch screen. The metal bridge comprises a bridge body in a fold line shape. The bridge body in the fold line shape can hardly be captured by human eyes, and therefore the ideal shallow eliminating effect can be achieved, and the display quality of the touch screen can be improved.

Owner:BOE TECH GRP CO LTD +1

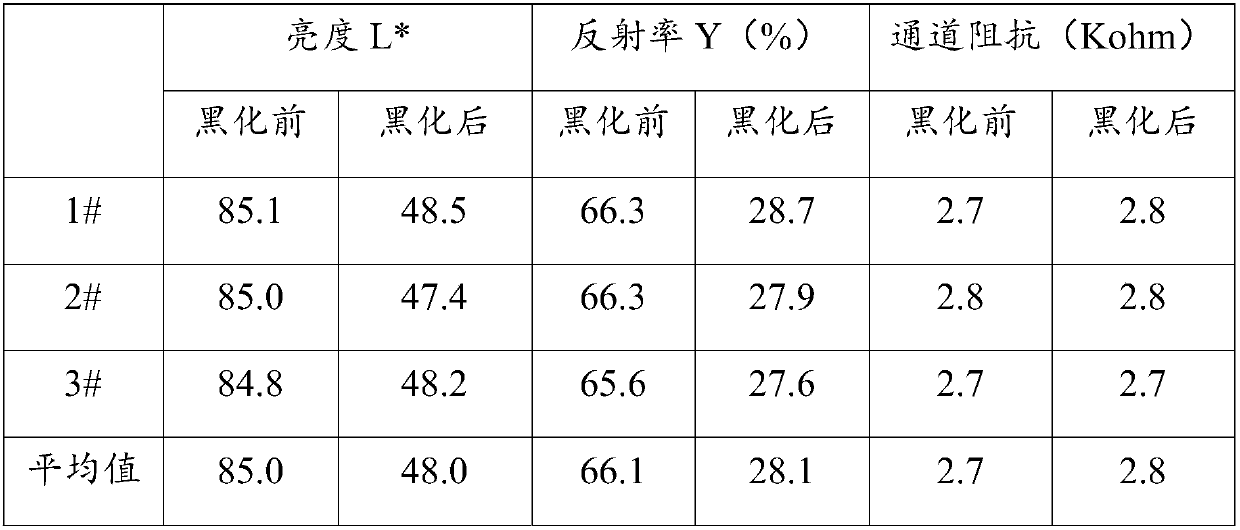

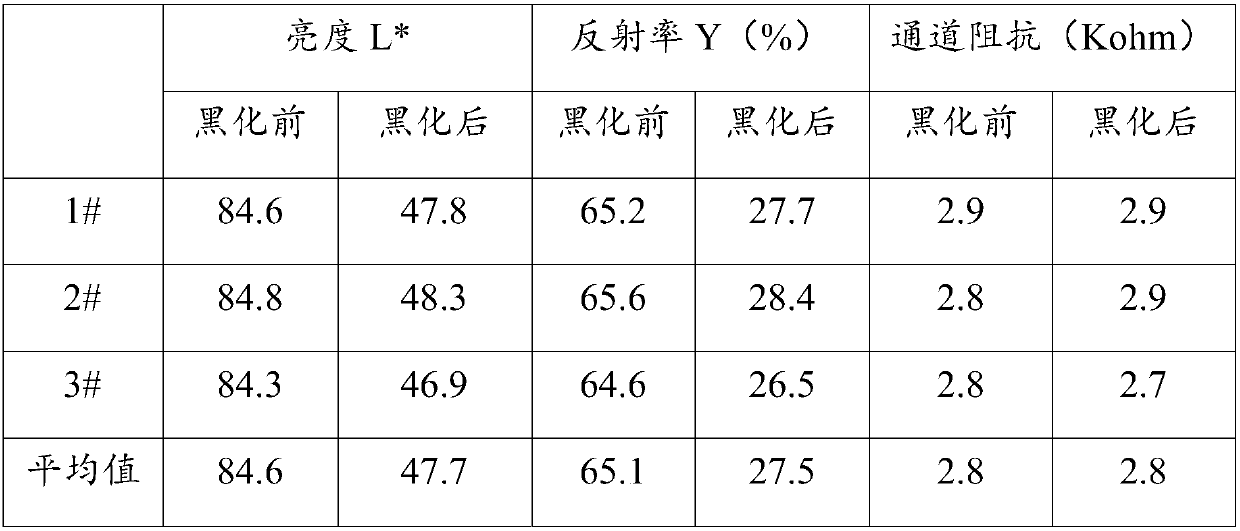

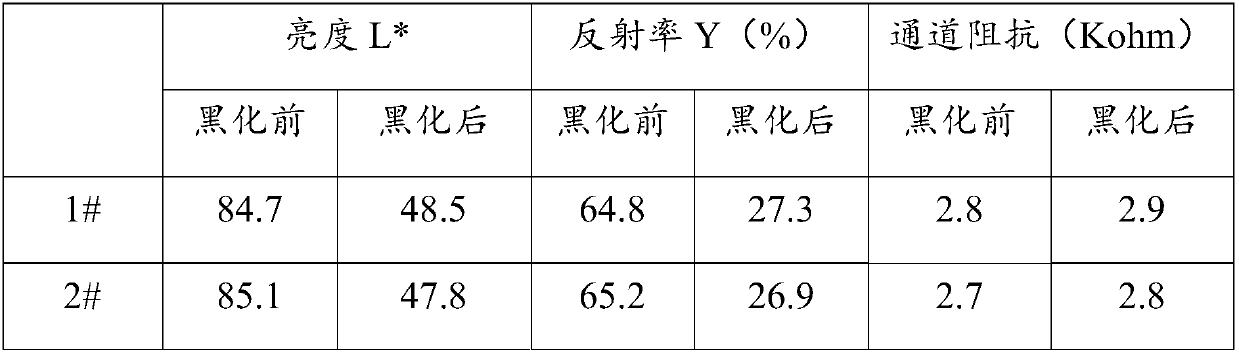

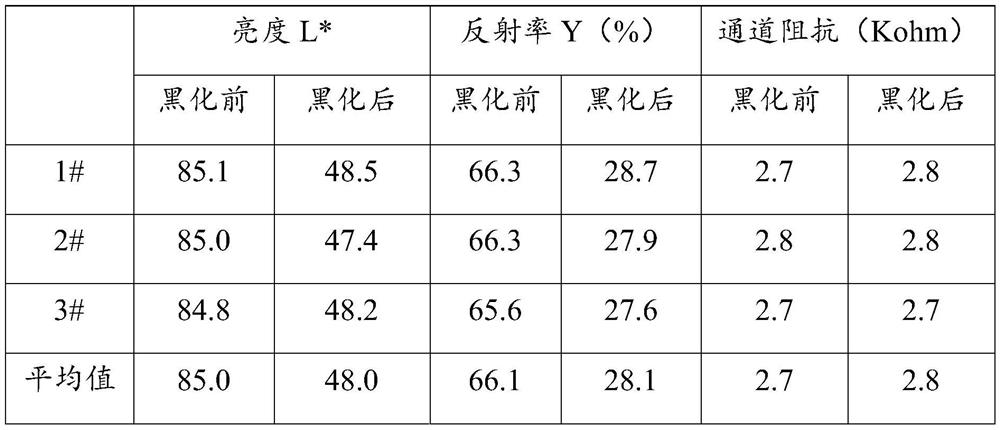

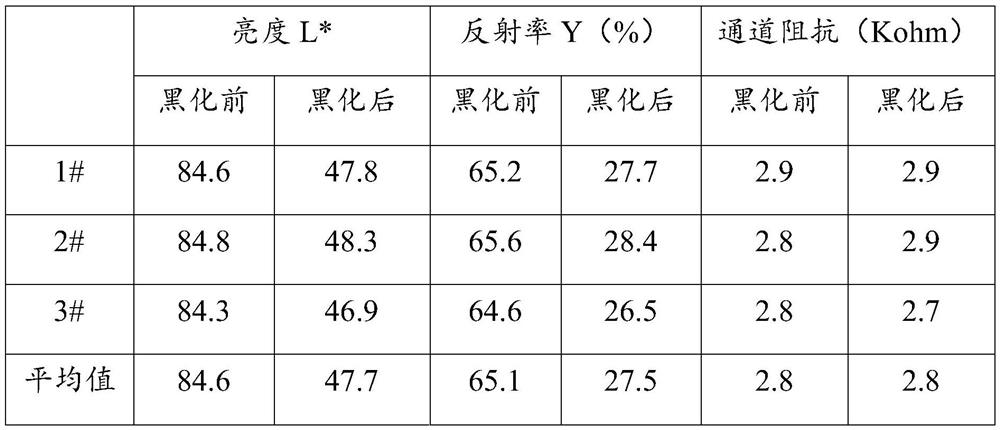

Blackening liquid medicine for metal meshes, blackening method of metal meshes, metal meshes and touch screen

ActiveCN109576696AAffect conductivityBlackening effect is obviousMetallic material coating processesInput/output processes for data processingSulfatePersulfate

The invention discloses a blackening liquid medicine for metal meshes, a blackening method of the metal meshes, the metal meshes and a touch screen, and relates to the technical field of the metal meshes. The blackening liquid medicine comprises the following components including, by mass percentage, 0.05% to 5% of selenite, 0 to 10% of persulfate, 0.01% to 1% of a stabilizer, 0.01% to 1% of an inhibitor and the balance water. The blackening method of the metal meshes comprises the step that the blackening liquid medicine is used for soaking the metal meshes. The defect that at present, the physical blackening manner for coating a blackening layer is complex, the disappearing effect is general, and the metal conductive property is easy are overcome. According to the blackening liquid medicine, the selenite, the stabilizer and the inhibitor are matched, so that the good blackening effect is achieved, the reflectance and brightness of metal are obviously reduced, the visual effect is notobvious, the disappearing effect is achieved, a line is intact after blackening is carried out, and the electrical conductivity is not influenced.

Owner:LENS TECH CHANGSHA

Method for processing single-face touch screen shadow eliminating conductive glass

ActiveCN105204704AGood electromagnetic shieldingLow energy consumptionInput/output processes for data processingElectrically conductiveElectromagnetic shielding

A method for processing single-face touch screen shadow eliminating conductive glass comprises the following steps: 1, treating a glass baseplate; 2, sputtering an intervention layer I and a transparent passivation layer on the glass baseplate; 3, sputtering an intervention layer II on the transparent passivation layer sputtered on the glass baseplate. The single-face touch screen shadow eliminating conductive glass has excellent electromagnetic shielding, stelectrostatic protection and shadow elimination functions, and can completely replace the conventional conductive glass, and the conductive glass, with low energy consumption, high uniformity and low cost, used for manufacturing capacitive screens can be provided for downstream clients.

Owner:LUOYANG KANGYAO ELECTRONICS

Blackening solution for metal grid, its blackening method, metal grid and touch screen

ActiveCN109576696BAffect conductivityBlackening effect is obviousMetallic material coating processesInput/output processes for data processingChemical solutionPhysical chemistry

The invention discloses a blackening chemical solution for metal grids, a blackening method thereof, a metal grid and a touch screen, and relates to the technical field of metal grids. The blackening medicinal solution comprises the following components in mass percentage: 0.05-5% of selenous acid, 0-10% of persulfate, 0.01-1% of stabilizer, 0.01-1% of inhibitor, and the rest is water. The blackening method of the metal grid uses the blackening liquid to soak the metal grid. The invention alleviates the defects that the current physical blackening method of coating the blackening layer is cumbersome, the effect of disappearing is general, and the conductive performance of the metal is easily affected. The blackening medicinal solution of the present invention can not only achieve a good blackening effect through the mutual cooperation of selenous acid, stabilizers and inhibitors, but also significantly reduce the reflectivity and brightness of metals, which is not obvious to the naked eye and achieve the effect of disappearing shadows. After blackening, the circuit is complete and does not affect its electrical conductivity.

Owner:LENS TECH CHANGSHA

A kind of processing method of double-sided coated glass for capacitive screen and double-sided coated glass

ActiveCN103218102BReduce energy consumptionImprove uniformityInput/output processes for data processingIndium tin oxideElectromagnetic shielding

The invention relates to the technical field of conductive glass, and discloses a method for machining a piece of double-sided coated glass for a capacitive screen and the double-sided coated glass. The double-sided coated glass is characterized in that a transparent conductive film I is arranged on a transparent passivation layer on a tin surface of a glass substrate; and a transparent conductive film II is arranged on a disapparation layer on an air surface. The machining method comprises the following steps of: firstly processing an original glass substrate, sputtering the disapparation layer (6) and the transparent passivation layer (4) onto the glass substrate, and then sputtering an indium tin oxide conductive film respectively on the transparent dissapparation layer and the transparent passivation layer of the glass substrate. Due to the adoption of the method, an indium tin oxide conductive film etching circuit can be prevented from being etched by an acid solution in a production process, and a good electromagnetic shielding, electrostatic protection or disapparation effect can be realized. The double-sided coated glass can completely substitute traditional conductive glass, the double-sided coated glass for the capacitive screen, which is low in energy consumption, high in uniformity and low in cost, can be provided for downstream customers.

Owner:LUOYANG KANGYAO ELECTRONICS

Touch unit, mutual capacitance touch screen and touch display device

ActiveCN108628483BGood shadow removal effectPrevent moiréInput/output processes for data processingDisplay deviceEngineering

The invention discloses a touch control unit, a mutual capacitance touch screen and a touch display device, wherein the touch control unit comprises: a base substrate and a first touch electrode and a second touch electrode located on the base substrate and arranged crosswise. The touch electrode, the first touch electrode includes: a first sub-electrode and a second sub-electrode, the first sub-electrode and the second sub-electrode are arranged along the first direction, and the first sub-electrode and the second sub-electrode are electrically connected; The sub-electrodes include at least one first strip-shaped electrode, the second sub-electrodes include at least one second strip-shaped electrode, and the extension direction of the first strip-shaped electrode is not on the same straight line as the extension direction of the second strip-shaped electrode. The touch control unit provided by the present invention not only has better shadow elimination effect, but also can effectively avoid the appearance of moiré.

Owner:BOE TECH GRP CO LTD +1

A kind of processing method of single-sided touch screen erasing conductive glass

ActiveCN105204704BReduce energy consumptionLow costInput/output processes for data processingSputteringElectromagnetic shielding

A method for processing single-face touch screen shadow eliminating conductive glass comprises the following steps: 1, treating a glass baseplate; 2, sputtering an intervention layer I and a transparent passivation layer on the glass baseplate; 3, sputtering an intervention layer II on the transparent passivation layer sputtered on the glass baseplate. The single-face touch screen shadow eliminating conductive glass has excellent electromagnetic shielding, stelectrostatic protection and shadow elimination functions, and can completely replace the conventional conductive glass, and the conductive glass, with low energy consumption, high uniformity and low cost, used for manufacturing capacitive screens can be provided for downstream clients.

Owner:LUOYANG KANGYAO ELECTRONICS

Film electrode, preparation method and application thereof

PendingCN113808781AGood shadow removal effectSimple processConductive layers on insulating-supportsApparatus for heat treatmentPhysicsThin membrane

The invention provides a film electrode, which comprises a base layer, wherein an electrode layer is arranged on the surface of the base layer and is divided into a conductive area and an insulating area, nanometer metal wires are distributed in the electrode layer, the surfaces of the nanometer metal wires are coated with an insulating glue, and in the electrode layer corresponding to the conductive area, a gap between the nanometal wires is also filled with a nano silicon oxide doped with metal ions. The invention also provides a preparation method and application of the film electrode. The film electrode provided by the invention is simple in process, low in cost and good in conductive pattern shadow elimination effect. The preparation method of the film electrode provided by the invention is simple, high in production efficiency and high in yield. According to the invention, the appearance of the conductive area and the appearance of the non-conductive area in the film electrode are almost the same; and when the film electrode is applied to a touch screen and a display screen, the shadow eliminating effect is good, the anti-aging performance is good, the b value is low, and the display effect of the display screen can be improved.

Owner:湖南兴威新材料有限公司

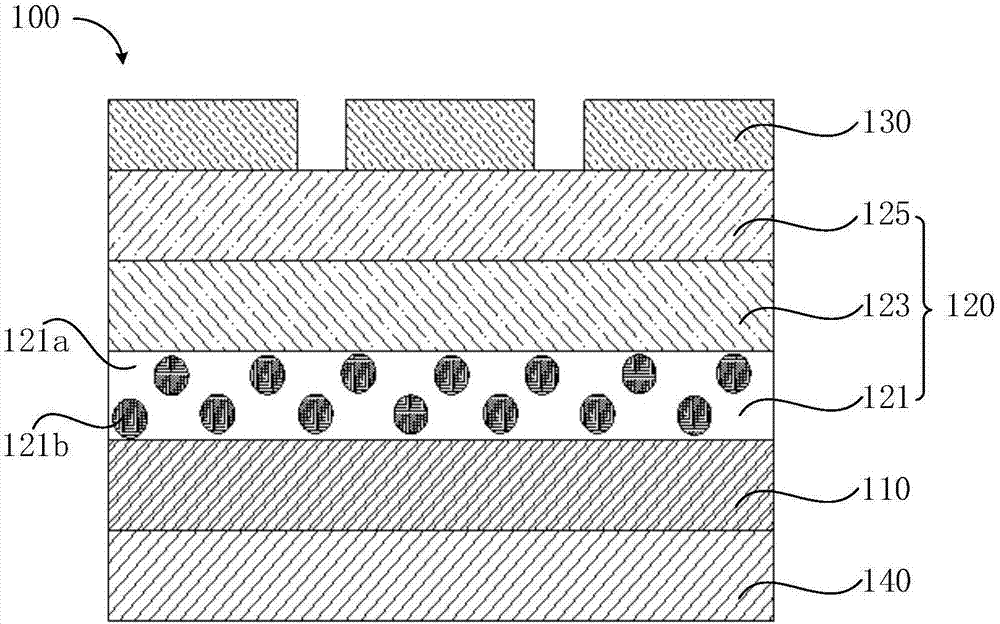

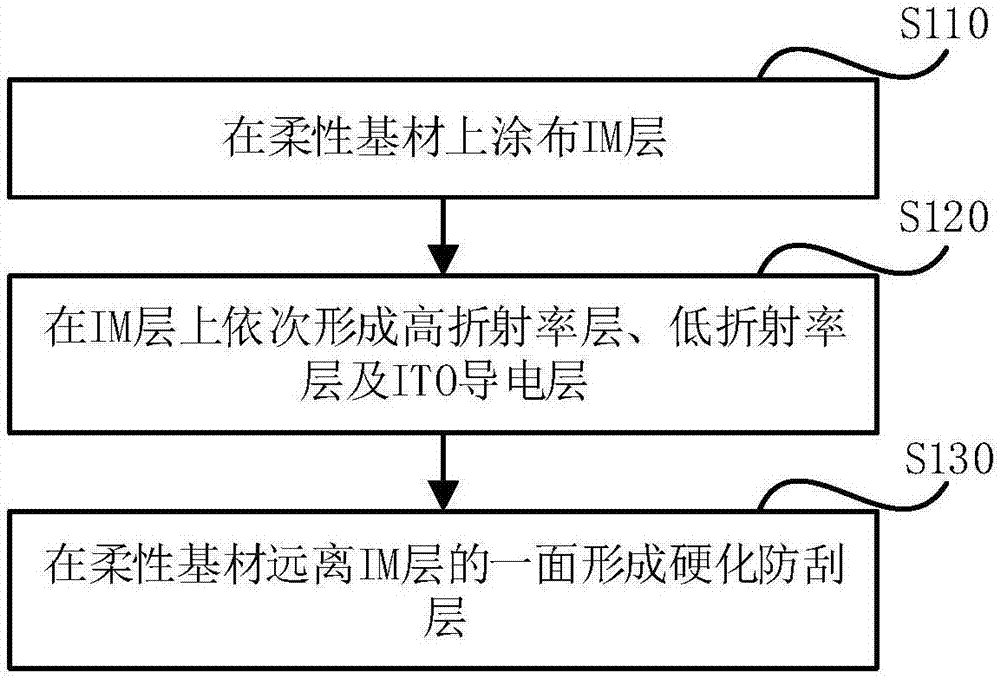

Flexible conducting film and preparing method thereof

PendingCN107170509AWide applicabilityGood shadow removal effectConductive layers on insulating-supportsSynthetic resin layered productsElectrical resistance and conductanceRefractive index

The invention relates to a flexible conducting film and a preparation method thereof. The flexible conducting film includes a flexible base material, a refraction composite layer and an ITO conducting layer which are successively laminated. The refraction composite layer is composed of an IM layer, a high refraction rate layer and a lower refraction rate layer which are successively laminated. The flexible base material is selected from at least one of the PET, COP, COC, PC and TAC. The IM layer includes an organic resin coating and high refraction rate particles, has a thickness of 0.8[mu]m-3[mu]m or 35nm-42nm. The high refraction rate layer material is selected from at least one of Nb205, Ti02 and Si3N4, and has a thickness of 3.5nm-24nm. The low refraction rate layer material is selected from at least one of the SiO2 and SiOxNy, and has a thickness of 7nm-38nm. The ITO conducting layer is subject to aging processing and obtains a square resistance of 45[omega]-50[omega]. The flexible conducting film defines the material and the thickness of the IM layer, the high refraction rate layer and the lower refraction rate layer, such that the ITO conducting layer obtains a square resistance of 45[omega]-50[omega] after being subject to aging processing. The flexible conducting film has better disapparate effects.

Owner:CSG HOLDING +1

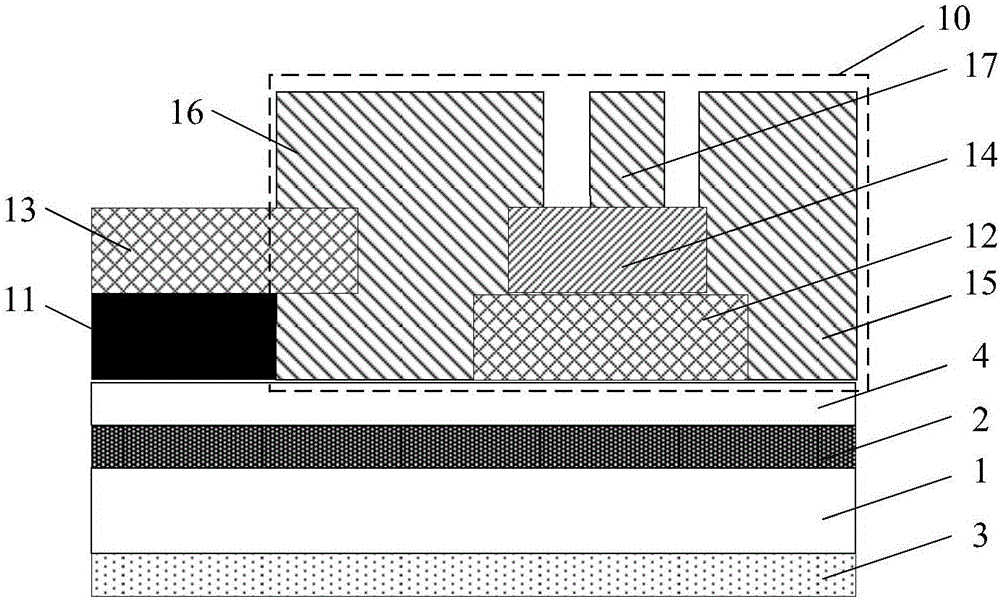

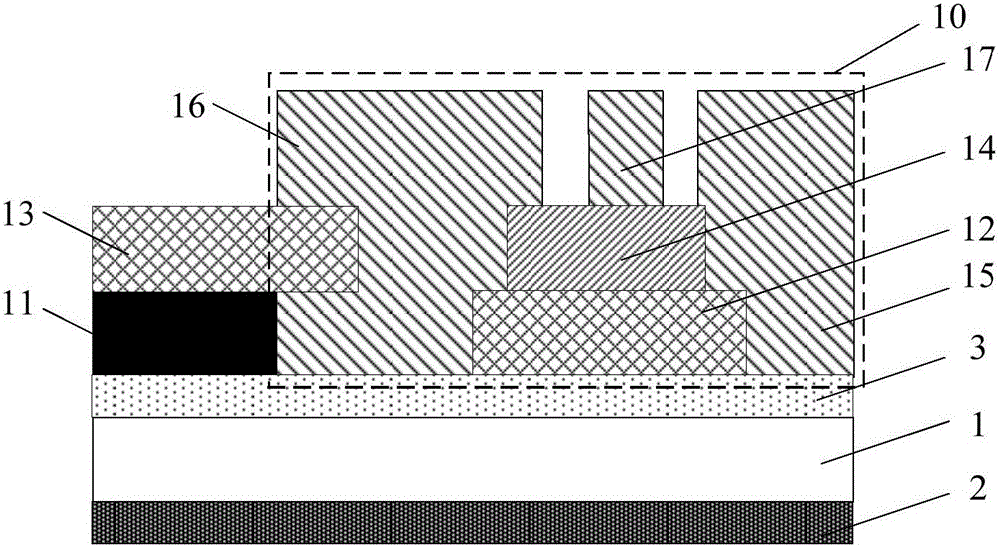

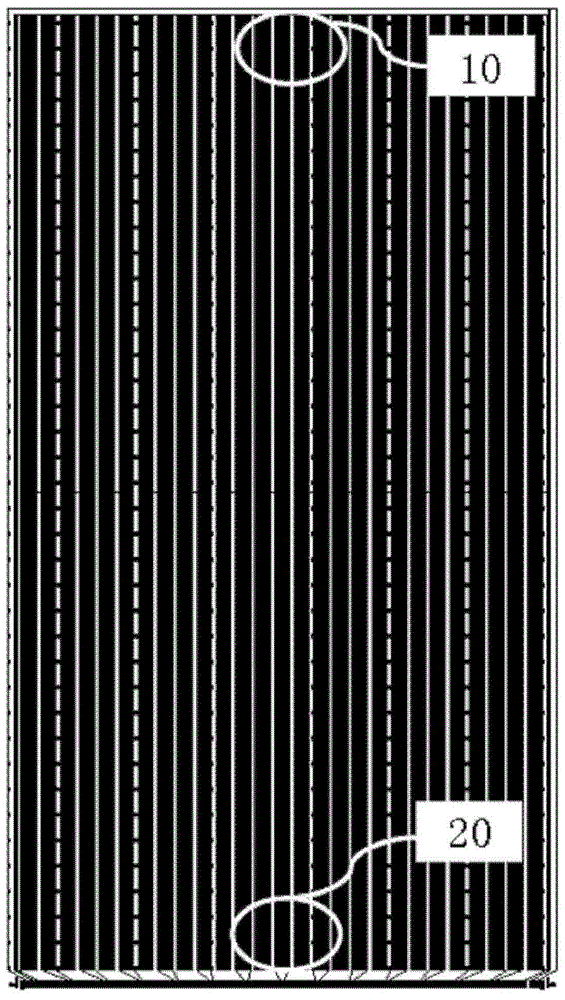

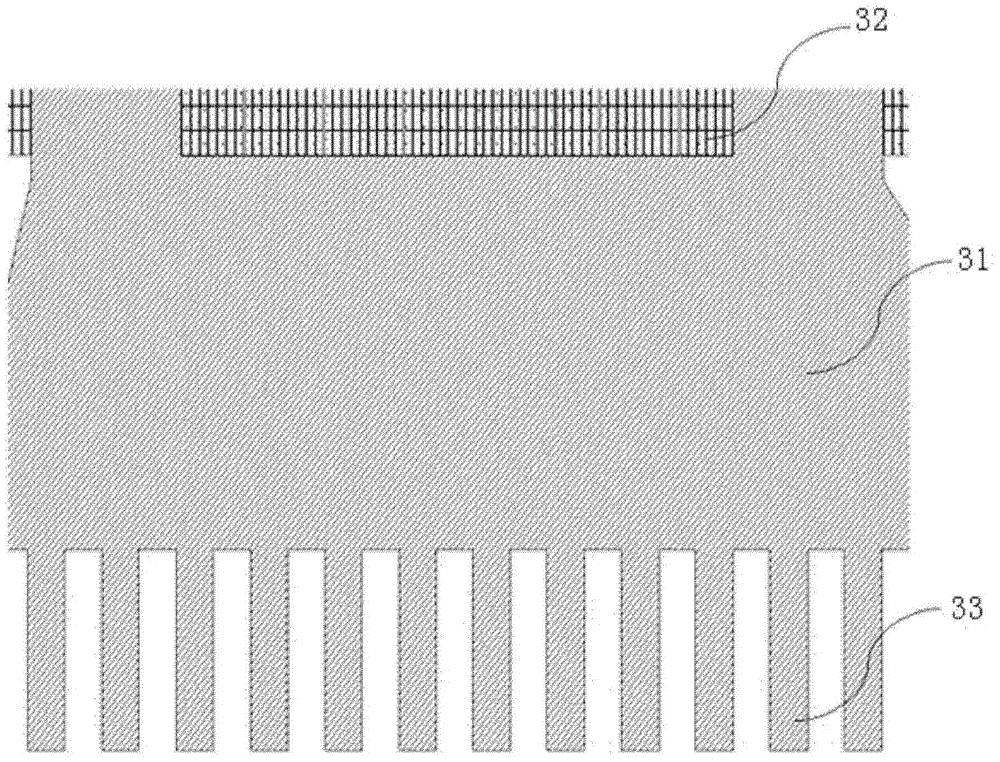

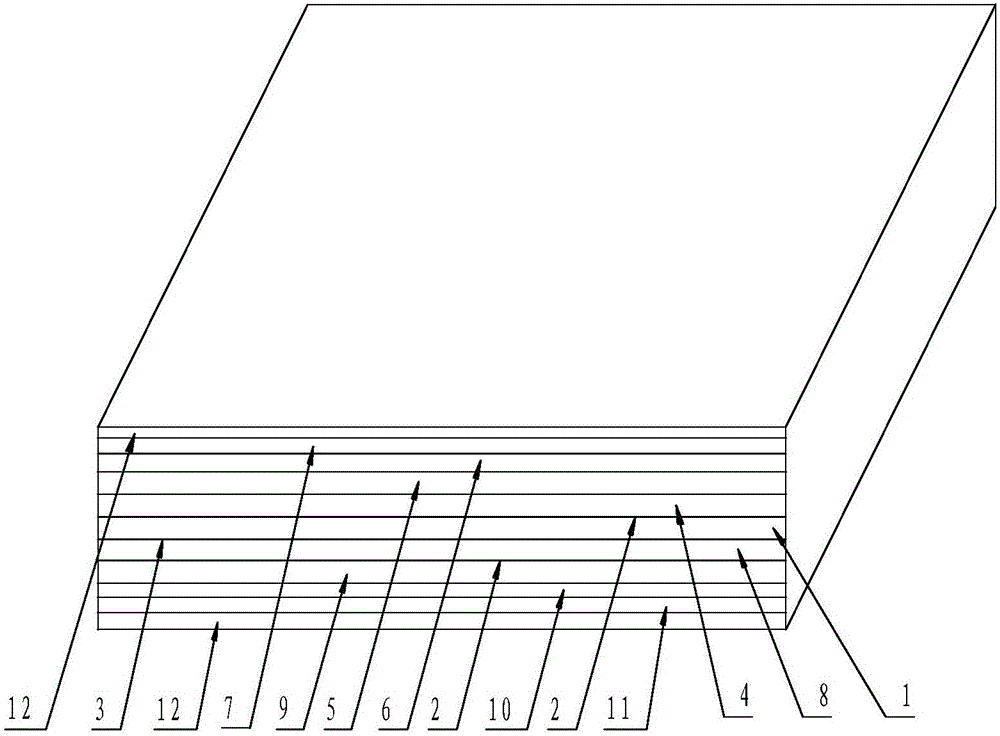

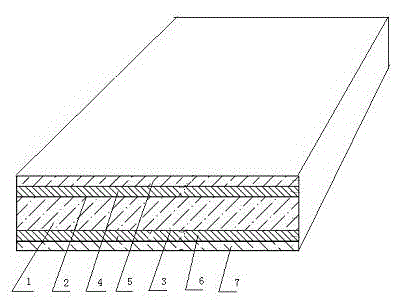

A projected capacitive screen without bridging and its manufacturing method

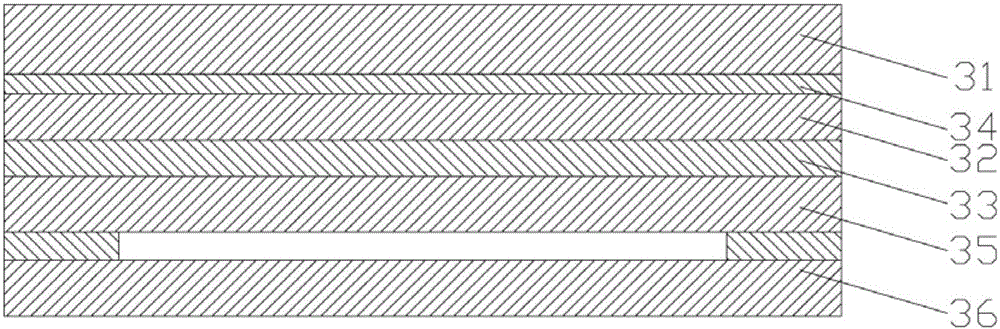

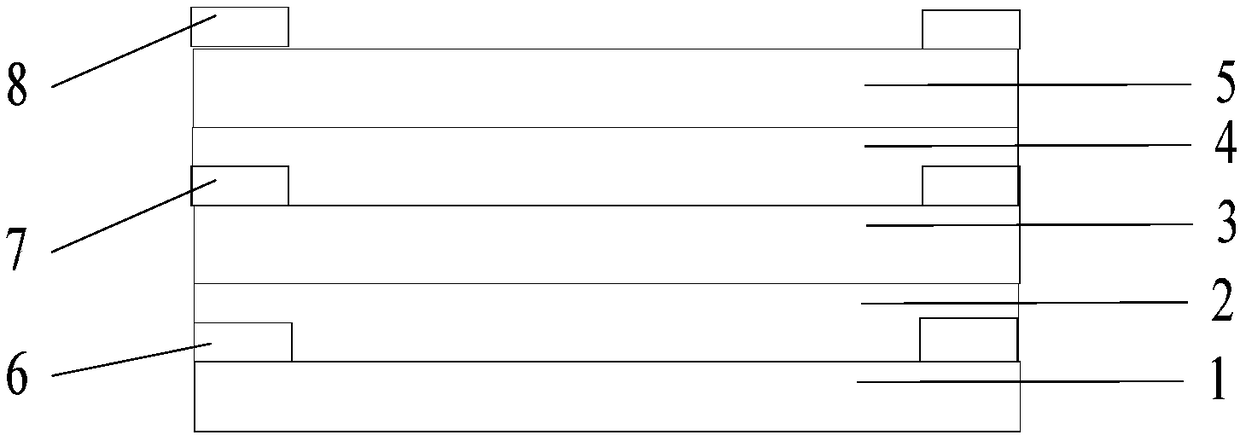

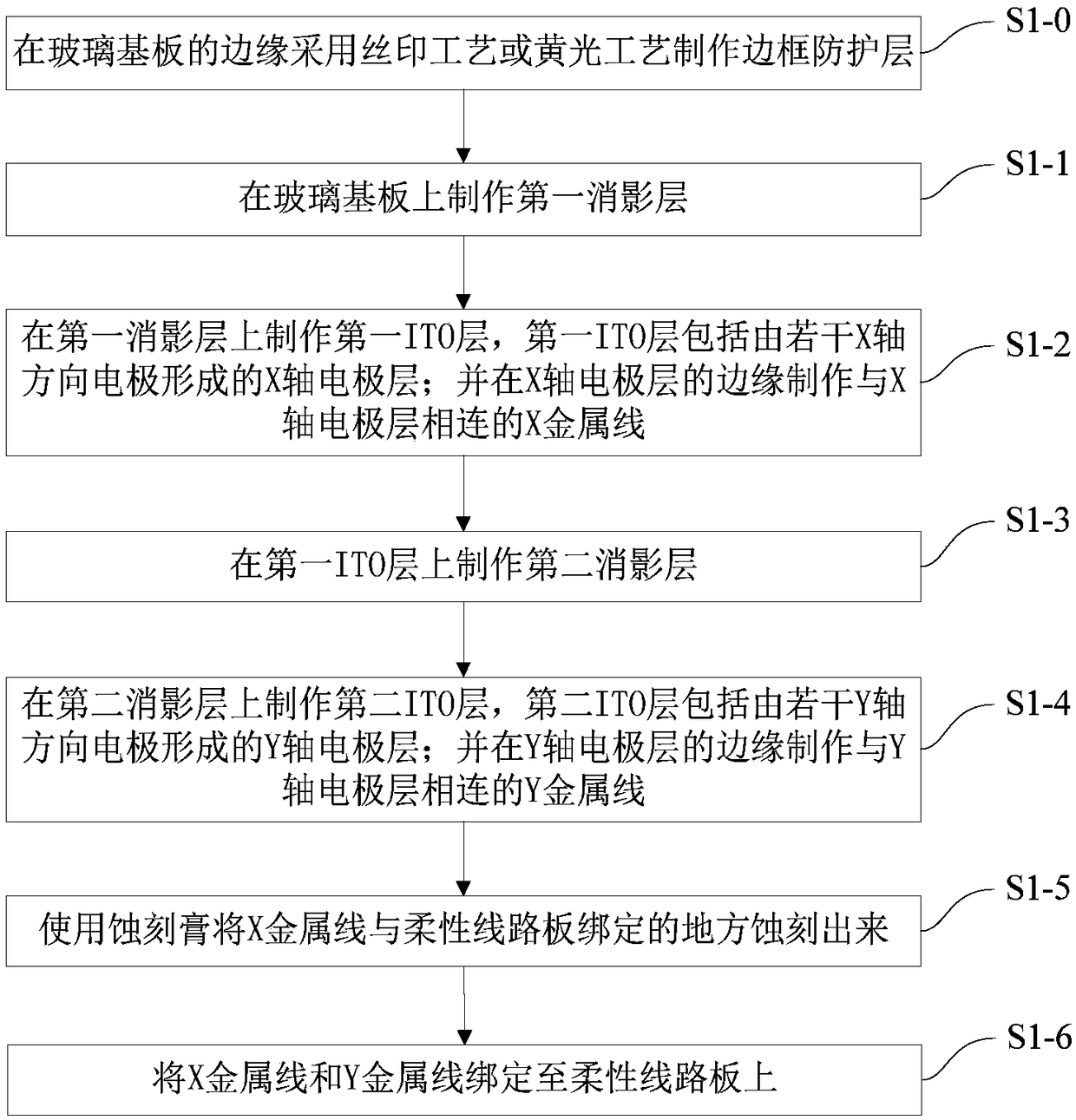

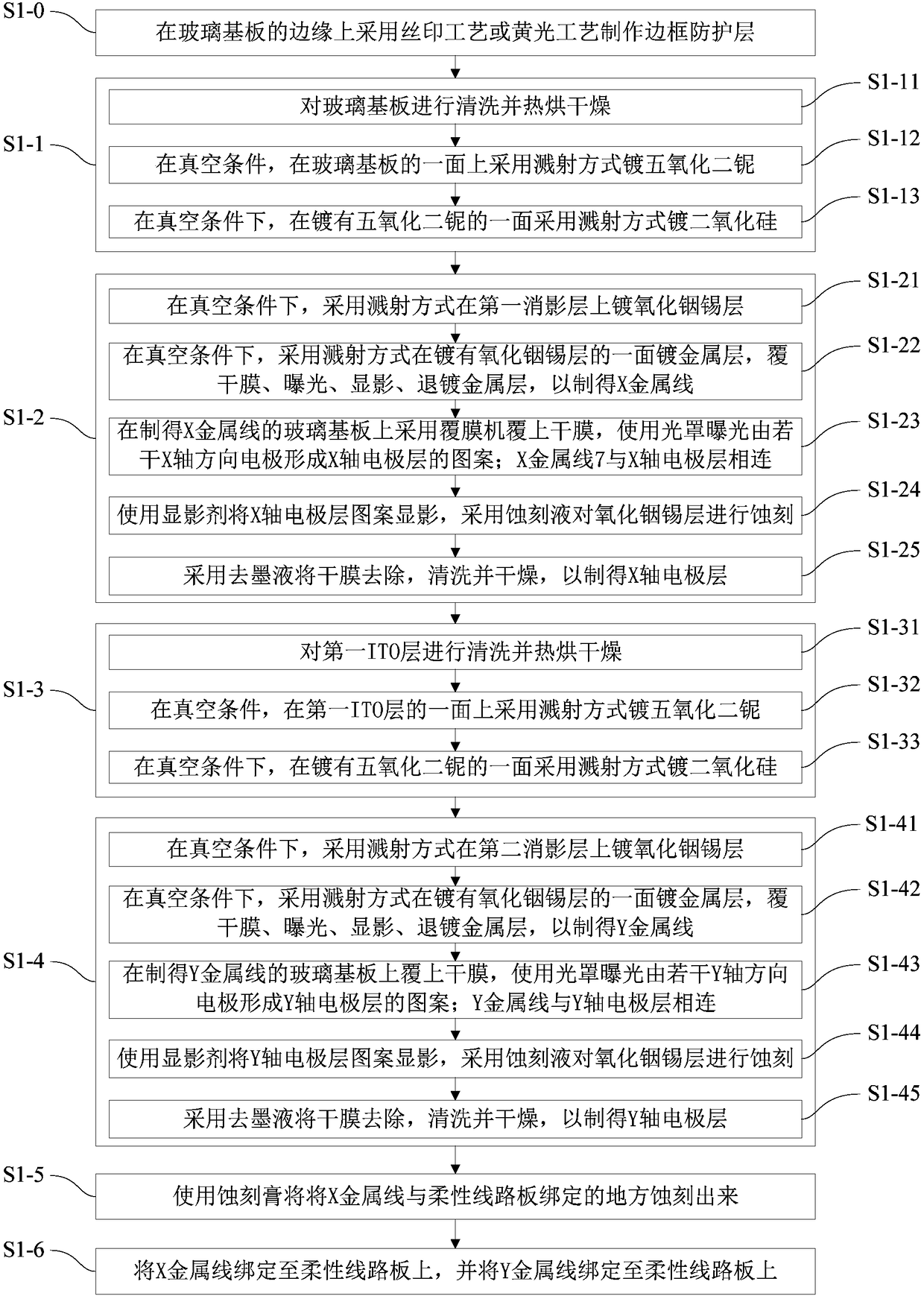

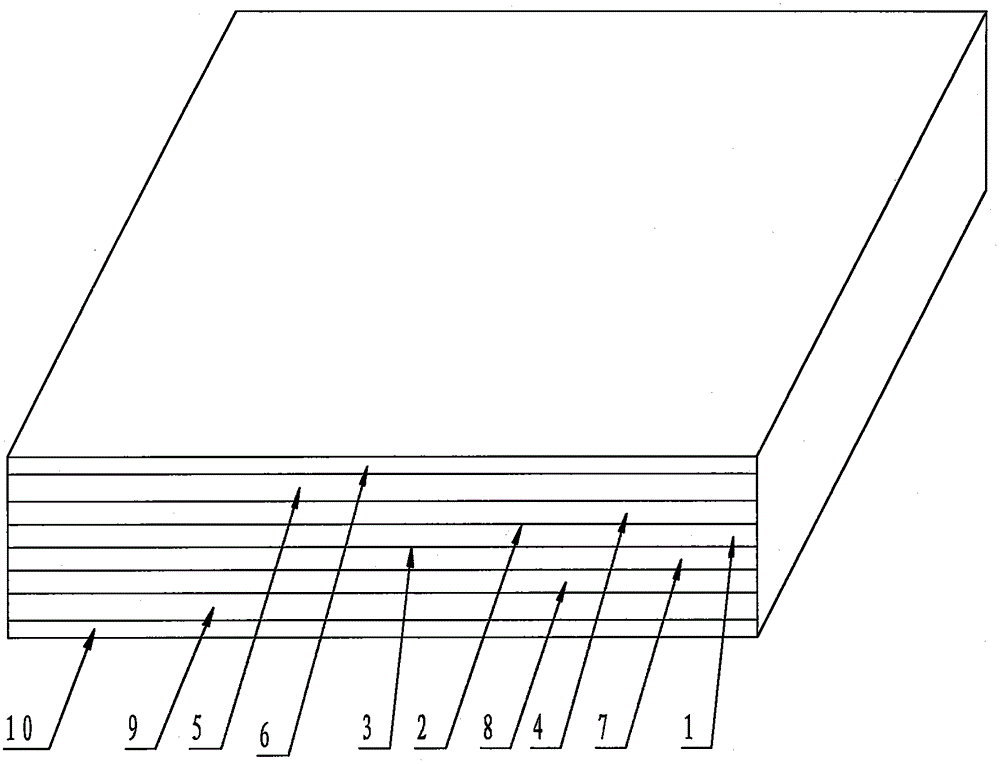

ActiveCN104049825BThin structureGood shadow removal effectInput/output processes for data processingFlexible circuitsCapacitive sensing

The invention discloses a bridging-free projection type capacitive screen and a manufacturing method of the bridging-free projection type capacitive screen. The bridging-free projection type capacitive screen comprises a glass substrate, a first shadow eliminating layer arranged on the glass substrate, a first ITO layer arranged on the first shadow eliminating layer, a second shadow eliminating layer arranged on the first ITO layer and a second ITO layer arranged on the second shadow eliminating layer. The first ITO layer comprises an X-axis electrode layer formed by a plurality of electrodes in the X-axis direction. The second ITO layer comprises a Y-axis electrode layer formed by a plurality of electrodes in the Y-axis direction. The bridging-free projection type capacitive screen further comprises metal wires X arranged on the edges of the X-axis electrode layer and metal wires Y arranged on the edges of the Y-axis electrode layer. The metal wires X and the metal wires Y are connected with a flexible circuit board respectively. The bridging-free projection type capacitive screen is light and thin in structure, good in shadow eliminating effect and beneficial for saving manufacturing processes since the bridging process is not needed in the manufacturing process.

Owner:四川点燃科技有限公司

Machining method of double-face touch screen shadow eliminating conducting glass

InactiveCN105236770AGood electromagnetic shieldingLow energy consumptionElectrically conductiveCapacitance

The invention provides a machining method of double-face touch screen shadow eliminating conducting glass. The machining method includes the steps that firstly, an upper glass substrate and a lower glass substrate are treated; secondly, a first upper interference layer, an upper transparent passivation layer, a first lower interference layer and a lower transparent passivation layer are sputtered on the upper glass substrate and the lower glass substrate; thirdly, a second upper interference layer and a second lower interference layer are sputtered on the upper transparent passivation layer and the lower transparent passivation layer sputtered on the upper glass substrate and the lower glass substrate. The good electromagnetic shielding, electrostatic protection and shadow elimination effects are achieved, existing traditional conducting glass can be completely replaced, and the conducting glass which is low in energy consumption, high in uniformity and low in cost and is used for manufacturing a capacitance screen is provided for downstream clients.

Owner:LUOYANG KANGYAO ELECTRONICS

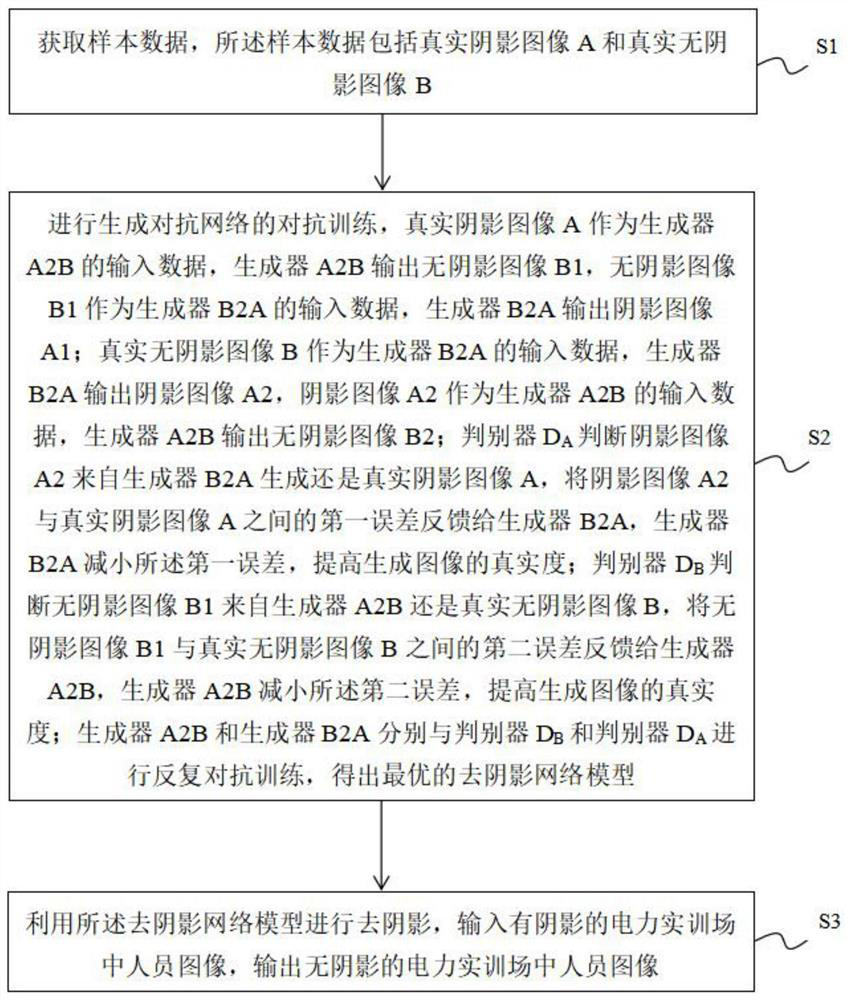

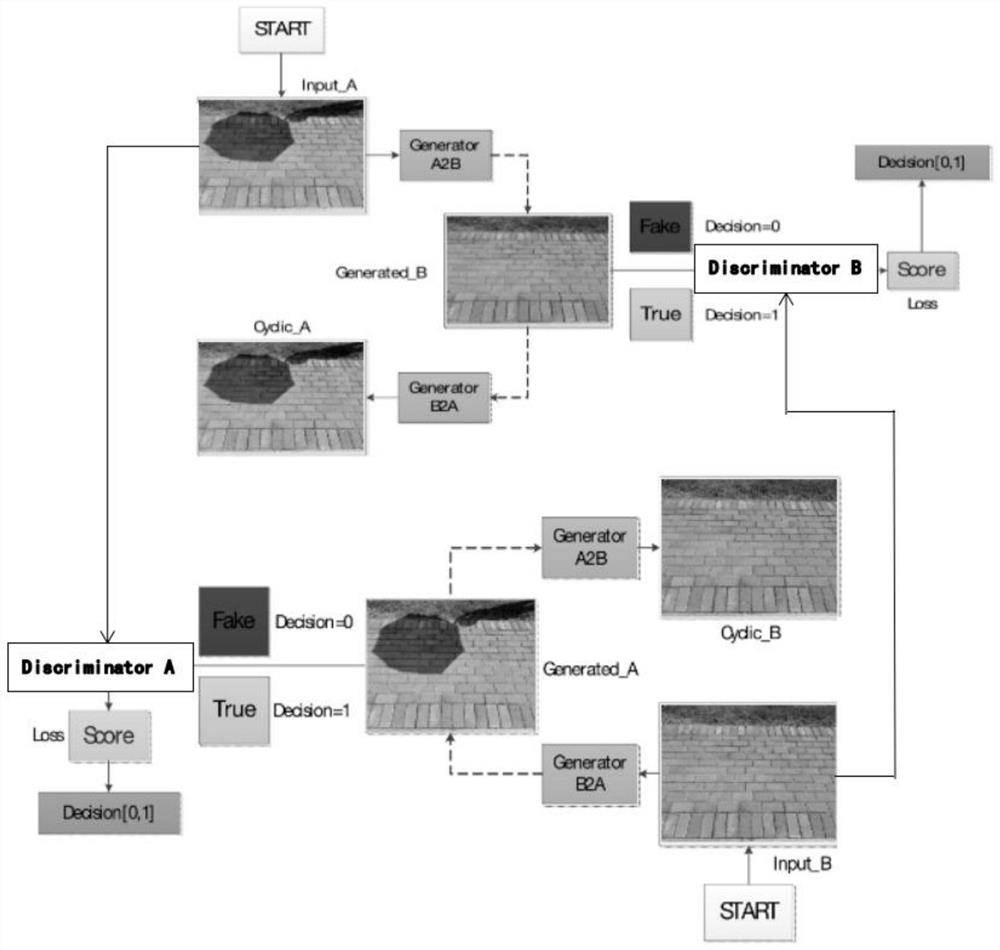

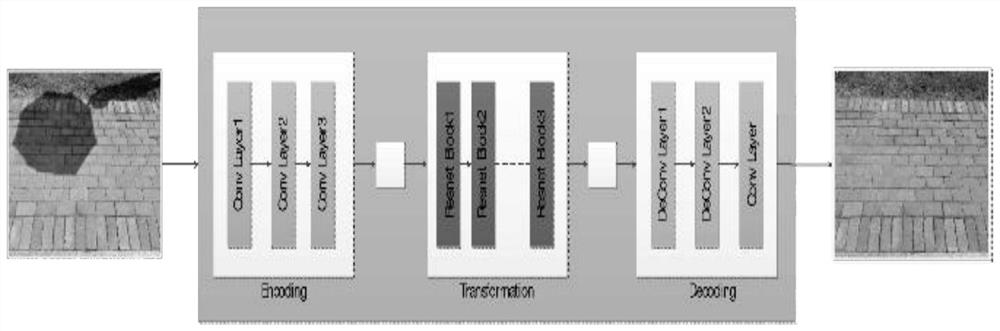

Shadow elimination method in personnel image detection in electric power practical training field

PendingCN113780298AImplement style transferAchieve eliminationCharacter and pattern recognitionNeural architecturesNetwork modelShadowings

The invention provides a shadow elimination method in personnel image detection in an electric power practical training field. The method comprises the following steps: sample data is obtained; the discriminator judges whether the shadow image is generated by the generator or a real shadow image, a first error between the shadow image and the real shadow image is fed back to the generator, and the generator reduces the first error; the discriminator judges whether the shadow-free image is from the generator or a real shadow-free image, a second error between the shadow-free image and the real shadow-free image is fed back to the generator, and the generator reduces the second error; the generator and the discriminator carry out repeated adversarial training to obtain an optimal shadow removal network model; and shadow removal is performed by using the shadow removal network model, thus inputting a shadow-containing personnel image in the electric power practical training field, and outputting a shadow-free personnel image in the electric power practical training field. Through massive training of a shadow data set, the neural network is enabled to continuously perform self-gaming in confrontation, so that style migration of a shadow image is better realized.

Owner:SHANGHAI MUNICIPAL ELECTRIC POWER CO

Colorless patterned carbon nanotube transparent conductive film and preparation method thereof

ActiveCN103280255BDoes not affect light transmissionGood shadow removal effectConductive layers on insulating-supportsCable/conductor manufactureTransmittanceElectric properties

The invention discloses a chromatism-free patterning carbon nanotube transparent conductive film and a preparation method of the chromatism-free patterning carbon nanotube transparent conductive film. The chromatism-free patterning carbon nanotube transparent conductive film comprises a transparent substrate, a patterning carbon nanotube film which is at least distributed in a visible area on the surface of the transparent substrate, and a patterning insulating material layer distributed on the surface of the transparent substrate, the insulating material layer and the carbon nanotube film are staggered and complemented at least in the visible area, and the light transmittance of the insulating material layer and the light transmittance of the carbon nanotube film are also fundamentally consistent. The preparation method includes the steps of forming the patterning insulating material layer on the surface of the transparent substrate, and forming the patterning carbon nanotube film at least in the visible area on the surface of the transparent substrate. Preferably, the insulating material layer can be mainly made of hydrophobic insulating material, and paint can be further mixed. According to the chromatism-free patterning carbon nanotube transparent conductive film and the preparation method of the chromatism-free patterning carbon nanotube transparent conductive film, high-efficiency, large-area and continual preparation of the chromatism-free patterning carbon nanotube transparent conductive film can be achieved, the technology is easy and controllable, needed equipment is simple, cost is low, optical and electric properties of products are good, and the chromatism-free patterning carbon nanotube transparent conductive film has wide application prospects.

Owner:SUZHOU HANANO MATERIALS TECH LTD

Touch substrate and preparation method thereof, and display device

ActiveCN106775167BGood shadow removal effectInput/output processes for data processingDisplay deviceRefractive index

The invention provides a touch substrate, a preparation method thereof, and a display device, which belong to the field of display technology. The touch substrate of the present invention includes a base, a plurality of touch electrode blocks arranged on the base, and a filling block is arranged between any two adjacent forests of the touch electrode blocks; wherein, the filling blocks The refractive index of the material is n 3 , the refractive index of the substrate material n 1 , the refractive index of the material of the touch electrode block is n 2 , and|n 2 ‑n 3 |<|n 2 ‑n 1 |. In the present invention, a filling block is set between each touch electrode block, and |n 2 ‑n 3 |<|n 2 ‑n 1 |, that is, the difference between the refractive index of the material of the filling block and the material of the touch electrode block is smaller than the difference of the refractive index of the material of the base material and the touch electrode block, and because the refractive index of the material determines its reflectivity, the filling The reflectivity of the block material is not much different from that of the touch electrode block. Therefore, the touch control substrate in the present invention has a better shadow elimination effect.

Owner:BOE TECH GRP CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com