Method for processing single-face touch screen shadow eliminating conductive glass

A technology of conductive glass and processing method, applied in electrical digital data processing, input/output process of data processing, instruments, etc., can solve problems affecting electromagnetic shielding, electrostatic protection function, viewing pattern effect, etc., and achieve high uniformity, Good electromagnetic shielding, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

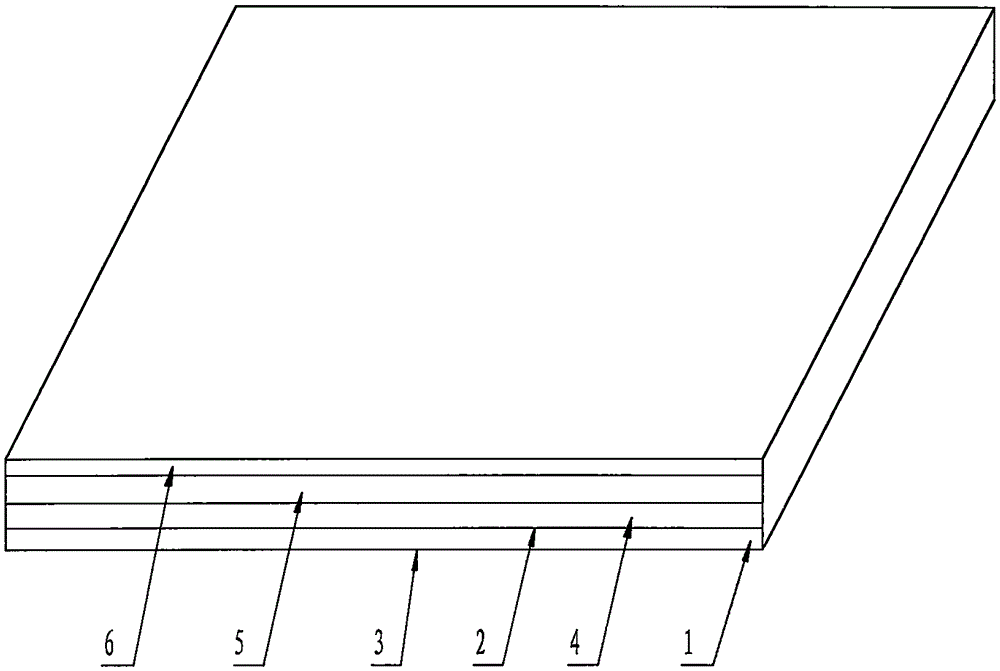

[0027] The two surfaces of the glass substrate 1 are a tin surface 2 and an air surface 3, respectively, an interference layer 4 is provided on the tin surface 2 of the glass substrate 1, and a transparent passivation layer 5 is provided between the interference layer 4 and the interference layer 6;

[0028] The transparent passivation layer 5 is made of transparent silicon dioxide or transparent silicon oxynitride;

[0029] The interference layer one 4 and the interference layer two 6 both use niobium pentoxide.

Embodiment 2

[0031] In the first step, the glass substrate 1 is processed,

[0032] A. Cut the glass substrate 1, X cut first, then Y cut, and then break the pieces;

[0033] B. Grinding and chamfering the cut glass substrate 1, first X grinding, then chamfering, rotating 90° and then Y grinding and chamfering;

[0034] C. Brush and blow dry;

[0035] D. Polish the glass substrate 1 after edge grinding and chamfering;

[0036] E. Brush and blow dry again;

[0037] The second step is to sputter the interference layer 4 and the transparent passivation layer 5 on the glass substrate 1;

[0038] A. Heating the glass substrate 1 after polishing, scrubbing and drying; the heating temperature used is 150-280 degrees Celsius;

[0039] B. Use magnetron sputtering vacuum coating equipment to sputter the interference layer 4 on the tin surface 2 of the heated glass substrate 1. The interference layer 4 is niobium pentoxide, and the transparent passivation layer is sputtered on the interference layer 4 5. The tra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com