Single-face shadow eliminating conductive glass and processing method thereof

A conductive glass and processing method technology, applied in the direction of chemical instruments and methods, glass/slag layered products, electronic equipment, etc., can solve the problems of viewing patterns, affecting electromagnetic shielding, electrostatic protection functions, etc., to achieve simple structure and low cost Low, good electromagnetic shielding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described below in conjunction with specific embodiments.

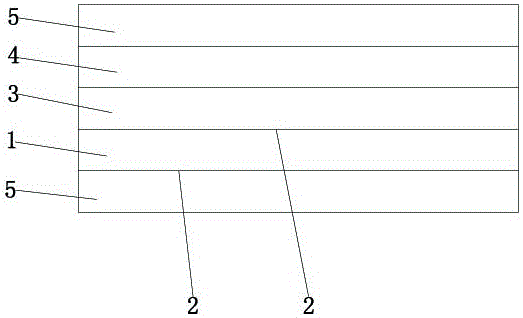

[0023] Such as figure 1 As shown, a single-sided shadow-eliminating conductive glass includes a glass substrate 1, a tin surface 2, an interference layer 3, a transparent passivation layer 4, and an ITO film 5. The upper and lower surfaces of the glass substrate 1 are provided with a tin surface 2, and the glass substrate 1 An interference layer 3 is provided above the tin surface 2 on the upper surface, a transparent passivation layer 4 is provided above the interference layer 3, an ITO mold 5 is provided above the transparent passivation layer 4, and an ITO mold 5 is provided below the tin surface 2 on the lower surface of the glass substrate 1. Film 5.

[0024] As preferred in this embodiment, the interference layer 3 is titanium dioxide.

[0025] As preferred in this embodiment, the transparent passivation layer 4 is silicon dioxide.

[0026] Furthermore, preferably in this ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com