Flexible conducting film and preparing method thereof

A technology of flexible conductive and conductive layers, which is applied to equipment for manufacturing conductive/semiconductive layers, chemical instruments and methods, cable/conductor manufacturing, etc. It can solve the problems of poor shadow elimination effect and achieve good shadow elimination effect , wide applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

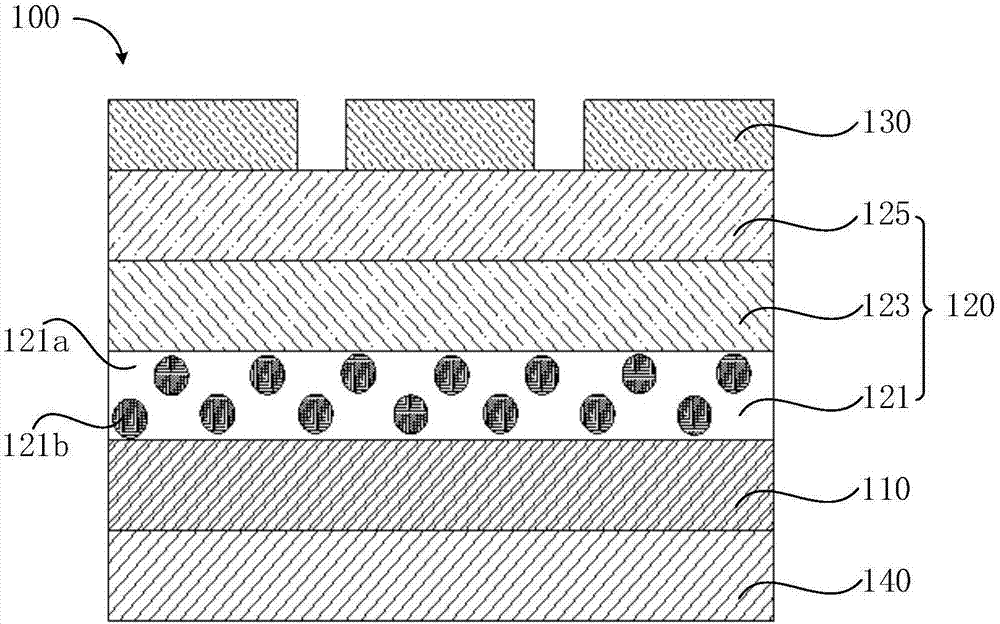

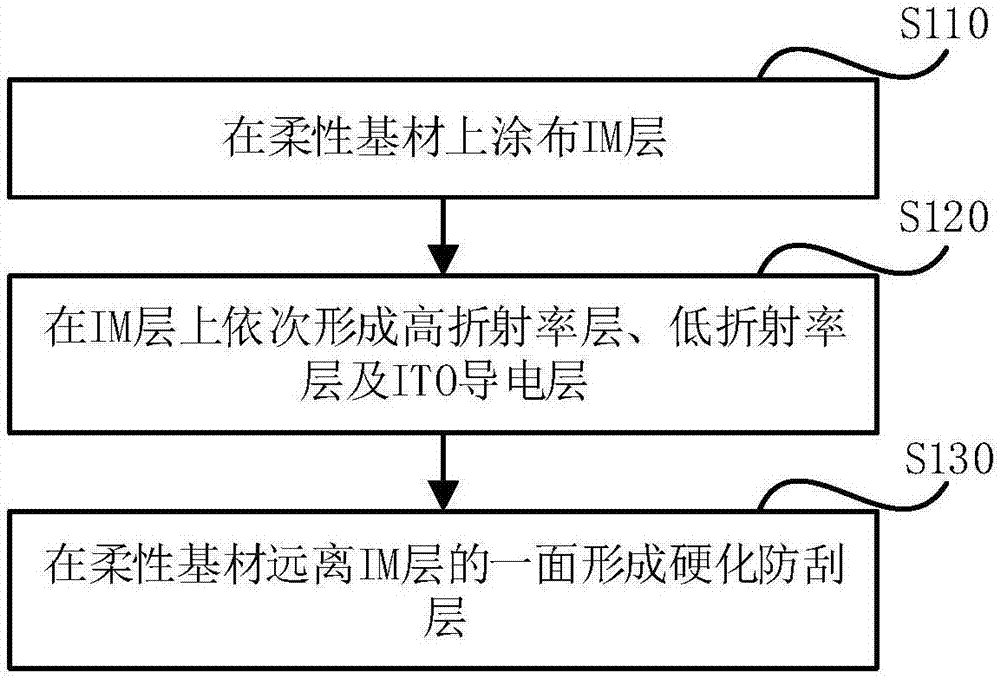

[0054] see figure 2 , the preparation method of the flexible conductive film of an embodiment comprises the following steps:

[0055] S110, coating the IM layer on the flexible substrate.

[0056] In one embodiment, the IM layer is coated on the flexible substrate by wet coating.

[0057] In one embodiment, the flexible substrate is sheet-shaped; the thickness of the flexible substrate is 50 μm˜125 μm. Preferably, the thickness of the flexible substrate 110 is 50 μm, 100 μm or 125 μm.

[0058] In one of the embodiments, the material of the flexible substrate is selected from polyethylene terephthalate (PET), cycloolefin polymer (COP), cycloolefin copolymer (COC), polycarbonate (PC) and At least one of cellulose triacetate (TAC).

[0059] In one embodiment, the thickness of the IM layer is 0.8 μm˜3 μm or 35 nm˜42 nm. In one of the embodiments, when the thickness of the IM layer is 0.8 μm to 3 μm, the IM layer also has the function of a hardening layer, which can improve t...

Embodiment 1

[0079] An optical-grade PET film with a thickness of 125 μm is selected as the flexible substrate; the IM layer is coated on the flexible substrate by wet coating, and the IM layer contains ZrO 2 Epoxy acrylate coating of high refractive index particles, the thickness of the IM layer is 1.0 μm, and the refractive index of the IM layer is 1.62; then a high refractive index layer is formed on the IM layer by magnetron sputtering, and the high refractive index layer TiO 2 layer, the thickness of the high refractive index layer is 6.5nm, and the refractive index of the high refractive index layer is 2.6; then a low refractive index layer is formed on the high refractive index layer by magnetron sputtering, and the low refractive index layer is SiO 2 layer, the thickness of the low refractive index layer is 30nm, and the refractive index of the low refractive index layer is 1.46; then on the low refractive index layer, an ITO conductive layer is formed by magnetron sputtering, the ...

Embodiment 2

[0081] An optical-grade TAC film with a thickness of 125 μm is selected as the flexible substrate; the IM layer is coated on the flexible substrate by wet coating, and the IM layer contains ZrO 2 Polyurethane acrylate coating of high refractive index particles, the thickness of the IM layer is 1.0 μm, and the refractive index of the IM layer is 1.67; then a high refractive index layer is formed on the IM layer by magnetron sputtering, and the high refractive index layer is Si 3 N 4 layer, the thickness of the high refractive index layer is 23nm, and the refractive index of the high refractive index layer is 1.9; then a low refractive index layer is formed on the high refractive index layer by magnetron sputtering, and the low refractive index layer is SiO 2 layer, the thickness of the low refractive index layer is 18nm, and the refractive index of the low refractive index layer is 1.46; then on the low refractive index layer, an ITO conductive layer is formed by magnetron spu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com