Blackening liquid medicine for metal meshes, blackening method of metal meshes, metal meshes and touch screen

A metal mesh and blackening technology, applied in metal material coating process, input/output process of data processing, instruments, etc., can solve problems such as reducing reflectivity and brightness, affecting metal conductivity, and general fading effect. , to achieve the effect of reducing brightness and reflectivity, good shadow removal effect, and stable blackening effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0114] A blackening medicinal solution, which is composed of the following components in mass percentage: 2% of selenous acid, 4.5% of sodium persulfate, 0.1% of copper sulfate, 0.1% of sodium gluconate and 93.3% of water.

[0115] The method for blackening the copper metal grid with the above-mentioned blackening liquid comprises the following steps:

[0116] (1) Soak the copper metal grid in the above-mentioned blackening liquid at a temperature of 15°C for 60s;

[0117] (2) Wash the metal grid with water after soaking, the washing temperature is 30°C, and the washing time is 60s;

[0118] (3) Dry the washed metal grid at a drying temperature of 65° C. and a drying time of 4 minutes.

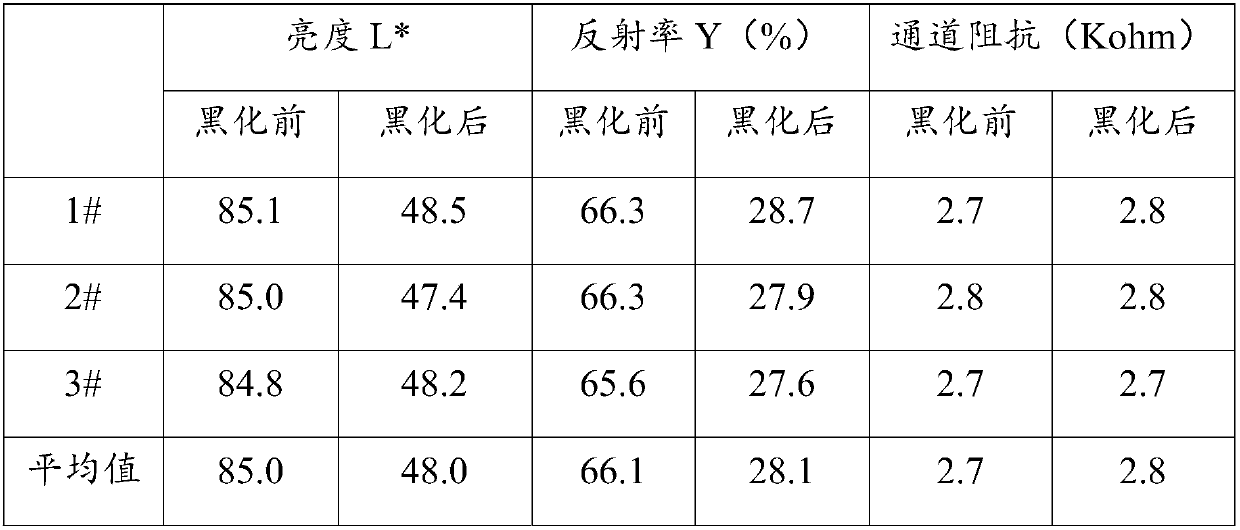

[0119] The brightness L*, reflectance Y value and channel impedance of the entire metal before and after blackening are shown in Table 1 below.

[0120] Table 1 Example 1 The brightness and conductivity of the entire metal before and after blackening

[0121]

Embodiment 2

[0123] A blackening medicinal liquid, which is composed of the following components in mass percentage: 0.2% of selenous acid, 1% of sodium persulfate, 0.2% of copper sulfate, 0.2% of sodium gluconate and 98.4% of water.

[0124] The method for blackening the copper metal grid with the above-mentioned blackening liquid comprises the following steps:

[0125] (1) Soak the copper metal grid in the above-mentioned blackening liquid at a temperature of 35°C for 5s;

[0126] (2) Wash the metal grid with water after soaking, the washing temperature is 40°C, and the washing time is 30s;

[0127] (3) Dry the washed metal grid at a drying temperature of 55° C. and a drying time of 6 minutes.

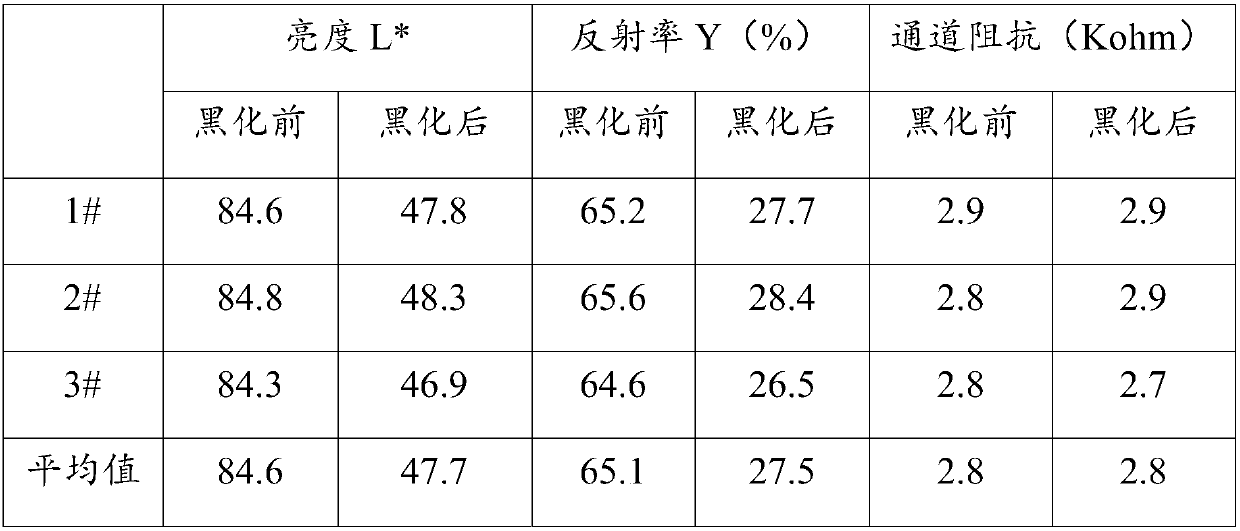

[0128] The brightness L*, reflectance Y value and channel impedance of the entire metal before and after blackening are shown in Table 2 below.

[0129] Table 2 Example 2 The brightness and conductivity of the entire metal before and after blackening

[0130]

Embodiment 3

[0132] A blackening medicinal liquid, which is composed of the following components in mass percentage: 0.05% of selenous acid, 0.1% of sodium persulfate, 1% of copper sulfate, 0.01% of sodium gluconate and 98.84% of water.

[0133] The method for blackening the copper metal grid with the above-mentioned blackening liquid comprises the following steps:

[0134] (1) Soak the copper metal grid in the above-mentioned blackening liquid at a temperature of 25°C for 30s;

[0135] (2) Wash the metal grid with water after soaking, the washing temperature is 35°C, and the washing time is 45s;

[0136] (3) Dry the washed metal grid at a drying temperature of 60° C. and a drying time of 5 minutes.

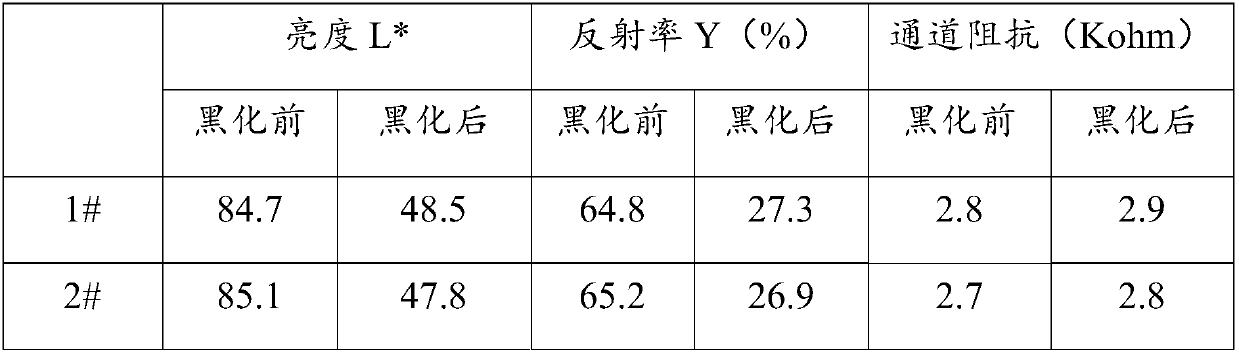

[0137] The brightness L*, reflectance Y value and channel impedance of the entire metal before and after blackening are shown in Table 3 below.

[0138] Table 3 Example 3 The brightness and conductivity of the entire metal before and after blackening

[0139]

[0140]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com