ITO conducting glass and preparation method thereof

A conductive glass and glass technology, applied in the input/output process of electrical digital data processing, instruments, and data processing, etc., can solve the problems of ITO film peeling, affecting product touch function, ITO adhesion, and compactness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

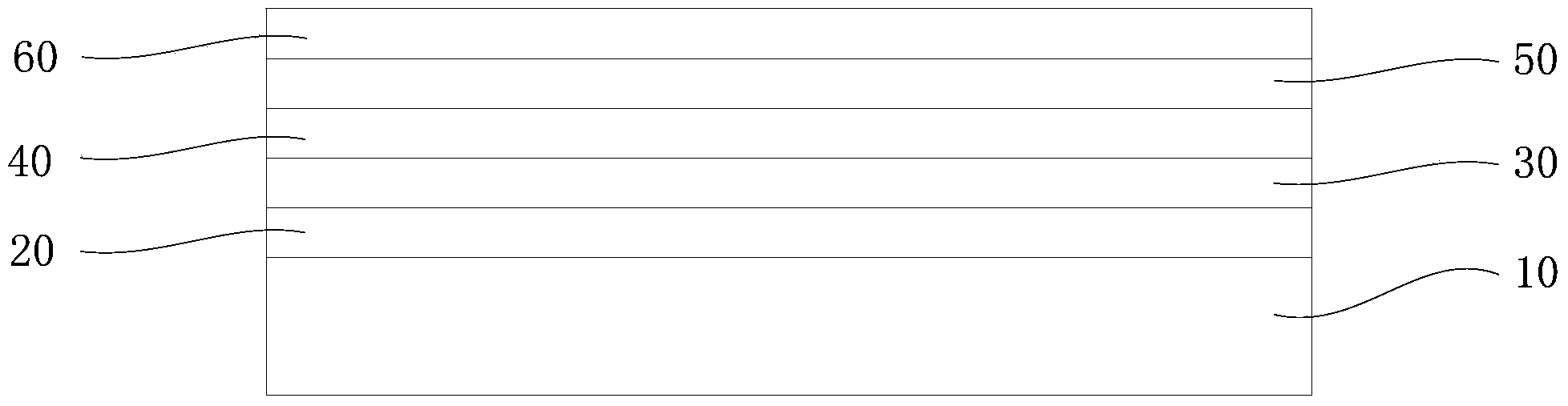

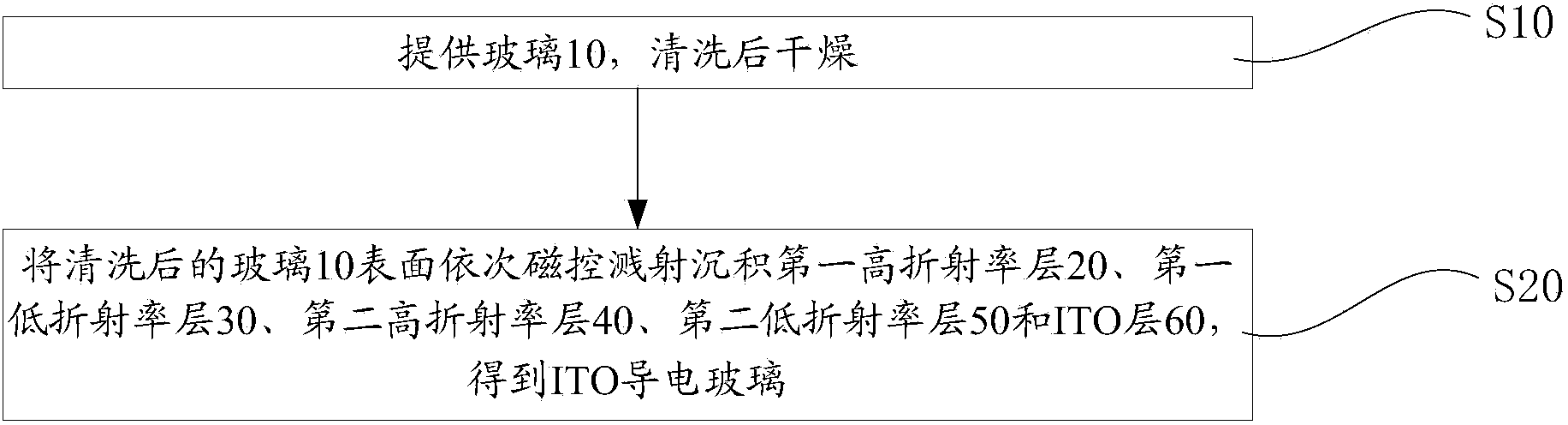

[0049] Such as figure 2 The preparation method of above-mentioned ITO conductive glass shown, comprises the steps:

[0050] S10, providing the glass 10, washing and drying.

[0051] The glass 10 can be selected from float glass or other conventional glass in this field.

[0052] S20, sequentially depositing the first high refractive index layer 20, the first low refractive index layer 30, the second high refractive index layer 40, the second low refractive index layer 50 and the ITO layer 60 by magnetron sputtering on the surface of the cleaned glass 10 , to obtain ITO conductive glass.

[0053] The material of the first high refractive index layer 20 is TiO 2 , ZrO 2 or Si 3 N 4 . TiO 2 The refractive index of 2.3, ZrO 2 The refractive index of 2.17, Si 3 N 4 The refractive index is 2.0. Using TiO 2 , ZrO 2 or Si 3 N 4 As the material of the first high refractive index layer 20 , the transmittance of the first high refractive index layer 20 is relatively low....

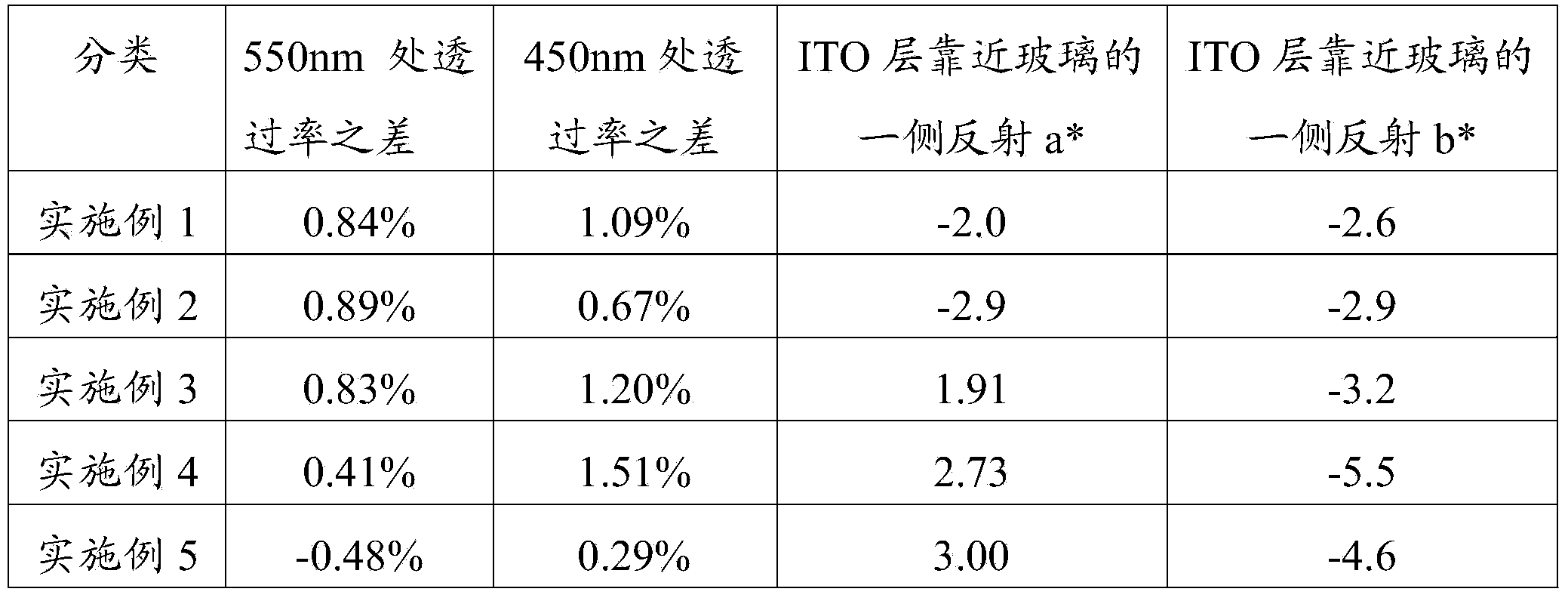

Embodiment 1

[0071] The float glass is washed and dried.

[0072] The working pressure is 2×10 -3 Under the condition of mbar, on the surface of float glass, the thickness is sequentially deposited as TiO 2 layer, thickness is SiO 2 layer, thickness is TiO2 layer, thickness is SiO 2 layers and thicknesses are The ITO layer, to obtain the required ITO conductive glass.

Embodiment 2

[0074] The float glass is washed and dried.

[0075] The working pressure is 3×10 -3 Under the condition of mbar, on the surface of float glass, the thickness is sequentially deposited as TiO 2 layer, thickness is SiO 2 layer, thickness is TiO 2 layer, thickness is SiO 2 layers and thicknesses are The ITO layer, to obtain the required ITO conductive glass.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com