Antireflection conductive film with matched refractive index and preparation method thereof

A refractive index matching and anti-reflection technology, which is applied in the field of refractive index matching anti-reflection conductive film and its preparation, can solve problems such as not being used, and achieve high hardness of the film layer, good repeatability of industrial production, film hardness and wear resistance Eclipse effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

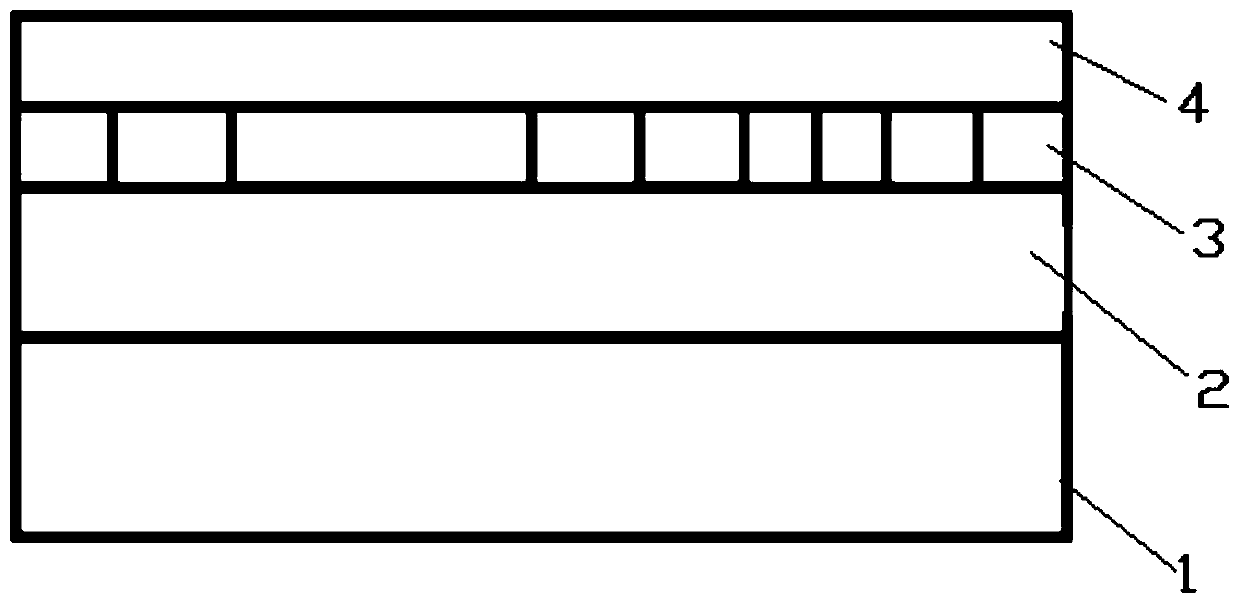

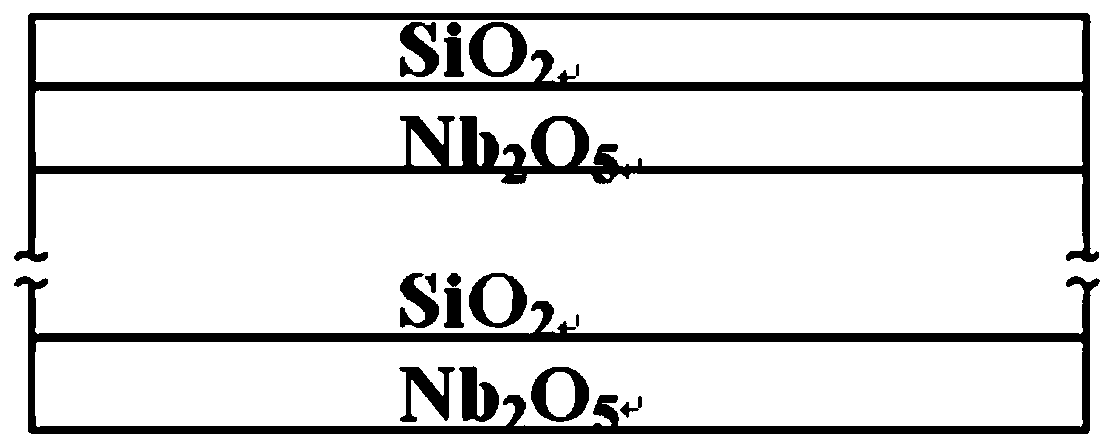

[0046] The anti-reflection layer in the designed film system is a three-layer film, specifically: quartz glass substrate, Nb 2 o 5 Film layer 10nm, SiO 2 Film layer 33nm, Nb 2 o 5 The film layer is 3nm, the ITO film layer is 20nm, and the diamond film layer is 102nm.

[0047] Preparation of Nb 2 o 5 : RF magnetron sputtering or intermediate frequency magnetron sputtering. In RF magnetron sputtering, the sputtering target uses Nb 2 o 5 Target, substrate temperature is room temperature, sample preparation is carried out in a mixed gas with oxygen partial pressure / total pressure of 1~40%, background pressure before sputtering is 2.0×10 -3 Pa, the oxygen-argon ratio is 1 / 10, the sputtering pressure is 0.67Pa, and the sputtering power is 200W. In intermediate frequency magnetron sputtering, the sputtering target is Nb target, the substrate temperature is 150°C, the sample preparation is carried out in a mixed gas with oxygen partial pressure / total pressure of 1~40%, and...

Embodiment 2

[0053] The anti-reflection layer in the designed film system is four-layer film, specifically: quartz glass substrate, Nb 2 o 5 Film layer 6nm, SiO 2 Film layer 50nm, Nb 2 o 5 Film layer 14nm, SiO 2 The film layer is 24nm, the ITO film layer is 20nm, and the diamond film layer is 106nm.

[0054] The preparation method is the same as in Example 1.

Embodiment 3

[0056] The anti-reflection layer in the designed film system is a four-layer film, and the thickness of the diamond layer is increased on the basis of Example 2, specifically: quartz glass substrate, Nb 2 o 5 Film layer 7nm, SiO 2 Film layer 51nm, Nb 2 o 5 Film layer 15nm, SiO 2 The film layer is 23nm, the ITO film layer is 20nm, and the diamond film layer is 130nm.

[0057] The preparation method is the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com