Touch screen and touch display panel

A touch display panel and display panel technology, applied in the direction of instruments, electrical digital data processing, data processing input/output process, etc., can solve the problems of poor disappearing effect, easy peeling, affecting OGS touch function, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

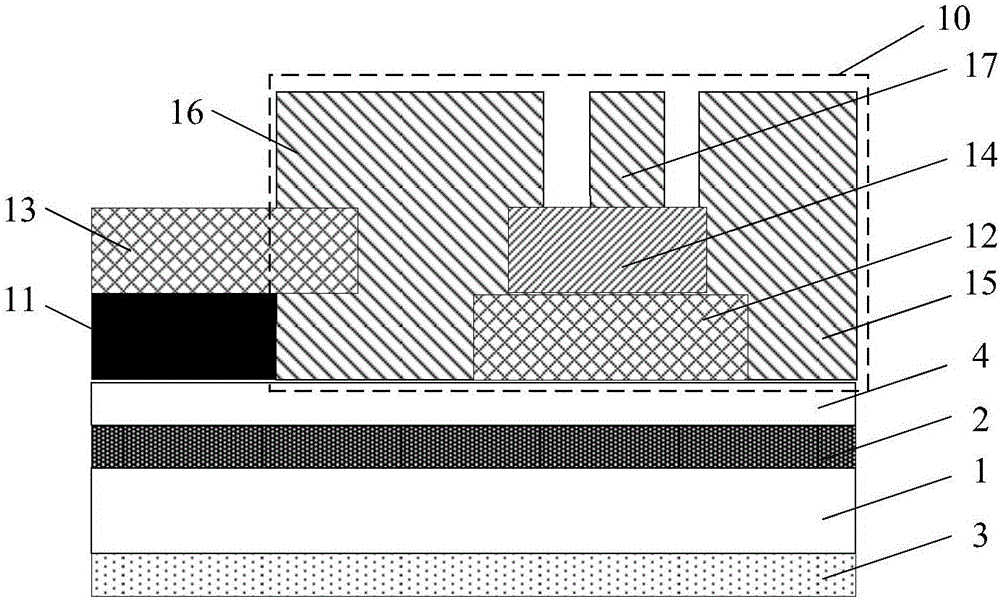

[0031] This embodiment provides a touch screen, which has good anti-shadow effect and good appearance effect.

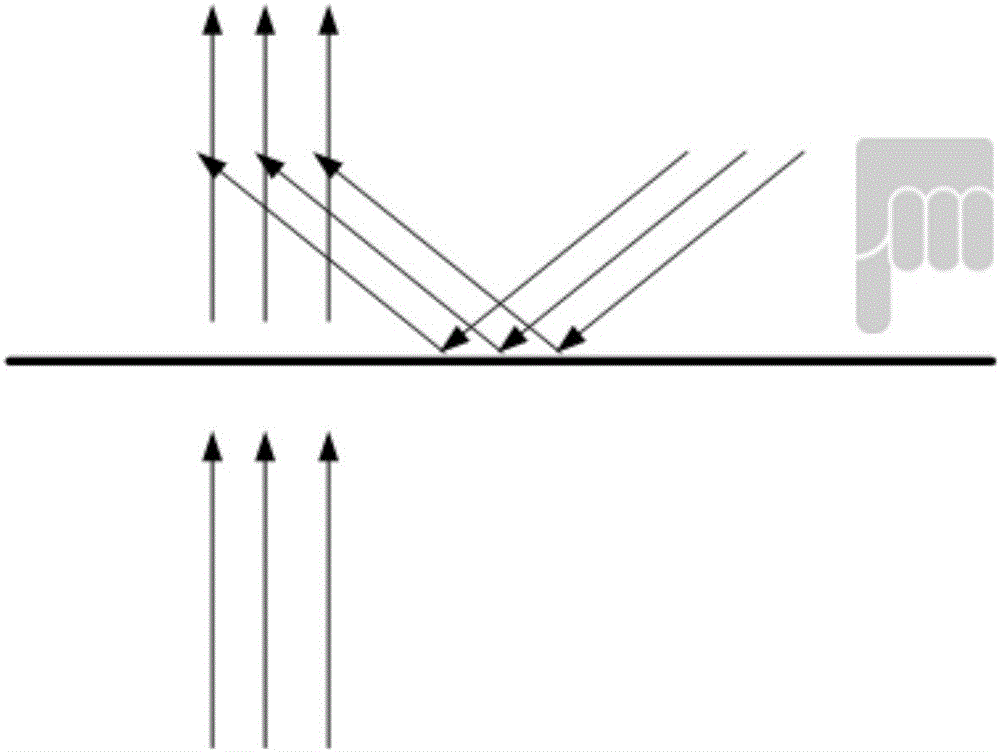

[0032] Such as figure 1 As shown, the touch screen includes a substrate 1 and a sensor 10 located above the substrate 1, and also includes a one-way light-transmitting film 2. The one-way light-transmitting film 2 is disposed between the substrate 1 and the sensor 10, and the one-way light-transmitting film 2 The light from the side of the sensor 10 is totally reflected, while the light from the side away from the sensor 10 is transmitted.

[0033] Among them, the unidirectional light-transmitting film 2 can be formed of a unidirectional light-transmitting insulating material or a unidirectional light-transmitting material with a higher transmittance, so that the external light from the touch side of the touch screen is fully The light from the inside of the display panel used in combination with the touch screen is transmitted, so as to achieve the effect that the touch ...

Embodiment 2

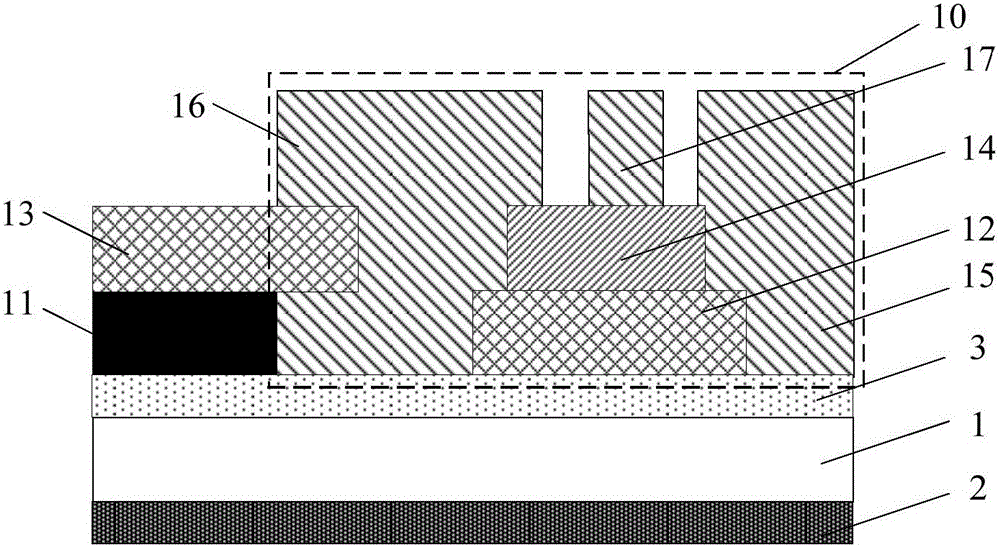

[0043] This embodiment provides a touch screen, which has good anti-shadow effect and good appearance effect. The difference from Embodiment 1 lies in the different setting positions of the unidirectional light-transmitting film 2.

[0044] Such as image 3 As shown, the touch screen includes a substrate 1 and a sensor 10 located above the substrate 1, and also includes a one-way light-transmitting film 2. The one-way light-transmitting film 2 is arranged on the side of the substrate 1 away from the sensor 10, and the one-way light-transmitting film 2 makes the light from the side of the sensor 10 totally reflected, while the light from the side away from the sensor 10 is transmitted.

[0045] In the touch screen of this embodiment, a unidirectional light-transmitting film 2 is added on the other side of the substrate 1 where the sensor 10 is provided, and an anti-reflection layer 3 is provided on the side of the sensor 10. Since the anti-reflection layer 3 is insulating, it is Va...

Embodiment 3

[0050] This embodiment provides a touch display panel including the touch screen in Embodiment 1 or Embodiment 2.

[0051] Such as Figure 4 As shown, the touch display panel includes a display panel 5 and a touch screen. The touch screen is arranged on the display side of the display panel 5 and a flat layer 6 is arranged between the touch screen and the display panel 5. At present, the touch screen and the display panel 5 generally use optical clear resin (Optical Clear Resin, OCR) or optical clear adhesive (Optically Clear Adhesive, OCA) fully bonded products. At this time, optical clear resin and optical clear adhesive are Can serve as a flat layer 6.

[0052] Here, the display panel is a liquid crystal display (Liquid Crystal Display, abbreviated as LCD) or an organic light-emitting diode (Organic Light-Emitting Diode, abbreviated as OLED) display substrate.

[0053] Among them, considering the poor transmittance of the aluminum layer forming the unidirectional light-transmitt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com