Rotary multi-angle equipment numbering device

A device numbering and multi-angle technology, applied to the identification of devices, instruments, etc., can solve the problems of low work efficiency and long waste, and achieve the effects of improving production efficiency, fast and accurate feeding, and reducing personnel care and communication time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

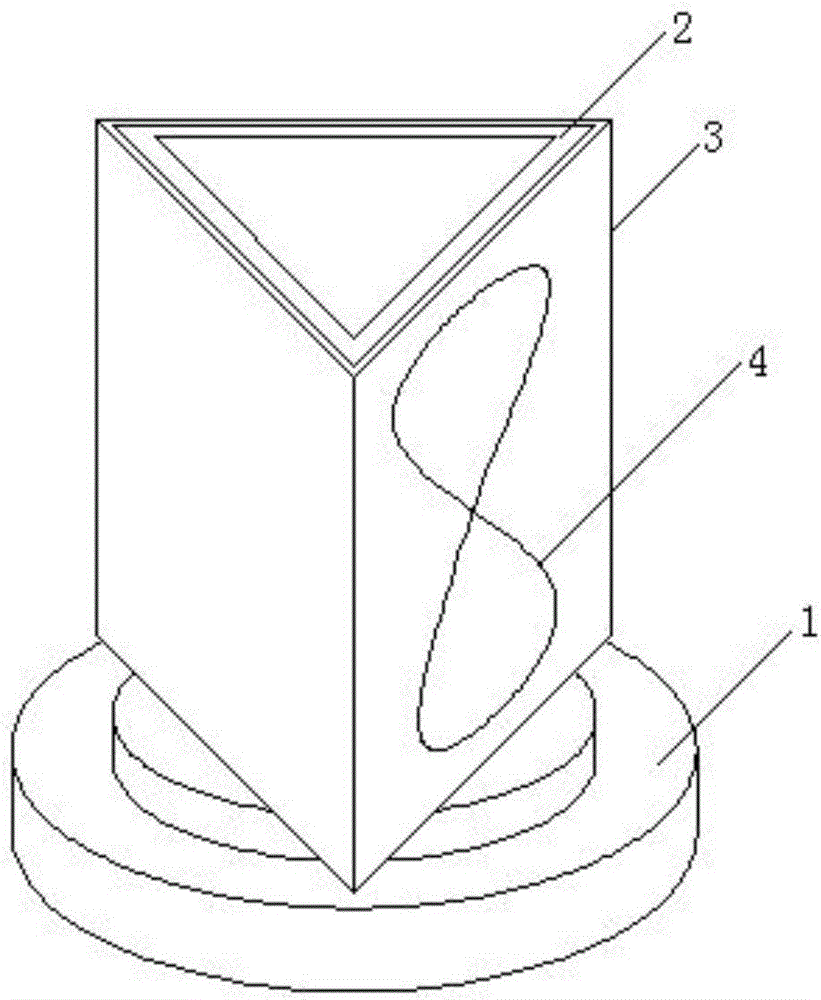

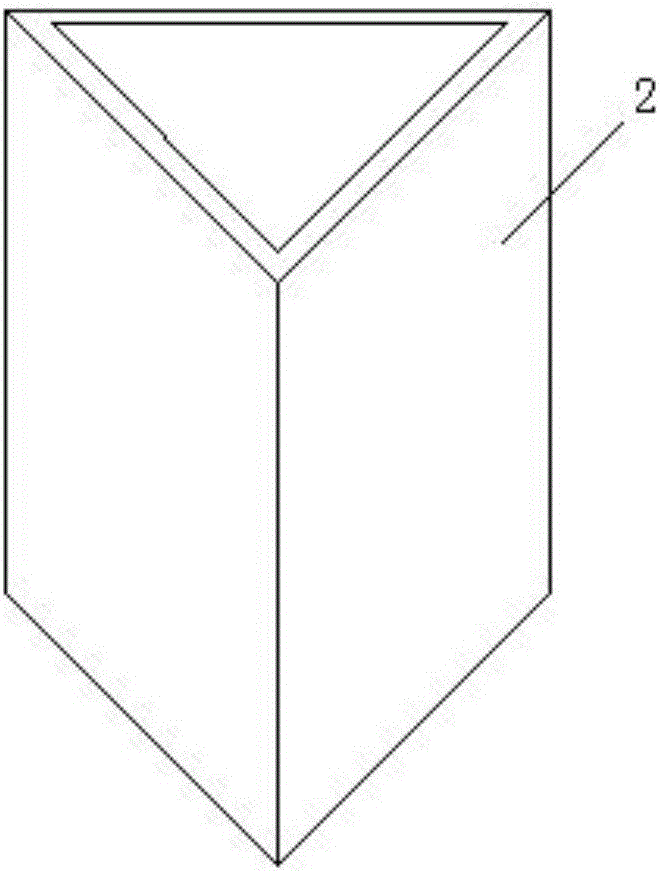

[0017] refer to Figure 1-Figure 2 , this embodiment includes a rotating base 1, a multi-angle combination module 2, a bracket 3 and a number plate 4, the bracket 3 is installed on the rotation base 1, the multi-angle combination module 2 is installed in the bracket 3, and the multi-angle There is a gap between the planes corresponding to the combination module 2 and the bracket 3 , and the number plate 4 is installed in the gap between the planes corresponding to the multi-angle combination module 2 and the bracket 3 .

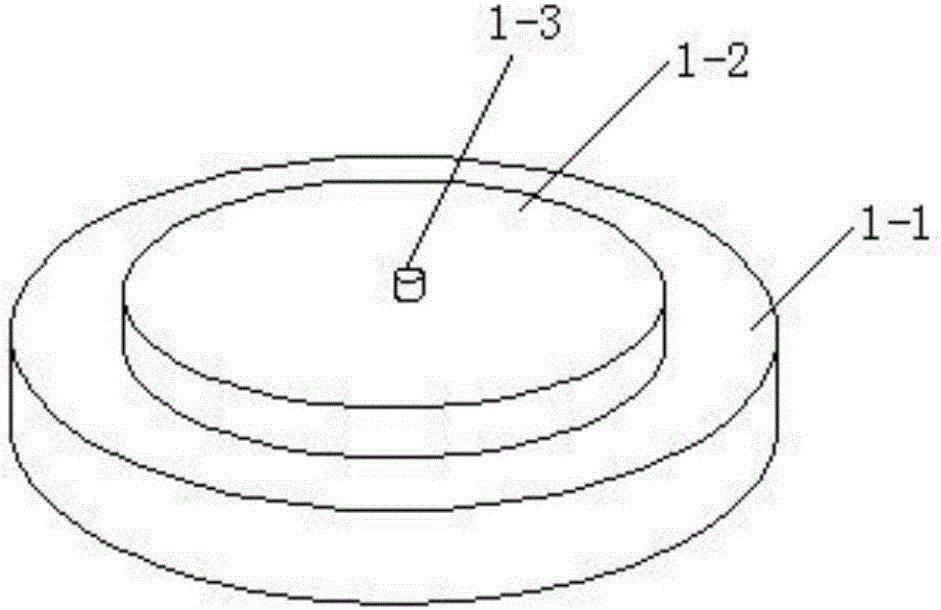

[0018] In this embodiment, the rotating base 1 includes a chassis 1-1 and a rotating disk 1-2, the center of the rotating disk 1-2 is provided with a rotating shaft 1-3, and the rotating shaft 1-3 passes through a bearing and a bearing The seat is connected with the rotating disk 1-2, and the rotating shaft 1-3 is connected with the driving device through a transmission mechanism. The chassis and the rotating disc can be made from PCB scraps, and the rotatin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com