Mother-daughter board connector module

A technology of board-to-board connectors and connectors, which is applied in the direction of connection, fixed/insulated contact components, coupling devices, etc., can solve the problems of high cost and many types of products, and achieve the effect of reducing product types and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

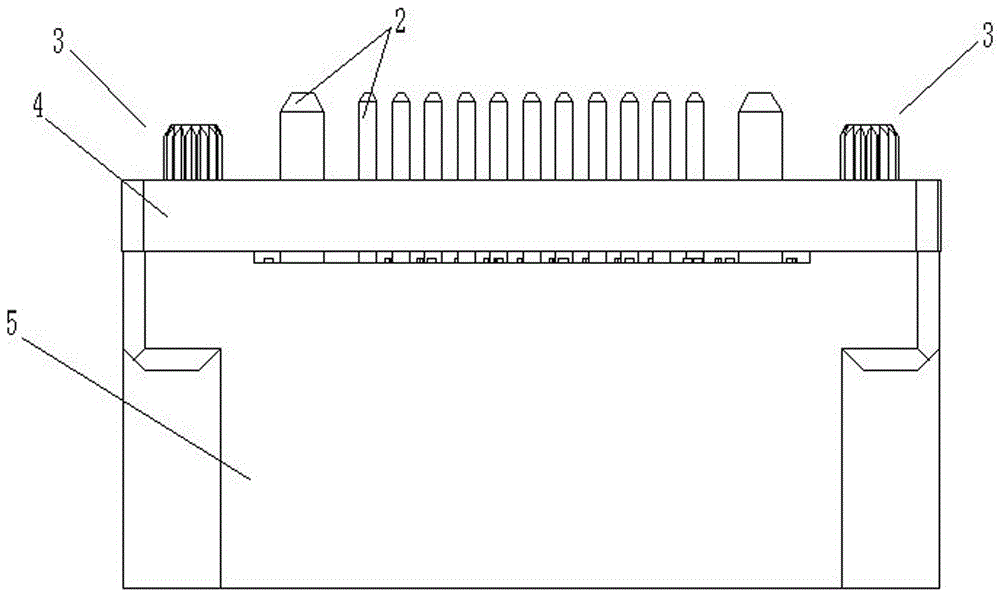

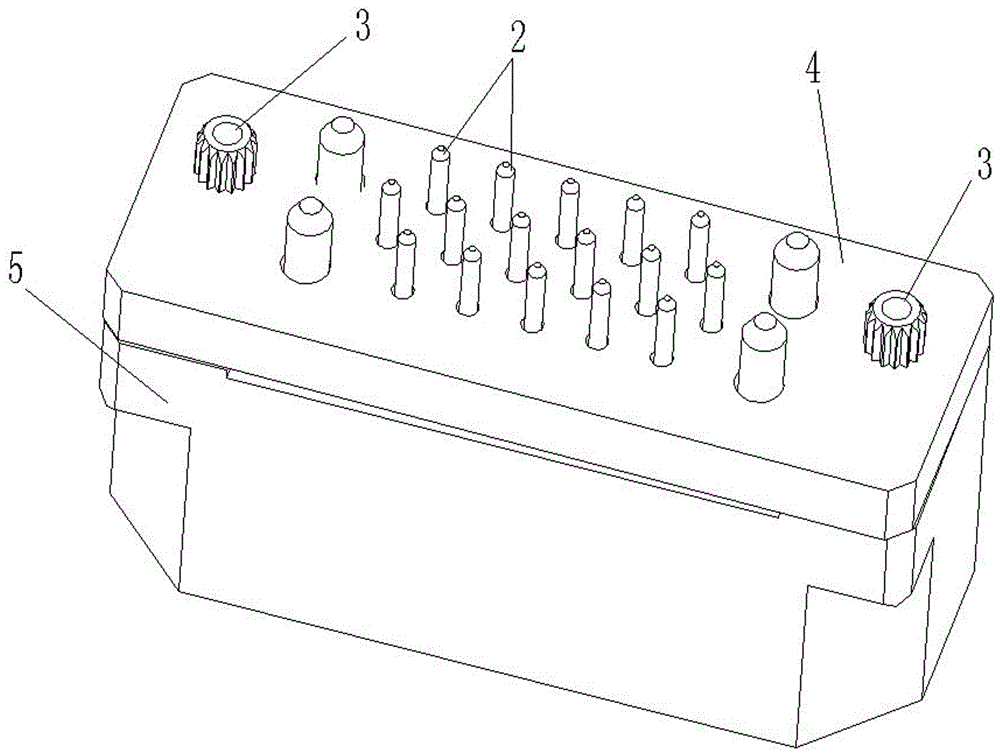

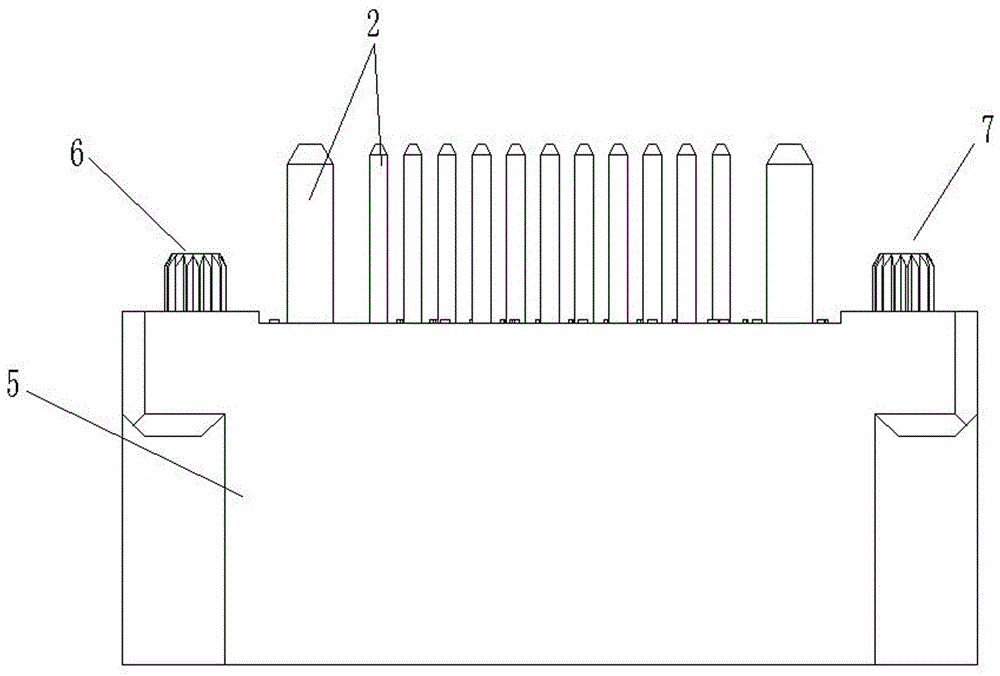

[0016] Examples of board-to-board connector assemblies are Figure 1~6 As shown: it includes an inter-board connector 7 and a backing plate 4, the inter-board connector includes a connector housing 5, and the connector housing 5 is provided with a plurality of contacts whose front ends are plug-in terminals (not shown in the figure) , the rear end of the contact piece is provided with a welding pin 2, the welding pin 2 and the contact piece are integrally formed, and the backing plate 4 is provided with pin through holes corresponding to the welding pins one by one. The rear end of the connector housing and the left and right sides of each contact piece are respectively provided with a left housing mounting column 6 and a right housing mounting column 7, and the left housing mounting column and the right housing mounting column both include a The cylinder is made of plastic, and the periphery of the cylinder has a tooth-shaped structure. The backing plate 4 is provided with a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com