Soluble fibrous structures and methods for making same

A technology of fiber structure and solubility, applied in the direction of fiber chemical characteristics, chemical instruments and methods, pharmaceutical formulations, etc., can solve problems such as no negative effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

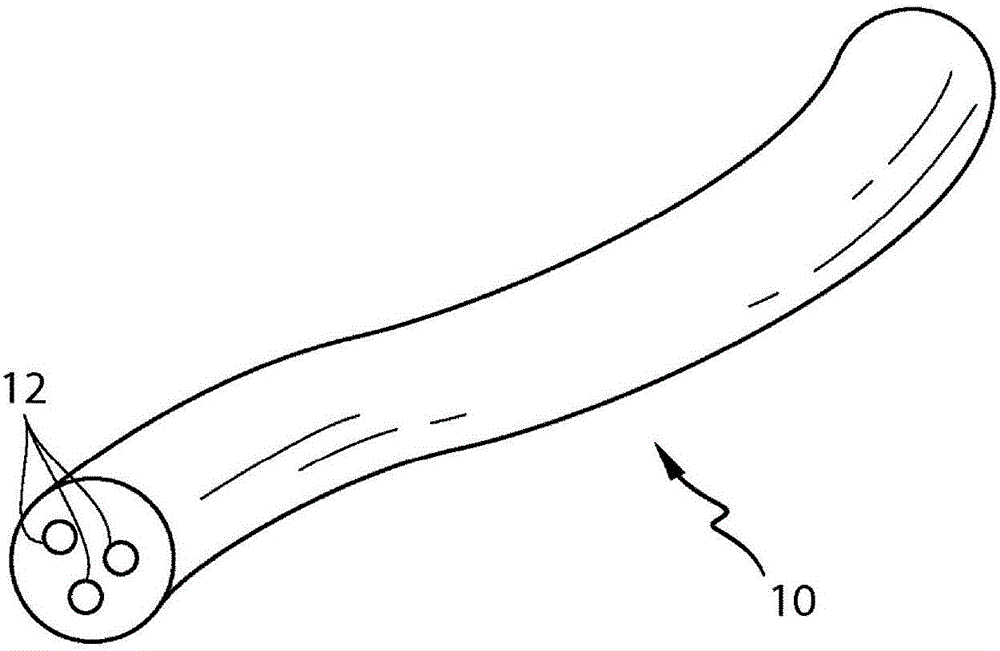

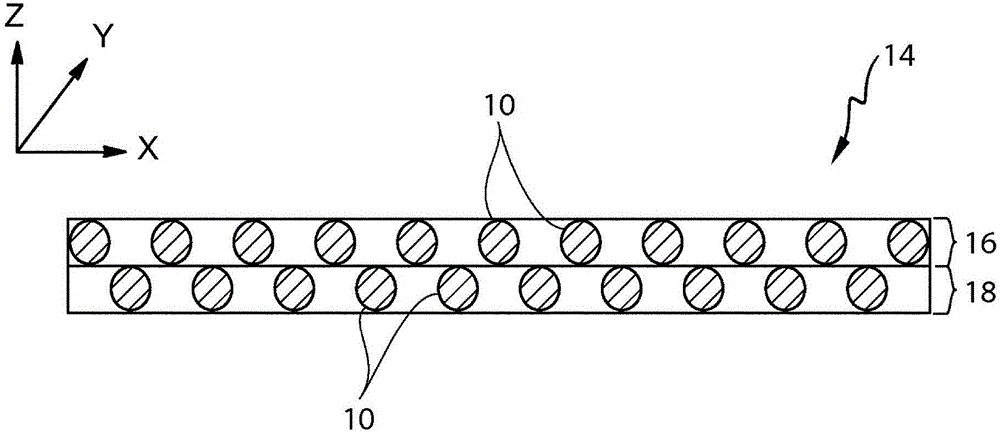

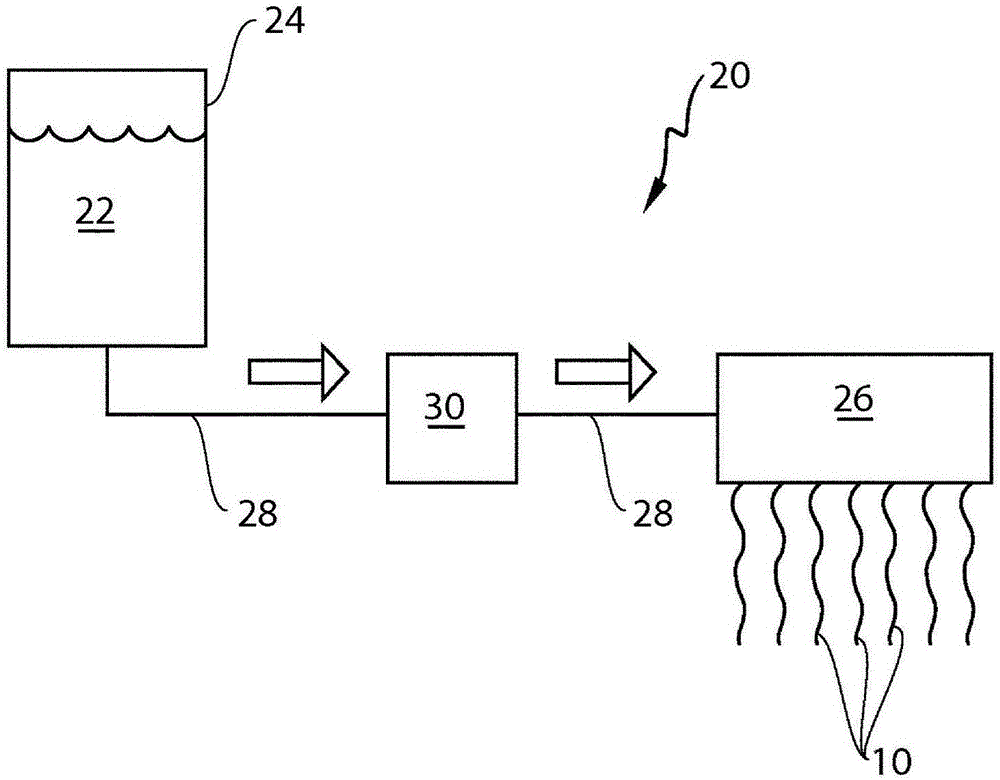

[0381] Embodiment 1 of the present invention - The fibrous element forming composition according to the invention is shown in Table 5 below for the preparation of the fibrous element and ultimately for the preparation as above image 3 and Figure 4 The soluble fiber structure according to the invention described in . The initial water transmission rate, hydration value, swelling value and viscosity value associated with the soluble fibrous structure are shown in Table 10 below.

[0382]

[0383]

[0384] 1 PVA420H, M w 75,000 g / mol, 78%-82% hydrolyzed, purchased from Kuraray America, Inc.

[0385] 2 PVA403, M w 30,000 g / mol, 78%-82% hydrolyzed, purchased from Kuraray America, Inc.

[0386] table 5

Embodiment 2

[0387] Embodiment 2 of the present invention - The fibrous element forming composition according to the invention is shown in Table 6 below for the preparation of the fibrous element and ultimately for the preparation as above image 3 and Figure 4 The soluble fiber structure described in . The initial water transmission rate, hydration value, swelling value and viscosity value associated with the soluble fibrous structure are shown in Table 10 below.

[0388] raw material preparation(%) distilled water 59.4001 Tri Quat 0.0960 Cationic Guar Gum Polymer 0.5144 Fibrous element molding material (polyvinyl alcohol) 1

5.2750 Fibrous element molding material (polyvinyl alcohol) 2

5.2750 Anionic Surfactant (Sodium Laureth-1-Sulfate (SLE1S)) 23.9455 Anionic Surfactant (Sodium Laureth-3-Sulfate (SLE3S)) 0.0000 amphoteric surfactant 5.2340 Citric acid (anhydrous) 0.2600 total 100.0000

...

Embodiment 3

[0392] Embodiment 3 of the present invention - The fibrous element forming composition according to the present invention is shown in Table 7 below for the preparation of the fibrous element and ultimately for the preparation as above image 3 and Figure 4 The soluble fiber structure described in . The initial water transmission rate, hydration value, swelling value and viscosity value associated with the soluble fibrous structure are shown in Table 10 below.

[0393] raw material preparation(%) distilled water 71.2500 Fibrous element molding material (carboxymethyl cellulose) 14.3000 Anionic Surfactant (Alkyl Polyglucoside – The Dow Chemical Company) 14.3000 Rheology Modifier (Polyacrylamide – SNF, Inc.) 0.1500 total 100.0000

[0394] Table 7

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com