Suspension clamp with monitoring function

A suspension clamp and function technology, which is applied in the field of suspension clamps with monitoring function, can solve the problems of difficulty in monitoring the force of suspension clamps in time, temperature changes of conductors and transmission wires, and difficult temperature changes, and achieves great practicality and efficiency. The effect of promotion value, accurate monitoring data and convenient installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

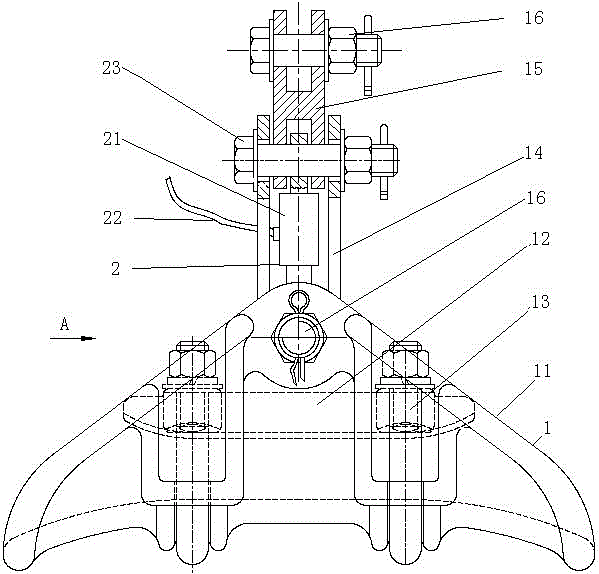

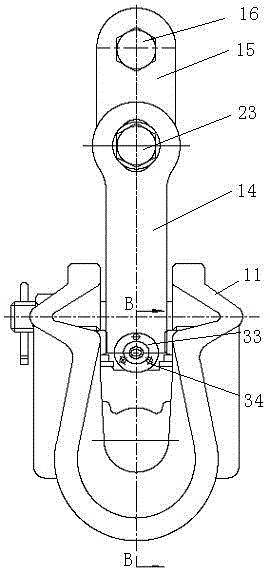

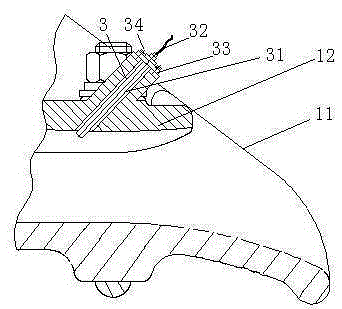

[0014] Refer to attached figure 1 , attached figure 2 , attached image 3 , a suspension wire clamp with monitoring function of the present invention, which is composed of a wire clamp main body 1, a tension sensor device 2, and a temperature sensor device 3. The tension sensor device 2 is arranged on the wire clamp main body 1. A device for changing the tension of the clamp; the temperature sensor device 3 is arranged on the pressing plate 12 of the clamp main body 1, which is a device capable of monitoring the temperature change of the wire in real time; the clamp main body 1 is composed of a clamp body 11, a clamp pressing plate 12, Composed of U-shaped bolts 13, U-shaped connecting plates 14, hanging plates 15, and fastening components I16, the clamp pressure plate 12 is connected to the clamp body 11 through U-shaped bolts 13; the U-shaped connecting plate 14 is connected to the clamp through fastening components I16 The body 11 is connected; the clamp body 11 is provi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com