Auxiliary keel connected with main keel in building template

A technology of main keel and auxiliary keel, applied in the field of auxiliary keel, can solve the problems of difficult processing, high cost, short service life, etc., and achieve the effects of high construction efficiency, weight reduction and strength assurance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0023] The present invention will be described in detail below in conjunction with the drawings.

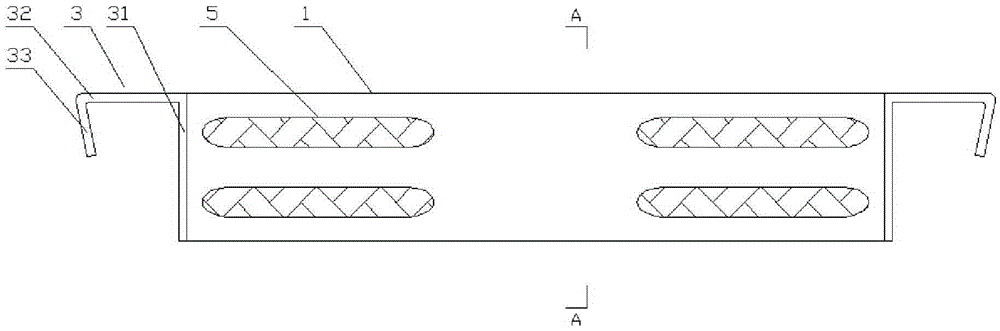

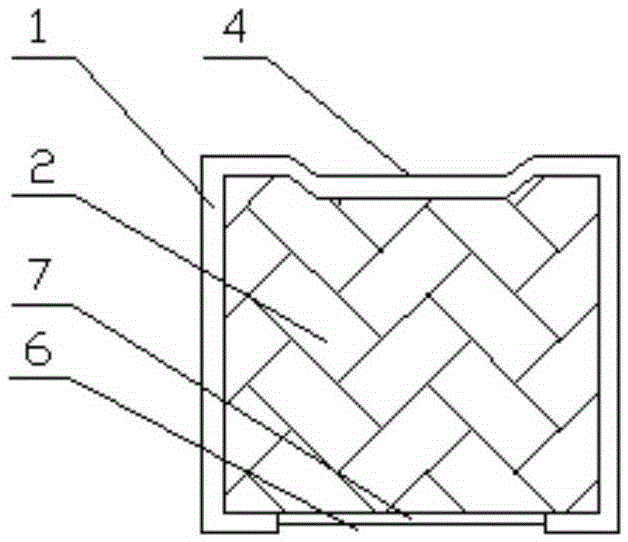

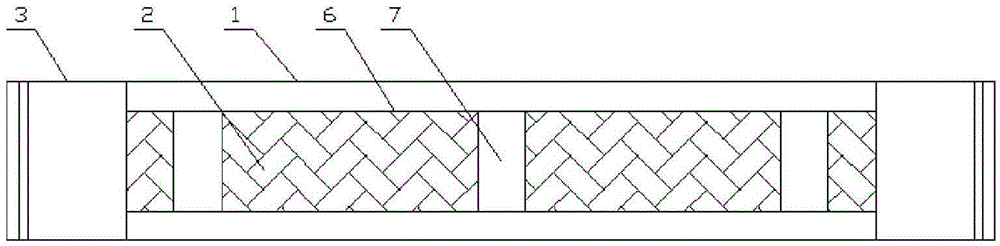

[0024] Such as figure 1 As shown in the structural diagram of the present invention, the present invention provides a secondary keel for connecting the main keel in a building template, which is characterized in that it includes a steel frame 1, a square timber 2 and a splice plate 3, and the square timber 2 is fitted In the steel frame 1, the plug-in boards 3 are fixed at both ends of the steel frame 1, and the top surface of the steel frame 1 has grooves 4 embedded in the square timber 2, and the two sides of the steel frame 1 are opposite to each other. Two rows of strip holes 5 are provided, and the bottom surface of the steel frame 1 is provided with through grooves 6 along the axial direction.

[0025] The plug-in plate 3 includes a fixed plate 31, a horizontal plate 32, and a folded plate 33. The fixed plate 31 is fixed on the end surface of the steel frame 1 in parallel, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com