A prefabricated underground garage and its construction method

A technology of underground garage and construction method, applied in the direction of building construction, buildings for parking cars, excavation, etc., can solve problems such as structural damage, and achieve the effects of optimizing internal structures, reducing bending, and reducing construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

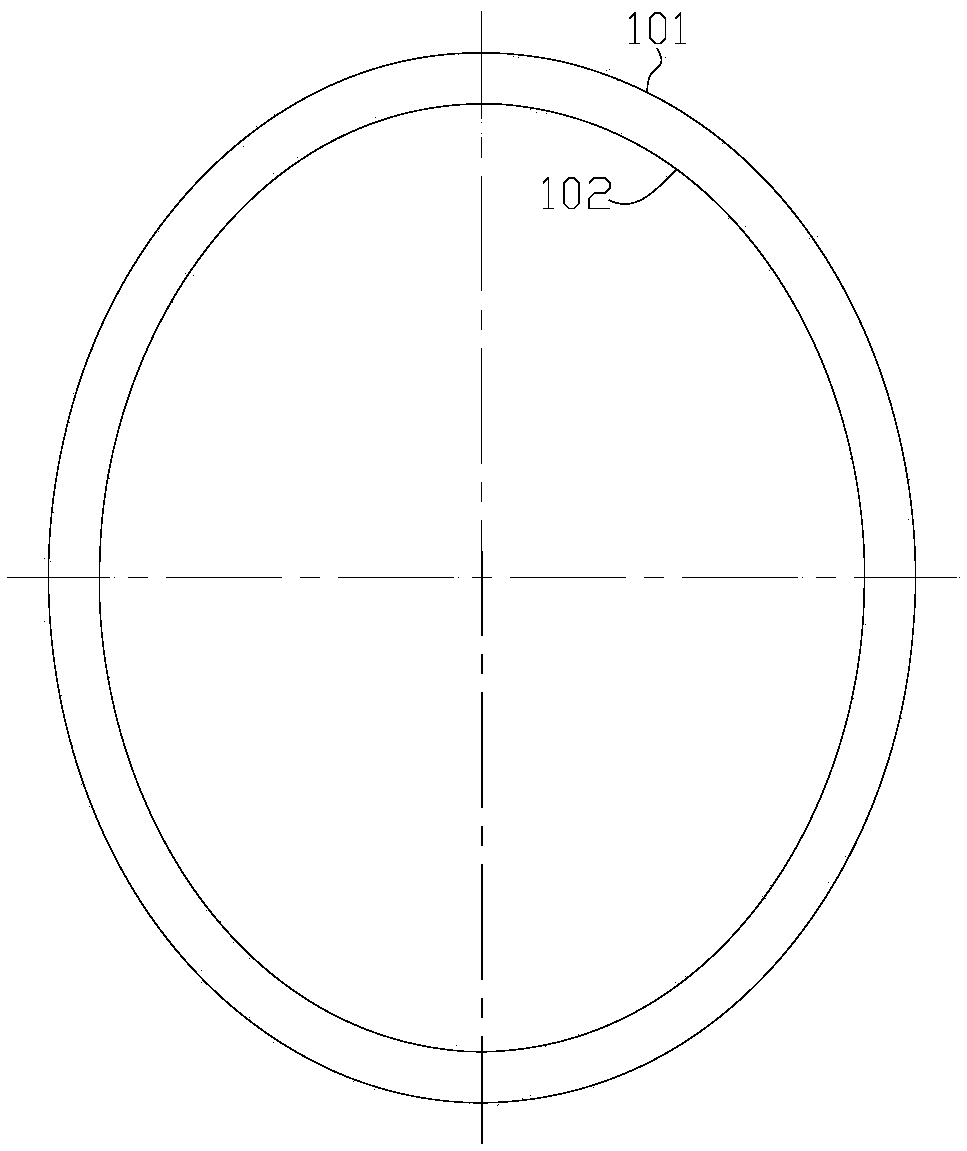

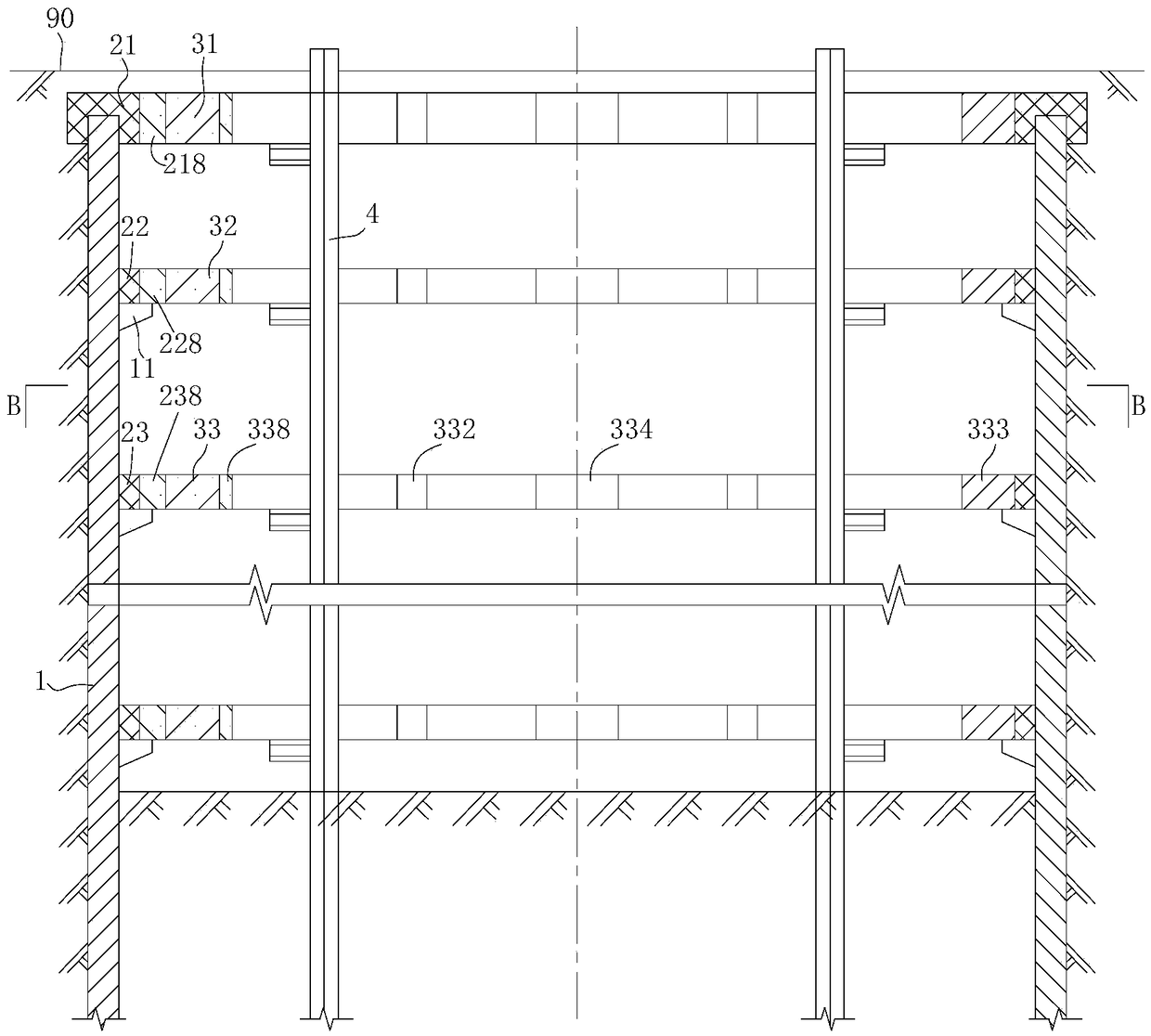

[0065] A prefabricated underground garage, which includes a closed underground wall formed by mutually overlapping enclosure piles, the horizontal section of the underground wall is rectangular; in this embodiment, reinforced concrete sheet piles are specifically used as the enclosure pile.

[0066] According to the specific geological structure and standard requirements, the enclosure piles can also use steel piles such as steel sheet piles or similar sheet piles, steel pipe piles, H-shaped steel piles, or various types of cast-in-place piles constructed on site. Long auger bored piles, short auger bored piles for dry operation, cast-in-situ piles for mud retaining method, and cast-in-place piles for casing retaining method.

[0067] The underground garage also includes a top plate, a base plate, and four intermediate parking floors, and four permanent columns are arranged vertically in the underground garage; in other embodiments, the number of permanent columns can be adjus...

Embodiment 2

[0093] This embodiment is to construct the prefabricated underground garage described in Embodiment 1, and the symbol 90 in the drawings represents the ground.

[0094] The specific steps of construction are as follows:

[0095] (1) Please refer to image 3 and Figure 5 , the reinforced concrete sheet piles used as enclosure piles are sunk along the edge of the foundation pit to be excavated, the pile bottom elevation of the reinforced concrete sheet piles reaches the set elevation, and the adjacent reinforced concrete sheet piles overlap each other to form a closed underground wall 1. The horizontal section of the underground wall is rectangular; when other types of piles are used as enclosure piles, corresponding construction needs to be carried out according to the specific type of piles.

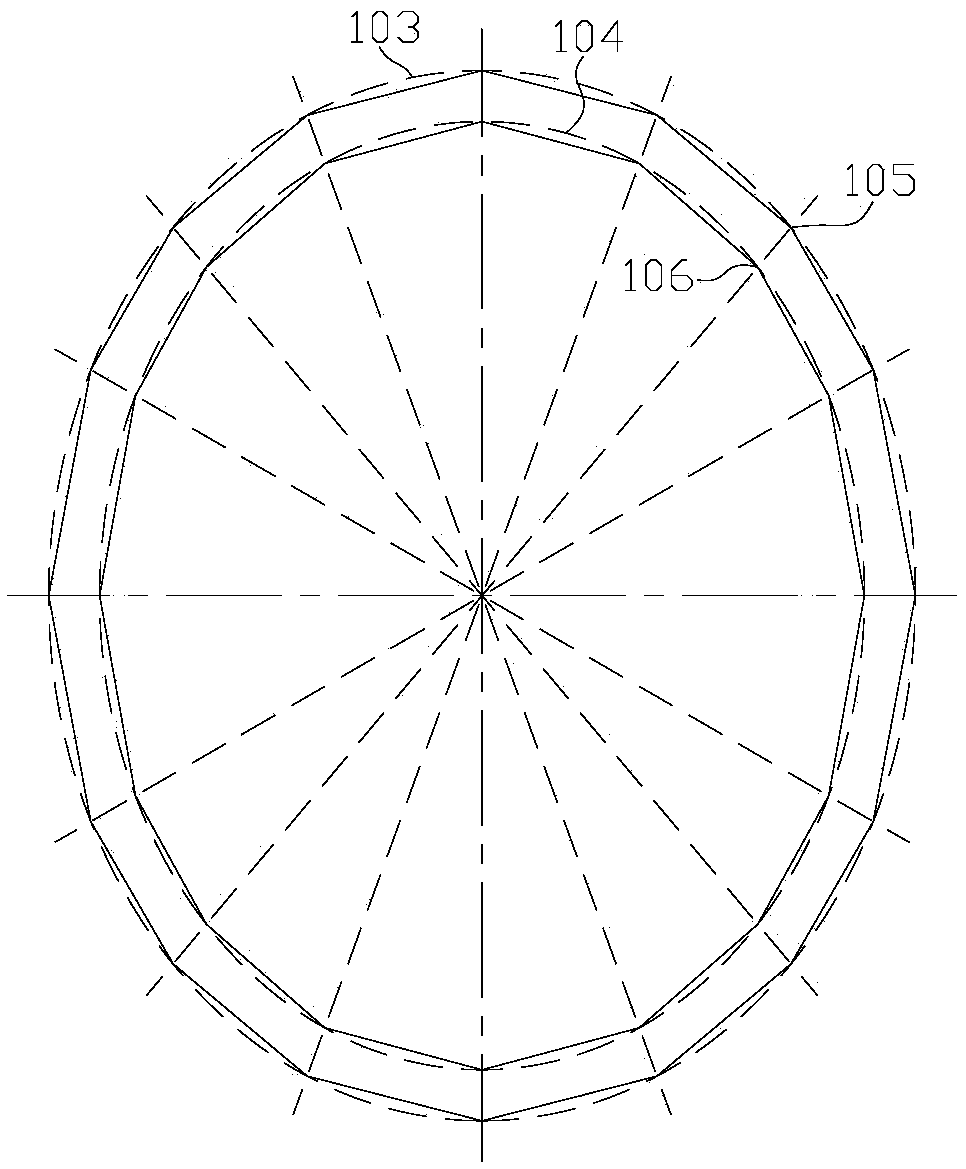

[0096] (2) Sink the temporary column 4 to the set position, so that the temporary column is arranged along an ellipse.

[0097] (3) In the area of the foundation pit to be excavate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com