An improved combined tire nut for automobile tires

An improved technology for automobile tires, applied in the directions of nuts, threaded fasteners, connecting components, etc., can solve the problems of inability to drive, poor bonding tightness, difficult disassembly of the positioning guide bushing washer, etc., and achieves convenient replacement and riveting operation. handy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

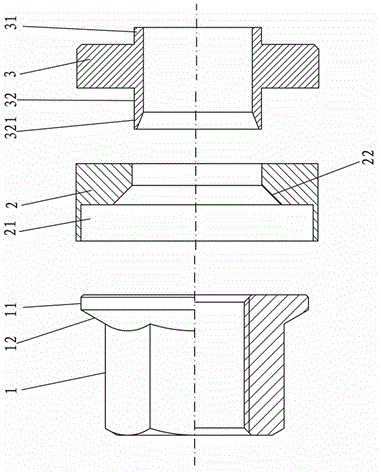

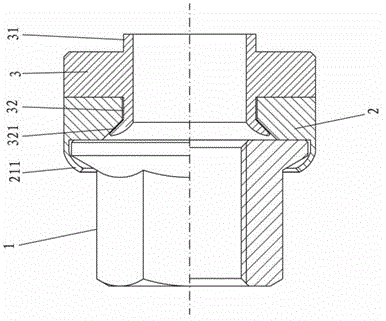

[0019] An improved combined tire nut of the present invention, such as figure 1 , 2 As shown, including nut 1, movable washer 2 and positioning guide sleeve washer 3, the nut 1, movable washer 2 and positioning guide sleeve washer 3 are all hollow structures with openings at both ends, and the axial direction of the movable washer 2 is first end and the first axial end of the nut 1 are movably socketed together in a relatively rotatable manner, and the first axial end of the movable washer 2 and the first axial end of the nut 1 are provided to prevent the nut 1 from The movable washer 2 is the first riveting structure that is axially separated. The first riveting structure includes the first riveting section and the first riveting surface for the first riveting section to be riveted together, that is, the axial direction of the nut 1. The first end face is protruded with a hollow annular protruding ring 11 whose outer diameter is greater than the outer diameter of the nut 1, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com