Wheel bearing with improved cage

A cage and wheel technology, applied in the direction of rotating bearings, bearings, wheels, etc., can solve problems such as the inability to ensure the positional accuracy of seals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The following detailed description will illustrate the present invention by way of example, rather than limit the present invention. This description will clearly enable one skilled in the art to make and use the invention, and will explain what we presently believe to be the best mode of carrying out the invention.

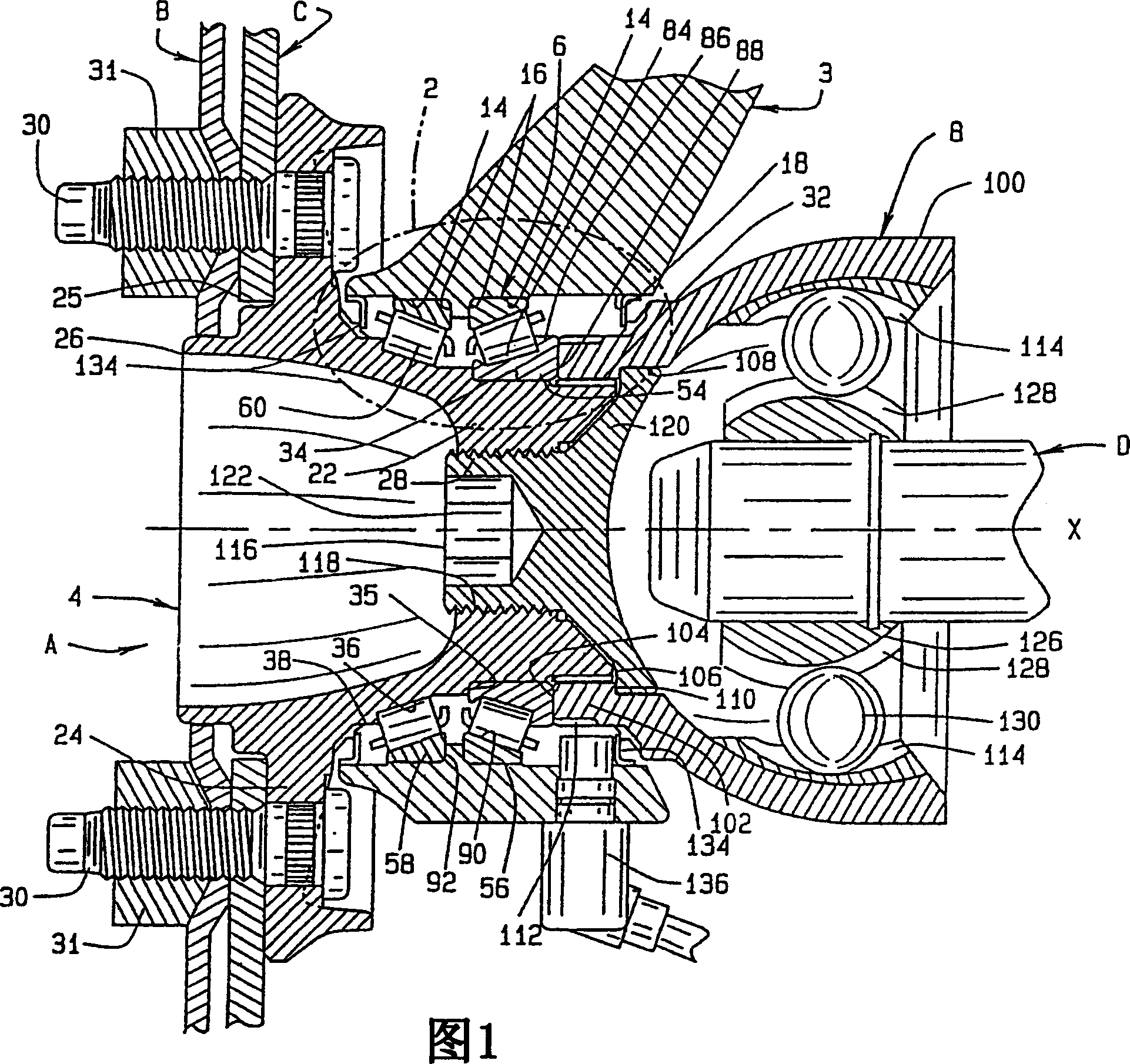

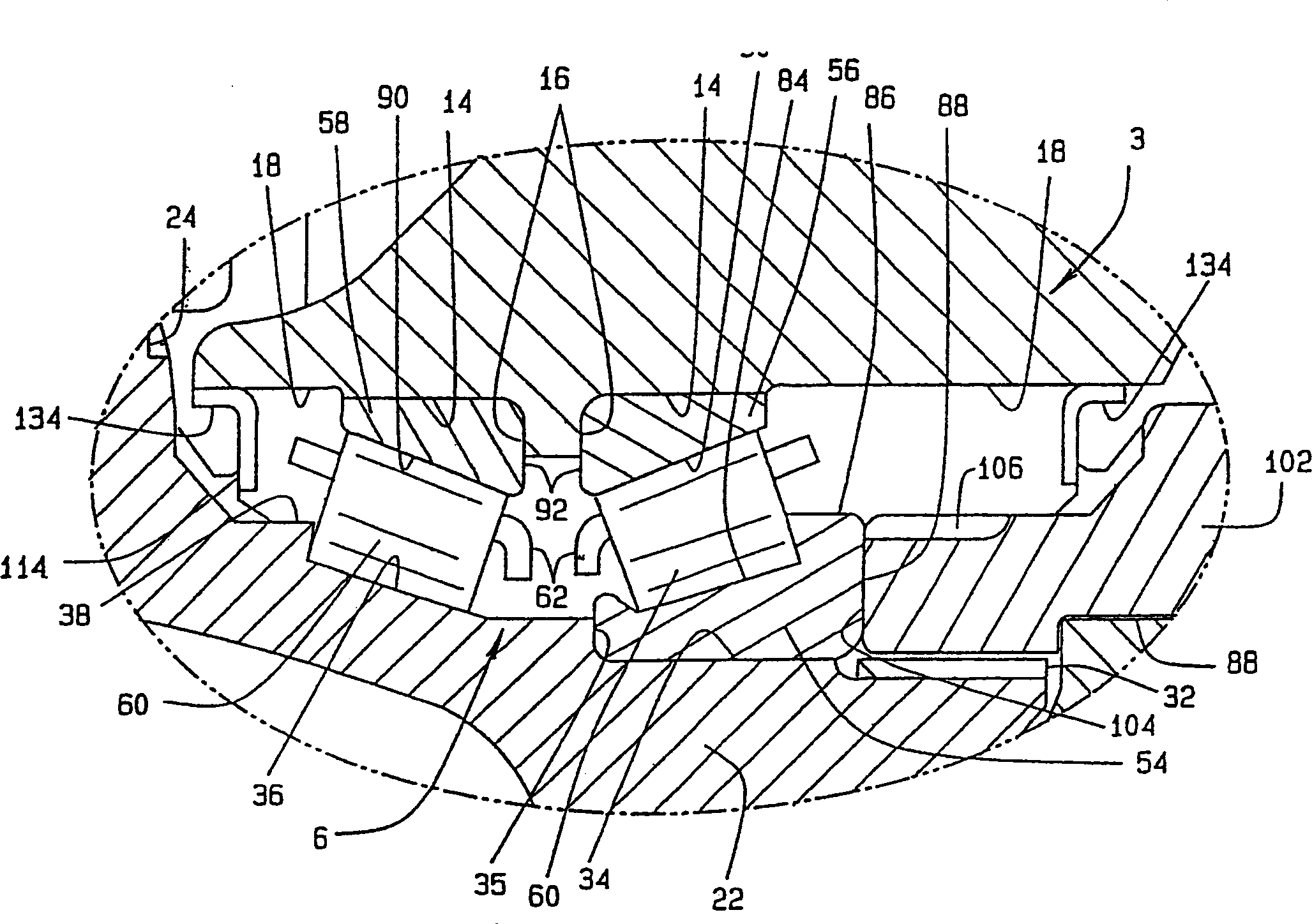

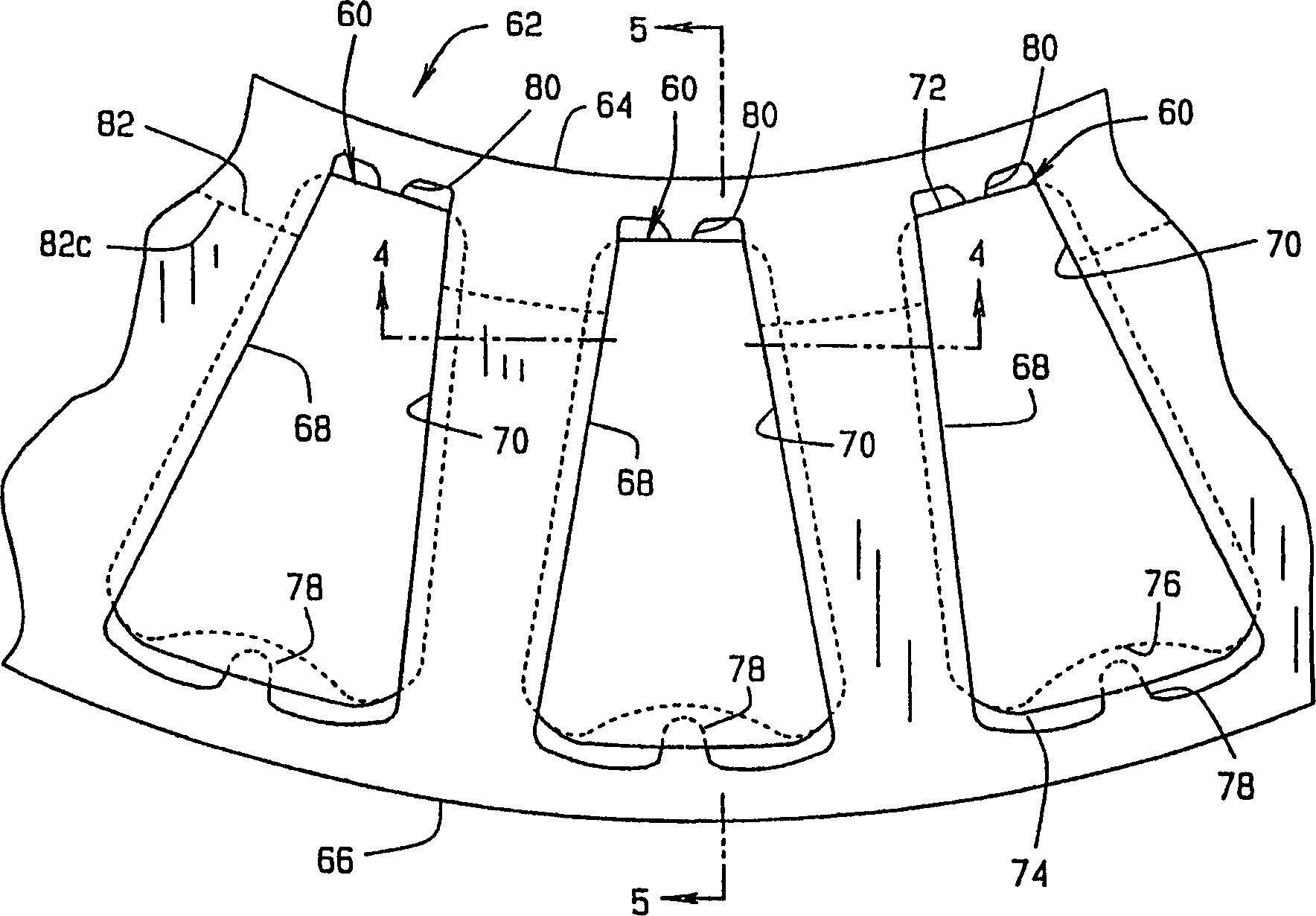

[0024] Referring now to FIG. 1 , a hub assembly A connects a wheel B and brake rotor C of a motor vehicle to the vehicle's suspension system and may further connect wheel B to a drive shaft D forming part of the vehicle's driveline. The suspension system includes (FIG. 1) a suspension member 3 designed to move generally perpendicular to the vehicle, preventing deflection of the springs or torsion bars. When the wheel B connected to the hub assembly A is at the front of the vehicle so that the vehicle can be steered, the suspension member 3 generally takes the form of a steering knuckle. On the other hand, when the wheel B is located at the rear of the veh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com