High strength elastic body assembly for overturning cab of mine car

A high-strength, cab-based technology, applied to vehicle parts, upper structures of trucks, upper structures, etc., to achieve smooth turning, low cost, and good results

Active Publication Date: 2014-02-19

SINO TRUK JINAN POWER

View PDF7 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The traditional elastomer assembly uses rubber material, the elastomer of this material has a short life and poor reliability under heavy load and impact load

Nowadays, the elastomer assembly with integral vulcanization structure is usually used. The service life of this assembly is longer than that of the traditional structure. However, the vulcanized rubber is easy to Degumming, tearing and extrusion will eventually lead to the failure of the elastomer assembly and affect the performance of the vehicle, so the assembly also has certain limitations

Due to the comprehensive consideration of the cost and working conditions of mining vehicles, air suspension is not suitable, but a suitable shock absorber is required, so there is an urgent need for a suitable high-strength elastomer assembly for mining vehicle cab turning

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

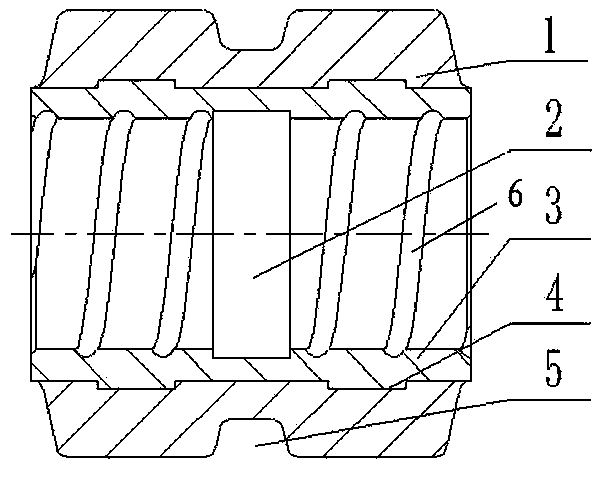

Login to View More Abstract

The invention provides a high strength elastic body assembly for overturning a cab of a mine car. The high strength elastic body assembly comprises a high strength elastic polyurethane barrel body and a steel bushing which is arranged on the high strength elastic polyurethane barrel body in a lining mode. Lubrication grooves are formed in the inner circumferential face of the steel bushing, annular grooves are formed in the inner circumferential face of the high strength elastic polyurethane barrel body, and annular protrusions which are right matched with the annular grooves are formed at the positions, corresponding to the annular grooves, of the outer circumferential face of the steel bushing. The high strength elastic polyurethane barrel body and the steel bushing are compounded into a whole in a vulcanizing mode. The high strength elastic body assembly and cab overturning parts are assembled in a flexibility mode, axial and radial loads can be effectively borne, the cushioning function is also achieved, the structure is simple, manufacturing and split charging are easy, cost is low, the effect is good, and excellent economic benefits can be achieved.

Description

technical field [0001] The invention relates to a high-strength elastic body assembly for turning over the cab of a mining vehicle. Background technique [0002] The operating conditions of mining vehicles are harsh, and the cab is greatly impacted when driving. The cab tilting assembly is an important stress-bearing part of the cab tilting system. Its high damage rate has always been a headache for vehicle and component manufacturers. The main part of the damage is the elastic body assembly. The traditional elastomer assembly uses rubber material, and the elastomer of this material has a short life and poor reliability under heavy load and impact load. Nowadays, the elastomer assembly with integral vulcanization structure is usually used. The service life of this assembly is longer than that of the traditional structure. However, the vulcanized rubber is easy to Degumming, tearing and extrusion will eventually lead to the failure of the elastomer assembly and affect the...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B62D33/067B62D33/10

Inventor 王玥李文龙曹建宏

Owner SINO TRUK JINAN POWER

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com