Garlic harvester

A harvester and garlic technology, which is applied to digging harvesters, harvesters, topping machines, etc., can solve problems such as insufficient power, waste, and high labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

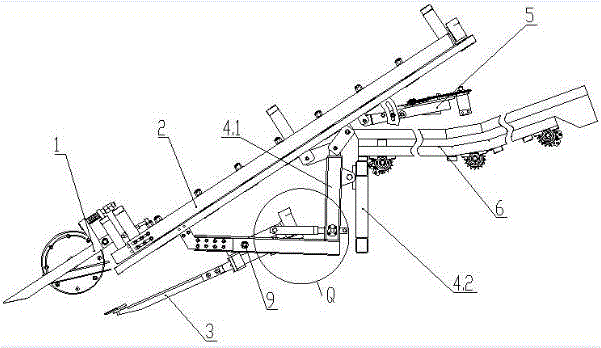

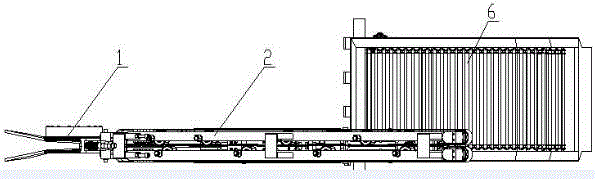

[0030] Such as figure 1 Shown a kind of garlic harvester, comprises frame, and is installed on the frame and starts to send garlic unit 2, boosts vibrating shovel 3 and all garlic stem-cutting unit 5, and the garlic stem-breaking unit 5 below is provided with frame. The affixed conveying garlic unit 6 is equipped with a grass cutting device 1 at the front end of the garlic unit 2 .

[0031] In this embodiment, the frame includes a bottom frame 4.1 and a side frame 4.2 that is located behind the bottom frame 4.1 and is connected to the bottom frame through a rotating pair. On the bottom frame 4.1, the conveying garlic unit 6 is fixed on the side frame 4.2.

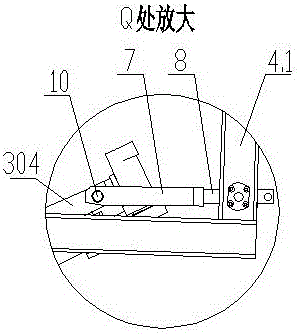

[0032] The booster vibrating shovel 3 includes a mounting seat 304 hinged to the base frame 4.1 through the hinge shaft 9 and a vibrating rod 303 pierced on the mounting seat 304. The vibrating rod 303 is provided with two sliding bearings 312, and the sliding bearings 312 pass through the bearing seat. 311 is fixed on th...

Embodiment 2

[0052] Such as Figure 10 As shown, the difference between the present embodiment and the first embodiment is that the garlic unit, the booster vibrating shovel, the garlic stem-breaking unit, and the grass-cutting device form a module through the chassis, and a plurality of these modules are arranged adjacently, which can Realize simultaneous harvesting of multiple rows of equal-spaced garlic.

Embodiment 3

[0054] Such as Figure 11 As shown, the difference between the present embodiment and the second embodiment is that two or more modules composed of a garlic feeding unit, a power-increasing vibrating shovel, a garlic stem cutting unit, and a grass cutting device are set according to the garlic row spacing, It can realize simultaneous harvesting of multiple rows of garlic with different row spacing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com