Dispersion mixing equipment and material dispersion mixing method

A kind of mixing equipment and dispersing technology, which is applied in the direction of mixers, chemical instruments and methods, chemical/physical processes, etc., can solve the problems of reduced efficiency of dispersing and mixing, and the inability to realize continuous production, etc., and achieve the effect of high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

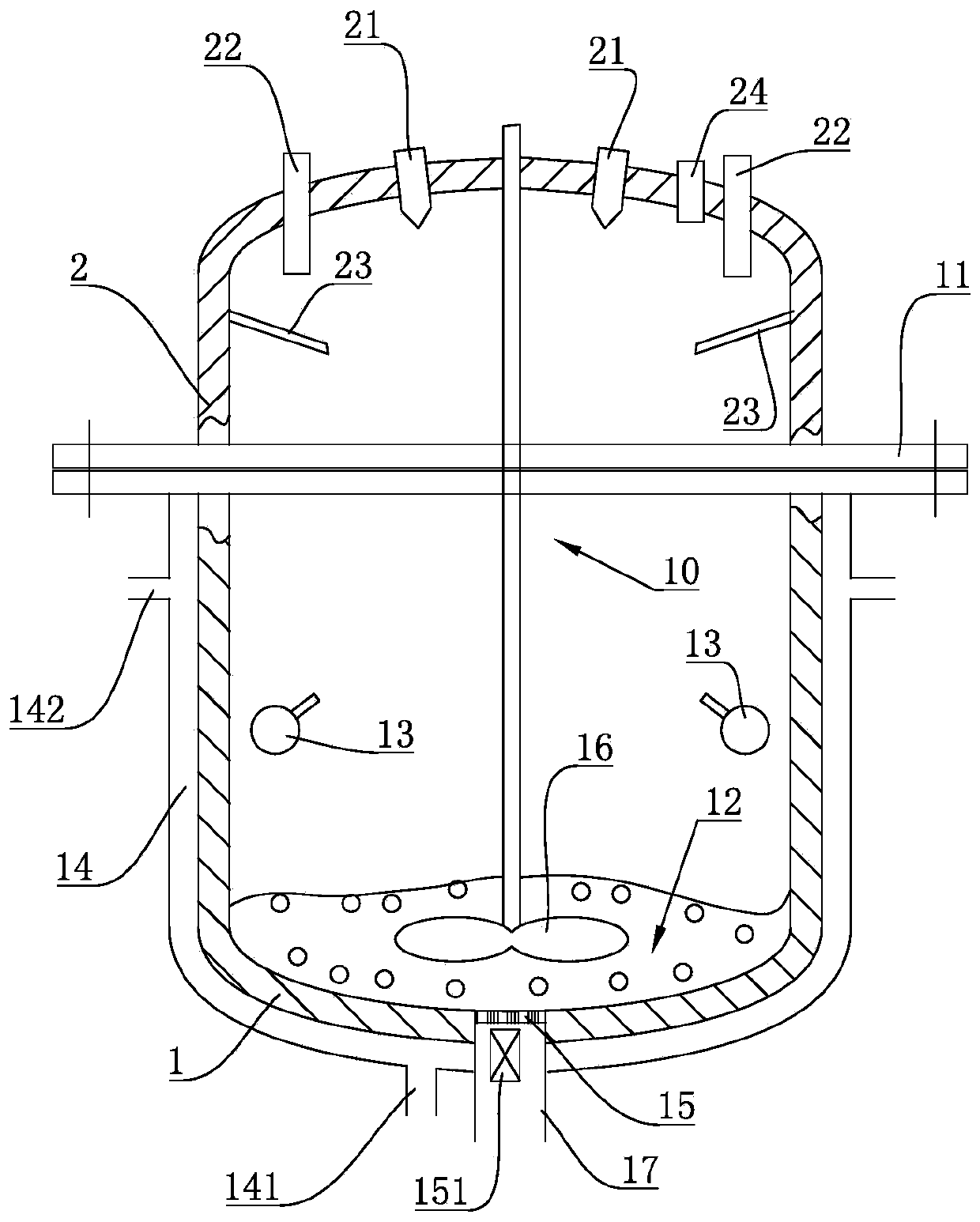

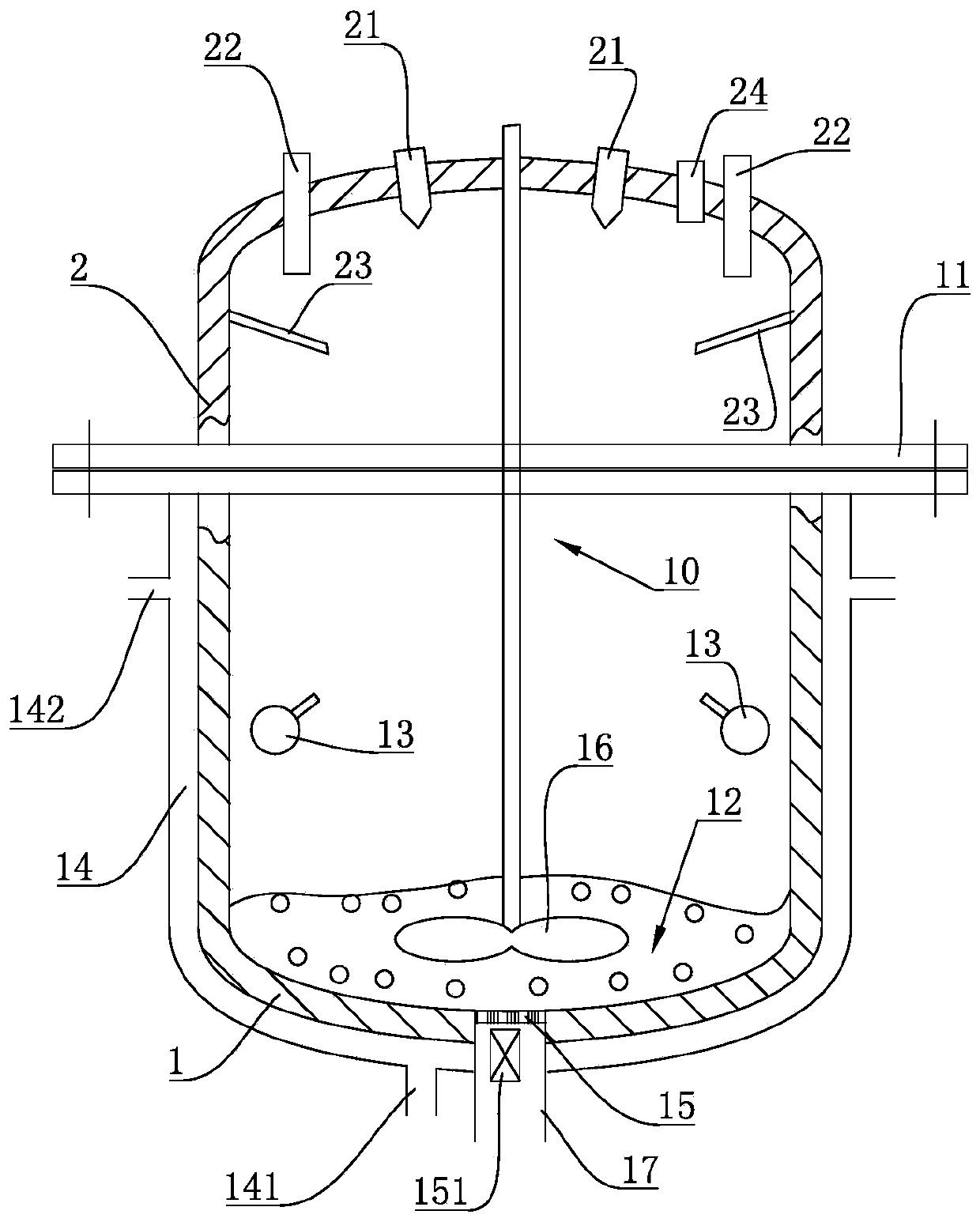

[0021] Below in conjunction with accompanying drawing and embodiment the present invention is further described:

[0022] Dispersion and mixing equipment, including a closed container body, at least a first spray head 21 and a second spray head 13 are arranged inside the container body, and the first spray head 21 and the second spray head 13 are for spraying mist liquid or powdery solid The nozzle of the nozzle; the ejection direction of the first nozzle 21 and the second nozzle 13 intersect in the smog confluence area 10 in the container body, and the smog confluence region 10 leads to the dispersion space 12 below, and the dispersion space 12 is filled with dispersed particles, and the dispersion space 12 is also provided with a stirring device 16, and the low part of the wall where the dispersion space 12 is located is provided with a discharge port 17 leading to the outside of the container body, and the feed end of the discharge port 17 is provided with a valve for preven...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com