Quick flow type dispersing and mixing machine with three-vane push type rotor

A propellant and mixer technology, which is applied to mixers, mixers, chemical/physical/physical-chemical stationary reactors with rotary stirring devices, etc. Function and other problems, to achieve the effect of uniform mixing, fast mixing speed and short response time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with specific implementation examples and drawings, but the protection scope of the present invention should not be limited by this.

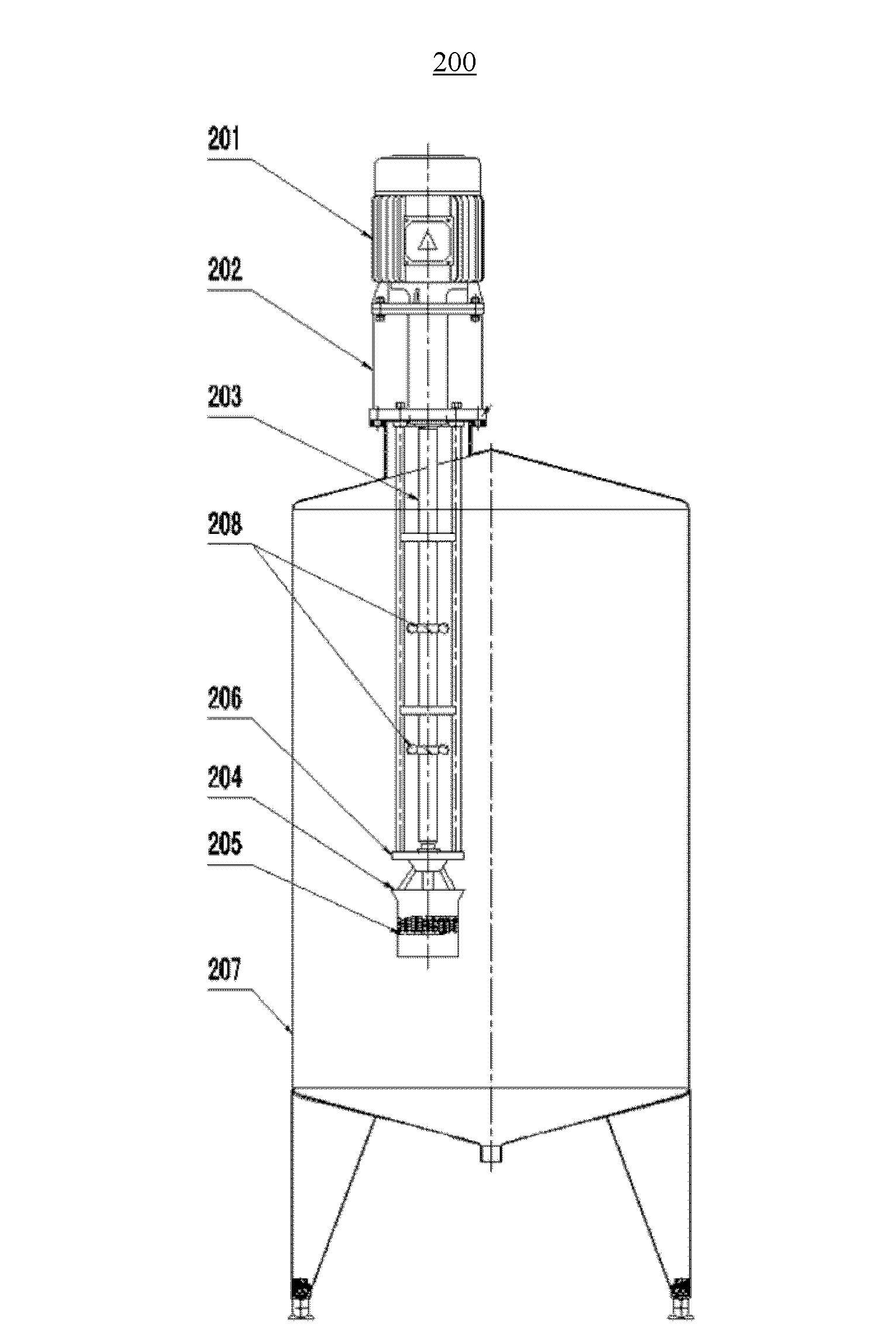

[0015] figure 2 It is a schematic structural diagram of a quick-flow dispersing mixer with a three-blade propeller rotor according to an embodiment of the present invention. As shown in the figure, the jet flow dispersing mixer 200 with a three-blade propeller rotor can include: a motor 201 to provide power, a coupling 202 that connects the motor 201 and a main shaft 203, and a main shaft 203 to transmit power, which has a shearing function. The stator 204, the rotor 205 that pushes the liquid to flow, and the reactor 207 that contains the dispersed mixed medium.

[0016] The jet flow dispersing mixer 200 with a three-blade propeller rotor may further include an inverted impeller 208 that pushes the mixed liquid to rotate counterclockwise, three uprights 206 that make the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com