Jet stream type high-efficiency dispersing mixer with four blades

A jet-flow, mixer technology, applied in mixers, mixers, mixing methods and other directions with a rotary stirring device, can solve the problems of easy agglomeration of the mixed liquid, difficult to stir evenly, no shearing function, etc., and achieve the dispersion time. Short, optimize the production process, improve the effect of dispersing and mixing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

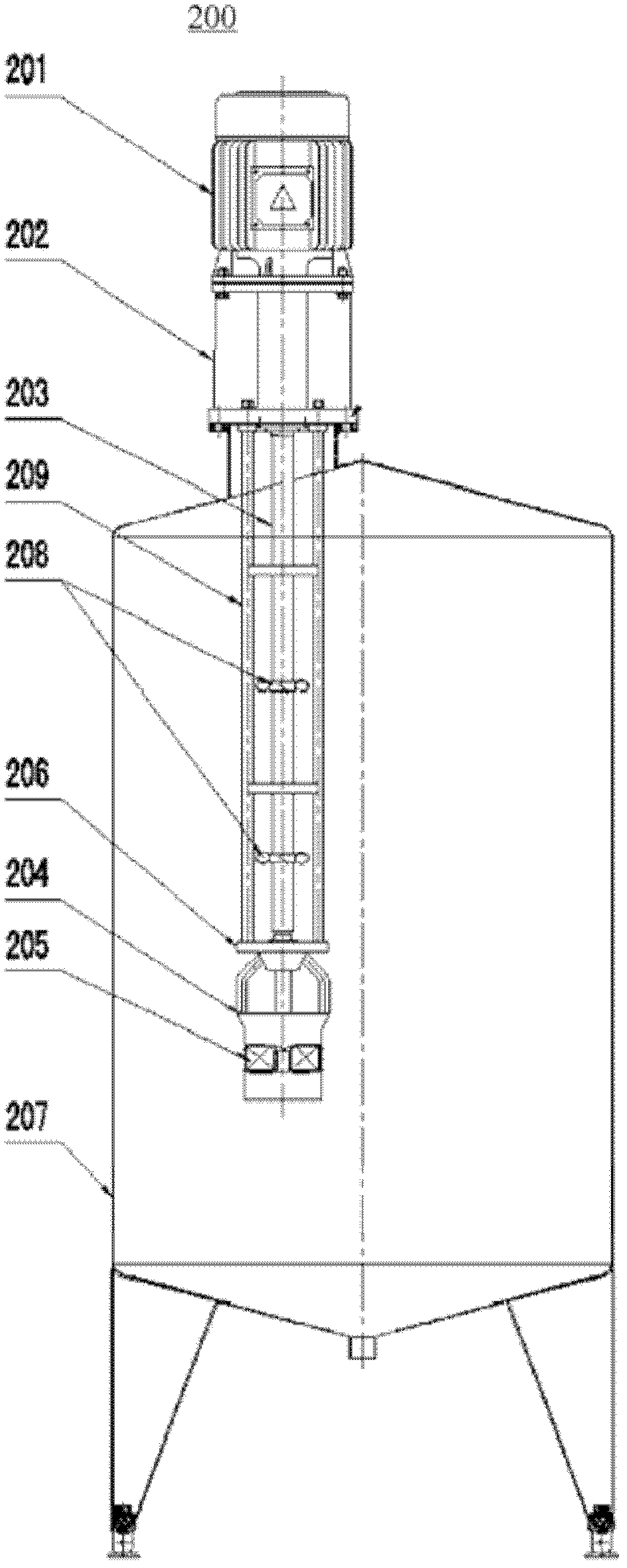

[0015] Such as figure 2 As shown, in one embodiment of the present invention, the high-efficiency dispersing mixer 200 includes: a motor 201 for power supply, a main shaft 203 for transmitting power, a coupling body 202 connecting the motor 201 and the main shaft 203, a stator 204 for shearing, and a driving force The rotor 205 where the liquid flows and the reaction kettle 207 that holds the dispersion mixing medium. The coupling body 202 is connected to the top of the reaction kettle 207 by a flange, the motor 201 is mounted on the coupling body 202 and supported by the coupling body 202 , and the main shaft 203 extends downward from the coupling body 202 and is inserted into the reaction kettle 207 . The stator 204 is installed on the stator fixing column 209 , preferably, is fixed on the lower end of the stator fixing column 209 through the stator fixing flange 206 , and the upper end of the stator fixing column 209 is connected to the coupling body 202 . The lower end o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com