A kind of disassembly-free hanging cage for construction site

A construction site, disassembly-free technology, which is applied in the field of construction equipment, can solve the problems of hanging cage smashing or crushing, manual coordination, life-threatening, etc., and achieve the effect of saving labor and improving the efficiency of transportation and unloading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

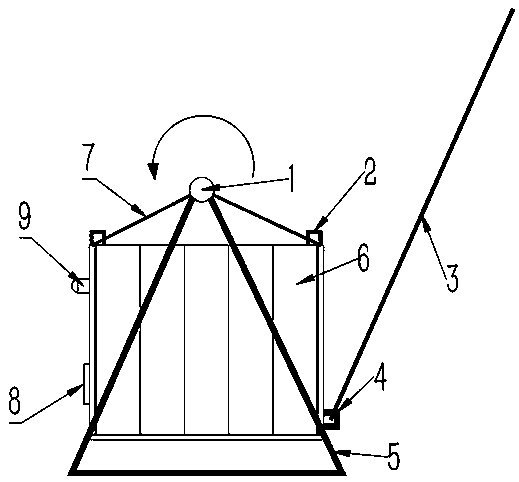

[0023] In the first embodiment, the connecting piece 7 is a chain, and the top end of the triangular bracket 5 is fixedly connected to the top shaft 1; the cage 6 is a rectangular parallelepiped, and the top hanging rings 2 are arranged at the top four corners. With this arrangement, when unloading, the tripod bracket 5 and the top shaft 1 do not move, and the cage 6 and the top shaft 1 move relatively.

Embodiment 2

[0024] In the second embodiment, the connecting member 7 is a rod member, and a sleeve or a bearing is provided on the top of the tripod bracket 5, which is rotatably connected with the top shaft 1; the cage 6 is a cylinder, and the top ring 2 is uniformly arranged on the top. With this arrangement, during unloading, the tripod 5 does not move, and the cage 6 and the top shaft 1 rotate in the same way.

Embodiment 3

[0025] The third embodiment is different from the first embodiment in that the connecting member 7 is a rod member.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap