Tensioning device for net

A technology of tensioning device and netting, which is applied in the direction of fabric elongation, heating/cooling fabric, textiles and papermaking, etc. It can solve the problems of troublesome operation and low efficiency, and achieves simple manufacture, improved tensioning efficiency and simple structure practical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

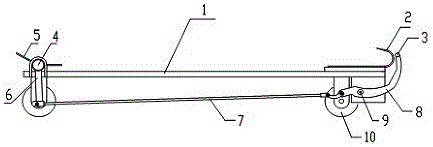

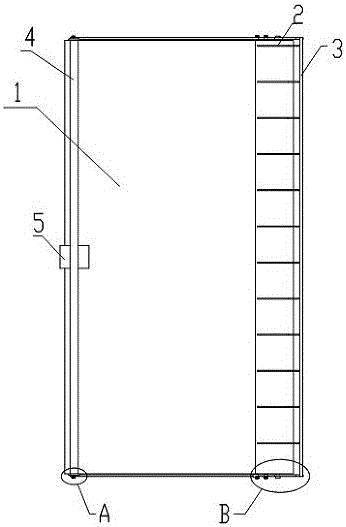

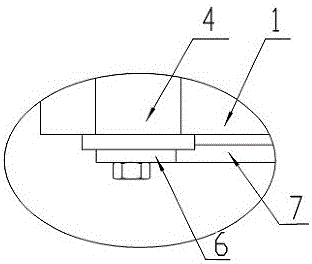

[0012] The present invention will be described in detail below in conjunction with the drawings and embodiments.

[0013] As attached Figure 1-2 As shown, a tensioning device for nets includes a fixing plate 1. A plurality of hooks 2 extending from the end of the fixing plate are provided on one end surface of the fixing plate, and the plurality of pulling hooks 2 are evenly arranged along the width direction of the fixing plate. The end of the hook 2 is welded to the fixing plate as a whole.

[0014] As attached Figure 1-2 As shown, on the outer edge of the hook body of the hook 2 is provided a decoupling rod 3 that can swing up and down. The decoupling rod 3 is arranged along the width direction of the fixed plate. The length of the decoupling rod is greater than or equal to the width of the fixed plate. When the decoupling rod swings to the upper vertex The height of the hook body is higher than the height of the hook body when the hook body is positioned. When the hook body s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com